Patents

Literature

136results about How to "Avoid huge losses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

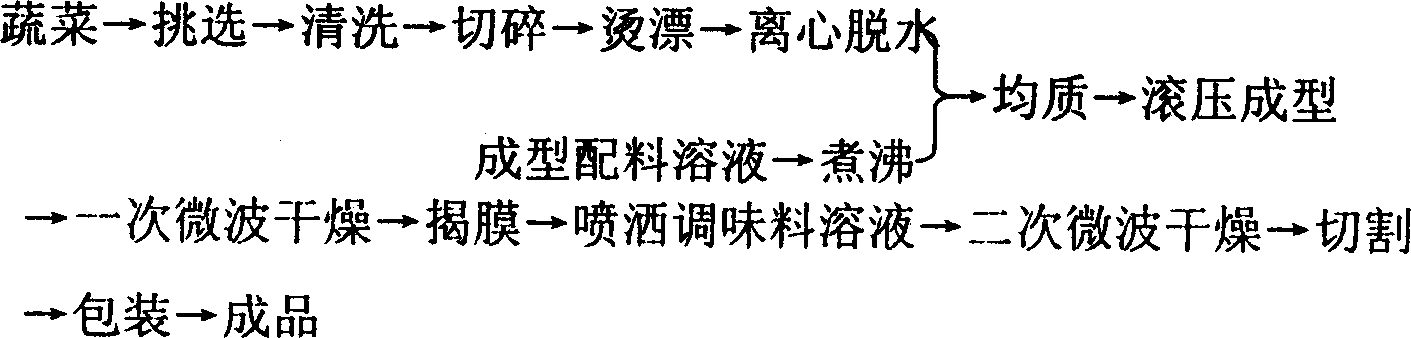

Paper-like vegetables processing method

InactiveCN1792232ARich in colorRich flavorFood preservationFood shapingVegetable processingMicrowave

Owner:JINAN UNIVERSITY

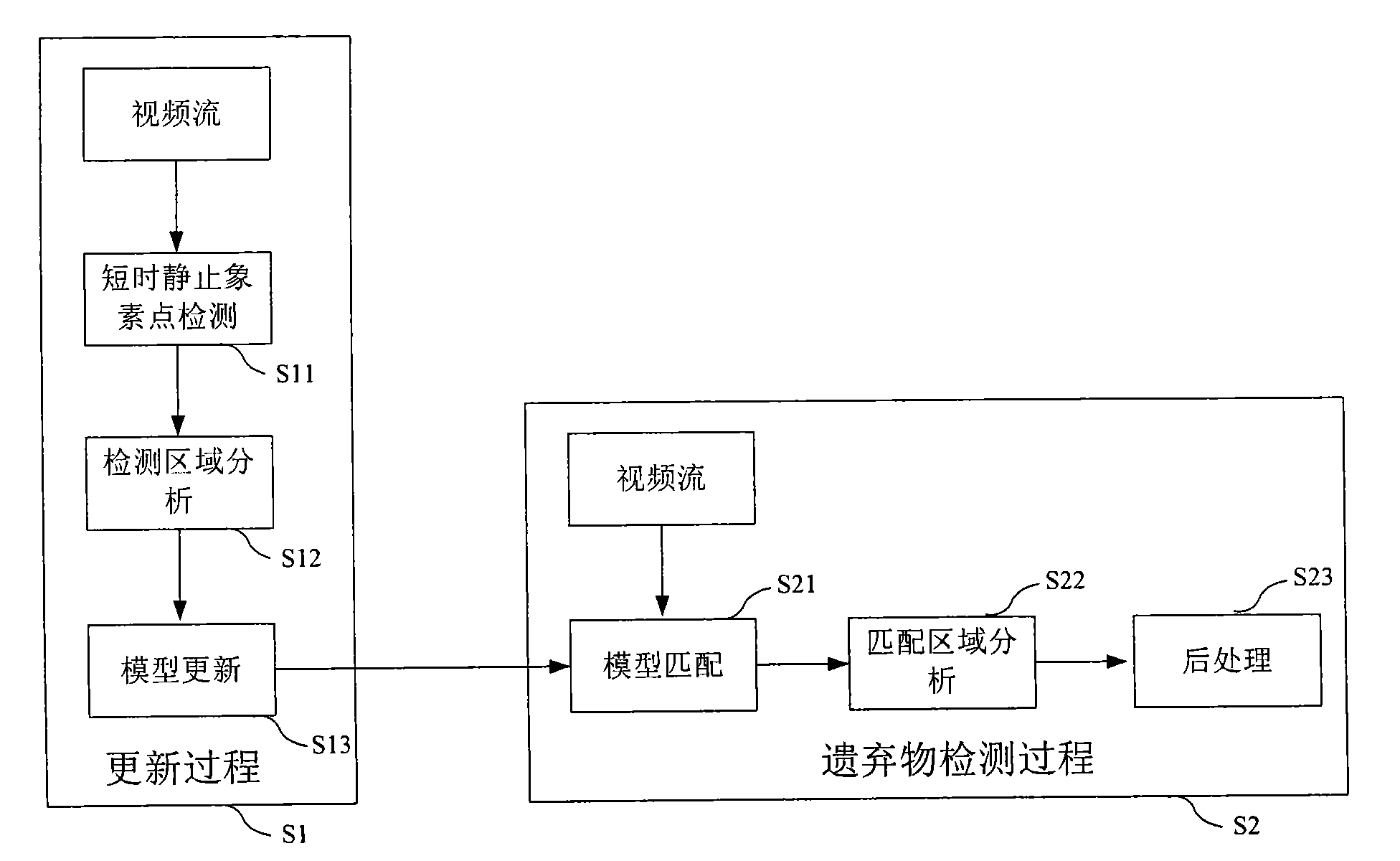

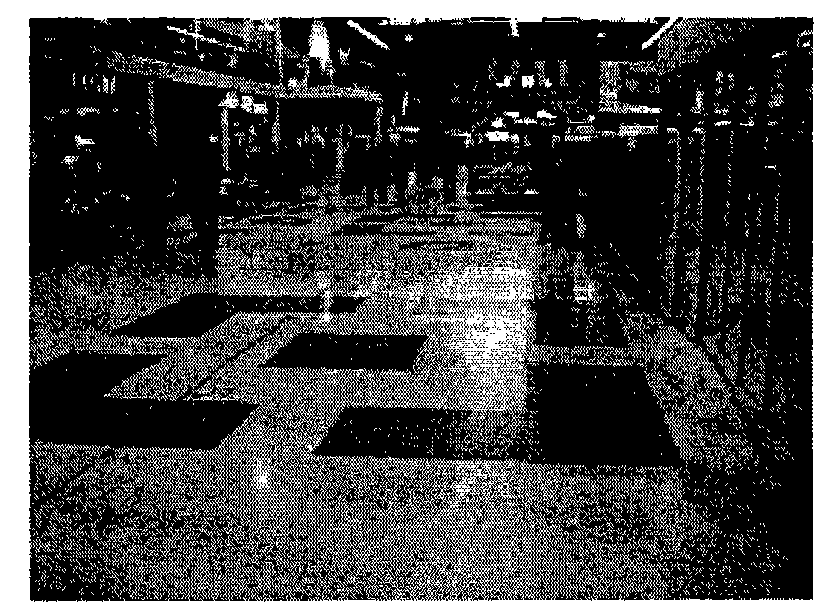

Method for detecting derelict without tracking process

InactiveCN101635026AObvious superiorityEasy to implementCharacter and pattern recognitionClosed circuit television systemsVideo monitoringPublic place

The invention discloses a method for detecting a derelict without a tracking process, which comprises the following steps: extracting pixel points probably belonging to the derelict from each frame of an image input by a camera by using a method based on the pixel points, and updating a Gaussian mixture model of a corresponding position by using RGB color information of each pixel point probably belonging to the derelict; and inputting the RGB color information of each pixel point in the image into the updated corresponding Gaussian mixture model, detecting out the pixel points matching with the color information describing the derelict probably appearing at the pixel point of the corresponding position, finishing the detection of the derelict in a video, and giving an alarm if a derelict is detected. The derelict detection without the tracking process contains no tracking process so that the derelict detection plays a very important role of improving the precise detection on the derelict in a monitored scene by a monitoring system in a complex scene. The method can be applied to an intelligent video monitoring system for the help of recognizing the derelict in a public scene so as to improve the security of public places.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

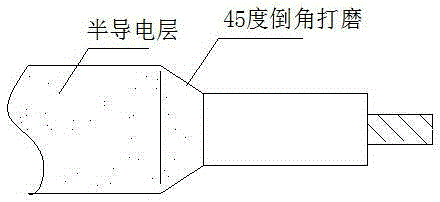

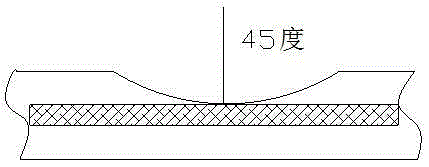

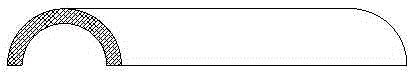

Insulation repair method for 10 kV high-voltage cable

InactiveCN105262013AGuaranteed factory workmanshipReduce the chance of failureApparatus for repairing insulation/armouring cablesElectrical conductorHigh pressure

The invention belongs to the technical field of cable repair, and specifically relates to an insulation repair method for a 10 kV high-voltage cable. According to the method, when the 10 kV three-core cable has a phase core breakdown fault, according to the damaged conditions of insulation and a wire core, three wire core bodies can be maintained without sawing three conductor wire cores of the cable if the conductor wire cores of the cable after breakdown are not obviously damaged, and the 10 kV high-voltage cable "main insulation repair" manufacturing process is employed at a fault wire core insulation breakdown position for rapid repair processing. According to the method, cable wire core insulation with fault breakdown can be rapidly, simply, and effectively repaired, and recovery of power transmission is rapidly achieved.

Owner:JIUQUAN IRON & STEEL GRP

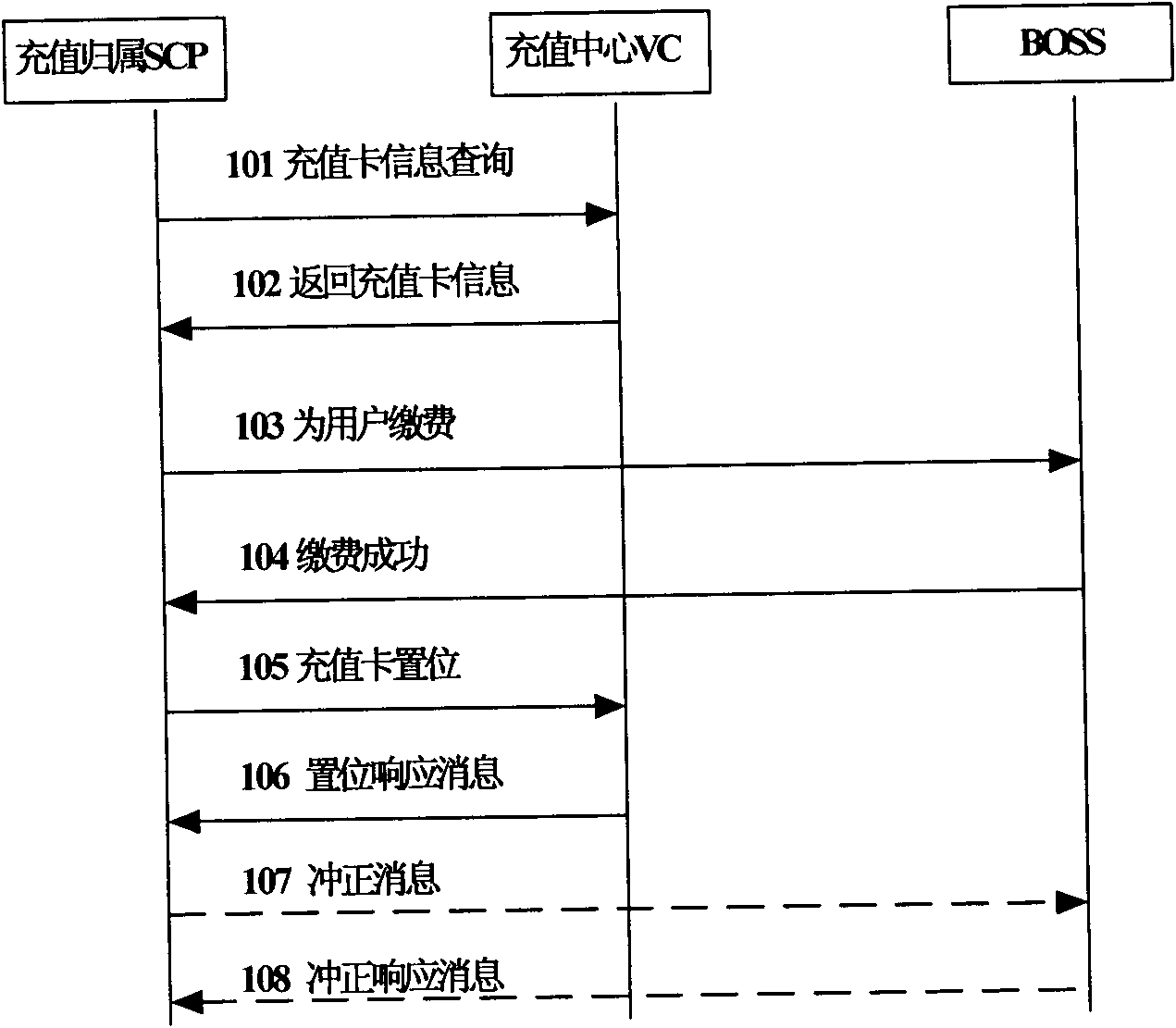

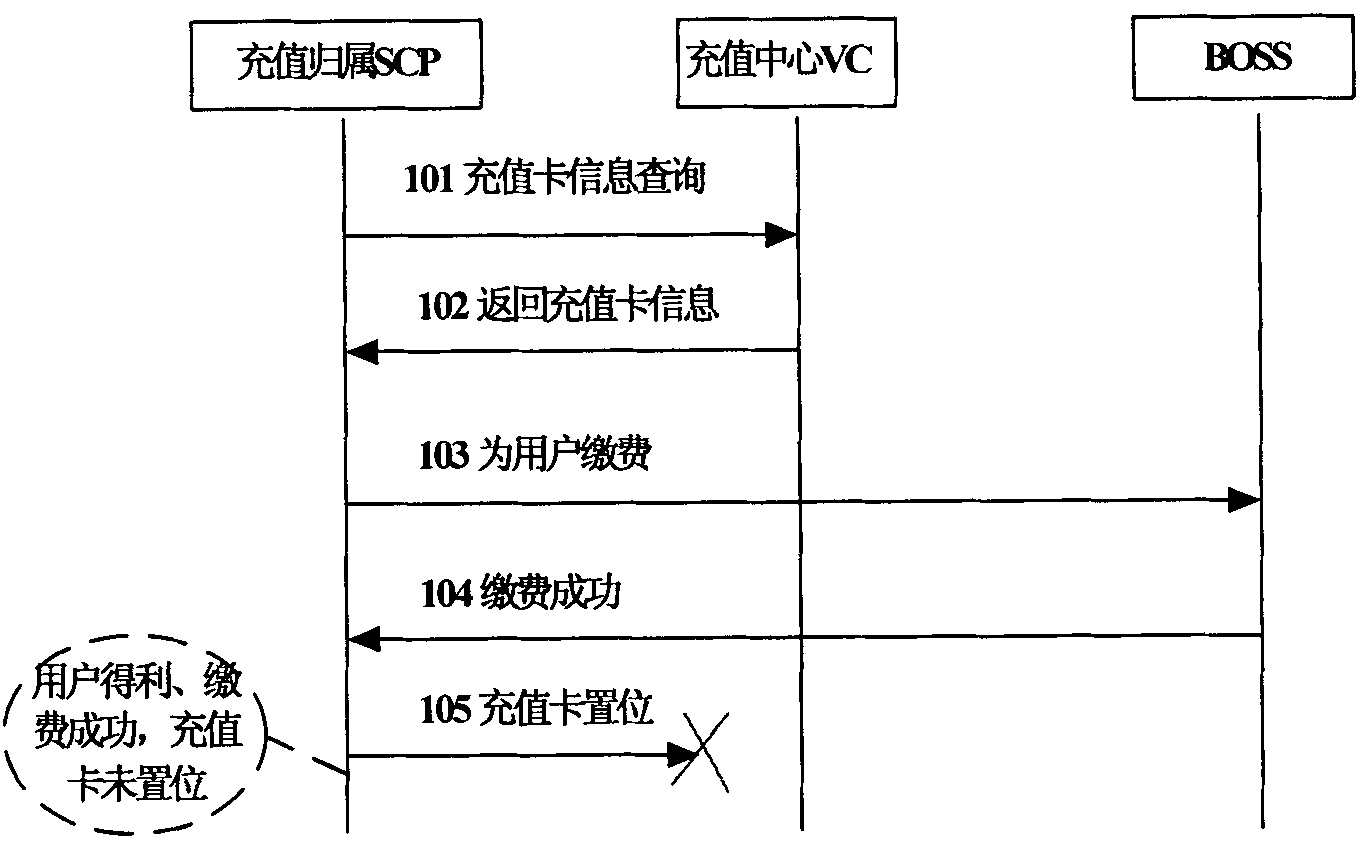

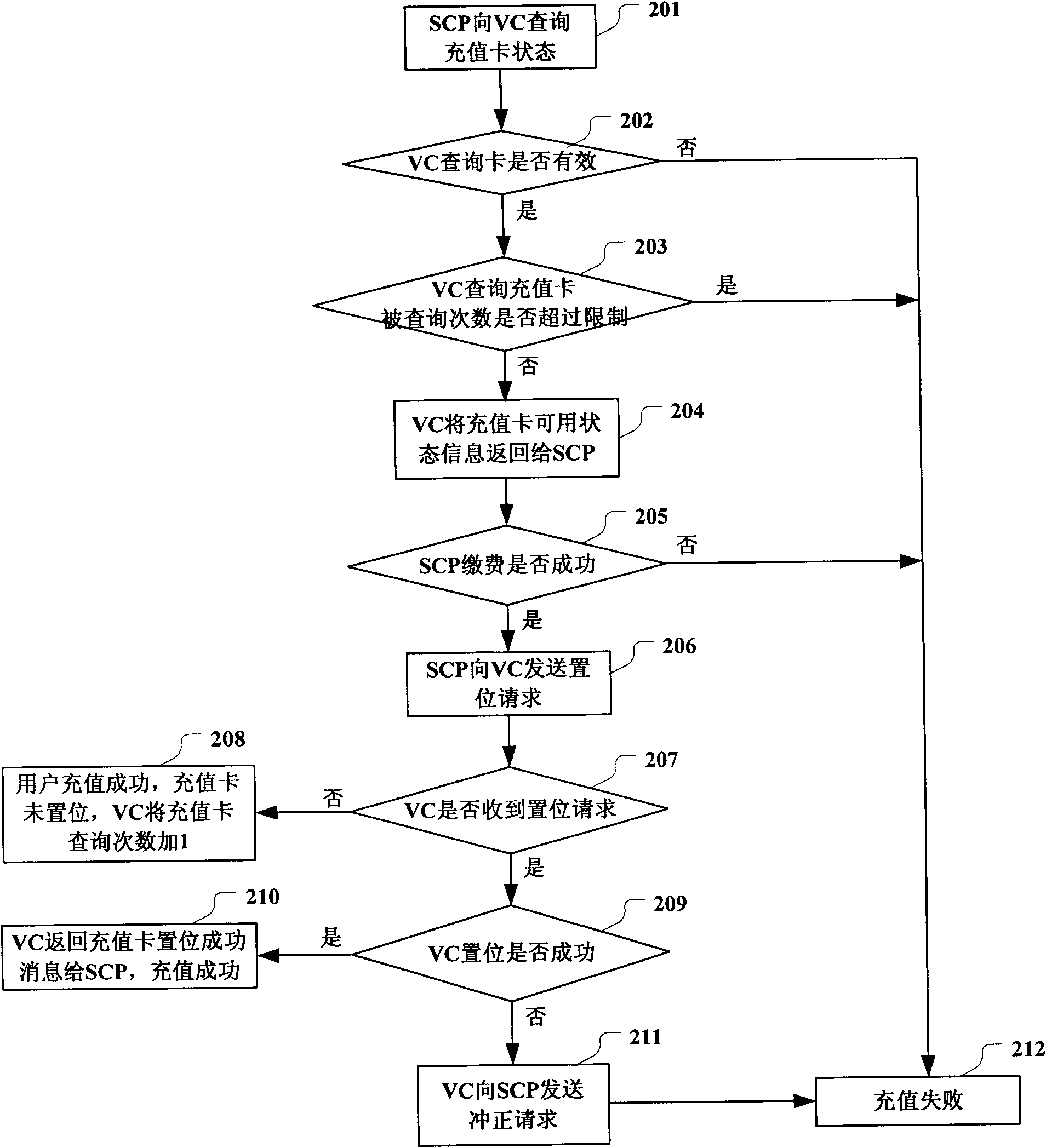

Method, device and system for recharging by using voucher card

ActiveCN102467770ATo achieve the locking effectReduce and timely eliminate the risk of repeated rechargeCoded identity card or credit card actuationComputer hardwareVoucher

The invention discloses a method, a device and a system for recharging by using a voucher card. The method for recharging by using the voucher card comprises the steps that a service control point (SCP) inquires a voucher center (VC) about the inquired times of the voucher card according to received subscriber voucher card information; and when the inquired times of the voucher card reach a preset threshold, the VC locks the voucher card. By using the method, the device and the system, the repetitive recharging risk of the voucher card is effectively reduced and precluded in time, and the situation that great losses are brought to an operator because one voucher card is repetitively used for recharging is avoided.

