Insulation repair method for 10 kV high-voltage cable

A repair method and high-voltage cable technology, applied in the direction of insulation/armored cable repair equipment, etc., can solve the problems of time-consuming manufacturing process, difficult repair, unfavorable insulation, etc., to reduce material costs, shorten fault repair time, avoid The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further described below:

[0018] Taking the 10kV secondary power receiving cable of JISCO's comprehensive material yard as an example, on June 24, 2014, the cable had a C-phase breakdown fault at the corner of the belt corridor of the transfer station. After inspecting and analyzing the actual situation on site by the operators, it was decided not to saw off all three phases of the faulty cable, and use this method to repair the main insulation.

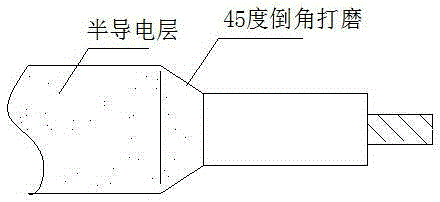

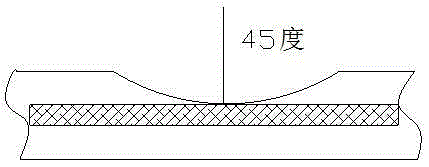

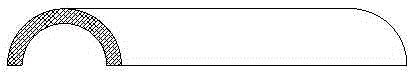

[0019] 1. Peel off the outer sheath of the cable to observe the damage of the insulation and core, and determine the plan.

[0020] 1.1 The 10kV secondary power receiving three-core cable in the comprehensive material yard is faulty and the phase C is broken down. The insulation is burned and the core is not broken. The recovery process can be carried out according to the cable "main insulation repair" production process.

[0021] 1.2 Straighten the three-core cable, the outer sheath dimensions L1, L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com