Method for monitoring crack defects in heavy load runway girder

A technology for driving girders and heavy loads, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve problems such as cracking, inconvenient detection in high-altitude inspection operations, and inability to detect cracks and defects in key parts of the girders in time, to avoid huge losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

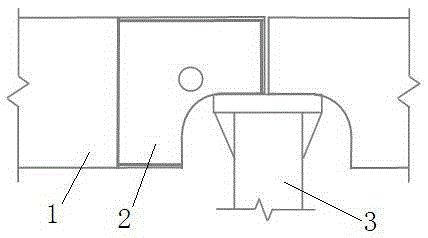

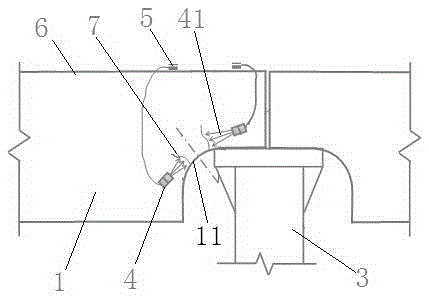

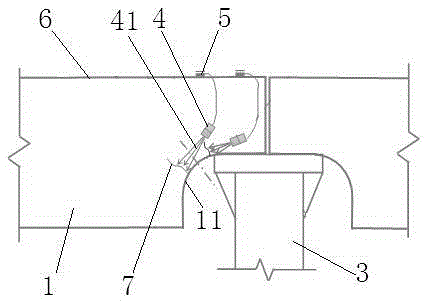

[0018] Example figure 2 and image 3 As shown, the monitoring method for the crack defect of the heavy-duty traveling girder of the present invention comprises the following steps:

[0019] Step 1. Pass the sensitivity test, that is, use the comparison test block to clearly show the echo of the artificial groove with a certain size from the probe as a benchmark, and select two electromagnetic ultrasonic surface wave probes 4 that meet the monitoring sensitivity requirements; The size of the driving girder is different, and the detection distance is different, so the sensitivity test is carried out with a certain size of the probe distance from the comparison test block, which is determined according to the size of the driving girder and the detection distance;

[0020] Step 2. Based on the convenience of the vehicle frame structure and probe arrangement, two surface wave probes 4 are arranged opposite or side by side at the arc-shaped part 11 of the vehicle frame web 1 locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com