Owner:CHINA MOBILE GROUP ANHUI

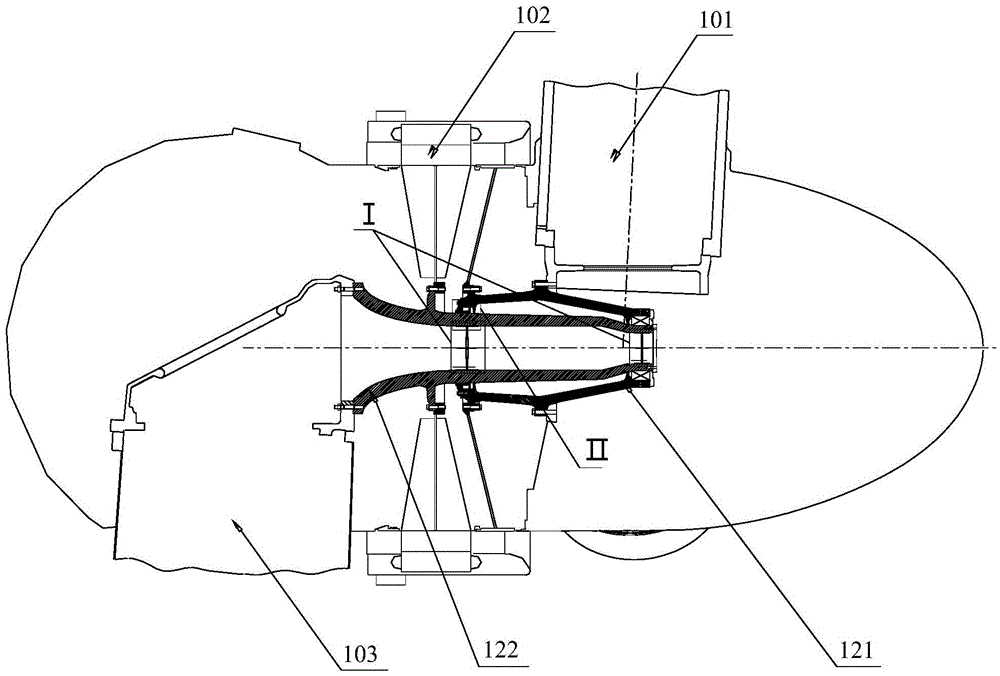

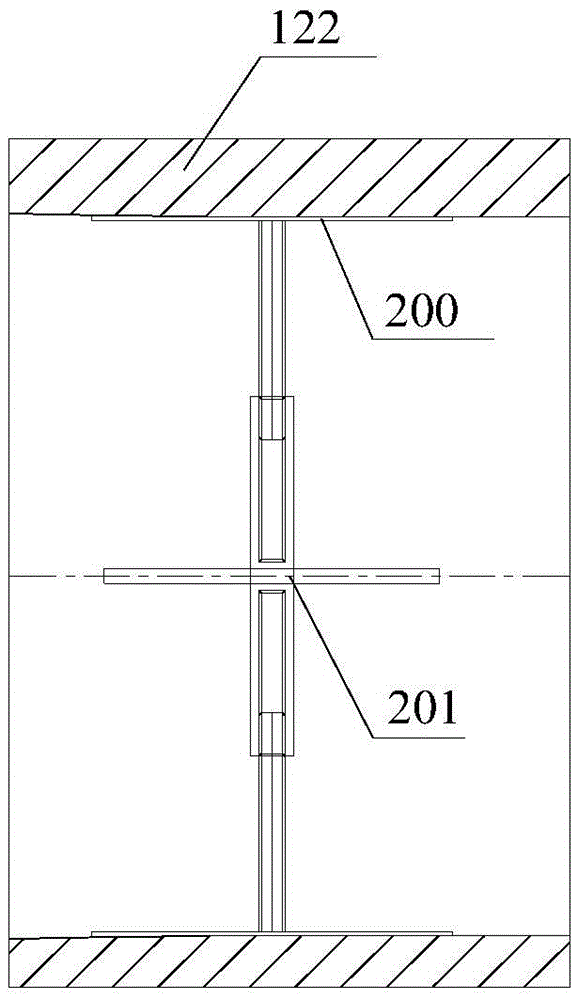

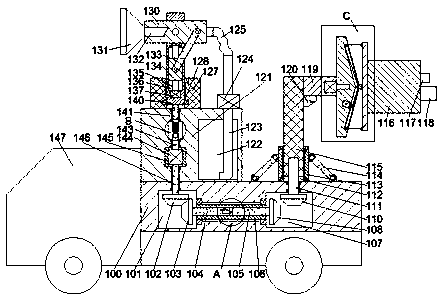

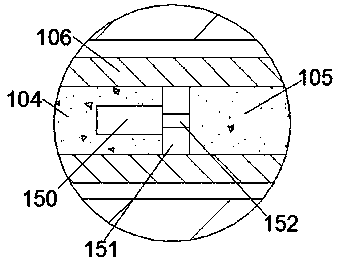

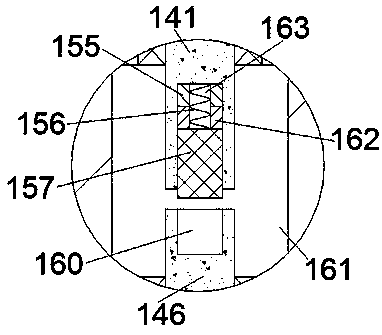

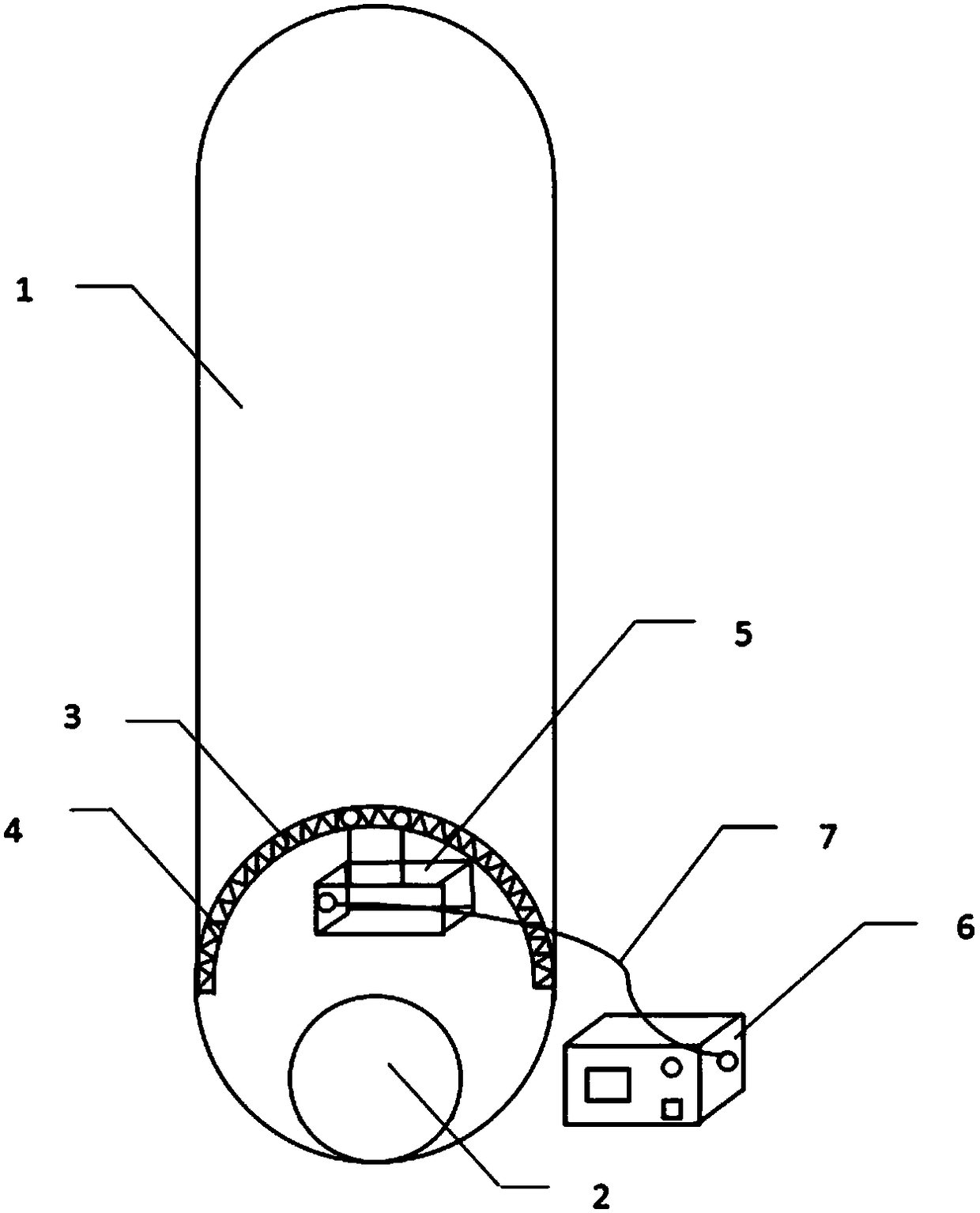

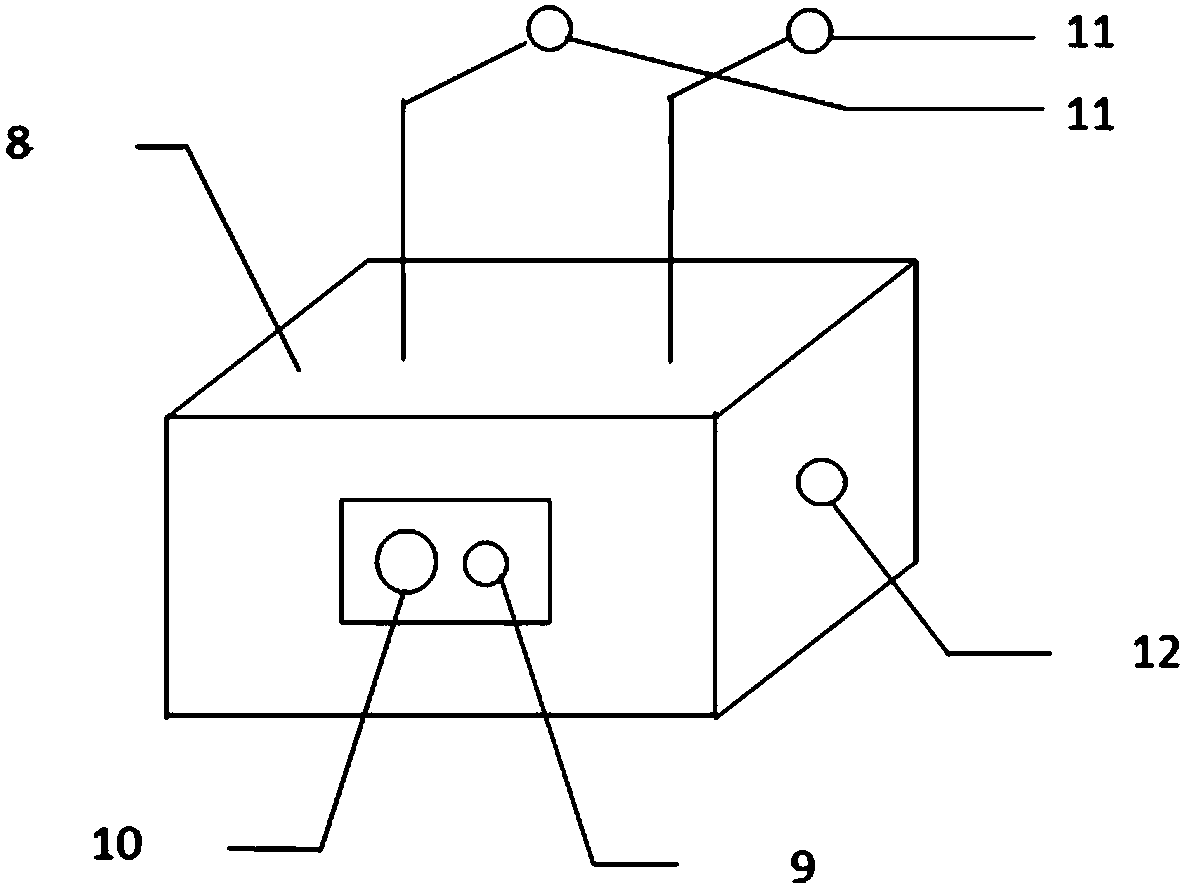

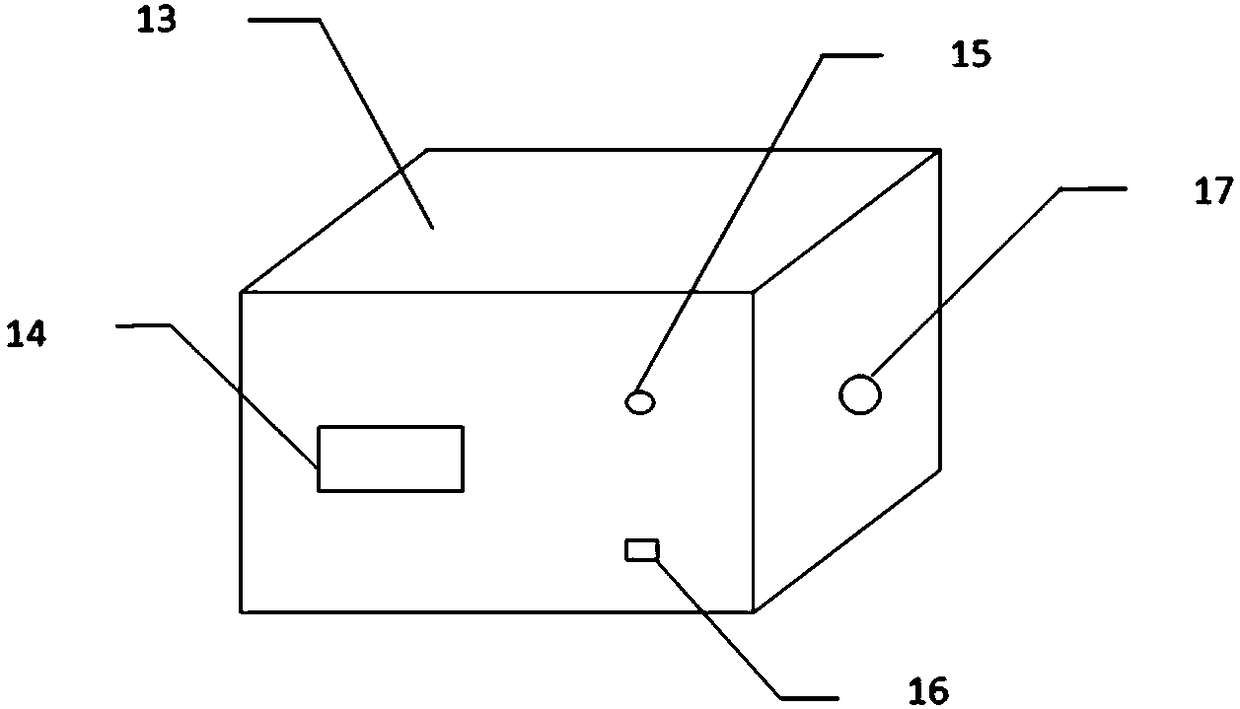

Bearing protection method and device for wind driven generator

ActiveCN105484949AAvoid huge lossesRun-in time is shortBearing componentsMachines/enginesWind drivenFailure rate

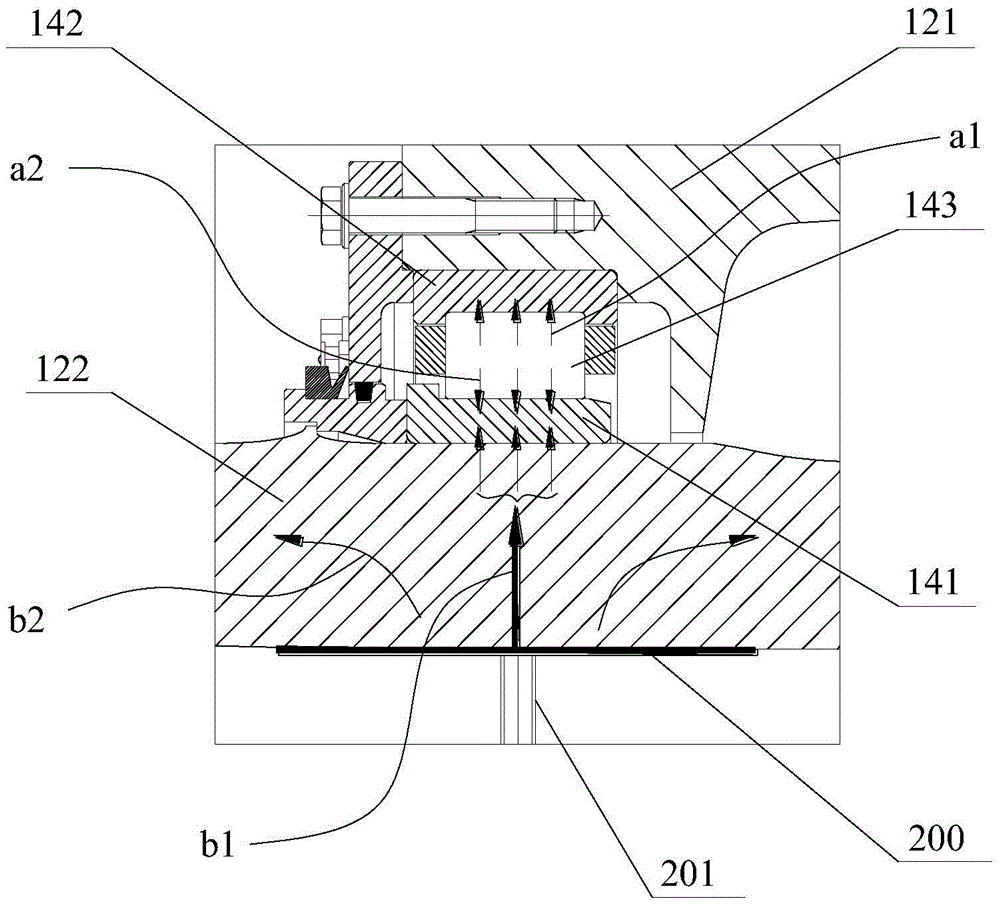

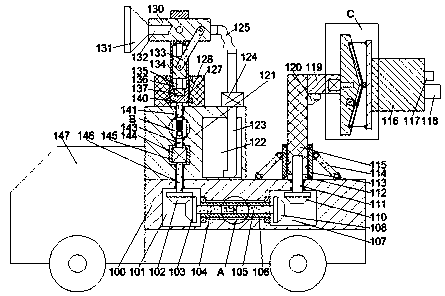

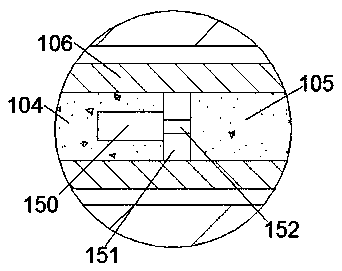

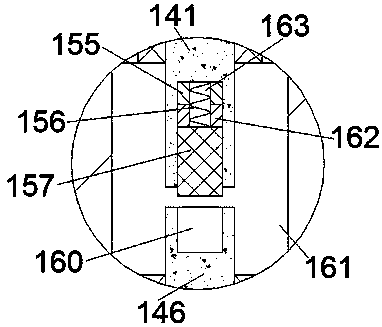

The invention discloses a bearing protection method for a wind driven generator. A bearing is arranged between a stator spindle of the wind driven generator and a rotor shaft of a generator rotor, and the stator spindle, the bearing and the rotor shaft form a shaft system of the wind driven generator; a heat source is arranged at the position corresponding to the bearing in the radial direction of the shaft system. The bearing protection method comprises the steps that when the wind driven generator is continuously stopped for a preset time and the environmental temperature is within a preset temperature range, the heat source is started to build a temperature field in the radial direction of the shaft system, the temperature of the temperature field is sequentially increased from the rotor shaft and the bearing to the stator spindle, and through control over the temperature field, lubricating grease of the bearing reaches the set fluidized temperature; the wind driven generator is started. According to the method, bearing wear caused due to the fact that the wind driven generator is started at once when wind comes at a low-temperature environment can be reduced, and the bearing failure rate can be decreased. In addition, the invention further provides a bearing protection device for the wind driven generator.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Device resetting method based on watchdog

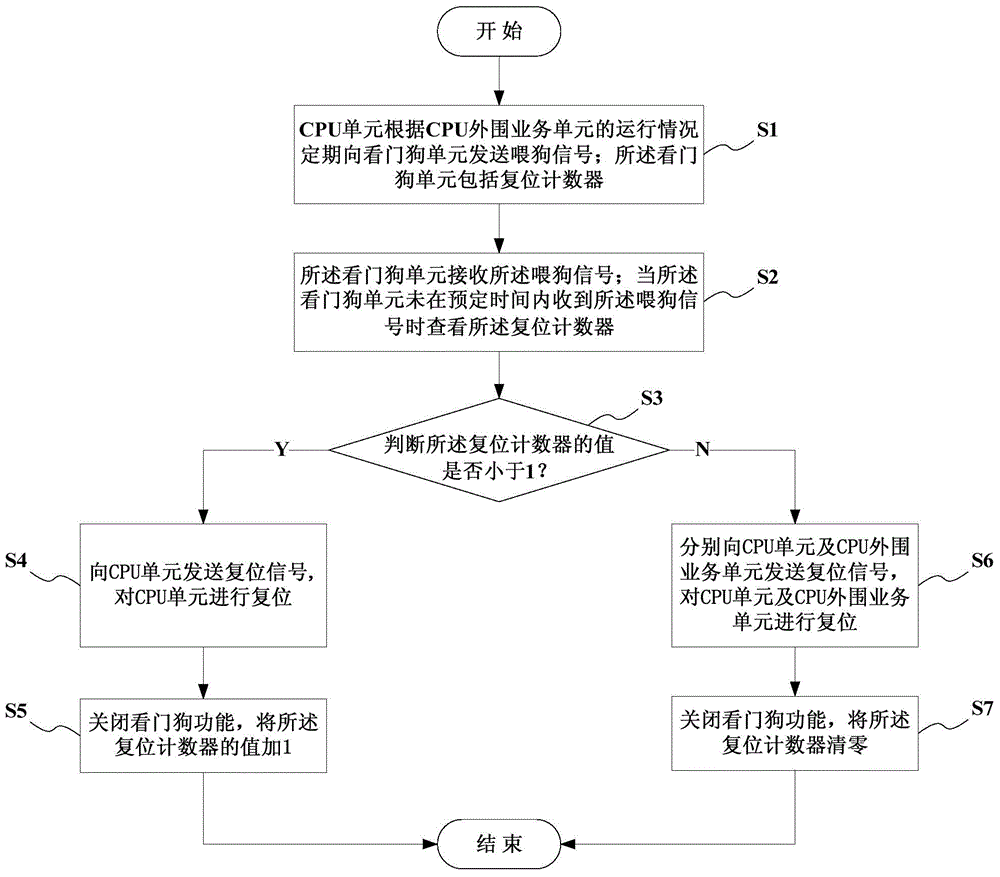

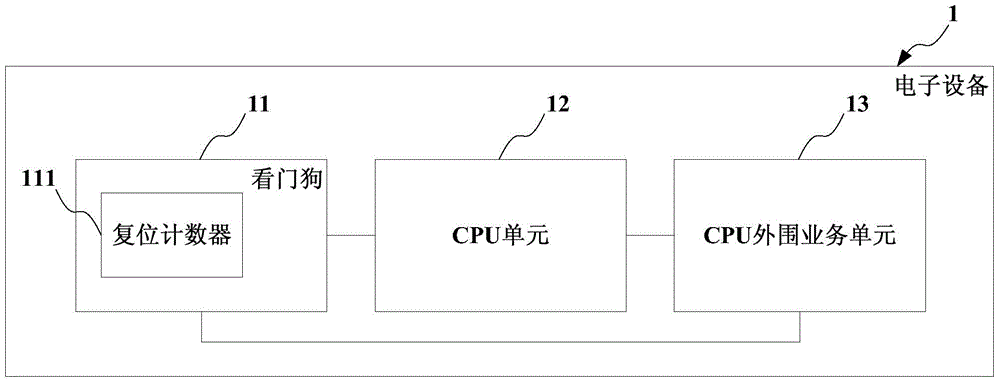

InactiveCN105068880AImprove experienceAvoid huge lossesFault responseData resettingCanis lupus familiarisEmbedded system

The present invention provides a device resetting method based on a watchdog, comprising: periodically sending, by a CPU unit, a feeding-dog signal to a watchdog unit according to a running situation of a CPU peripheral service unit, wherein the watchdog unit comprises a reset counter; receiving, by the watchdog unit, the feeding-dog signal; checking the reset counter when the feeding-dog signal is received in a preset time; determining whether a value of the reset counter is less than 1, if yes, sending a reset signal to the CPU unit, resetting the CPU unit, turning off a watchdog function, and adding 1 to the value of the reset counter; and if no, sending a reset signal separately to the CPU unit and the CPU peripheral service unit, resetting the CPU unit and the CPU peripheral service unit, turning off a watchdog function, and performing zero clearing on the reset counter. A reliable watchdog reset mechanism is provided, to implement proper recovery for various "system halted" situations of an electronic device, thereby preferably avoiding loss caused by direct service interruption of the device.

