Patents

Literature

45results about How to "Solve problems such as cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

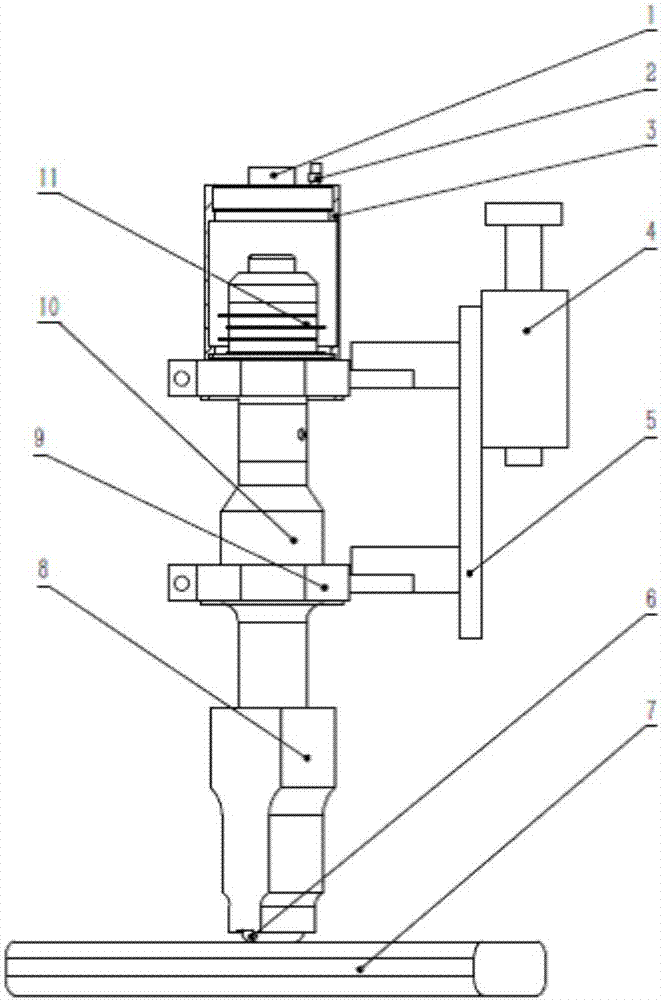

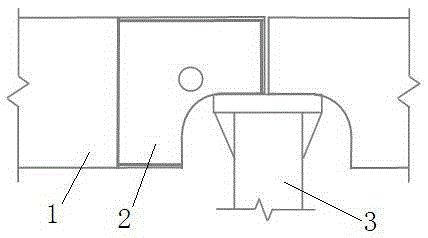

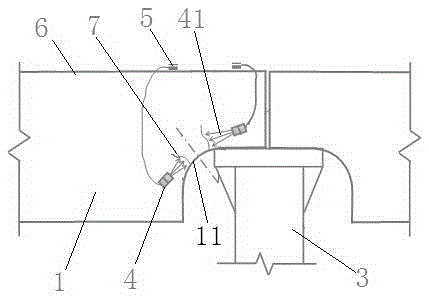

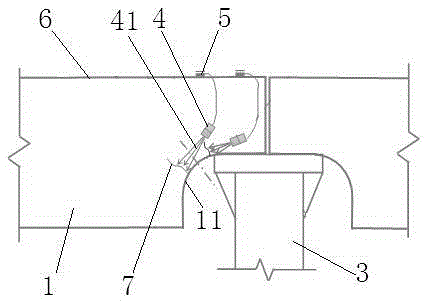

Ultrasonic and micro-forging composite device for improving microstructure and performance of additively manufactured metal and additive manufacturing method

ActiveCN107470628AImprove efficiencyHigh speedAdditive manufacturing apparatusIncreasing energy efficiencyComposite effectManufacturing technology

