Bearing protection method and device for wind driven generator

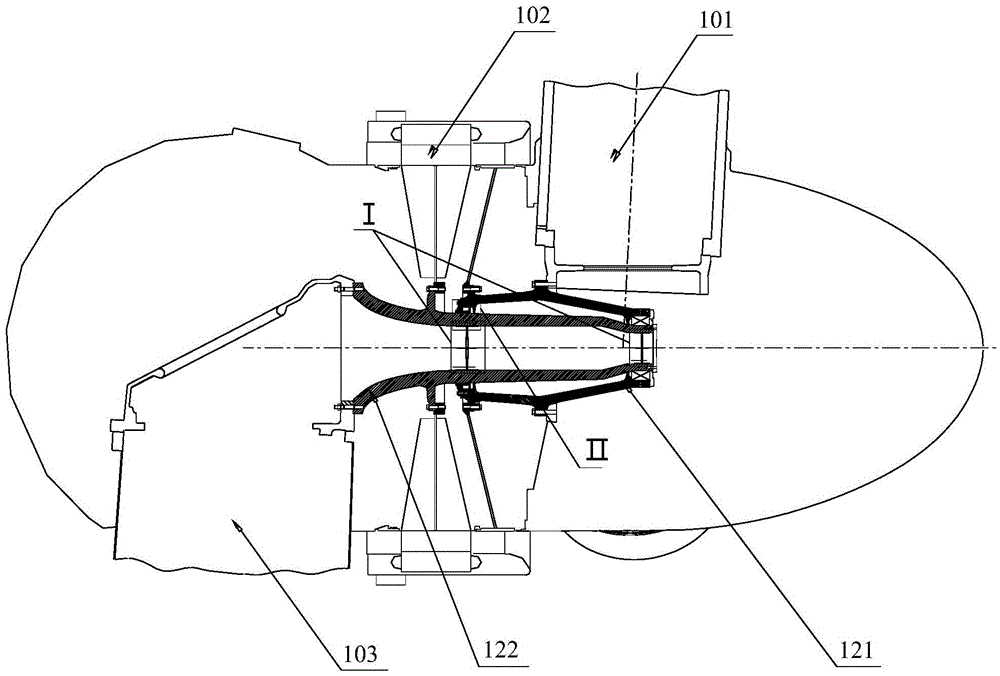

A bearing protection device, wind turbine technology, applied in wind turbines, wind power generation, engine lubrication, etc., can solve the problems of bearing failure, inability to replace in the air, and high replacement costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