Owner:PHICOMM (SHANGHAI) CO LTD

Quick response type remote sensing big data processing system

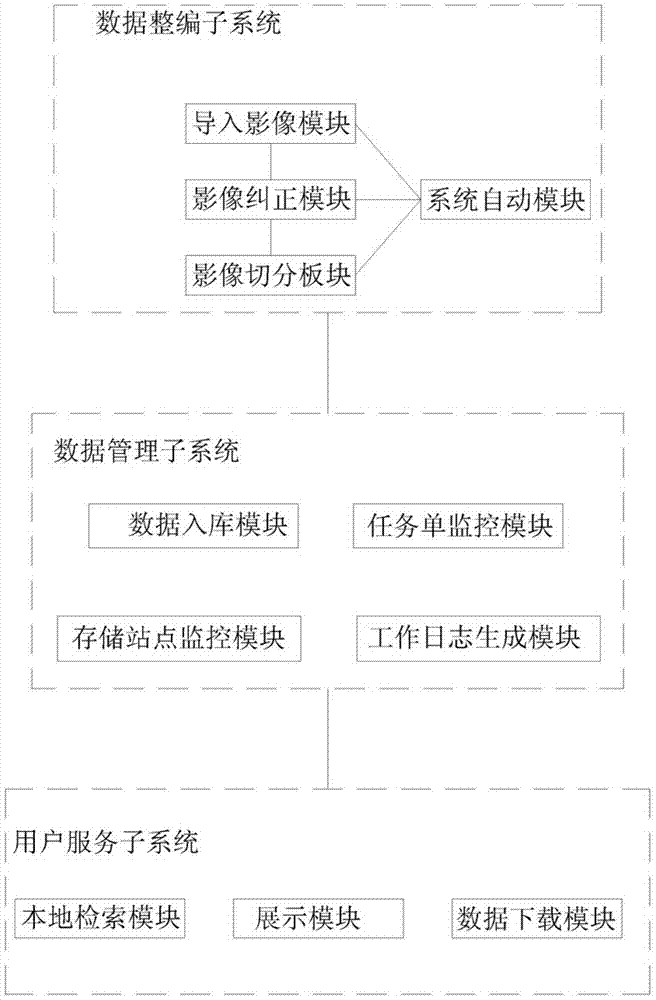

InactiveCN103970904AEasy to handleImprove response speedSpecial data processing applicationsData processing systemSensing data

The invention provides a quick response type remote sensing big data processing system. A system hardware layer comprises a main control server connected with a cluster node, and software comprises a data reorganizing subsystem, a data management subsystem and a user service subsystem. According to the quick response type remote sensing big data processing system, an original remote sensing data system is optimized, the response speed and the computing speed of the system are increased, a huge amount of remote sensing image original data can be quickly processed, and massive losses caused by data delay are avoided.

Owner:CHONGQING UNIV

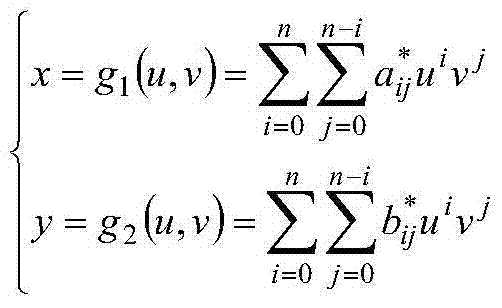

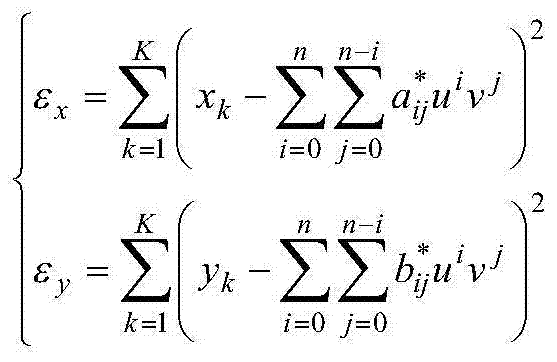

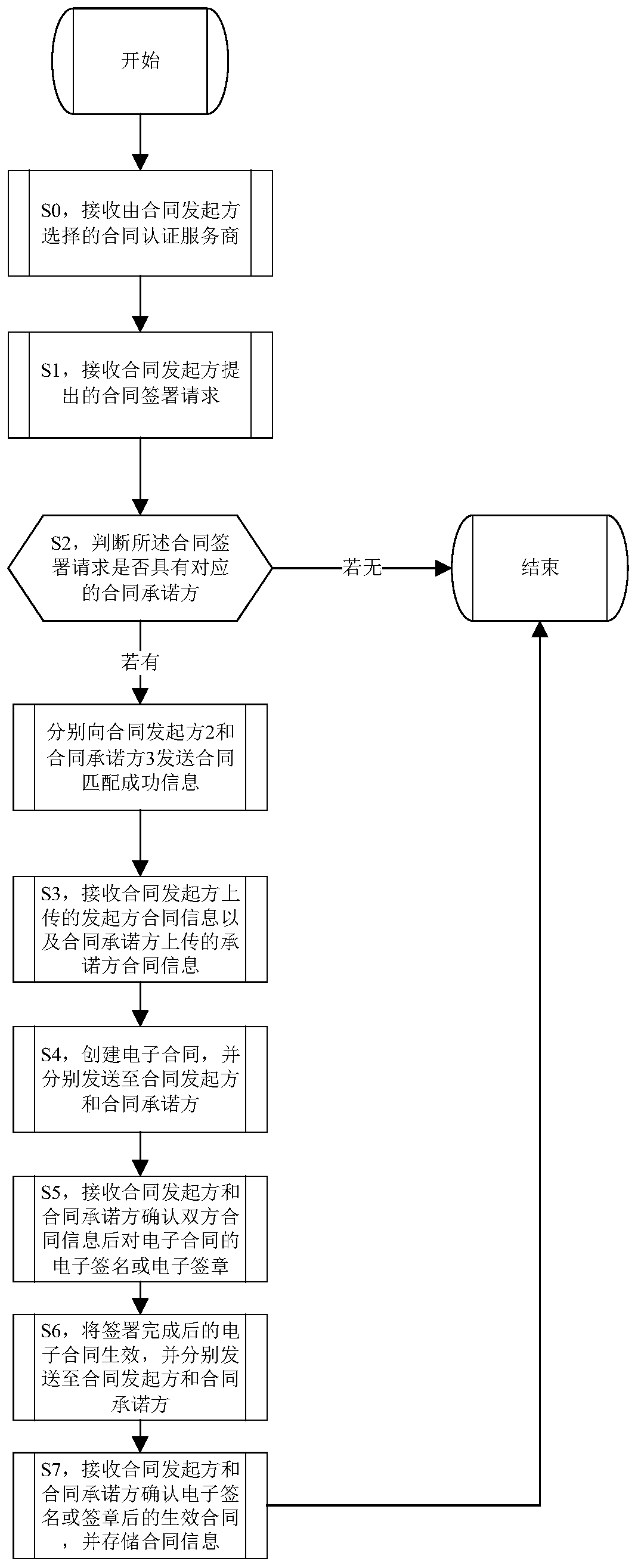

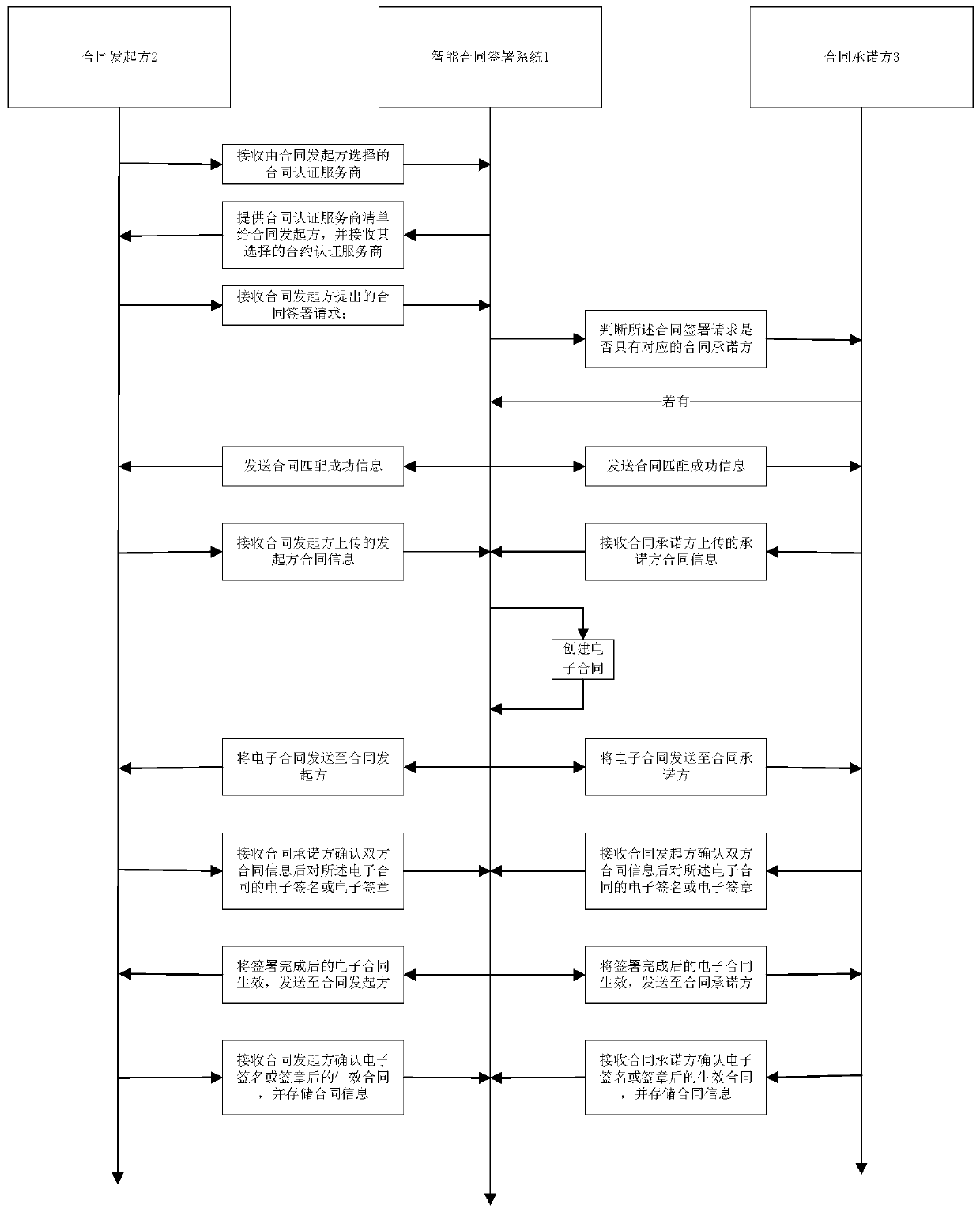

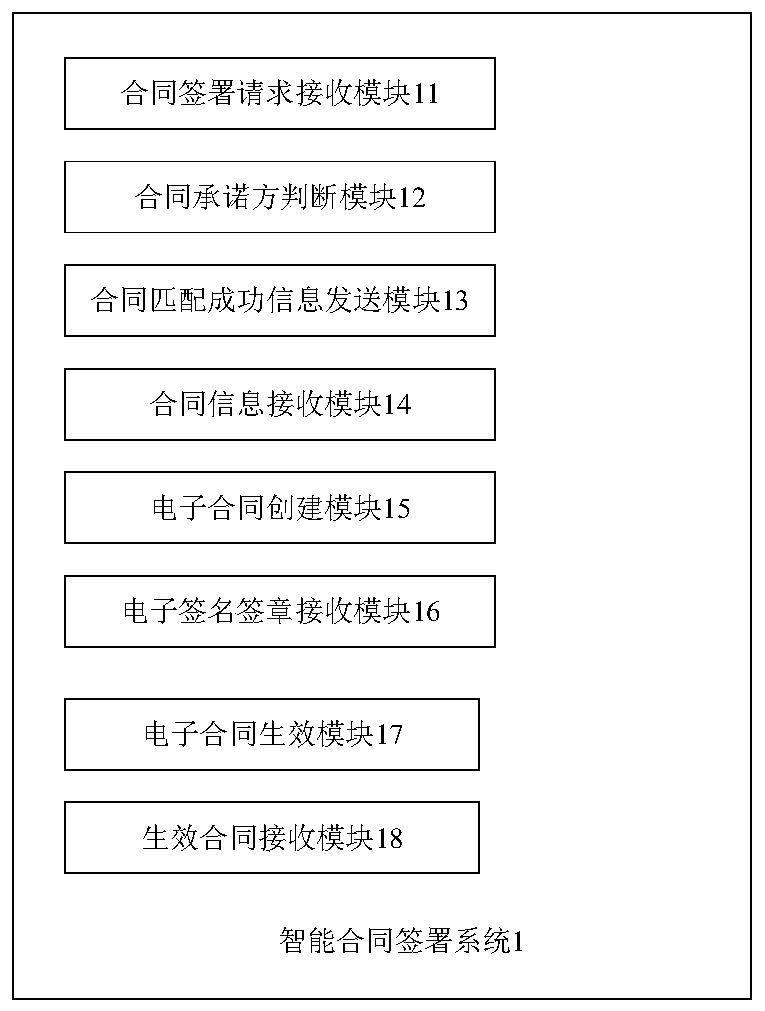

Intelligent contract signing method and system, computer equipment and storage medium

PendingCN109816329AImprove production efficiencyImprove conversion efficiencyOffice automationElectronic contractsWorking pressure

The invention provides an intelligent contract signing method and system, computer equipment and a storage medium. The method comprises the following steps: receiving a contract signing request proposed by a contract initiator; judging whether the contract signing request has a corresponding contract committer or not; receiving initiator contract information and committer contract information; Creating an electronic contract; receiving an electronic signature or an electronic signature of the electronic contract; The signed electronic contract takes effect; And receiving the electronic signature or the signed effective contract. According to the technical scheme, the electronic signature or electronic signature of the electronic contract is realized based on the block chain, so that the fatigue strength and the working pressure of an operator are greatly reduced, the selection range of a user is expanded, convenience is provided for the user to select an appropriate electronic authentication service provider, and the safety and the accuracy of the electronic contract are ensured; The operation steps of electronic signatures or electronic signatures are simplified, the requirementsof complex commercial environments are met, and the accuracy and the inspection efficiency of electronic contracts are improved.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