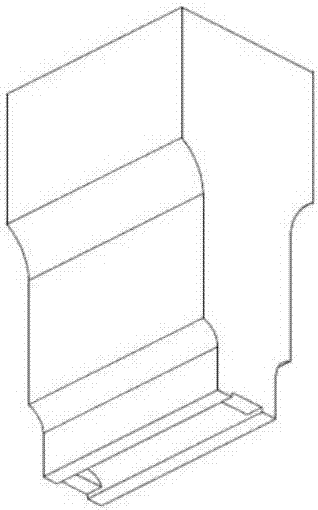

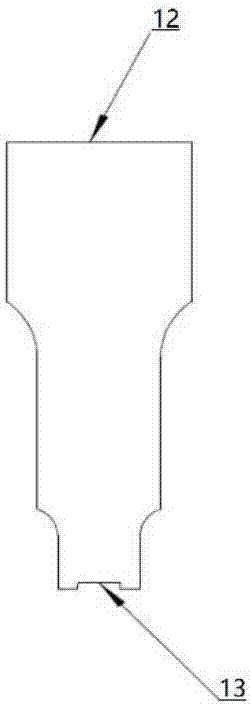

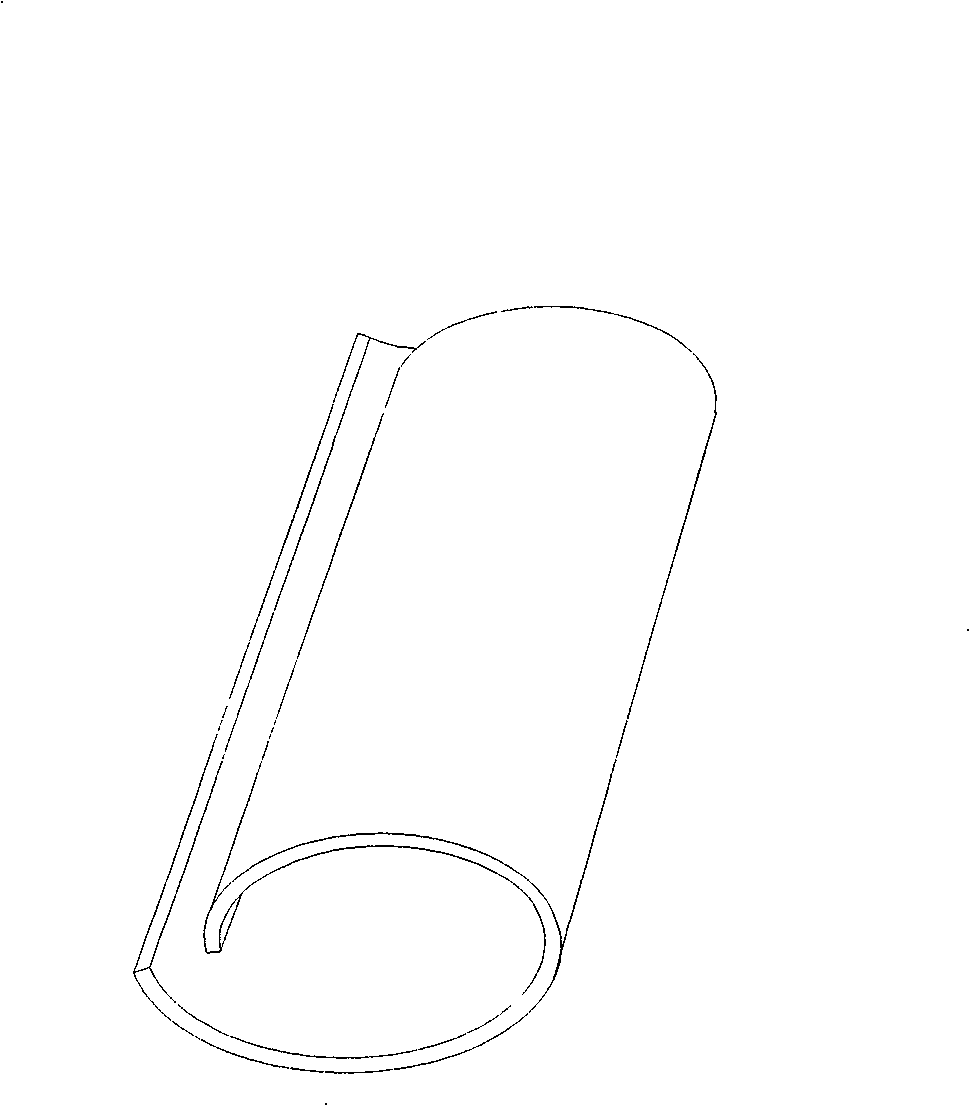

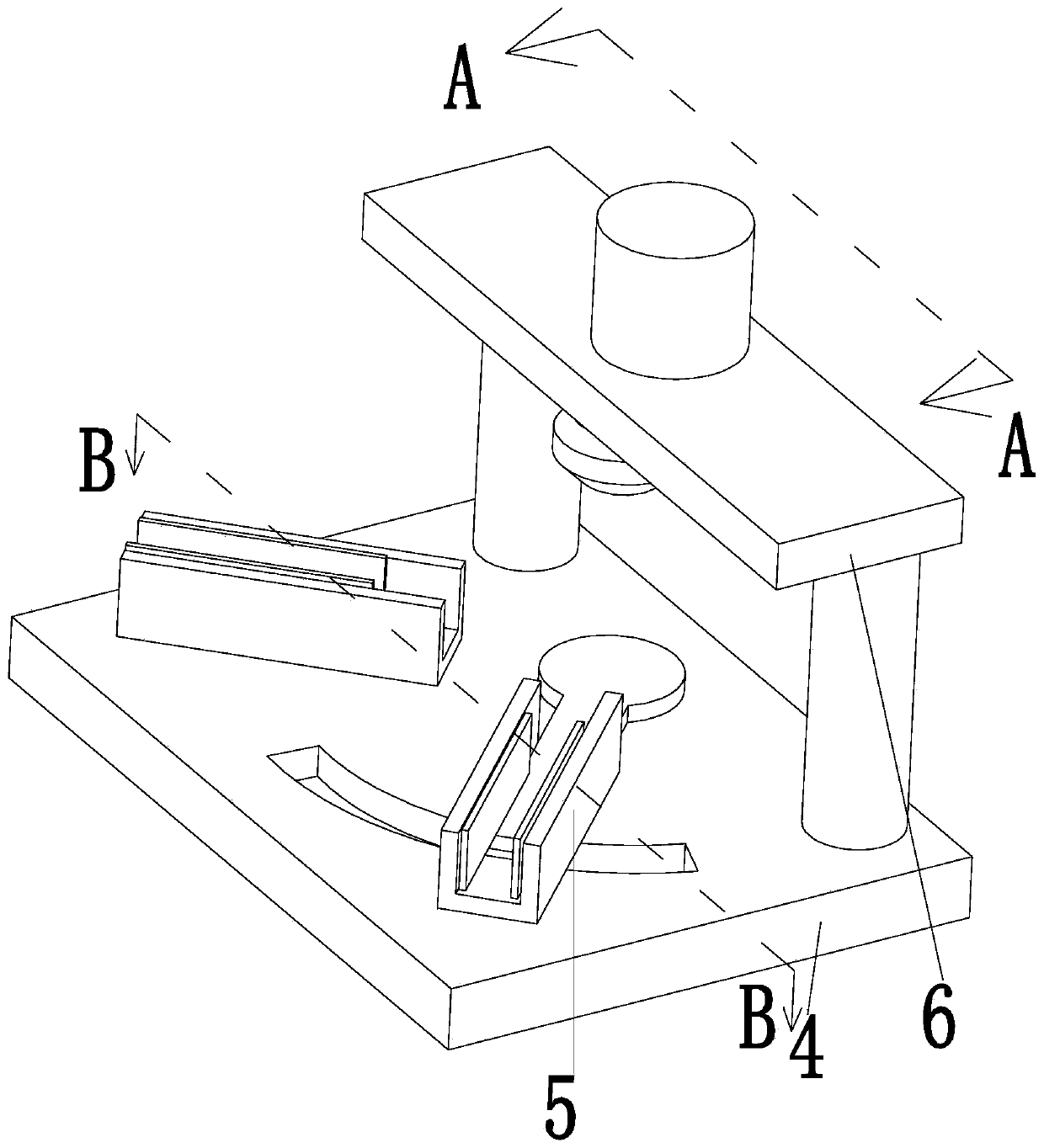

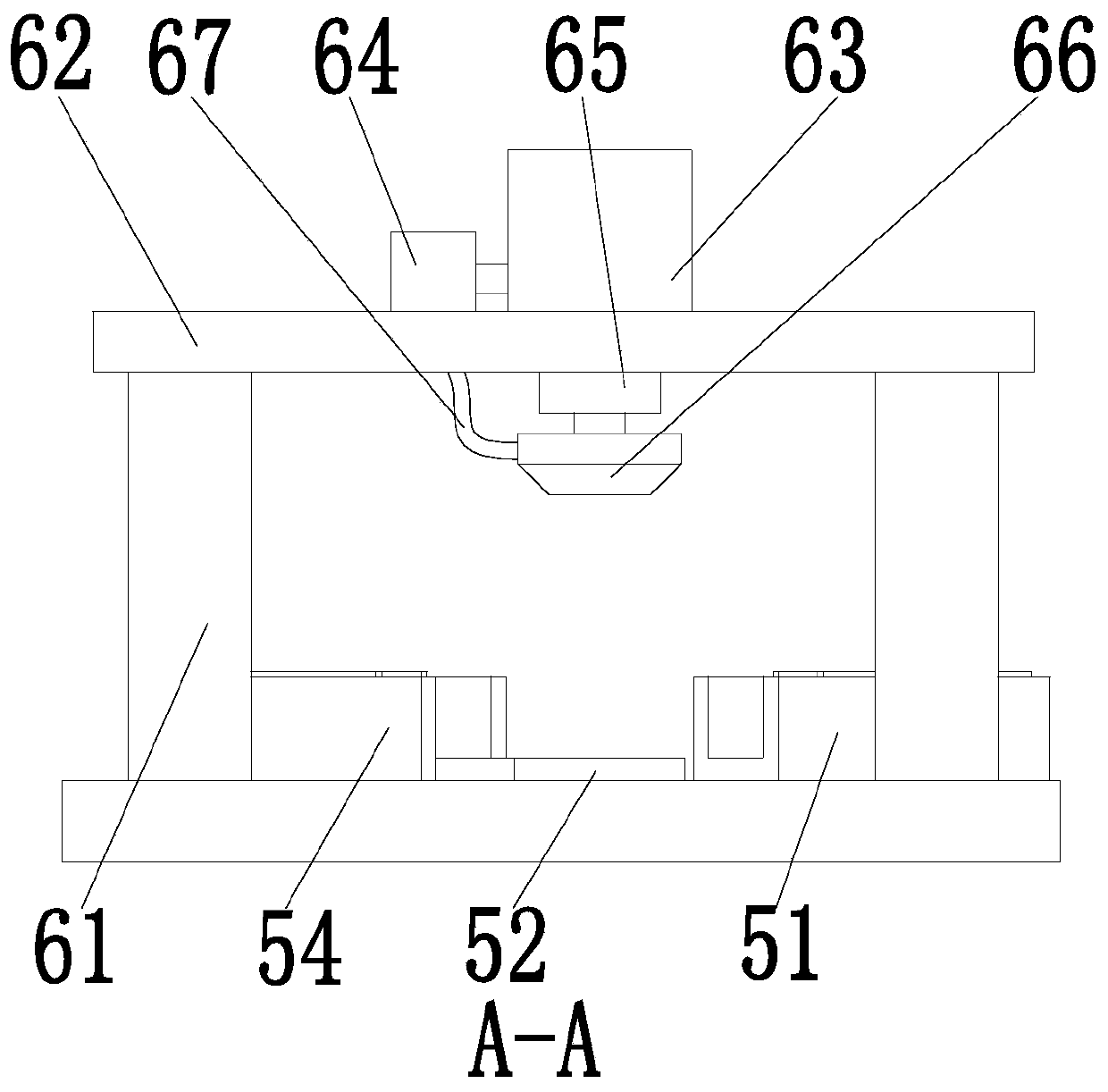

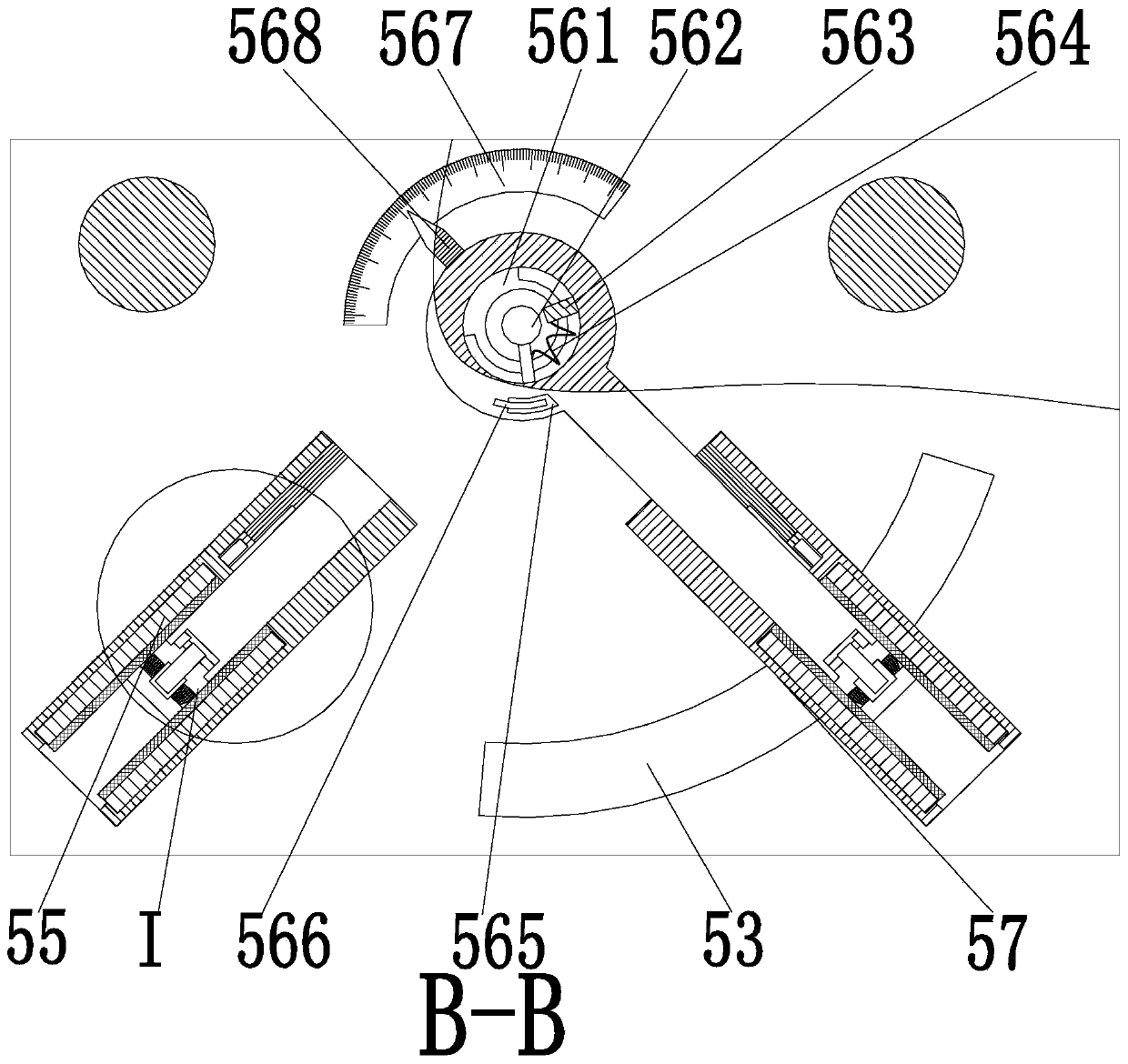

The invention provides an ultrasonic and micro-forging composite device for improving the microstructure and performance of additively manufactured metal and an additive manufacturing method. The ultrasonic and micro-forging composite device comprises an energy converter, a pneumatic slider, a pneumatic slider connection frame, an amplitude transformer, a tool head and a roller. The energy converter is arranged in an energy converter shell, the energy converter shell is provided with an inserting piece and a pipeline connector, the amplitude transformer is connected to the lower end of the energy converter, the tool head is connected below the energy converter, the roller is located between the tool head and a workpiece, and the pneumatic slider is connected with the energy converter shell and the amplitude transformer through the pneumatic slider connection frame. By means of the ultrasonic and micro-forging composite device, the advantages that ultrasonic impact frequency is high and deformation generated by mechanical rolling is large are combined, the composite effect of ultrasonic impact and continuous rolling micro-forging can be achieved, and the purpose of improving the microstructure of the additively manufactured metal and the mechanical performance of parts is achieved. Through organic combination of the ultrasonic and micro-forging composite device and the additive manufacturing method with an existing additive manufacturing technology, the technical bottleneck that structure control is easy while performance control is difficult in existing metal additive manufacturing is solved, and innovation and development of metal rapid forming and manufacturing technologies are induced.

