Cooling method for blower in sulfuric acid production

A sulfuric acid production and blower technology, which is applied in chemical instruments and methods, inorganic chemistry, sulfur compounds, etc., can solve the problems of blower operating temperature rise, equipment maintenance difficulty, product quality decline, etc., to save equipment investment and pipeline installation The effect of simple method and few process changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

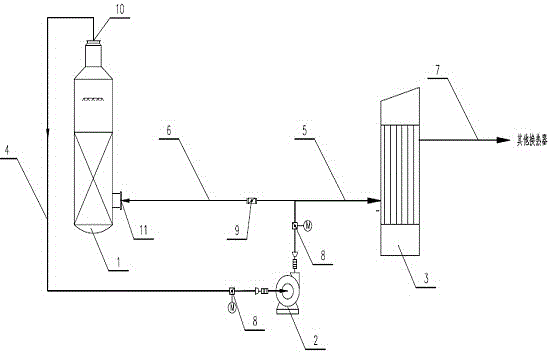

[0016] Embodiment: This embodiment is attached figure 1 Shown, SO 2 The flue gas passes through SO from the drying tower outlet (10) 2 The flue gas pipeline (4) is blown into the heat exchanger (3) by the blower (2). Due to the long-term work, the temperature of the blower (2) equipment increases, and the anti-surge valve (9) is opened to make part of the SO 2 The flue gas enters the inlet (11) of the drying tower through the cooling return pipeline (6), so that the SO in the drying tower (1) 2 The flue gas temperature drops, and then enters the blower's SO 2 The flue gas temperature drops, thereby realizing the temperature drop of the blower equipment itself.

[0017] The automatic cooling of the air blower is realized through the adjustment method of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com