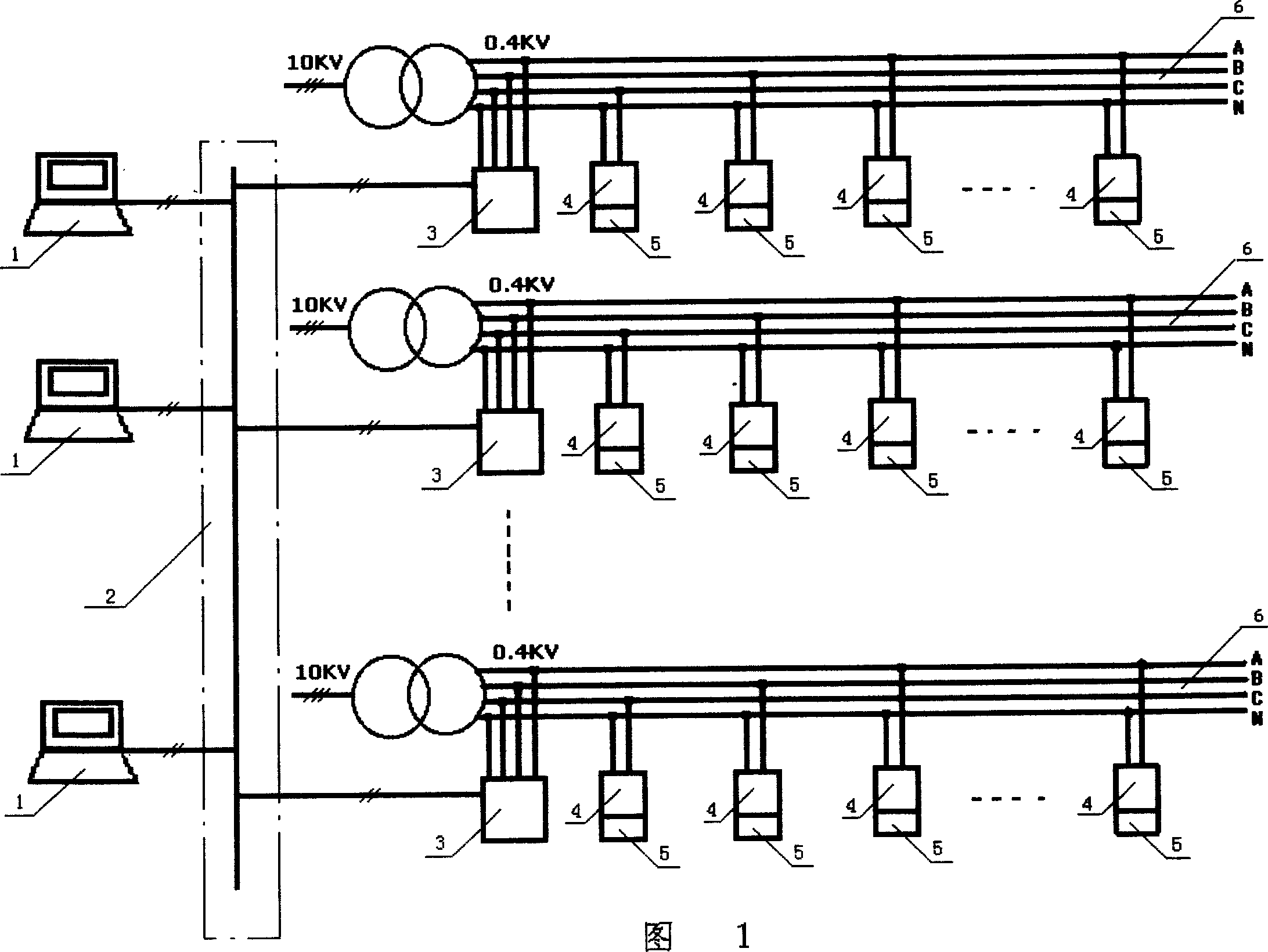

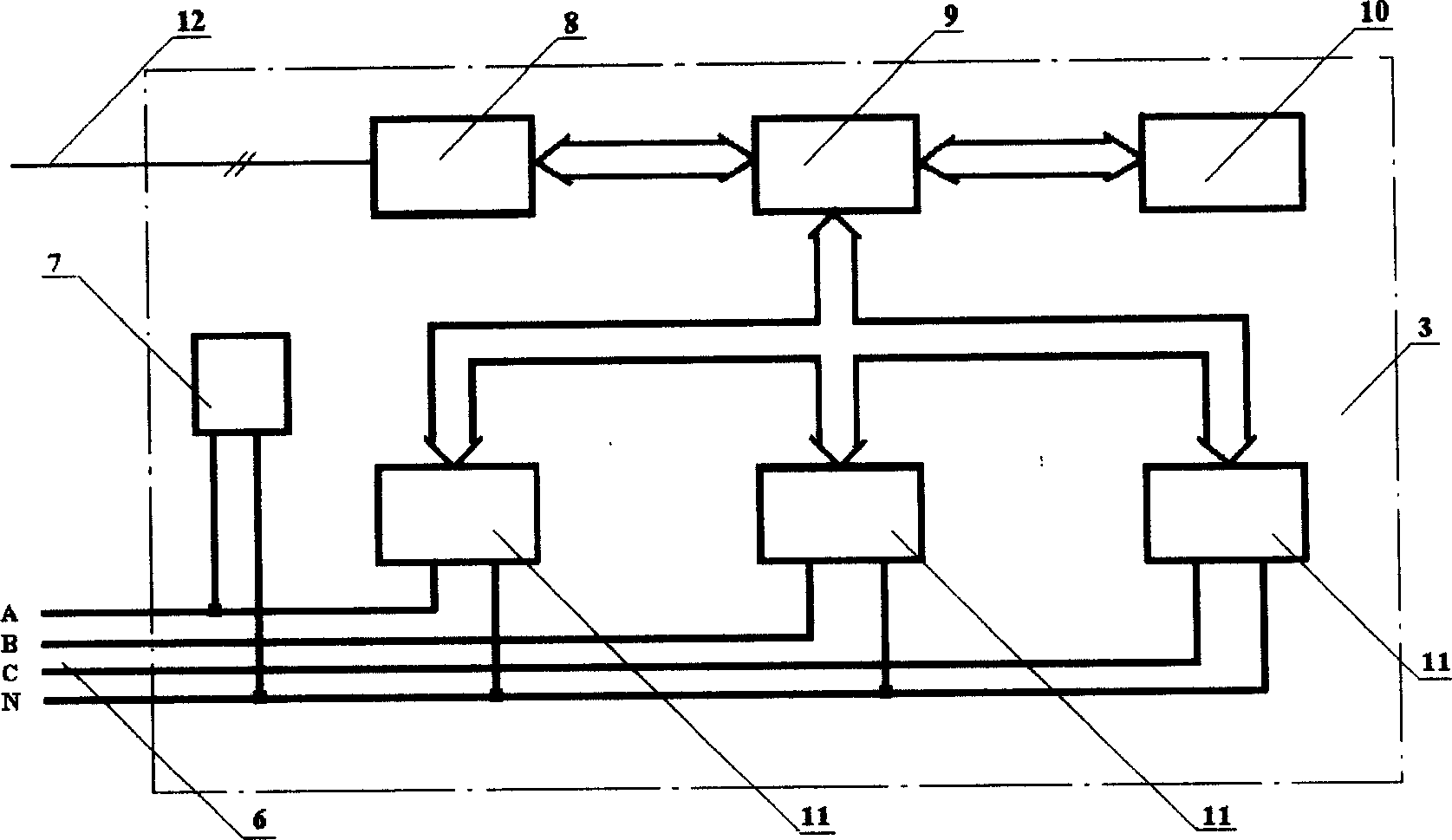

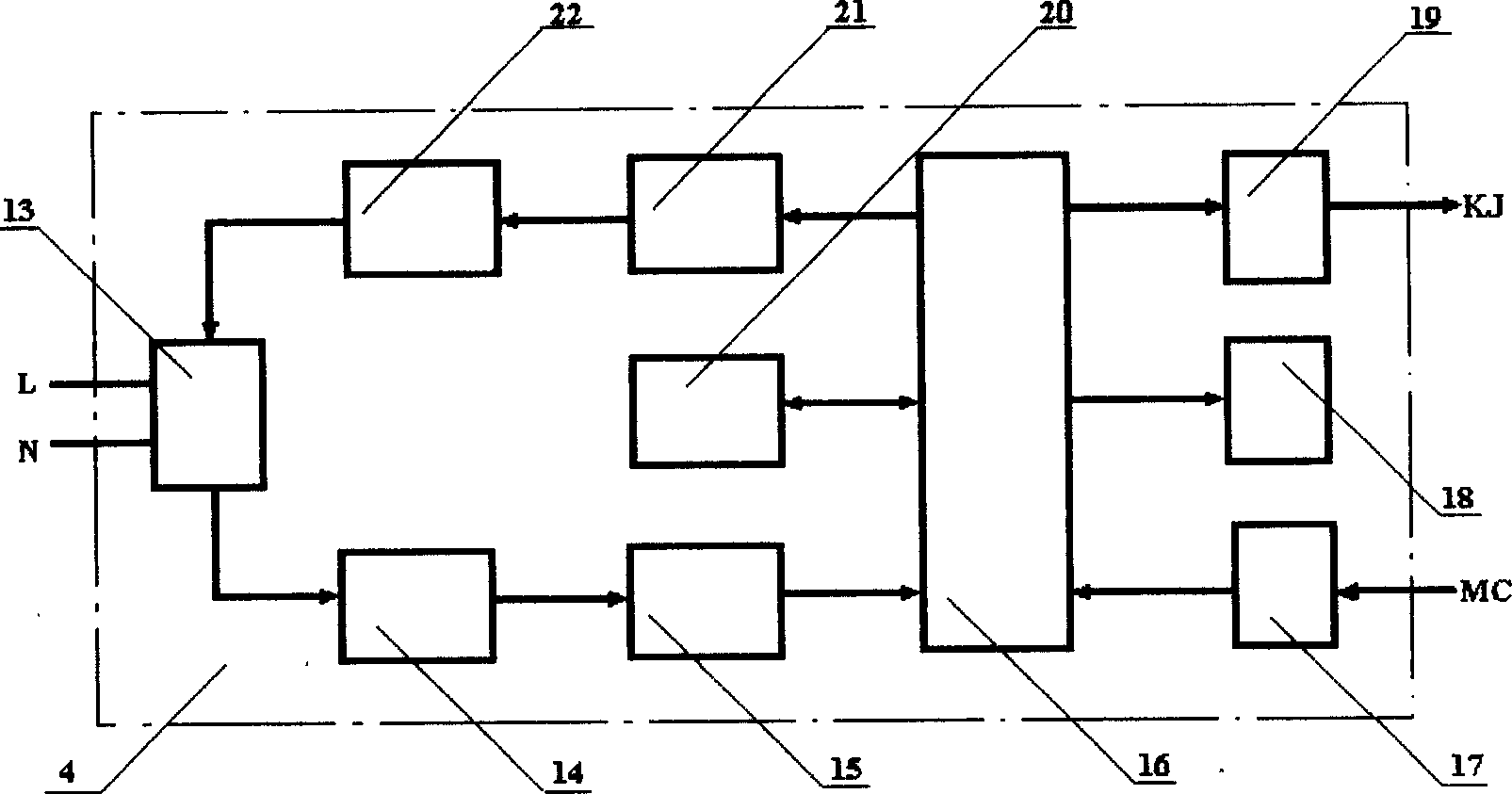

Carrier data safety protection method and recording system device of pre-payment meter

InactiveCN1560638AAvoid arrearsReal-time monitoring of running statusSpecial tariff metersLow voltageCarrier signal

The invention is a data security protection and meter reading system device for an advance payment ammeter. When the user pays for electricity, the worker sends the electricity purchasing data to user ammeter through electric wire directly; the user ammeter carrier model receives the data, stores it into the electricity purchasing data memory circuit with determined format, and returns the affirmance information to the meter reading electricity sale computer through electric wire to be checked. The system is made up of meter reading electricity sale computer, meter reading collector, carrier of data memory circuit containing nonvolatile RAM device, user ammeter assembled together with the carrier model, a downstream channel and a upstream channel made up of low voltage electricity supplying circuit.

Owner:齐长远

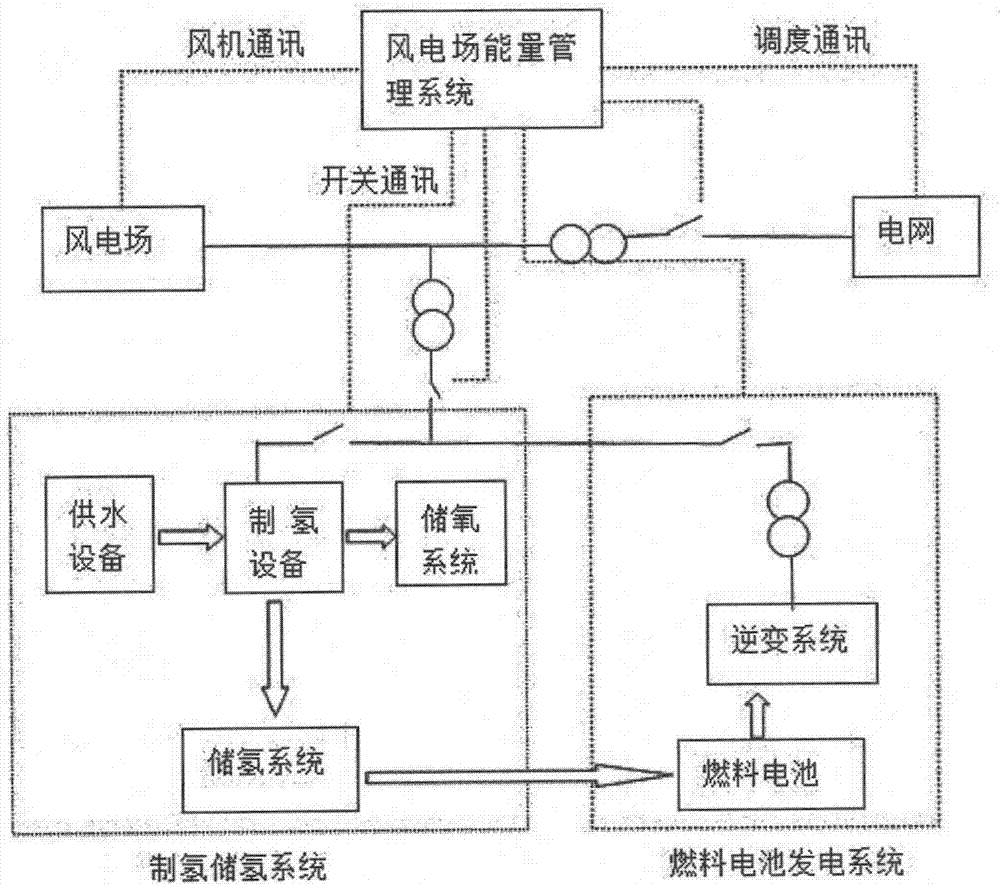

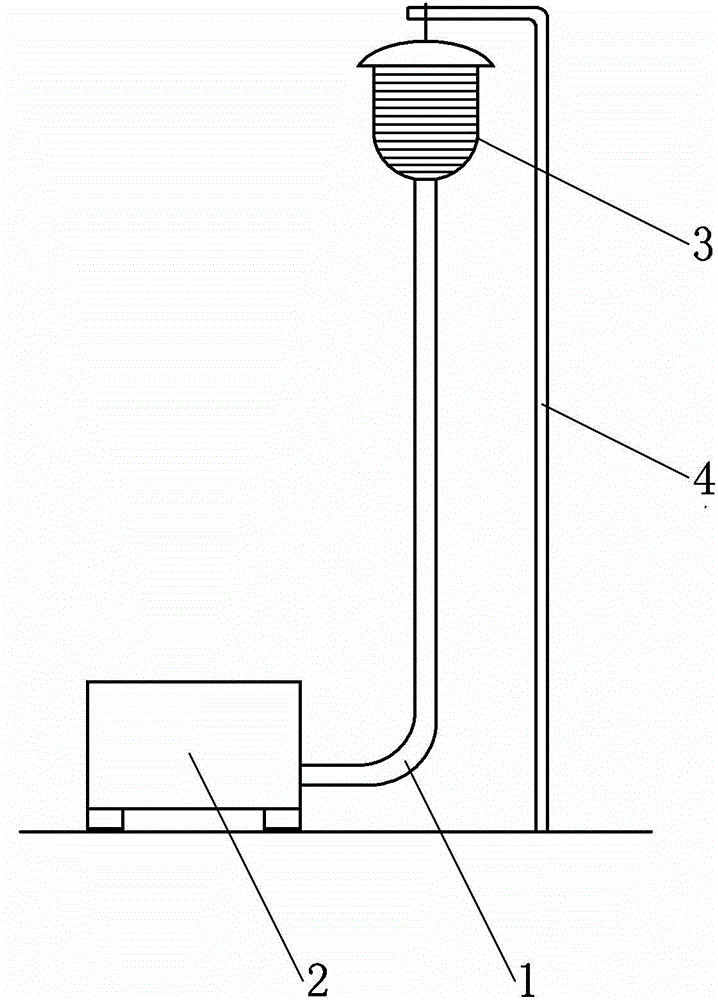

Large-scale wind power storage system and method

The invention provides a large-scale wind power storage system, which comprises a hydrogen production and hydrogen storage system, a fuel cell power generation system and a wind power plant energy management system. The wind power plant energy management system is connected with a wind power plant, a power grid, the hydrogen production and hydrogen storage system and the fuel cell power generation system; the wind power plant is connected with the power grid, the hydrogen production and hydrogen storage system and the fuel cell power generation system; and the hydrogen production and hydrogen storage system is connected with the fuel cell power generation system. The invention also provides a large-scale wind power storage method. The wind power plant energy management system serves as a control system of the whole wind power plant and is responsible for operation management and energy control of the wind power plant; the wind power plant realizes wind power generation to supply power to the power grid; when wind power is abundant, surplus power is provided for the hydrogen production and hydrogen storage system for water electrolysis hydrogen production and hydrogen storage; and when power is not sufficient, the stored hydrogen is converted into electric energy through the fuel cell power generation system, thereby realizing large-scale wind power storage. The system and method improve wind utilization efficiency and prevent huge loss.

Owner:SHANGHAI DIANJI UNIV

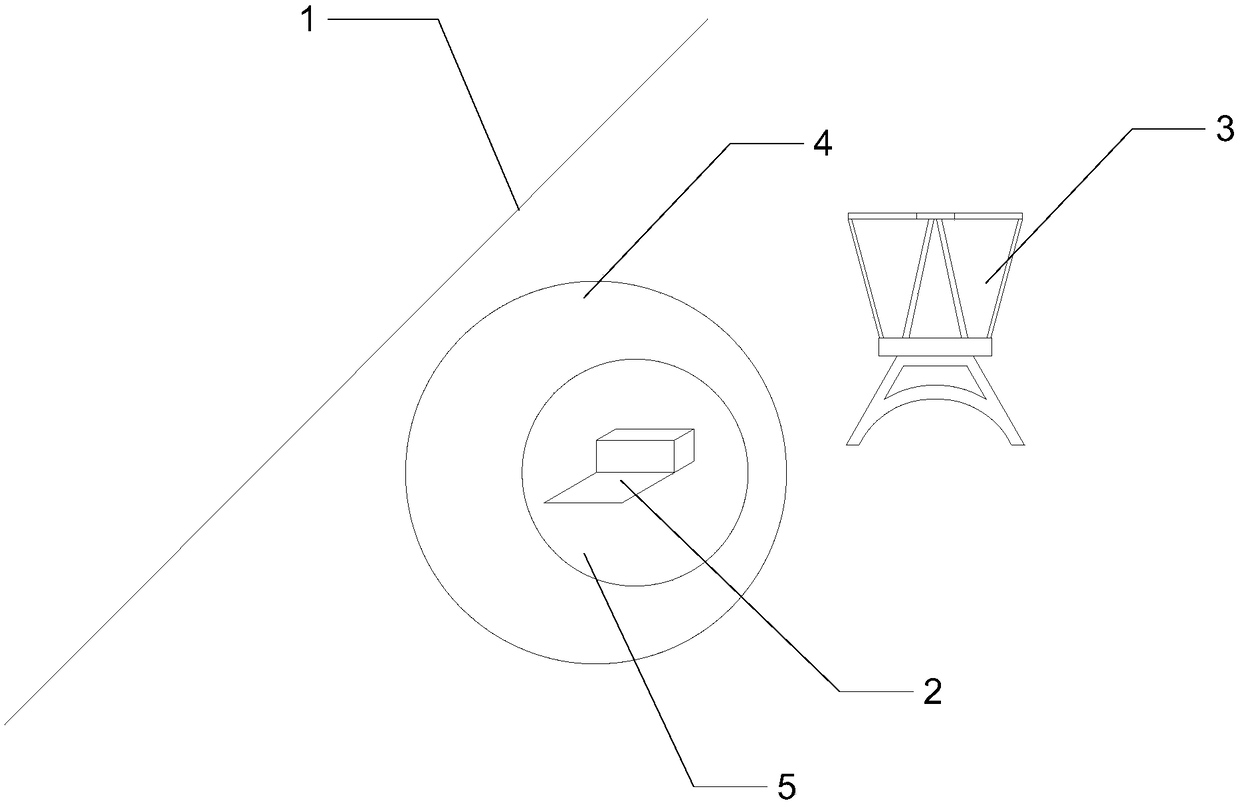

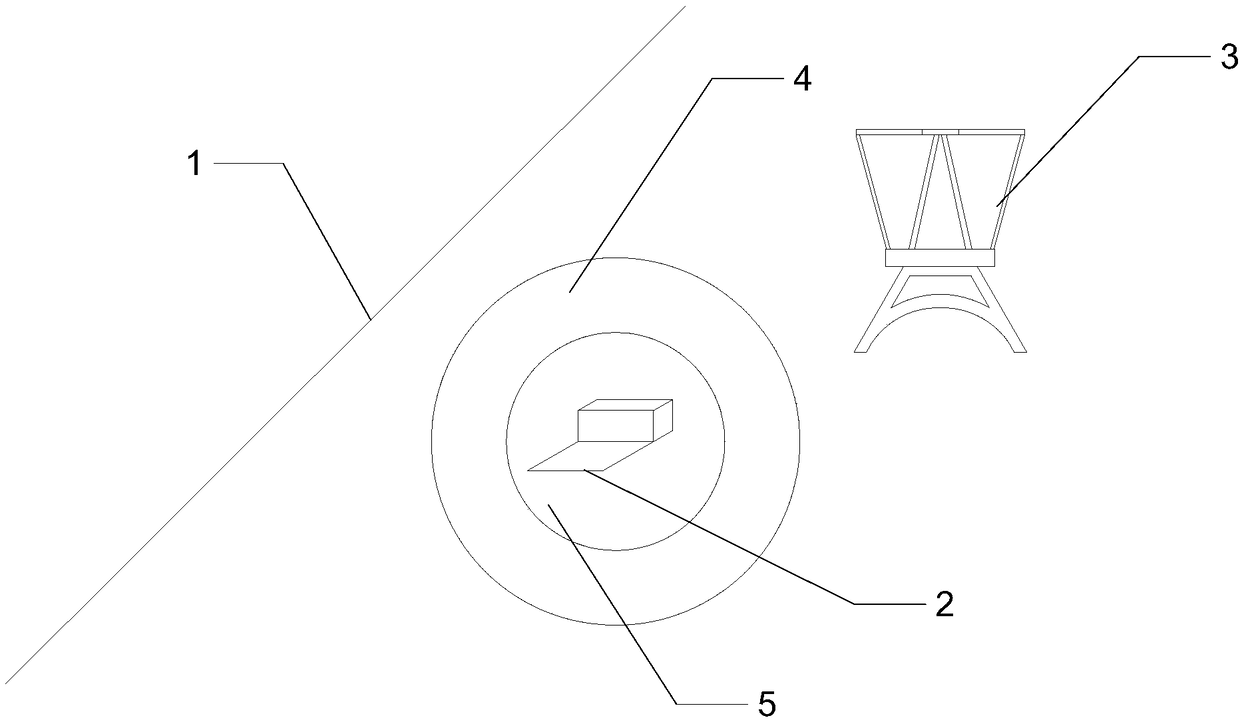

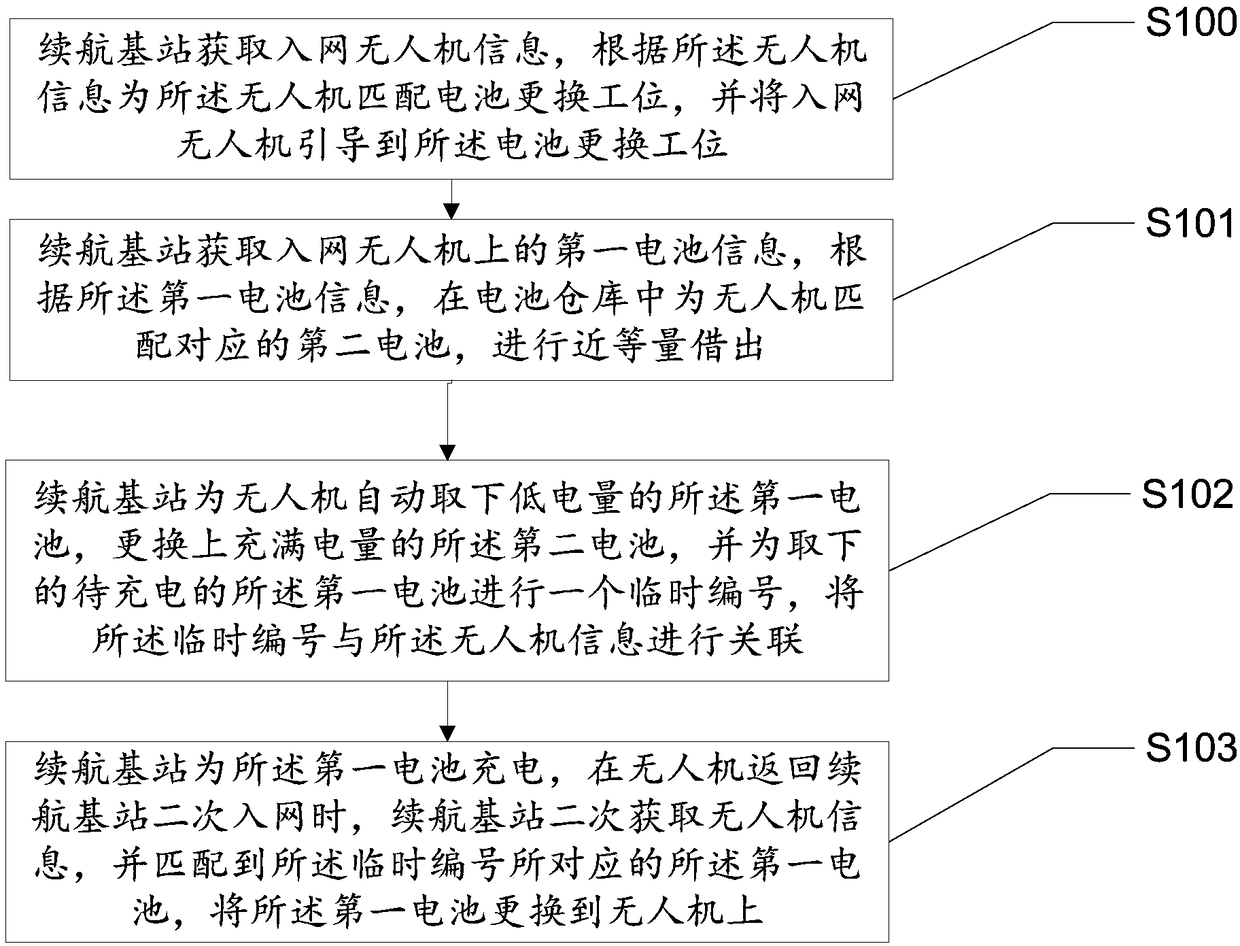

a third-party UAV endurance base station

ActiveCN109018424AAvoid collisionImprove battery lifeElectric vehicle charging technologyVehicular energy storageThird partyEngineering

The invention provides a third-party UAV endurance base station. The endurance base station matches the battery replacement station for the UAV according to the information of the UAV and guides the UAV to the battery replacement station by acquiring the information of the UAV entering the network., acquires the first battery information on the UAV, matches the second battery corresponding to theUAV in the battery warehouse according to the first battery information, and lends the second battery to the UAV in nearly equal amount; Automatically removes the first battery with low charge capacity for the unmanned aerial vehicle, replaces the second battery with full charge capacity, performing a temporary number for the first battery to be charged, and associates the temporary number with the unmanned aerial vehicle information; When the unmanned aerial vehicle (UAV) returns to the endurance base station and enters the network again, the information of the UAV is obtained twice, the first battery corresponding to the temporary number is matched, and the first battery is replaced on the UAV. The invention not only greatly prolongs the endurance of the unmanned aerial vehicle, but alsoavoids the huge loss brought to both sides due to the new and old batteries.