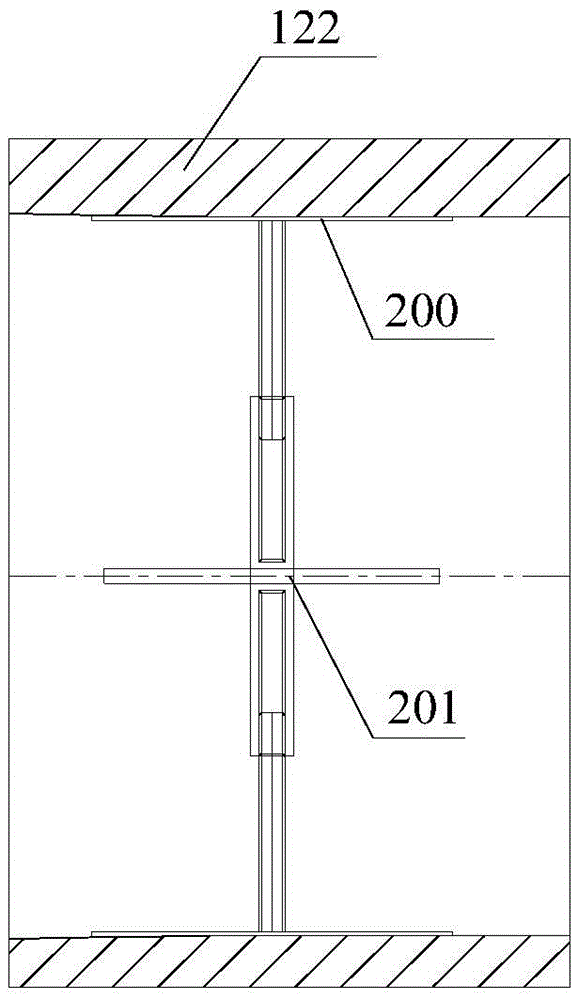

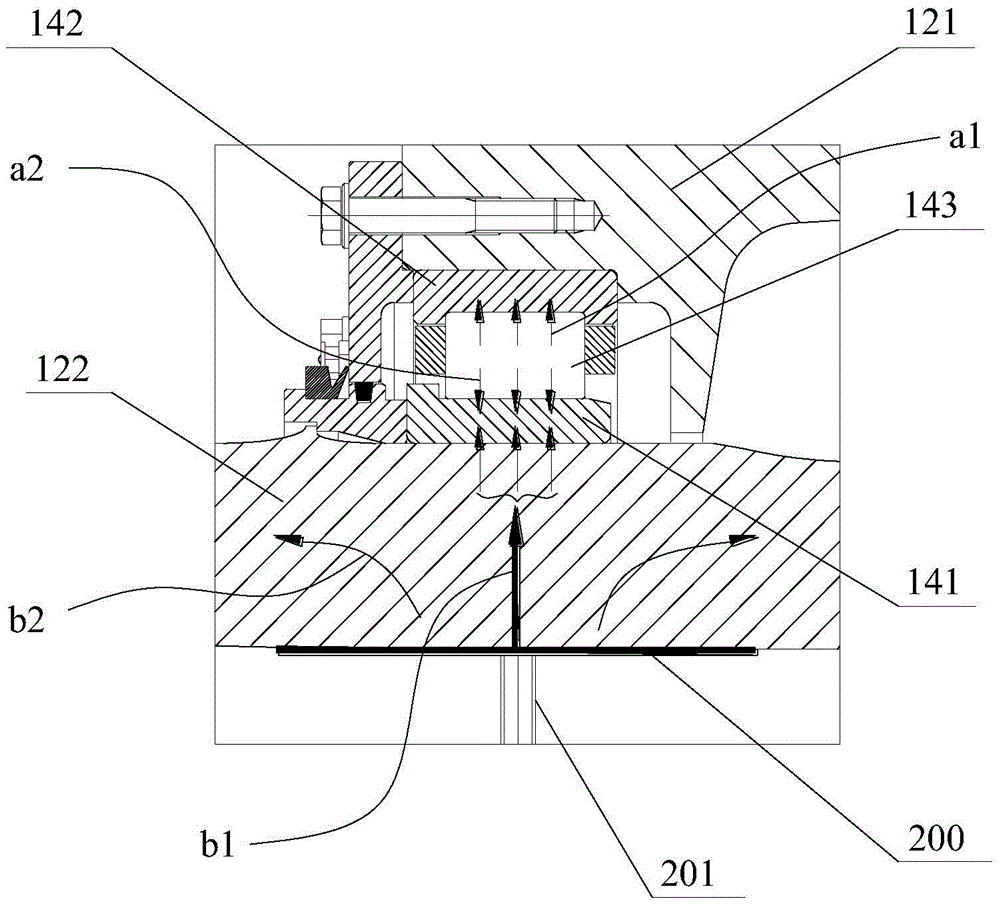

Embodiment Construction

[0096] According to the research and analysis, in the low temperature environment, there are two main reasons for the failure of the bearing wear of the wind turbine, one is the influence of the bearing grease, and the other is the "loss" of the interference between the stator main shaft and the bearing due to thermal deformation impact. Details are given below respectively.

[0097] For bearing grease, under normal circumstances, the amount of grease filled in the bearing exceeds the actual demand. In the initial stage of bearing operation, most of the grease is quickly (less than a minute) squeezed out of the raceway and accumulates in the holding In the cavity of the frame and the bearing cover, and form a contour on the periphery of the rolling elements, during this process, due to the resistance of excess grease, the bearing temperature rises rapidly; although most of the excess grease is squeezed out at the beginning of operation , but the grease squeezed near the racew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com