Module of gas saving valve for mini engine

A throttle and engine technology, applied in engine control, machine/engine, electrical control, etc., can solve the problems of poor compatibility of motorcycle engines, increased manufacturing and use costs, irregular shape geometry, etc., to achieve compact structure, light weight Small size, easy maintenance and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

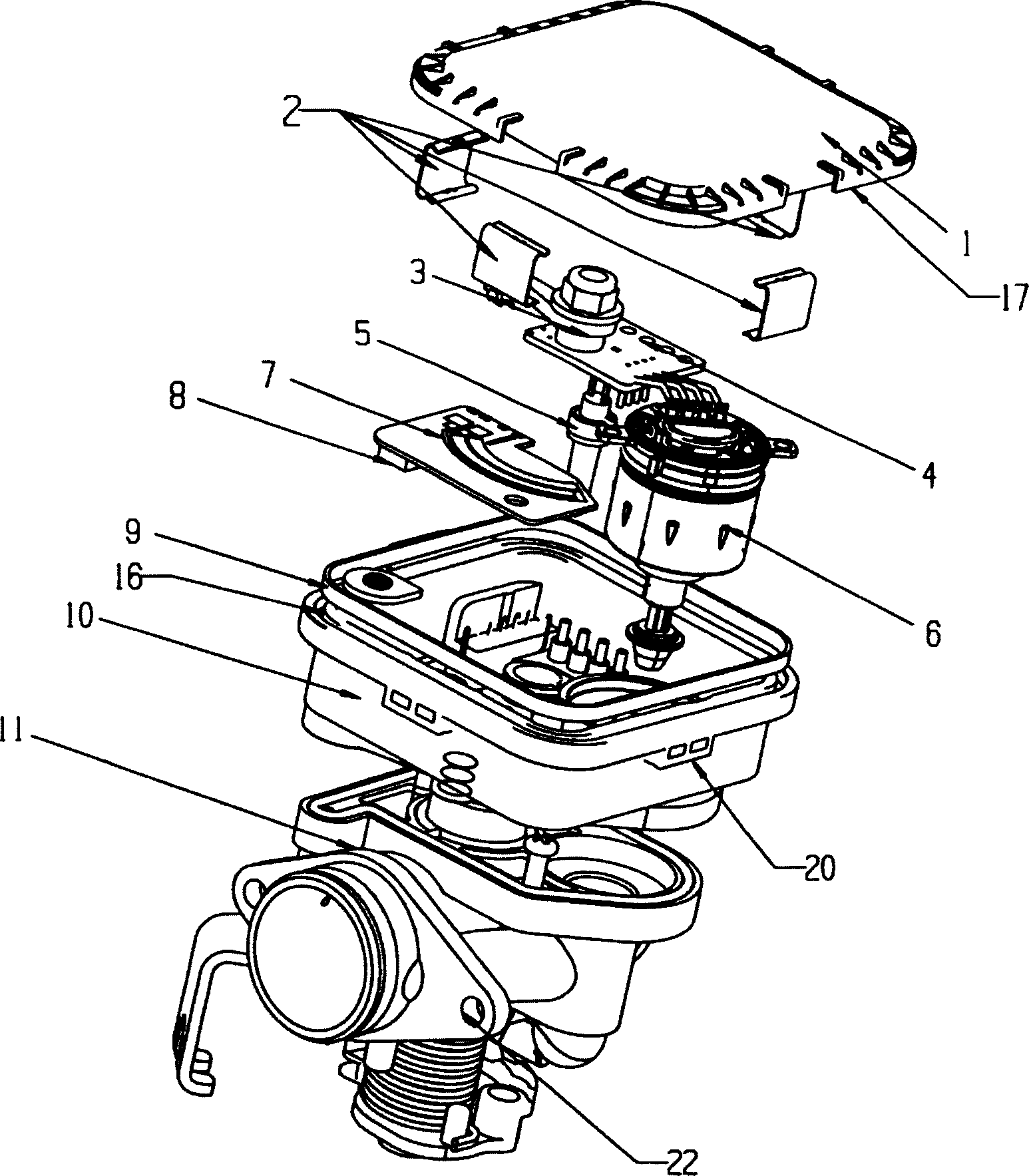

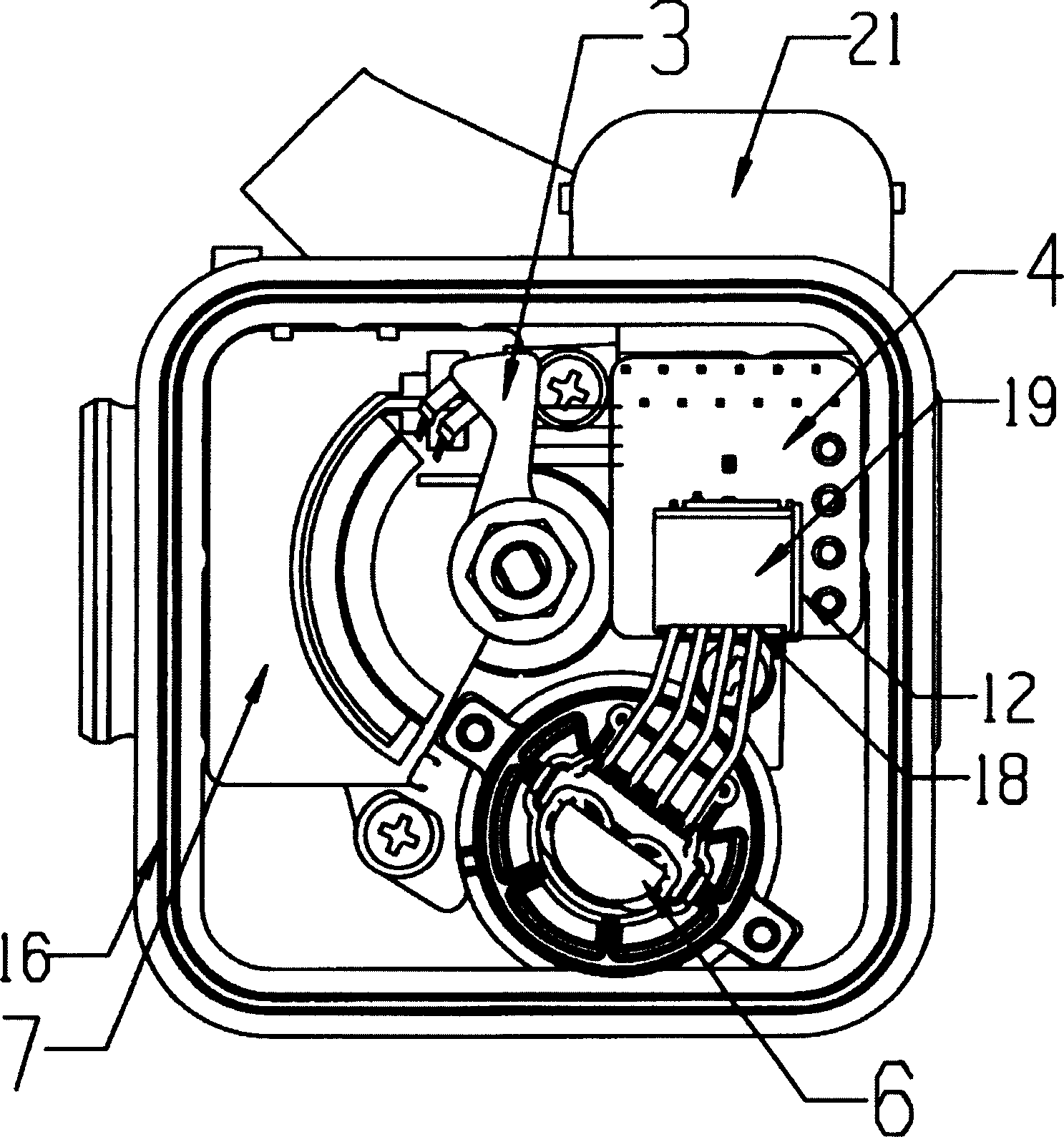

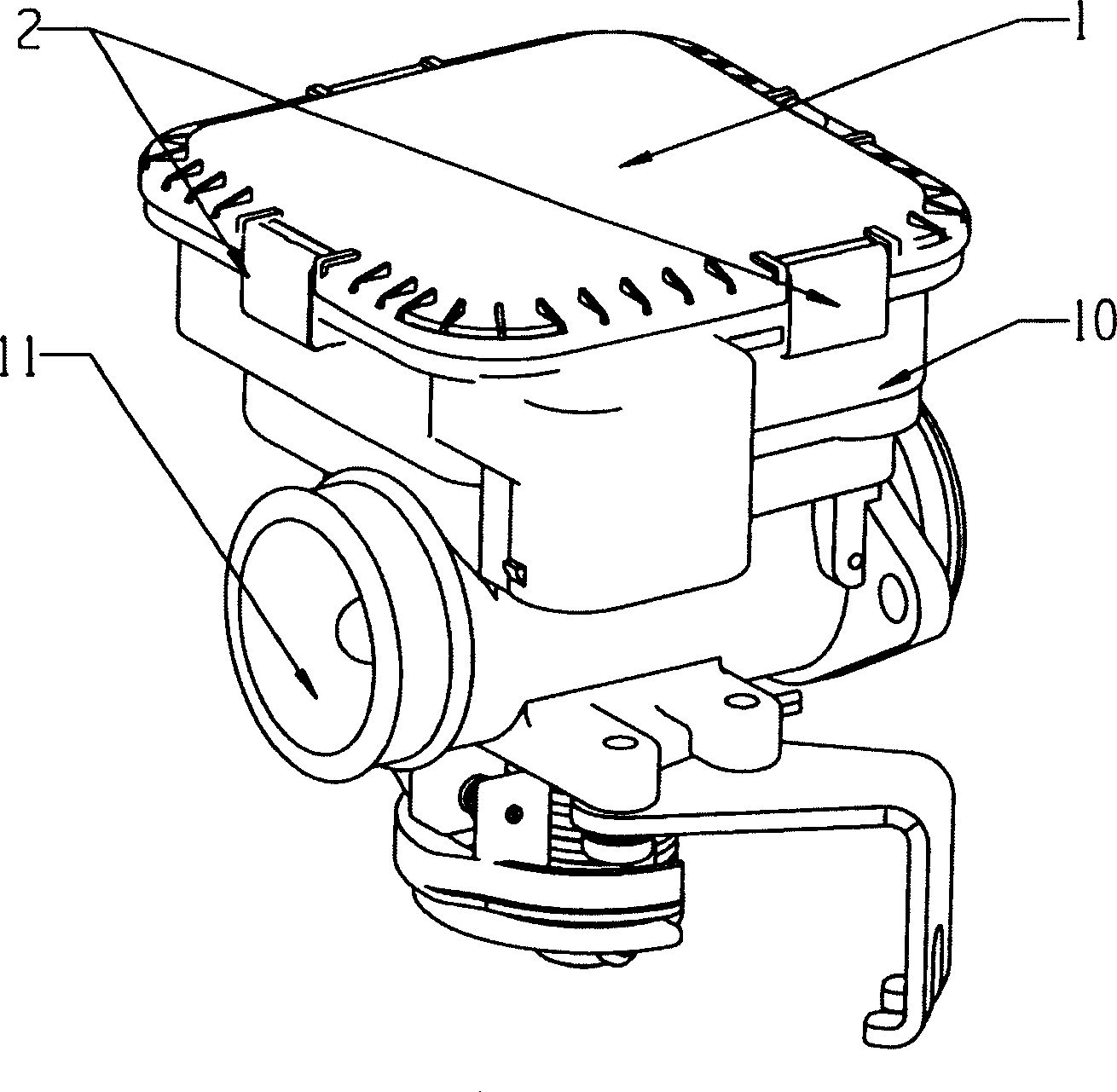

[0016] Such as figure 1 As shown, the small engine throttle module of the present invention is composed of a throttle body assembly 11 and an intake air temperature sensor 5, an intake air pressure sensor 8, a throttle position sensor, a stepping motor 6 and a PCB board 4 arranged in the housing. The throttle body assembly 11 body is made of cast aluminum (other parts of the throttle body assembly 11 are made of stainless steel or other materials), and the housing is made of high-strength plastic. The throttle body assembly 11 and the shell There is a sealing ring between the bodies, and then they are fixedly connected together by screws. This reduces the weight of the entire module and reduces manufacturing costs.

[0017] combine image 3 As shown, the housing is square and includes a housing assembly 10 and a cover plate 1 . The surrounding outer walls of the housing assembly 10 are respectively provided with an engaging protrusion 20, and the clip 2 is engaged between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com