Owner:武汉梓俊信息科技有限公司

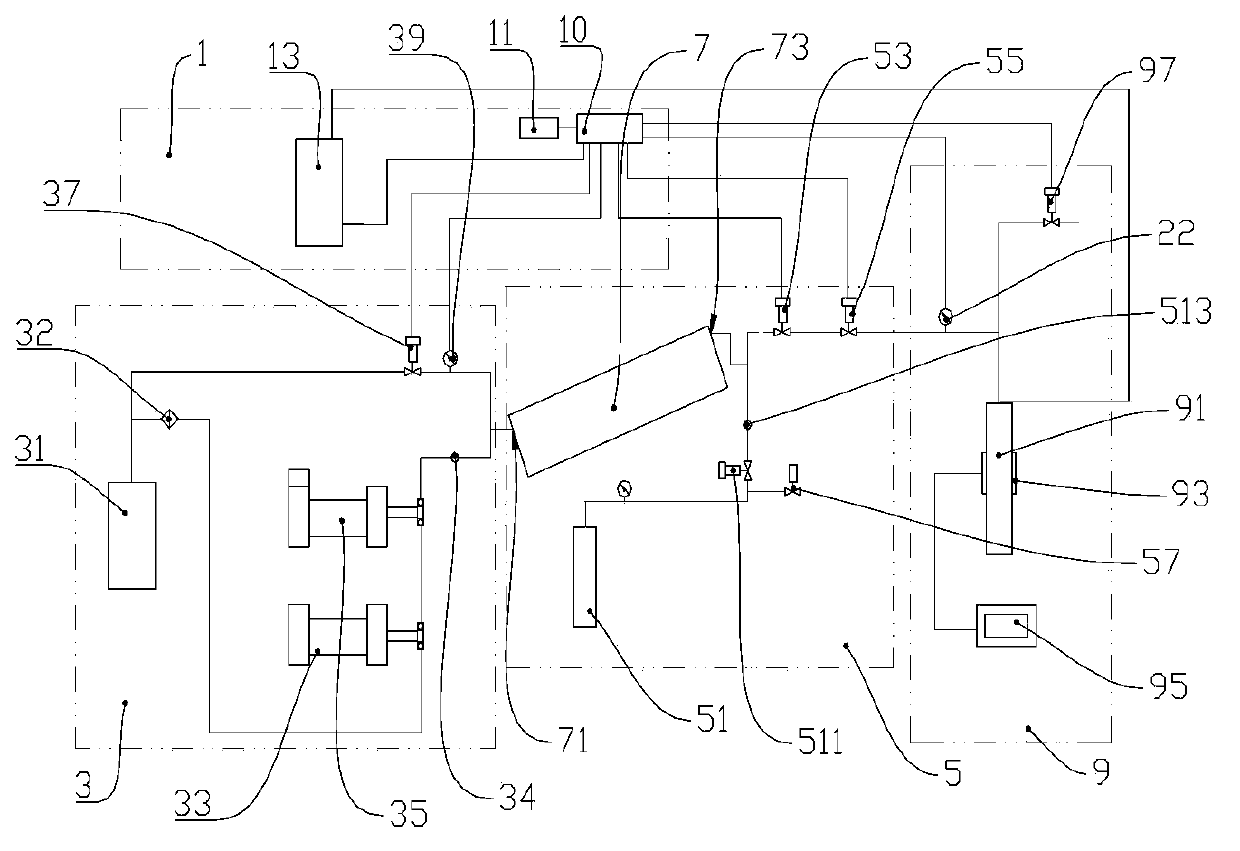

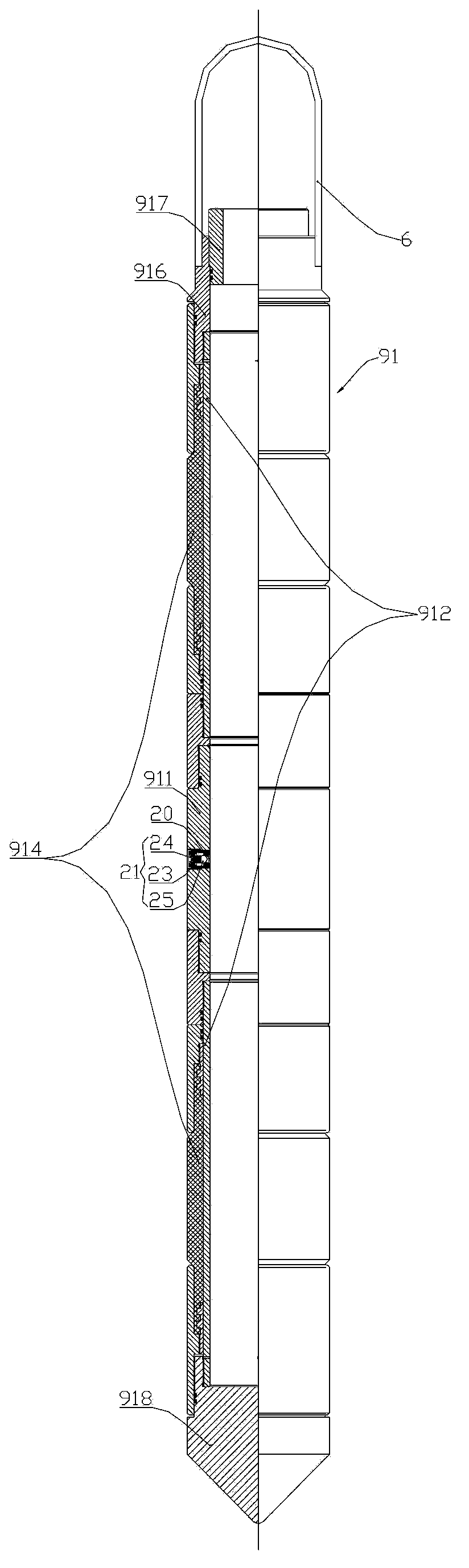

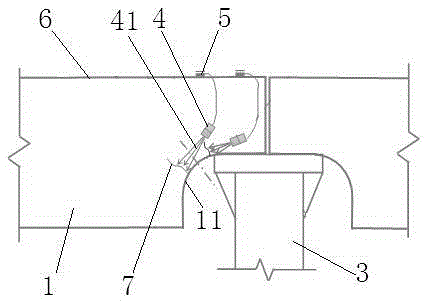

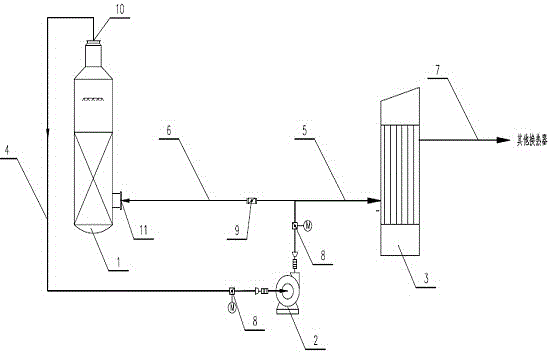

Air-tight sealing detection apparatus of threaded connection of oil casing tubes

ActiveCN103994865AAccurate removalEasy to operateMeasurement of fluid loss/gain ratePetroleumLiquid gas

The invention, which belongs to the field of petroleum and gas engineering and gas storage, discloses an air-tight sealing detection apparatus of threaded connection of oil casing tubes. The air-tight sealing detection apparatus comprises a liquid-gas power system, a detection gas source system and a detection execution system. The detection gas source system includes a booster energy storage device and a detection gas source. The detection execution system includes a detection tool, a gas collection sleeve and a leakage detection instrument; the detection tool includes a detection body, at least one central tube and a packer rubber sleeve; and a gas outlet valve is installed at the detection body. When detection is carried out, the detection gas enters a to-be-detected oil casing tube; and when detection is complete, the packer rubber sleeve is delocked and the detection gas is exhausted by an annulus cavity. The operation is convenient and the technology is reliable. Moreover, leakage data recorded by the leakage detection instrument can predict unsealed thread timely, thereby effectively removing the leaked thread. The secure guarantee can be provided for field detection of sealing of the oil casing tube; the massive loss caused by thread leakage can be avoided; and the long-time stable exploitation of gas well can be ensured.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

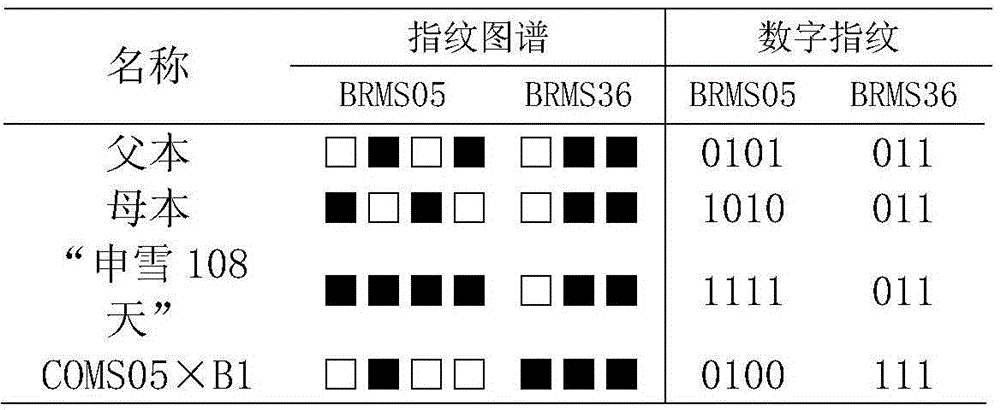

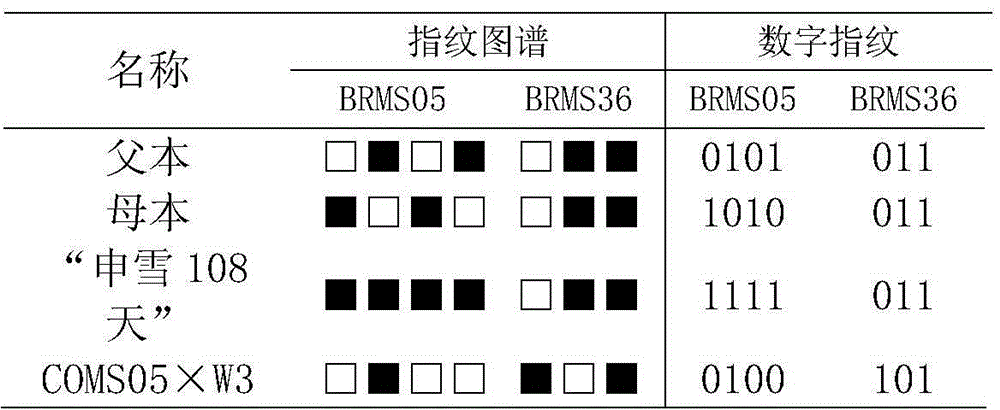

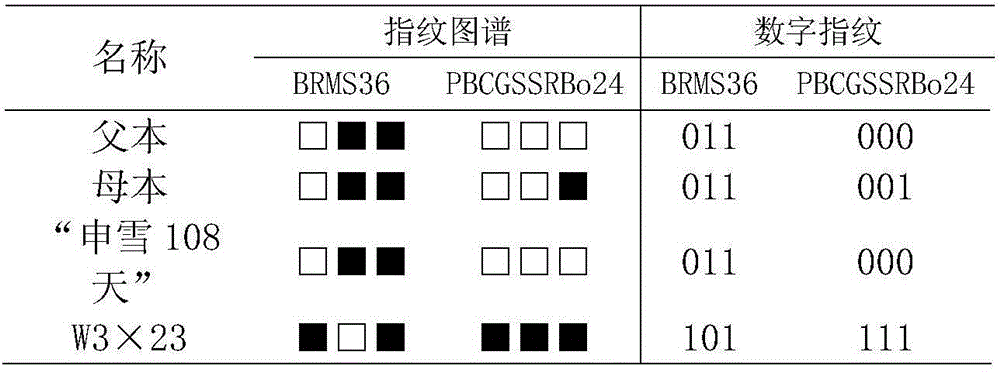

Fingerprint spectrum of cauliflower hybrid and construction method thereof

InactiveCN104561338AUniqueness guaranteedPrevent counterfeitingMicrobiological testing/measurementOrganismSibling species

The invention belongs to the technical field of molecular organisms and particularly relates to a fingerprint spectrum of cauliflower hybrid and a construction method thereof. The cauliflower hybrid is temporarily named as 'shenxue 108 day', and is a new cauliflower variety bred by multi-year hybrid in Shanghai funong seed industry limited company. The fingerprint spectrum and the construction method have the advantages that SSR molecular markers are utilized for carrying out quantitative marking on the 'shenxue 108 day', and the fingerprint spectrum different from sibling species or the same series of cauliflower varieties is constructed; the applicability to identification, selling and truth-falseness discrimination of farmers for the shenxue 108 day of the cauliflower is achieved. The fingerprint spectrum and the construction method have the effects that the mastering is easy and the benefit for producers and seed buyers can be protected.

Owner:SHANGHAI JIAO TONG UNIV

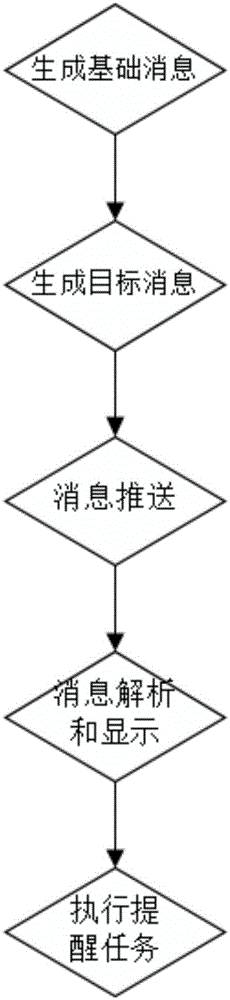

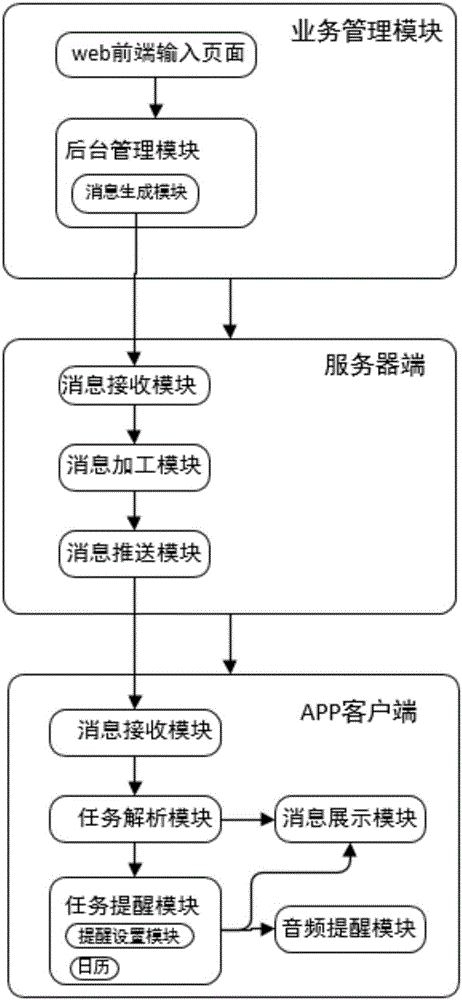

Message pushing based task tracking method and system

The invention discloses a message pushing based task tracking method and system, and belongs to the technical field of network communication. The message pushing based task tracking method comprises the steps of (1) generating a basic message; (2) generating a target message; (3) pushing the target message to an APP client; (4) analyzing and displaying the message, and setting a reminding task based on a task factor; and (5) carrying out the reminding task. The message pushing based task tracking method and system can generate the reminding task by regarding the target message as a carrier and cooperating with a task analysis module and a task reminding module of the APP client, can track and remind the message event sent to the APP client, can help a user to record important events which the user needs to participate, can avoid enormous losses of the user caused by missing the important events, and can improve the user experience of the software.

Owner:行愿环保科技有限公司

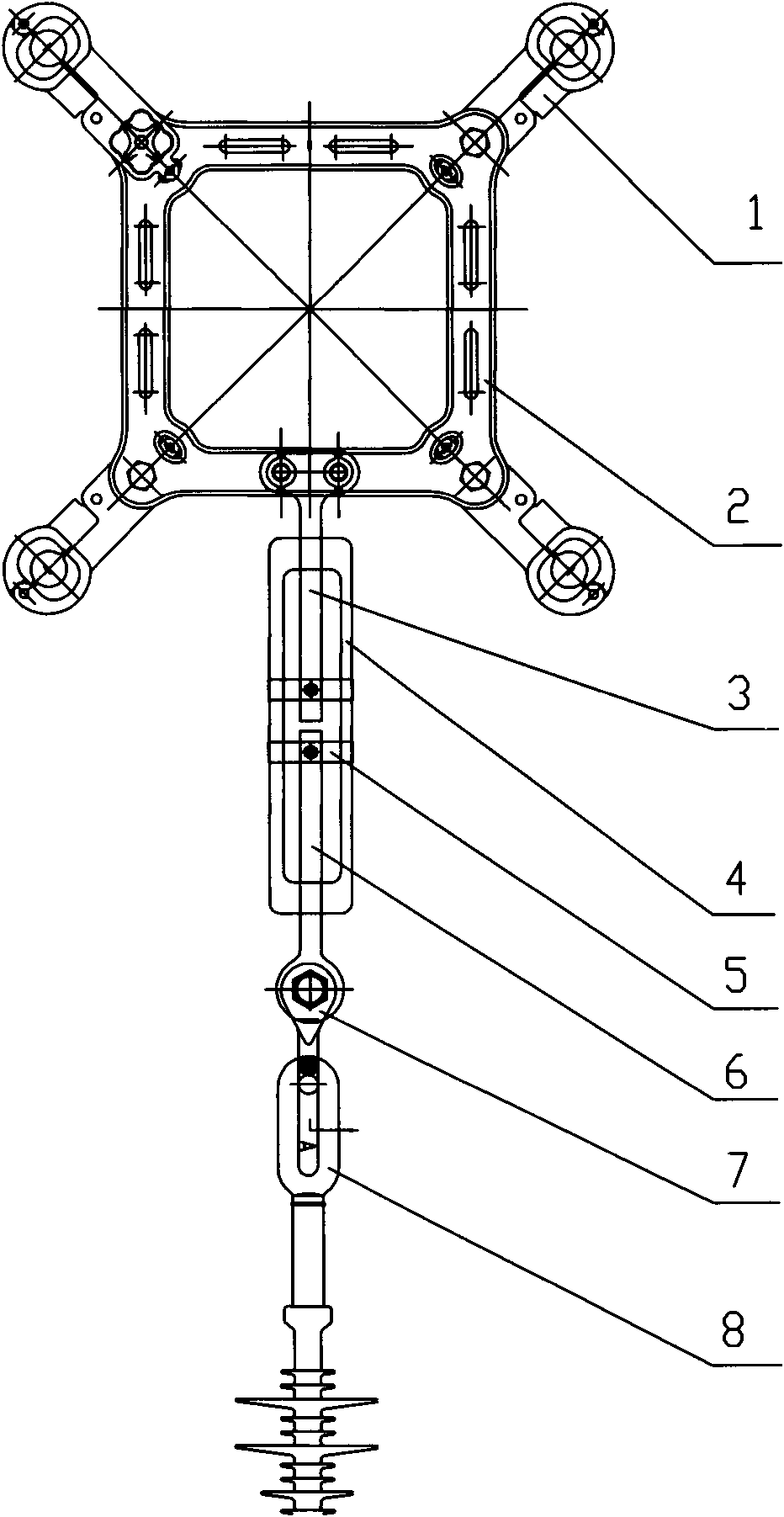

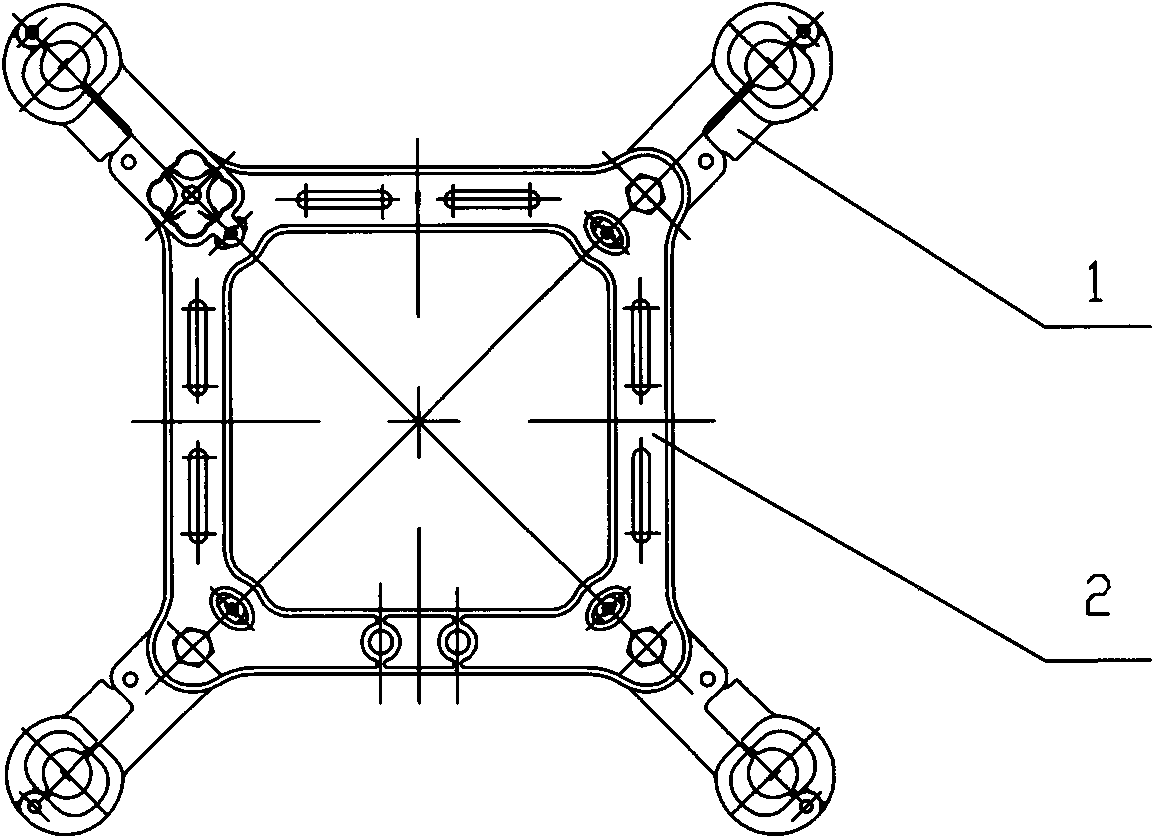

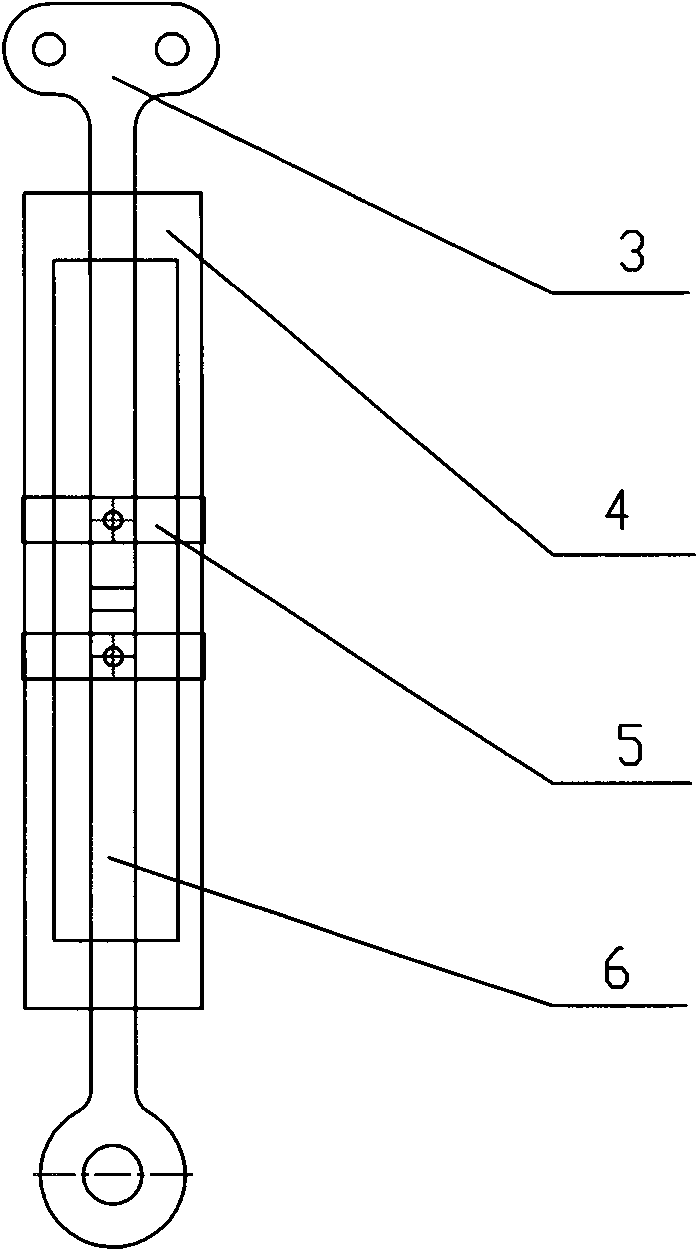

Turn buckle typed steplessly adjustable phase-to-phase spacer bracket

ActiveCN101931195ASolve sheddingFlexible installationMaintaining distance between parallel conductorsEngineering

The invention provides a turn buckle typed steplessly adjustable phase-to-phase spacer bracket. The bracket comprises an adjustable turn buckle body, an adjustable turn buckle screw rod I, an adjustable turn buckle screw rod II, an adjustable turn buckle fixing plate and a U-shaped ring, wherein the central line on a wider surface of the adjustable turn buckle body is provided with a slot for components to pass through along a length direction, and the two end points of the adjustable turn buckle body is provided with through holes along the length direction; one end of the adjustable turn buckle screw rod I passes through a through hole at one end of the adjustable turn buckle body, and one end of the adjustable turn buckle screw rod II passes through a through hole at the other end of the adjustable turn buckle body; the adjustable turn buckle screw rod I and the adjustable turn buckle screw rod II are fixed on the adjustable turn buckle body through the adjustable turn buckle fixing plate; and the other end of the adjustable turn buckle screw rod II is connected with the U-shaped ring. The adjustable phase-to-phase spacer bracket provided by the invention cooperates with a four bundle conductor spacer in a circuit swaying area to adjust proper installation length according to the phase interval of the installation positions of the phase-to-phase spacers; and the adjustable phase-to-phase spacer bracket is extremely flexible and the problem that a ball head is easy to fall off is solved.