Owner:HARBIN ENG UNIV +1

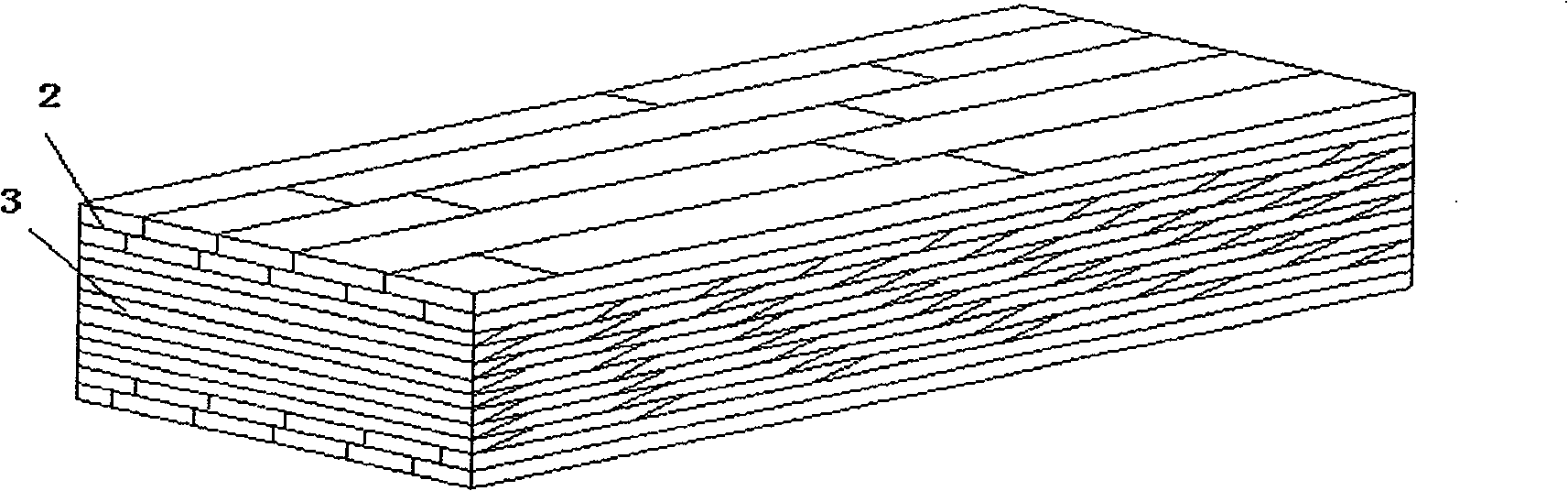

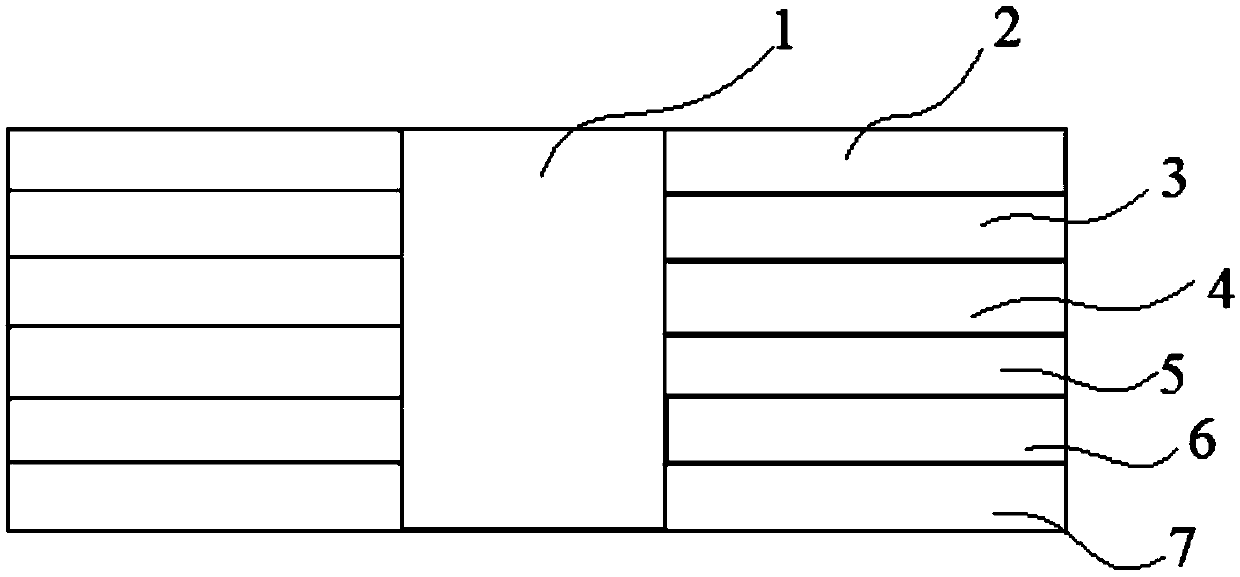

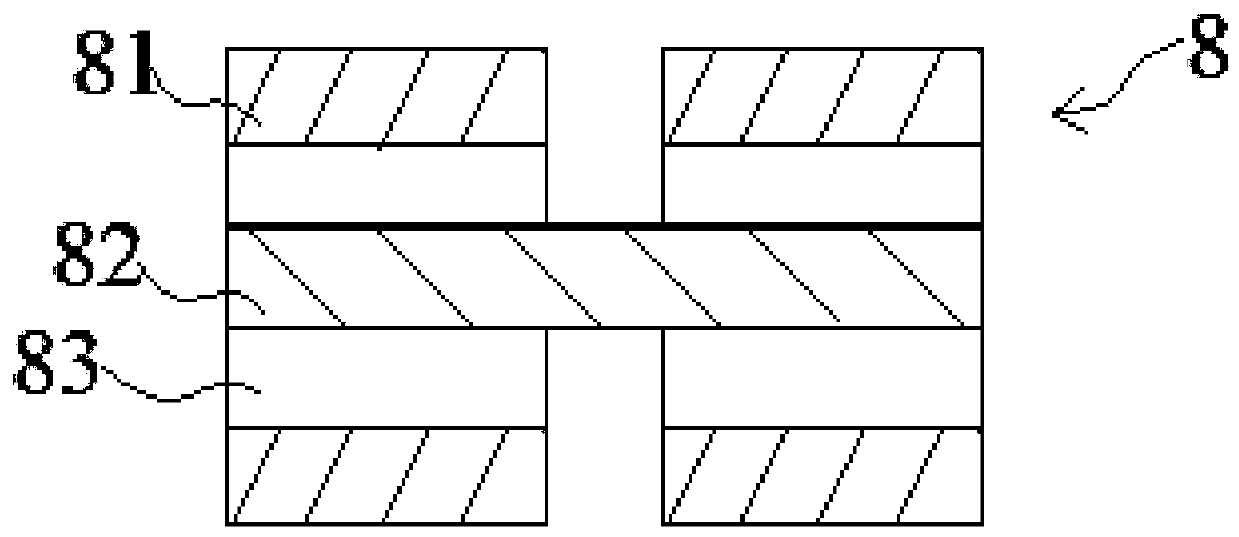

Super-thick bamboo-wood composite board and producing method thereof

ActiveCN101524858ASolve the problem of poor thermal conductivity that is difficult to produce by hot pressingSolve warpingPolyureas/polyurethane adhesivesAldehyde/ketone condensation polymer adhesivesAdhesiveEngineering

The invention provides a super-thick bamboo-wood composite board, which comprises a core board, a