Glue dispensing device and method thereof

A glue dispensing device and glue dispensing technology, applied in the direction of spraying device, liquid coating device on the surface, coating, etc., can solve the problems of poor adhesion of the lens barrel, easy to fall off, lens module failure, etc., to prevent Discontinuous dispensing, convenient assembly, and improved dispensing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

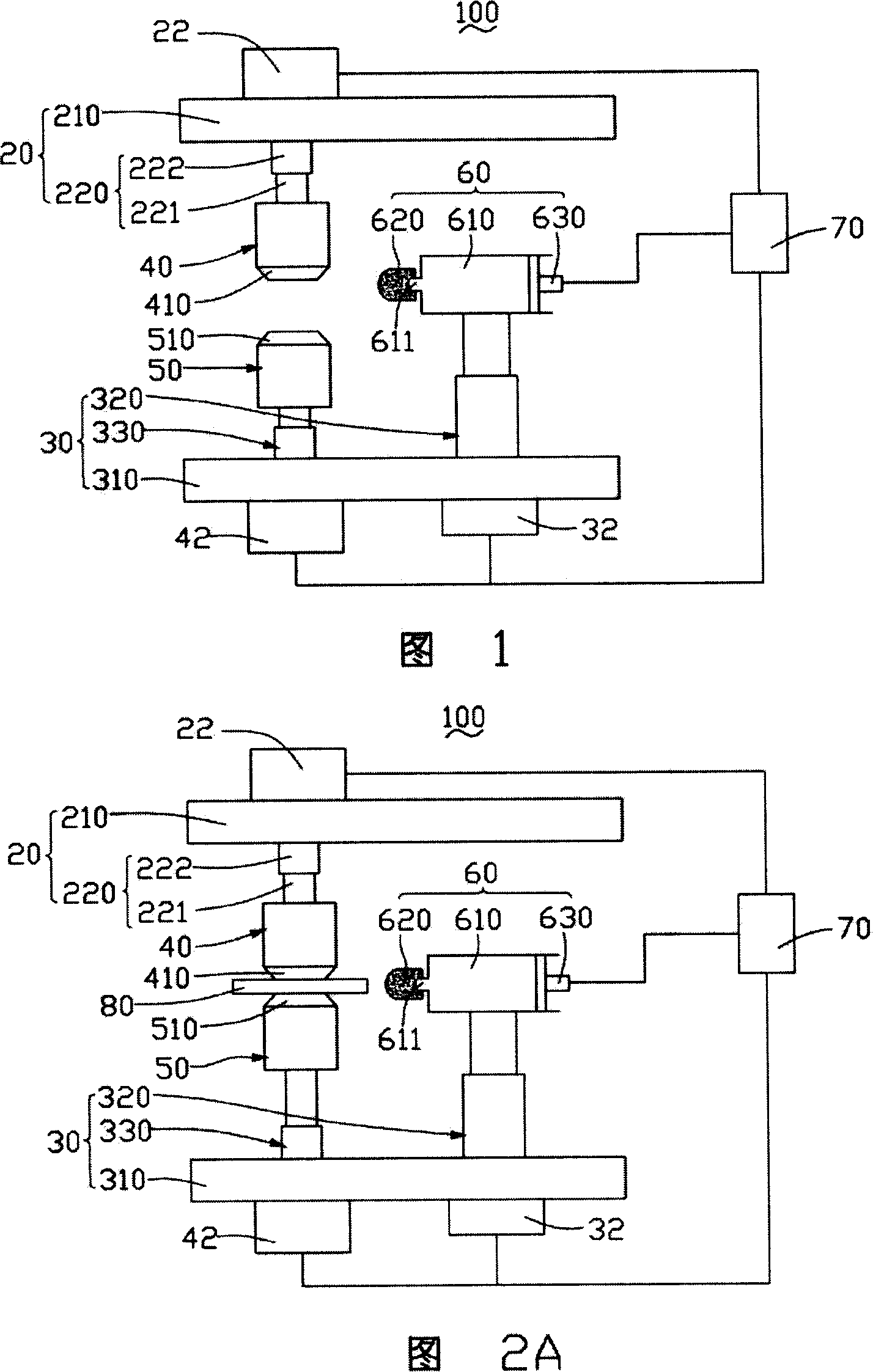

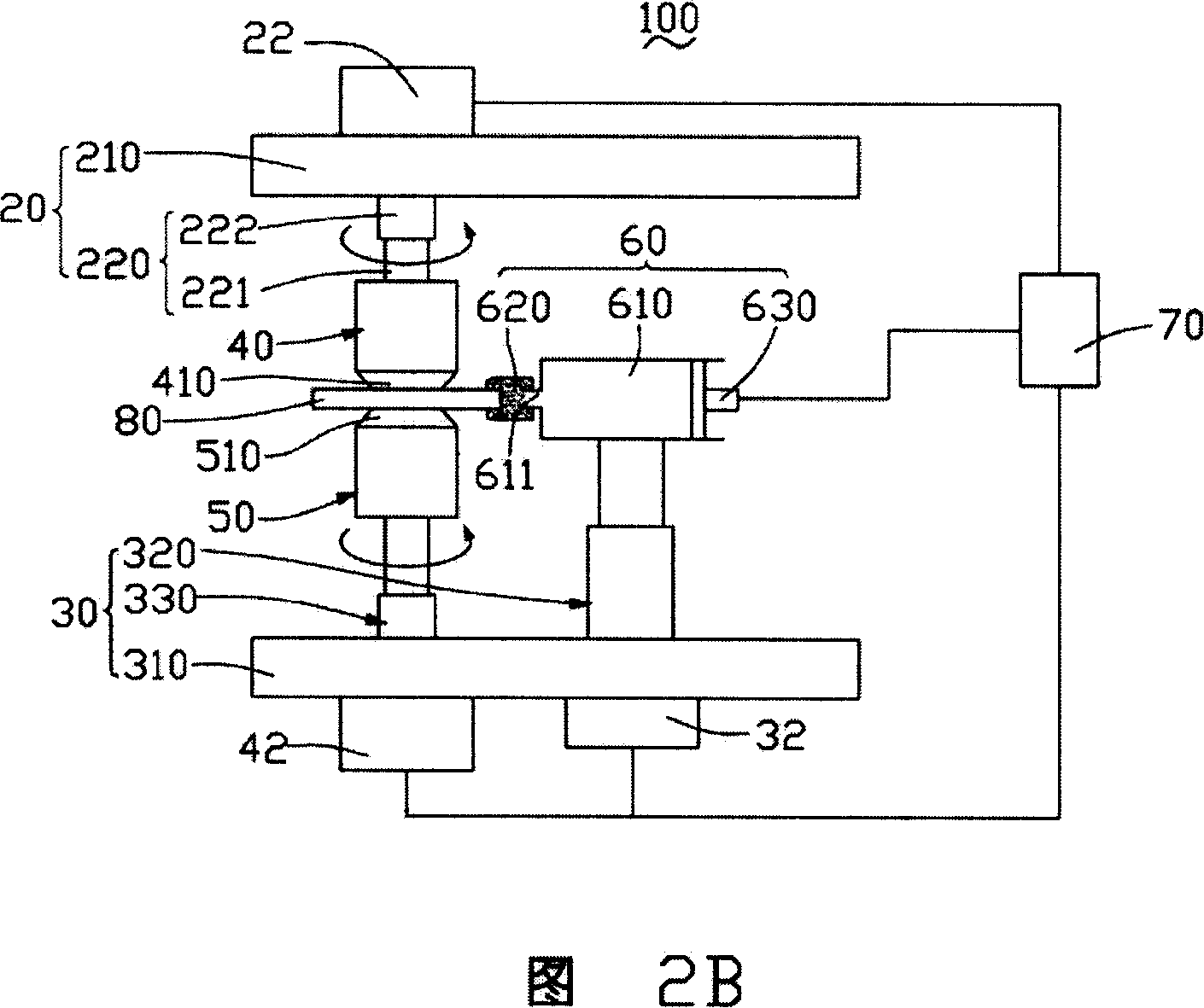

[0011] A dispensing device and a dispensing method using the device will be described below with examples.

[0012] Please refer to Fig. 1, the dispensing device 100 that embodiment one provides, it comprises a first base 20, a second base 30, a first vacuum adsorption device 40, a second vacuum adsorption device 50 and a dispensing device 60.

[0013] The first base 20 includes a first base bracket 210 and a connecting rod 220 . The first base support 210 is used to support the first vacuum suction device 40 . The connecting rod 220 passes through the first base bracket 210 , and a first driving device 22 is connected to one end of the connecting rod 220 . The first driving device 22 can be moved to a certain position on the first base support 210 and fixed, which can drive the connecting rod 220 connected to it to move correspondingly relative to the first base support 210, and fix the connecting rod 220 on the first base bracket 210 . Preferably, a chute can be provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com