Owner:CHINA ELECTRIC POWER RES INST +1

Method for monitoring crack defects in heavy load runway girder

ActiveCN106568841AResolve detectionCan't solveAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringHeavy load

The invention discloses a method for monitoring crack defects in a heavy load runway girder. According to the method, electromagnetic ultrasonic surface wave probes that satisfy the sensitivity requirement are chosen and oppositely / parallelly arranged on the arc parts of the runway girder web in the column shoulder beam; the plug ends of the cables of the probes are connected to an electromagnetic ultrasonic data collecting instrument so as to perform onsite echo data collection; the change of echo is observed, when the structural echo of the arc surface of the runway girder web just disappears, the position of the acoustic beam angle of the probes is taken as the position for fixing the probes; after the probes are fixed, the waveform data of each probe is collected and observed at regular intervals and compared; when obviously abnormal echoes are found, a reliable method is adopted to confirm the property of the echoes, the extension situation of the abnormal echoes of crack defects is determined through regularly collected echo data so as to judge whether the runway girder is cracked or not. The defects of conventional detection modes are overcome by the provided method, through the prediction, the safety hazards can be found in time, and the great loss of accidents is avoided.

Owner:SHANGHAI JINYI INSPECTION TECH

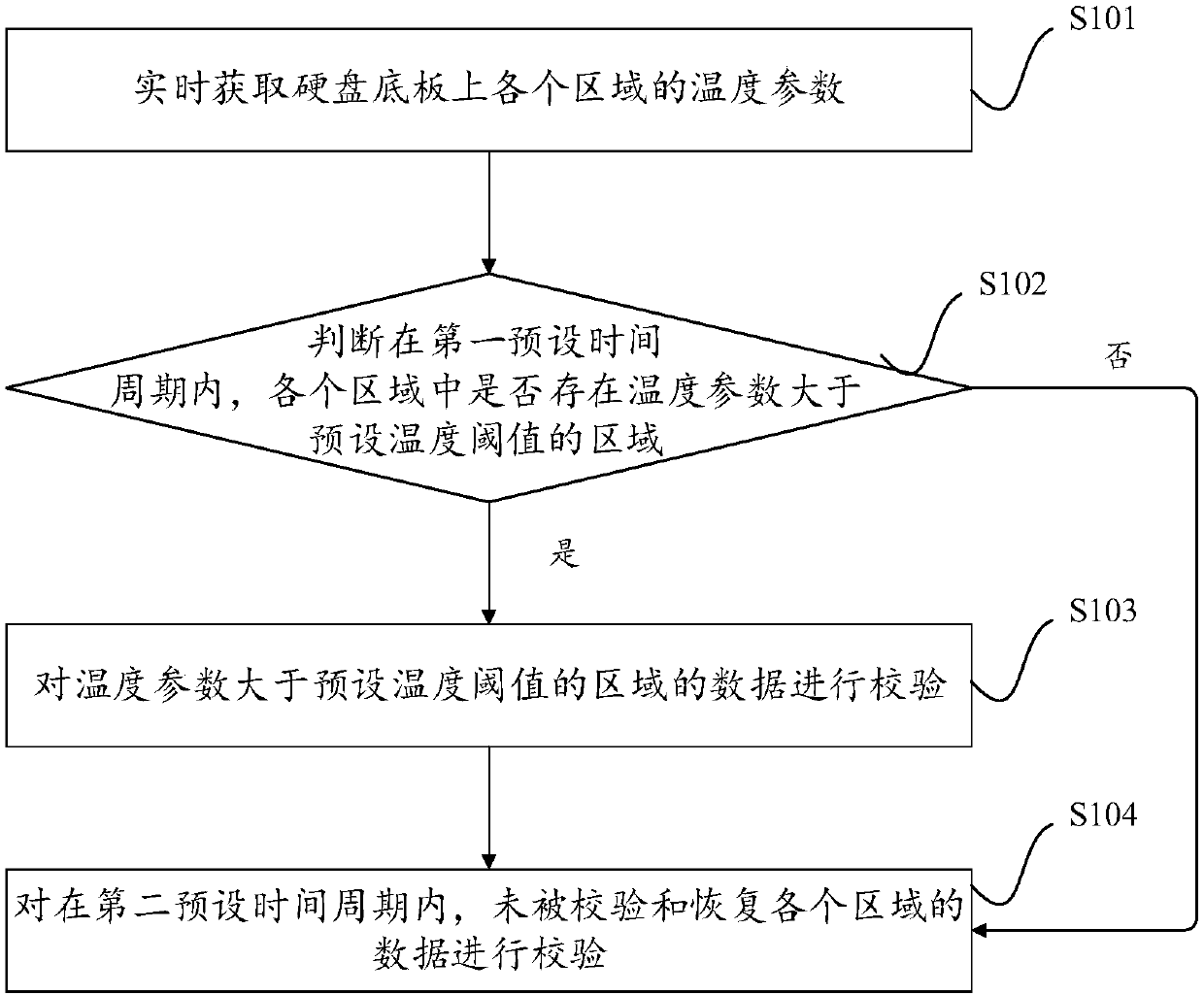

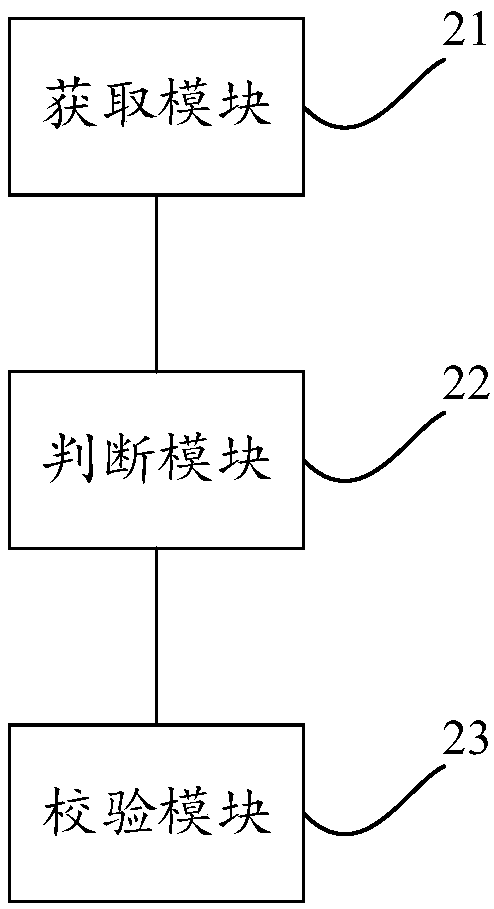

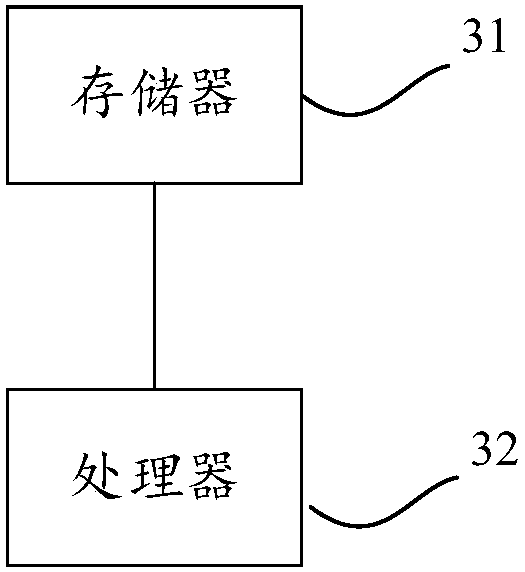

Hard-disk cold data verification method, device and equipment and readable storage medium of computer

ActiveCN107818025AReduce workloadImprove safety and reliabilityFault responseHardware monitoringSource Data VerificationData error

The invention discloses a hard-disk cold data verification method. The method includes the following steps that the temperature parameter of each area on a hard-disk base plate is obtained in real time; in the first preset time period, whether an area with the temperature parameter greater than the preset temperature threshold exists in each region or not is judged; if yes, data of the area with the temperature parameter greater than the preset temperature threshold is checked; in the second preset time period, data which is not checked and recovered in each region is checked; the first presettime period is longer than the second preset time period. The problem that the temperature is too high, data errors are caused, the wrong data is not checked timely and thus data can not be completely recovered is solved, and the data safety and reliability are improved. The invention further discloses a hard-disk cold data verification device and equipment and a readable storage medium of computer which have the above advantages.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

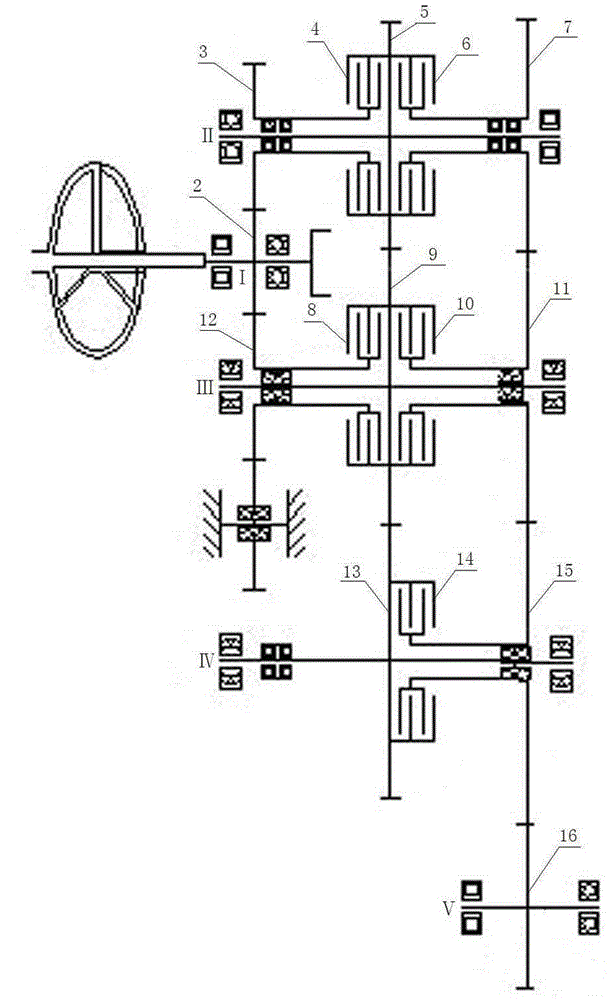

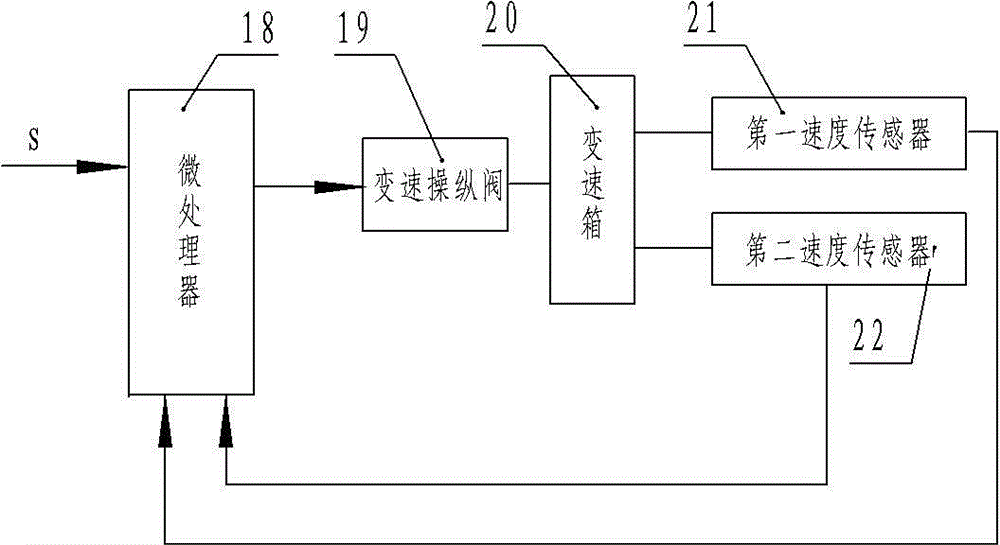

Real-time detection method for clutch engaging state of loader dead axle type gearbox

The invention discloses a real-time detection method for the clutch engaging state of a loader dead axle type gearbox. A microprocessor is adopted in the method, wherein the input end of the microprocessor is connected with a loader gear switch, the output end of the microprocessor is connected with the gearbox with a clutch, a first speed sensor and a second speed sensor are arranged on an input gear and an output gear of the gearbox respectively, and the output ends of the two sensors are connected with the feedback end of the microprocessor. The detection method comprises the steps that an expected gear signal is output to the microprocessor, and the microprocessor judges the clutch at the engaging gear according to the gear signal; then, the speed ratio of the first seat and the second senor is detected in real time, and the clutch is normal if the speed ratio is equal to a preset value in preset time; if the speed ratio exceeds the error range of the preset value, the clutch has the slip fault. The real-time detection method can achieve the purpose that when a certain gear or all gears of the loader are not available due to the abrasion of a certain clutch friction plate of the dead axle type gear body, the fault point can be accurately diagnosed in time.

Owner:GUANGXI LIUGONG MASCH CO LTD

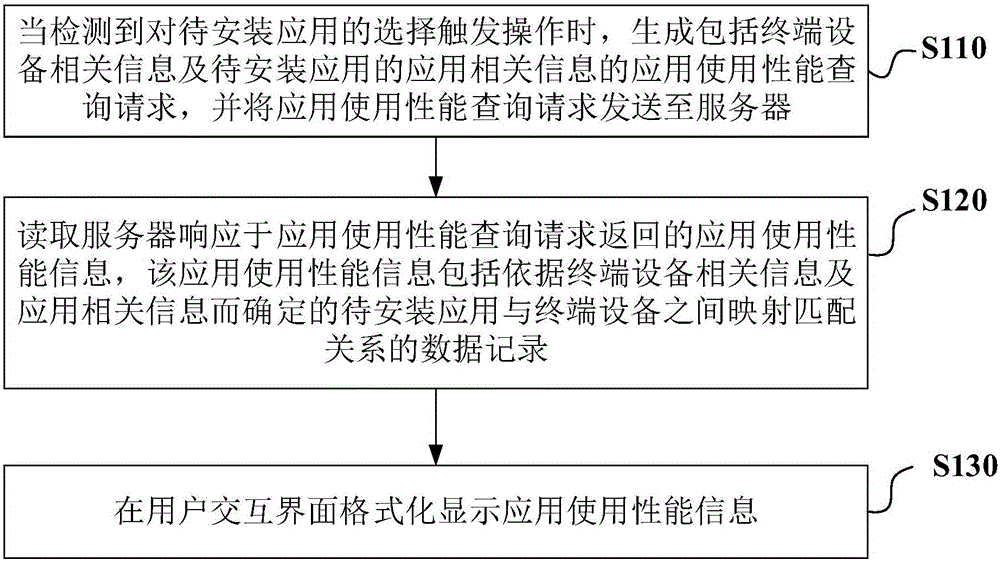

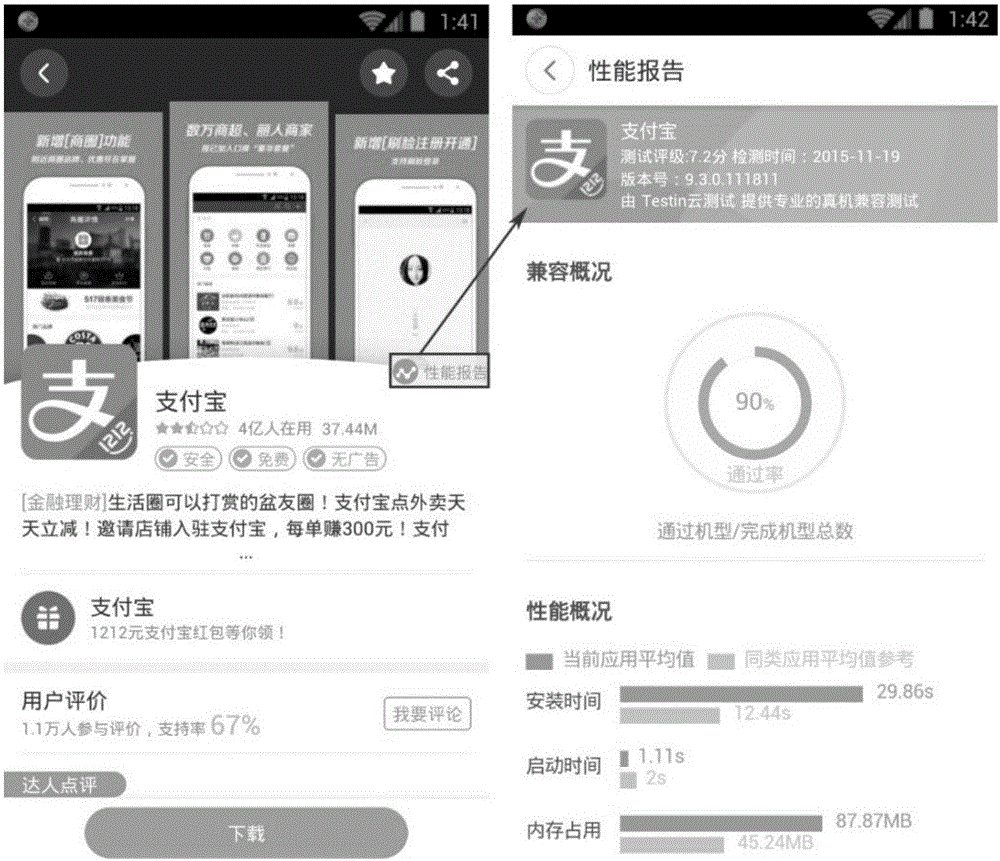

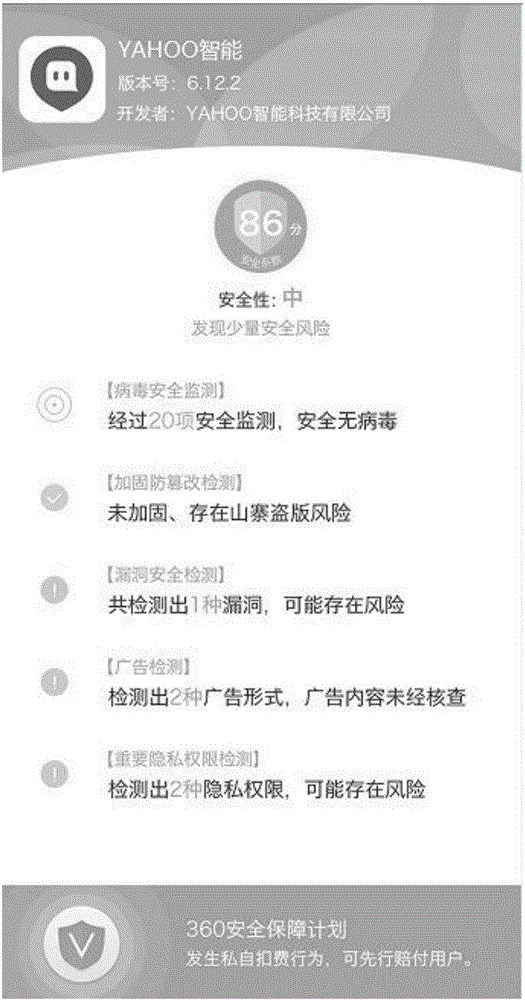

Method and device for providing application use performance information

InactiveCN105955768AAvoid wastingImprove the efficiency of installing applicationsWeb data indexingComputer security arrangementsTerminal equipmentComputer science

The invention provides a method and a device for providing application use performance information. The method comprises the following steps: when a selection trigger operation on an application to be installed is detected, generating an application use performance query request which comprises the relevant information of terminal equipment and the application relevant information of the application to be installed, and sending the application use performance query request to a server; reading the application use performance information which is returned from the server as a respond to the application use performance query request, wherein the application use performance information comprises a data record of a mapping matching relationship between the application to be installed and the terminal equipment, and the data record is determined according to the relevant information of terminal equipment and the application relevant information; and carrying out the formatted displaying of the application use performance information on a user interaction interface. The technical scheme of the invention causes the user to obtain the comprehensive application use performance information, and helps the user to integrally grasp the use performance aspect of the application to be installed before the application to be installed is installed.

Owner:BEIJING QIHOO TECH CO LTD +1

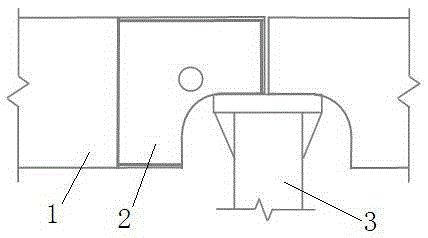

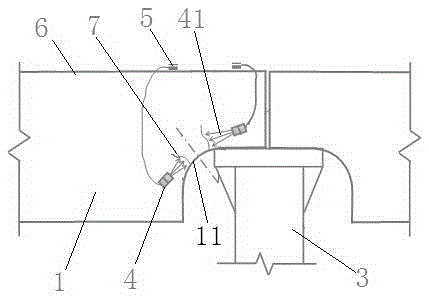

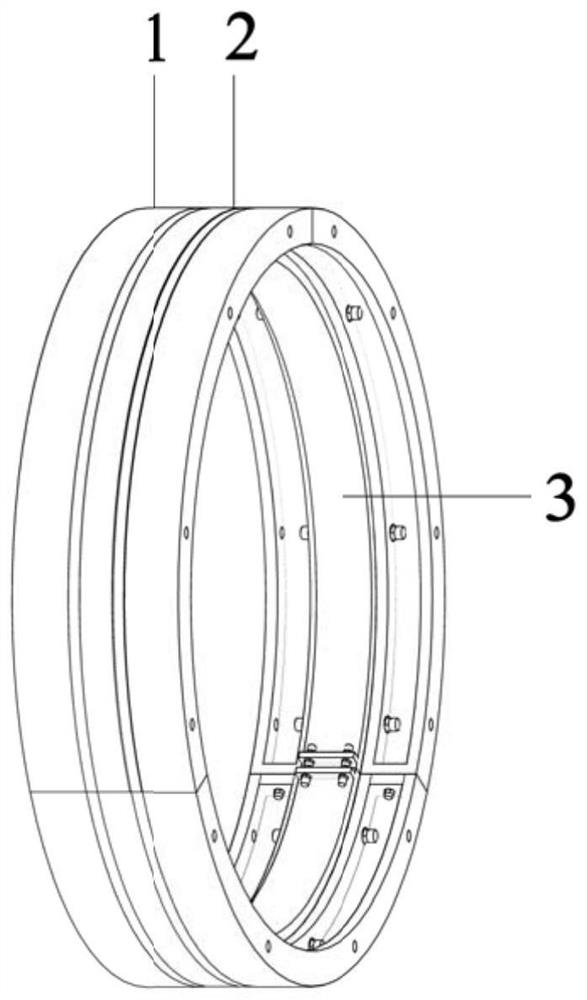

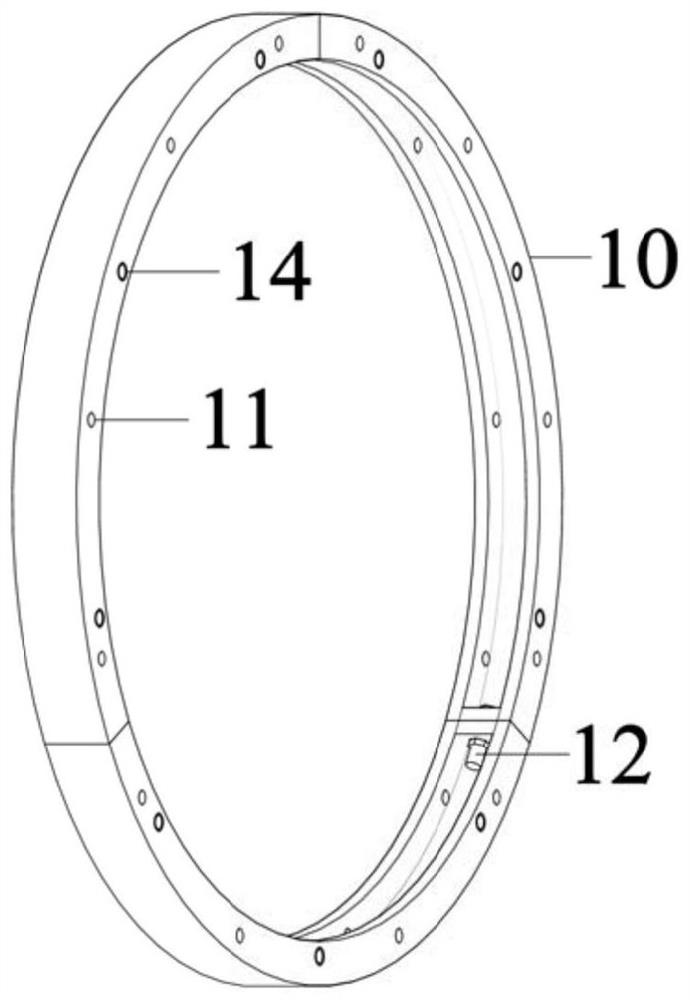

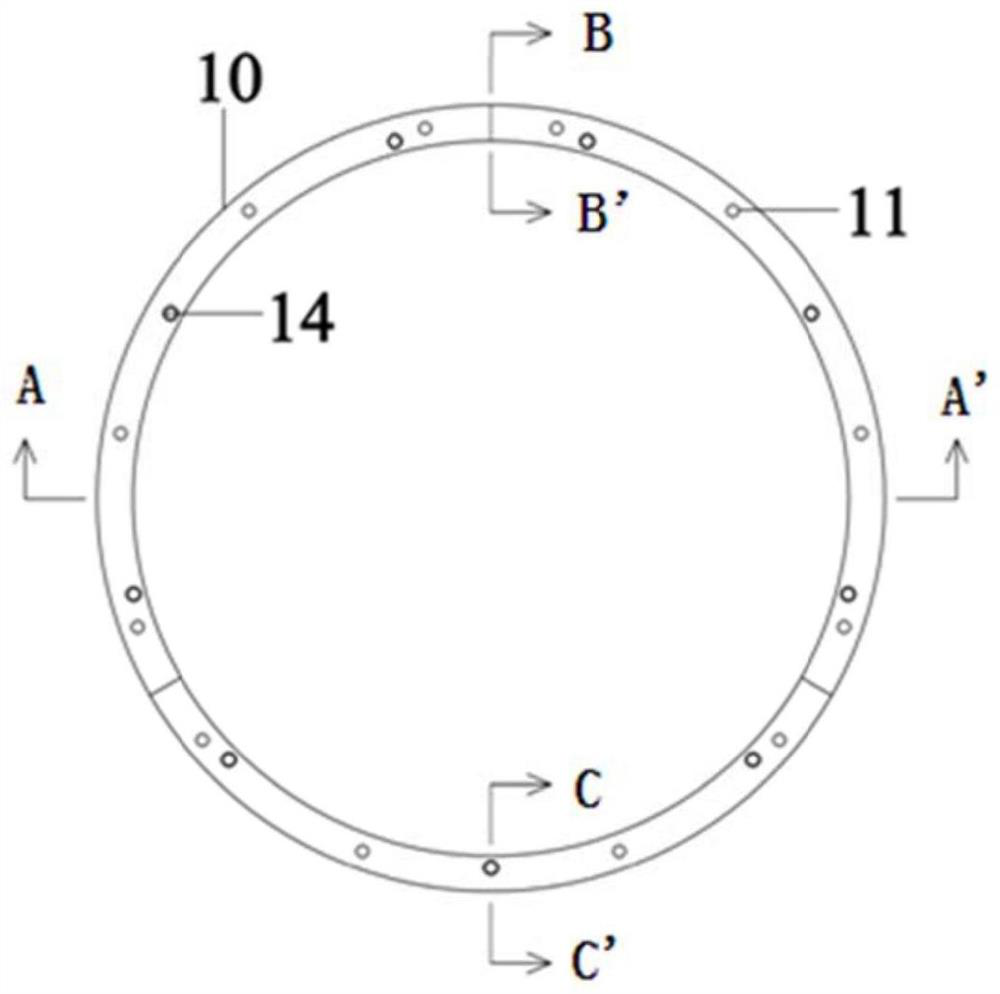

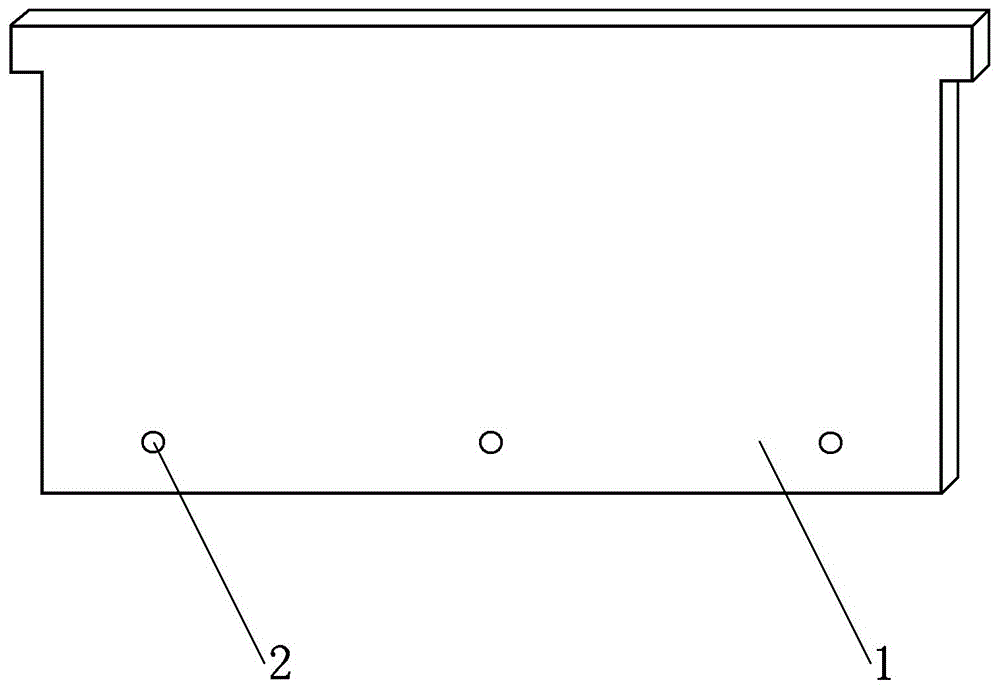

Subway shield tunnel damping segment ring suitable for differential settlement and high-intensity earthquake areas

PendingCN112302691AStrong adaptability to deformationPracticalUnderground chambersTunnel liningStructural deformationStress concentration

The invention provides a subway shield tunnel damping segment ring suitable for differential settlement and high-intensity earthquake areas, and aims to solve the problem that a tunnel structure is deformed and damaged due to structural stress concentration caused by differential settlement or earthquake waves. The damping segment ring comprises groove-shaped ring beam segment rings, a damper andan inner container steel drum; the damper is connected with the groove-shaped ring beam segment rings located at the left side and the right side of the damper through damper connecting bolts; the inner container steel drum is arranged at the inner side of the damper and tightly attached to the damper; and the damper is formed by connecting a left side loading plate, an inner core located in the middle and a right side loading plate through a damper spring mechanism. According to the subway shield tunnel damping segment ring suitable for the differential settlement and high-intensity earthquake areas, the shield subway tunnel structure in the differential settlement areas or the high-intensity earthquake areas has high deformation self-adjusting and stratum structure relative deformation adapting capacity, so that structural stress concentration caused by deformation is reduced or even eliminated, structural deformation damage is avoided, and the subway shield tunnel damping segment ring is convenient to manufacture and install and high in practicability.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

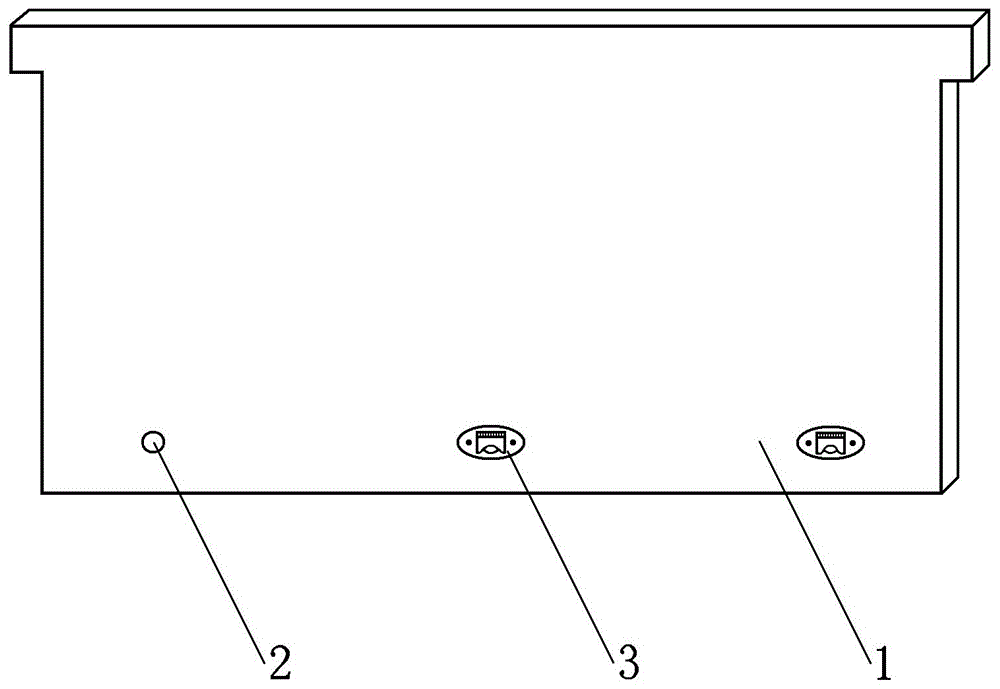

How to use the natural bee-separating wooden ram in the Chinese honey bee box

The invention provides a use method of a natural swarming gate plate in a hive of Chinese bees. By means of the use method, natural swarming of the Chinese bees can be achieved in the hive. The use method comprises the steps that firstly, the gate plate is installed in the middle of the hive; secondly, hive door hole queen excluders are installed on hive door holes of the hive; thirdly, bee colonies are placed in a first chamber with the face provided with queue bee exit holes, and hive frames with hive foundations are placed in the first chamber; fourthly, checking is carried out, the queen excluders on the virgin queen colony hive door holes are removed, and combs in an original colony are disposed or destroyed; fifthly, one bee colony is moved out. The use method is easy to implement, learn and understand, saves troubles and labor, greatly reduces the workload of manual breeding of the Chinese bees, avoids huge losses caused when the Chinese bees fly away from the hive and abscond, and is beneficial for protecting the Chinese bee resources.

Owner:CHEGNGDU CHENG KE TROTHER APICULTURE COMPANY

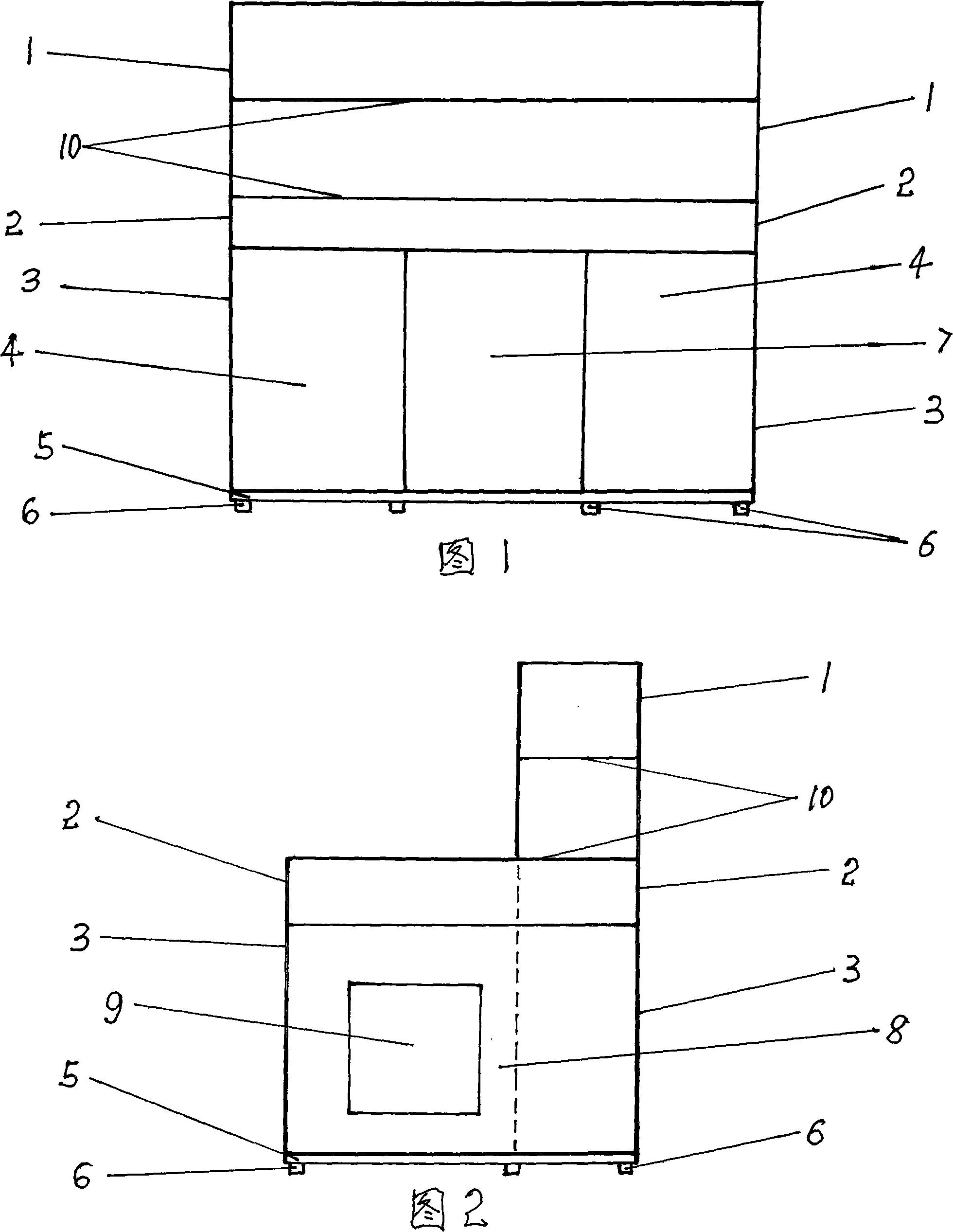

Multifunctional goods shelves counter for protection in earthquake

InactiveCN101313815AProtect life safetyWide range of usesSeismologyShow shelvesEngineeringEmergency light

The invention relates to a multifunctional earthquake-proof people protecting shelf counter. The multifunctional earthquake-proof people protecting shelf counter uses steel, wood, plastic, glass, sponge, fabric and other materials to manufacture a long cuboidal shelf, a cabinet, a counter, a business counter, etc.; the earthquake-proof shelf counter is manufactured into a pane box type structure by the steel and the wood; the earthquake-proof shelf counter consists of an upper-part flat box with a steel-wood structure, a middle flat box with a steel-wood structure, a lower-part cabinet box with a steel-wood structure and bottom steel plate legs and is provided with a damping device and an earthquake measuring and automatic warning device; the lower-part cabinet box is stored with bottled water, solid food, a flashlight, a battery, an extinguisher, an emergency light, a radio, a wireless communicator, a shovel, a hammer and other emergency life preservers and is also provided with a battery illuminating lamp. The multifunctional earthquake-proof people protecting shelf counter can remind people of rapidly hiding inside the earthquake-proof people protecting shelf counter when an earthquake occurs, effectively ensures life safety and avoids people from being injured; even if people are buried in a wasteland with earth and rocks, people can survive for a long time as the multifunctional earthquake-proof people protecting shelf counter can automatically emit a life-saving signal to wait rescue and ensure the safe escape of people; and the multifunctional earthquake-proof people protecting shelf counter can avoid an individual, a family and a county from suffering huge loss.

Owner:李震

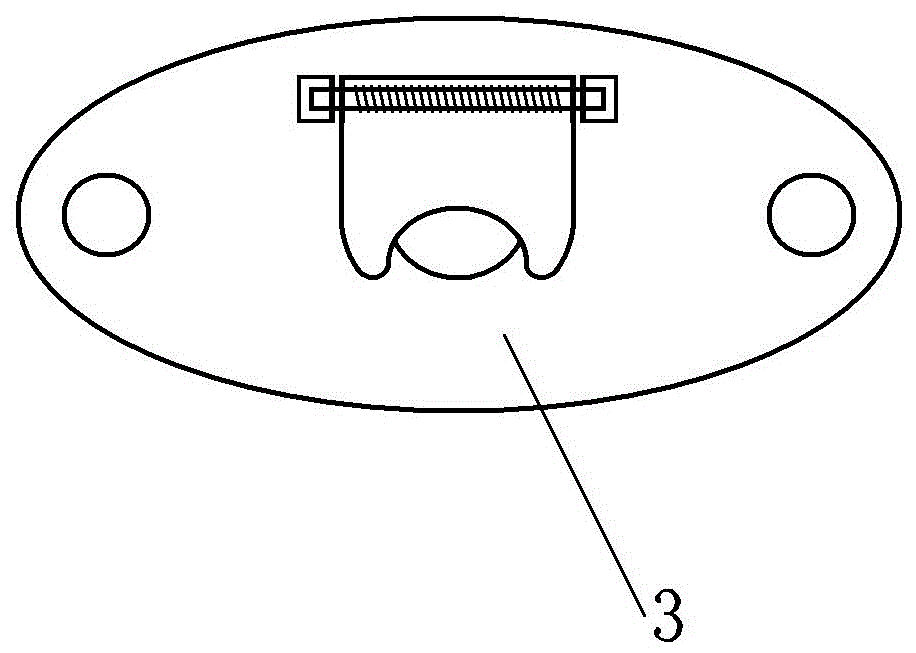

Natural collecting method for Chinese bees escaping from nests

InactiveCN104082274APromote reproductionMultiplied reproductive capacityAnimal huntingBeehivesDiseaseBiological property

The invention relates to a natural collecting method for Chinese bees escaping from nests. The method includes the steps of firstly, using one queen bee one-way passage sleeve; secondly, allowing one end of the sleeve to be connected to a bee box; thirdly, allowing the other end of the sleeve to be connected to a queen bee and bee colony escaping collecting cage or box; fourthly, shaking off the escaped bee colony in the collecting cage or box into a new bee box for reproduction after the bee colony escapes from the original bee box; fifthly, checking and processing the queen bee and bee colony in the original bee box. The natural collecting method has the advantages that the method is simple to operate, easy to learn and understand, trouble saving and also suitable for collecting western bee varieties, workload of beekeeping is relieved greatly, huge loss caused by Chinese bee escaping is avoided, and the method conforms to the living habits of the Chinese bees and the biological features that the reproductive capacity of the bee colony escaping the nests is multiplied and the disease resistance of the bee colony is increased evidently.

Owner:CHEGNGDU CHENG KE TROTHER APICULTURE COMPANY

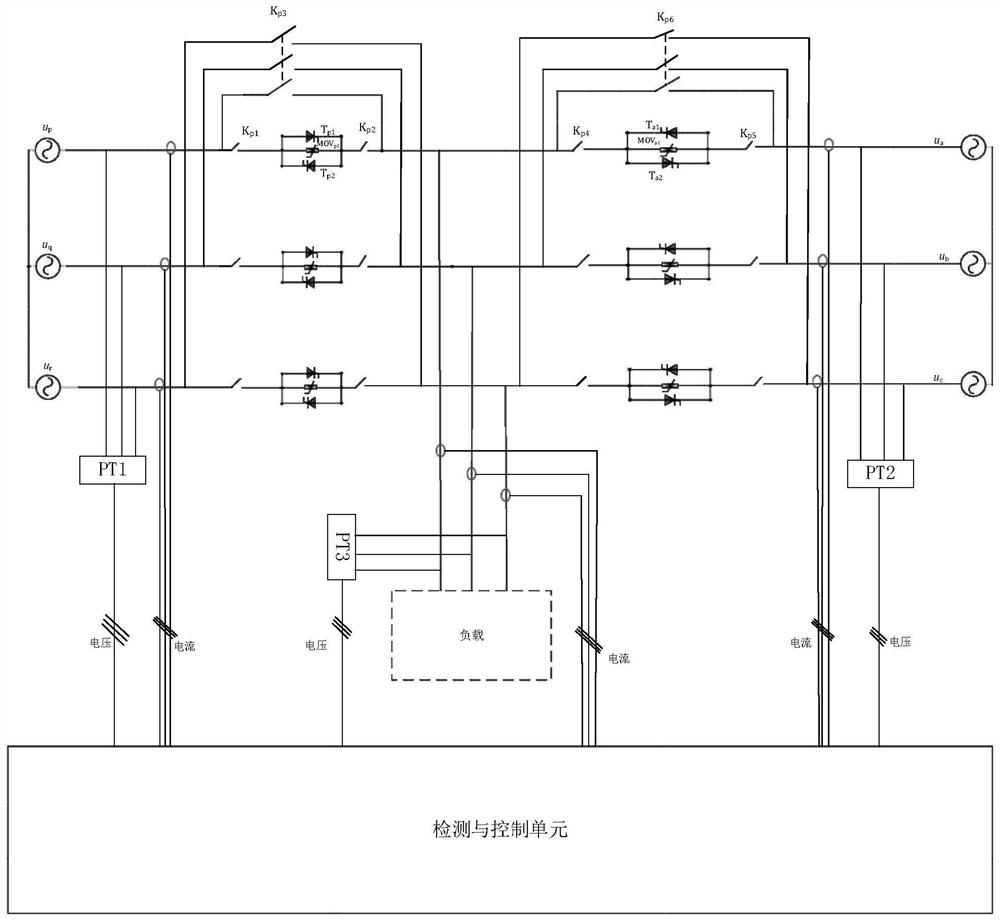

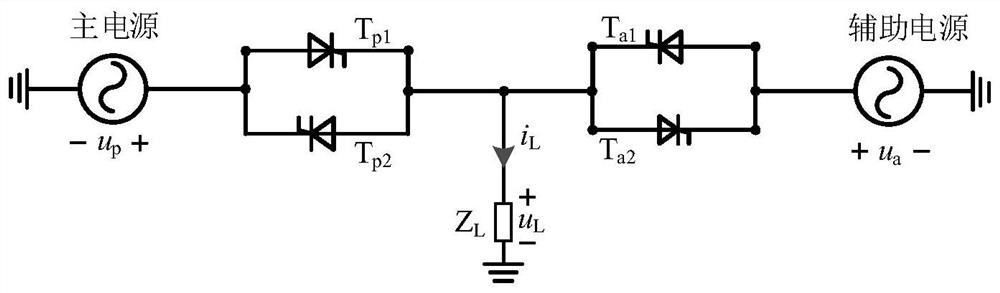

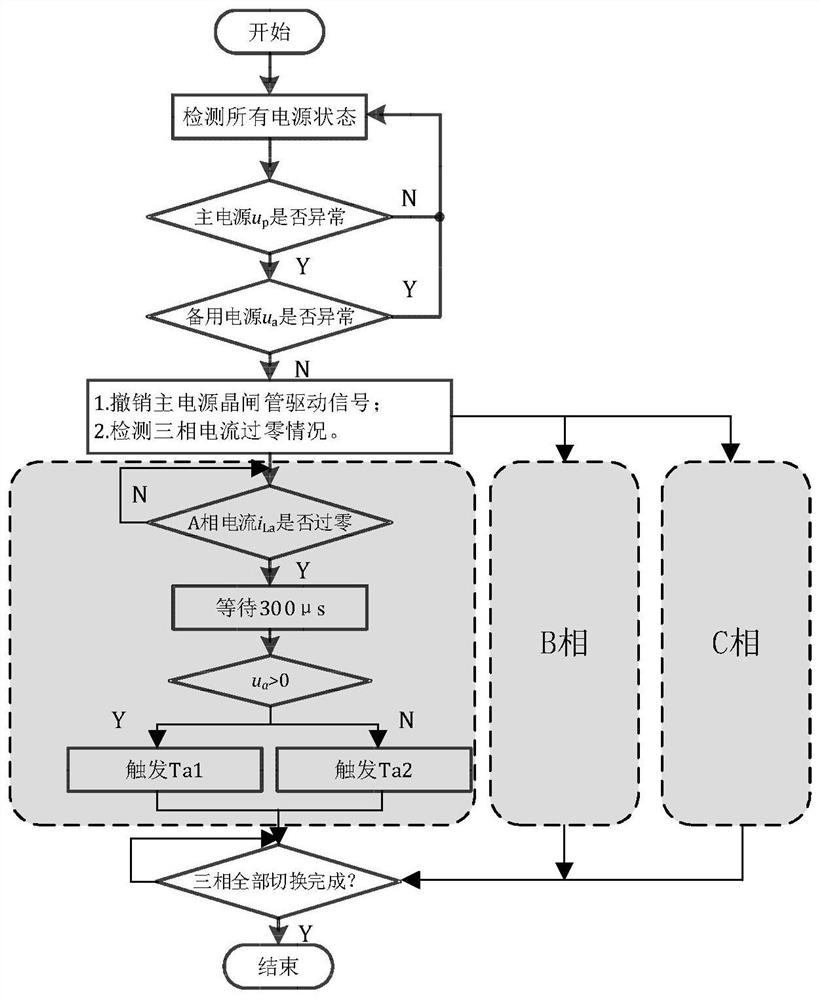

Rapid solid-state change-over switch control strategy and system

PendingCN112583007ASwitch in timeAvoid huge lossesAc network circuit arrangementsStandby powerVoltage drop

According to a rapid solid-state change-over switch control strategy and system provided by the invention, when the problems of voltage drop, voltage fluctuation, instantaneous power failure and the like occur, a main power supply and a standby power supply can be rapidly switched in time, huge losses brought to production and life of power consumers due to abnormal work of sensitive devices are avoided, and under the premise of safe system operation, the switching time is shortened, and the higher-quality voltage sag and voltage short-time interruption treatment are realized.

Owner:XIAN ACTIONPOWER ELECTRIC

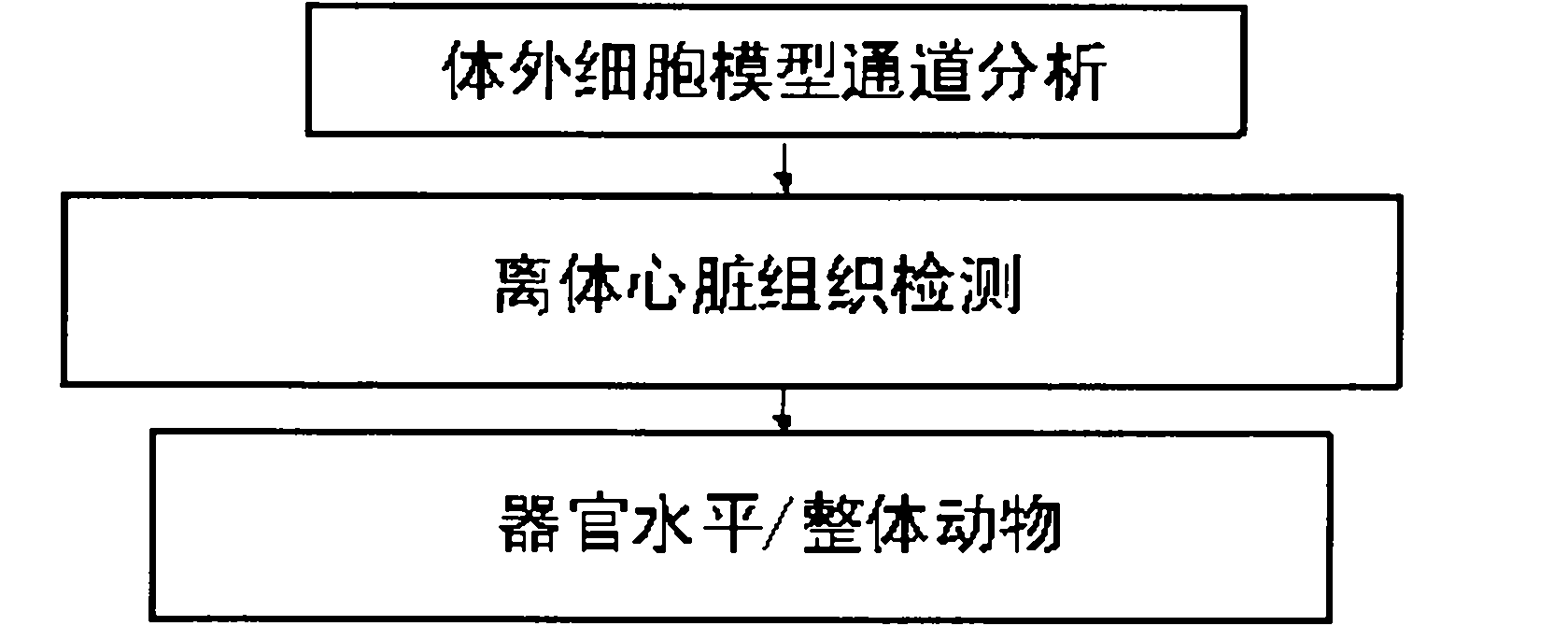

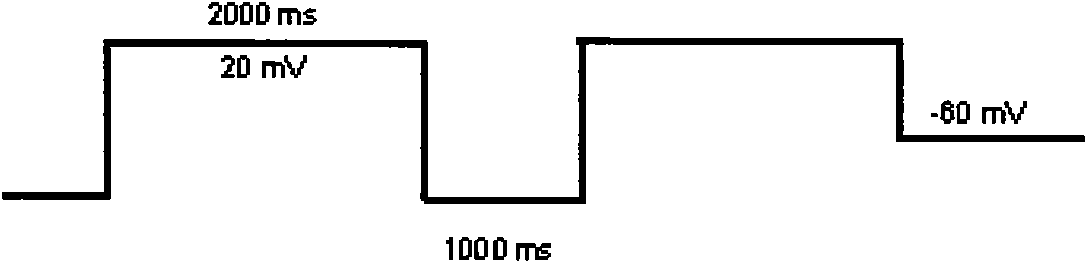

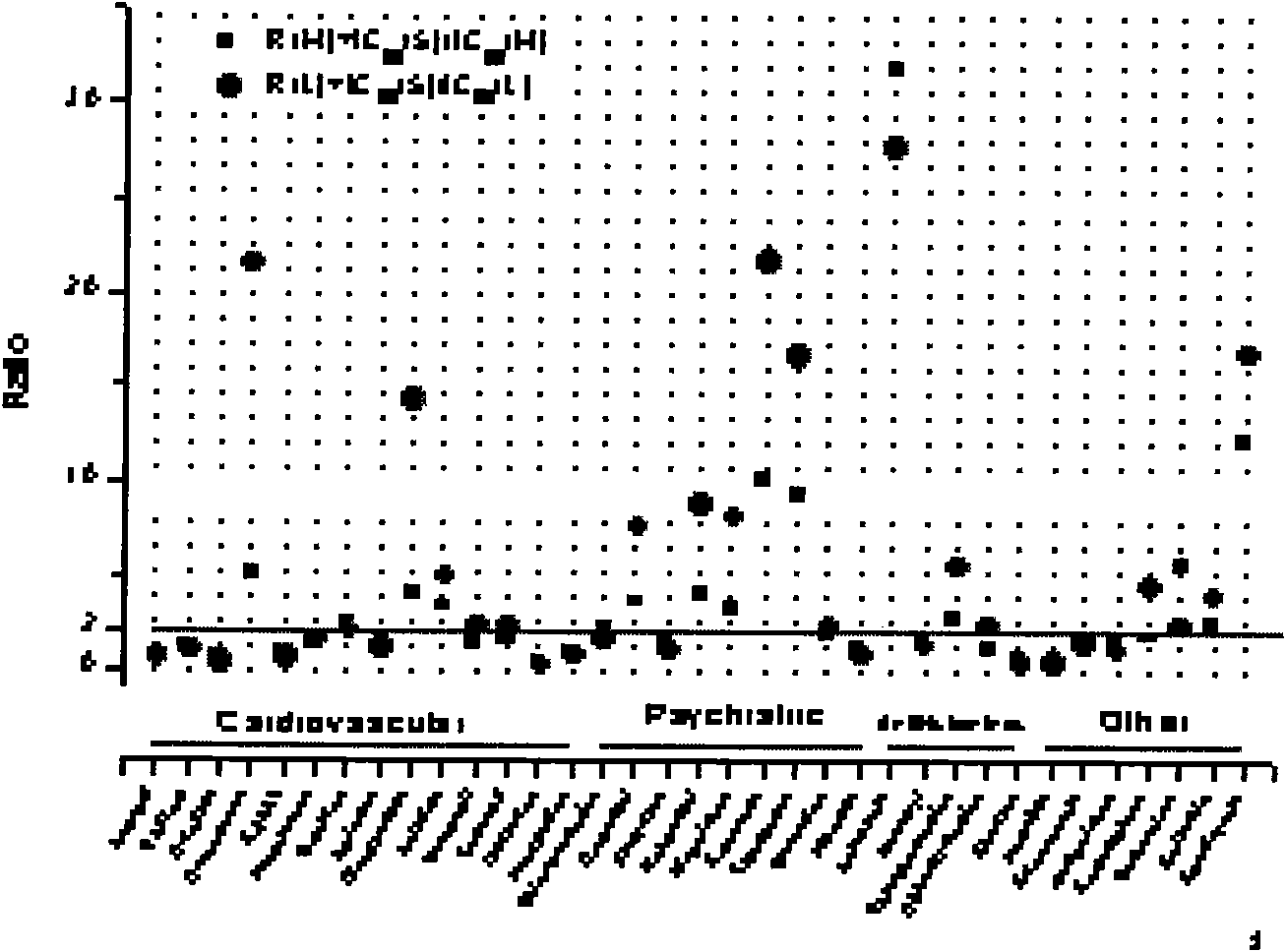

Test method for evaluating arrhythmia caused by action of medicament on human nether-a-gogo related gene (hERG)

InactiveCN102253084AAvoid huge lossesSimple processMaterial analysis by electric/magnetic meansIonHUMAN ETHER-A-GO-GO-RELATED GENE

The invention relates to a test method for evaluating arrhythmia caused by action of medicament on a human nether-a-gogo related gene (hERG). The test method is characterized by comprising the following steps of: depolarizing cells to 40 mv / 5ms conventionally to activate an hERG ion channel; returning thin pliers to -50 mv / s to record the deactivating process of the channel, wherein the maximum current recorded at -50 mv is the hERG ion channel current amplitude required to be recorded; performing a voltage clamp flow test to acquire the speed of the medicament separated from the channel; calculating the time dependence of the compound hERG ion channel at 500 ms and 2 s by inhibition concentration 50150 (IC50150) ms / IC50500ms and IC50150ms / IC502s, wherein if the ratio is high, the time dependence is high; and on the premise of determining that the medicament has remarkable time dependence in the blocking hERG ion channel test, calculating the recovery time index of the medicament hERG blocking agent by a formula of RRec equal to (IC150ms-2-IC502s) / IC150150ms-IC502s), wherein the medicament with the recovery time index of less than 25 is determined to have higher possibility of inducing TdP.

Owner:上海灏远生物医药科技有限公司

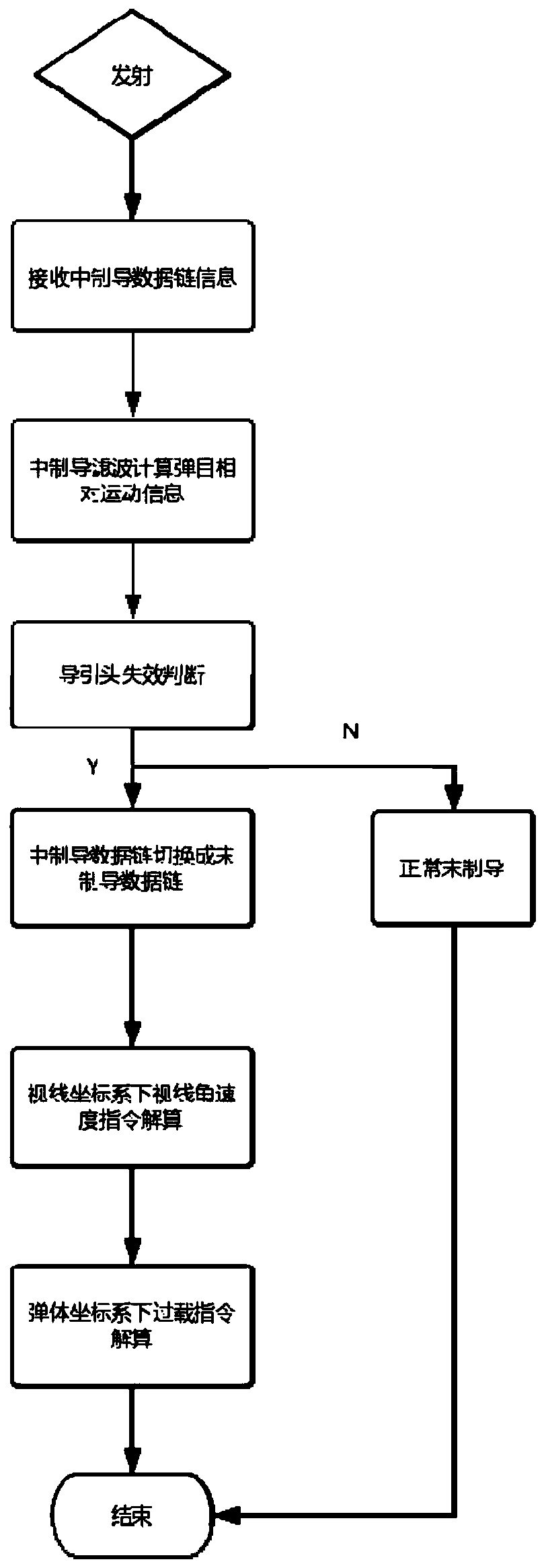

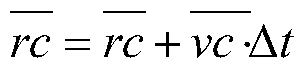

Data chain terminal guidance method in seeker failure mode

ActiveCN111397449AAvoid huge lossesDirection controllersSelf-propelled projectilesGuidance controlControl engineering

The invention relates to a data chain terminal guidance method in a seeker failure mode. The method comprises the following steps of firstly, judging the failure of a seeker; confirming the failure ofthe seeker, and switching from a midcourse guidance data chain to a terminal guidance data chain matching the update period of the seeker in real time; detecting and correcting the position and the speed of a target, in the terminal guidance data chain, in a sight line coordinate system through a missile flight control computer in real time; and solving the sight line angular speed in the sight line coordinate system and an overload command in a missile body coordinate system. According to the method, the motion information state of the target transmitted by the terminal guidance data chain with the high update rate is utilized to carry out guidance control over a missile with the failure of the seeker, and the problem that guidance command calculation cannot be carried out due to the failure of the seeker is avoided. The data chain information is used for solving, the guidance law is met, the failed missile is used for avoiding the huge loss caused by the scraping of the missile, andthe good effects are realized.

Owner:中国北方工业有限公司

Fire alarm device

The invention discloses a fire alarm device. The device comprises an inspection vehicle body and a device base arranged on the back of the inspection vehicle body. A main box body is fixedly arrangedon the left side of the upper end surface of the device base. A fire extinguishing device is arranged on the upper side of the main box body. A detection device is arranged on the right side of the upper end surface of the device base. A power device is arranged in the main box body, wherein the power device is used for driving the fire extinguishing device and the detection device to rotate. Thepower device comprises a motor mounting block arranged in the main box body. A power motor is arranged in the motor mounting block. A first rotating shaft is in power connection with the upper end ofthe power motor. A first transmission cavity located on the upper side of the motor mounting block is arranged in the main box body. The first rotating shaft extends into the first transmission cavity. A second rotating shaft fixedly mounted on the lower side of the fire extinguishing device is rotatably mounted on the upper end wall of the first transmission cavity.

Owner:浦江嘉通网络科技有限公司

Cooling method for blower in sulfuric acid production

InactiveCN105417501AReduce temperature riseExtended service lifeSulfur compoundsFlue gasProcess engineering

The present invention is applied to the technical field of sulfuric acid production apparatuses, and relates to a blower cooling method for a large sulfuric acid production apparatus. The apparatus is characterized by, on a basis of an original flue gas sulfuric acid-making conversion workshop section flow, connecting a loop pipe, the diameter of which is about half of a main pipeline on a pipe between the blower outlet and a heat exchanger, the loop pipe connected to a drying tower flue gas inlet pipe, and under a circulating action of the blower, effectively reducing an operation temperature of the blower by nature cooling of the loop pipe. The loop pipe should be mounted with an anti-surge valve, or the associated valve is provided by the blower manufacturer. The valve can be shut off when the blower temperature is not high; when the blower needs to be cooled, the valve is shut on. The cooling method solves problems that the temperature rise of blower operation is too high, flow variation is less, a pipe mounting method is simple and cost consumption is small, and is a convenient and economic improvement scheme.

Owner:CHINA PETROLEUM & CHEM CORP +1

Communication pipe deformation monitoring device and method

InactiveCN108519062AEasy to analyzeEasy to handleUsing optical meansContinuous measurementDeformation monitoring

The invention provides a communication pipe deformation monitoring device and method. The device comprises a distance measuring apparatus, a fan-shaped guide rail and a main control apparatus. The fan-shaped guide rail is installed along the inner wall of the mouth of a communication pipe, and the distance measuring apparatus faces the interior of the pipe and is connected to the fan-shaped guiderail. The distance from the mount of the communication pipe to the tail end of the communication pipe is measured, and the distance measuring apparatus can move along the fan-shaped guide rail. The distance measuring apparatus is connected with a main control apparatus. A communication pipe deformation monitoring method comprises the steps: controlling a stepping motor to operate at a fixed time interval through the main control apparatus, driving the distance measuring apparatus to move from one end of the fan-shaped guide rail to the other end for one measurement; determining that there is no abnormality if the difference between the measured data and an initial value does not exceed a set threshold; determining that the abnormality happens if the differences between the measured data, obtained through three continuous measurements, and the initial value exceed the set threshold and the measured data obtained through three continuous measurements is the same, giving an alarm to an upper computer, and uploading the position of an abnormality. The measurement data is stable and reliable, and the method and device can achieve the direct early warning of the deformation trend.

Owner:LIAONING TECHNICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com