surface board and a back board, wherein the core board is a super-thick rotary-cut single board with the thickness of 6-12 mm, the surface board and the back board are made of bamboo, the core board comprises a plurality of super-thick single boards, the contiguous layers of the super-thick single boards are in the combination along the grain, a glue layer is arranged between contiguous single boards, the adhesive of the glue layer is an aqueous macromolecule isocyanate adhesive, the super-thick single boards of the core layer are single boards after the processing of stress degradation, and spot-shape or segment-shape crack grains are formed in the direction along the grain of the loosened surface of every single board. Compared with the prior composite board of the same thickness, the composite board has greatly-reduced glue amount and no deformation or distortion.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

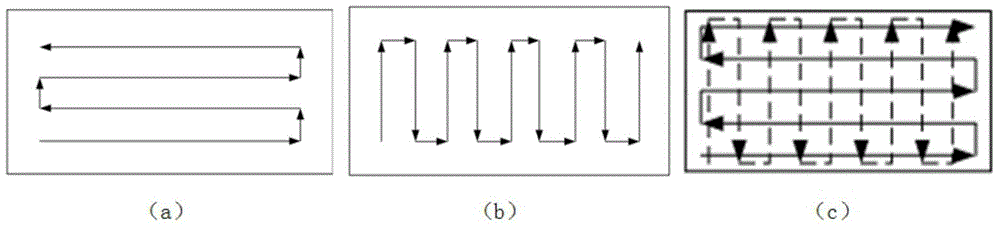

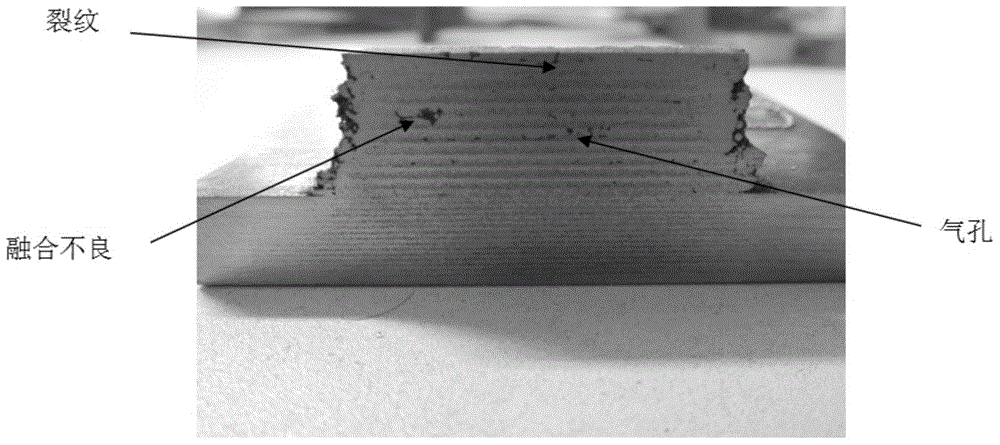

Laser additive manufacturing technology of high-temperature alloy parts

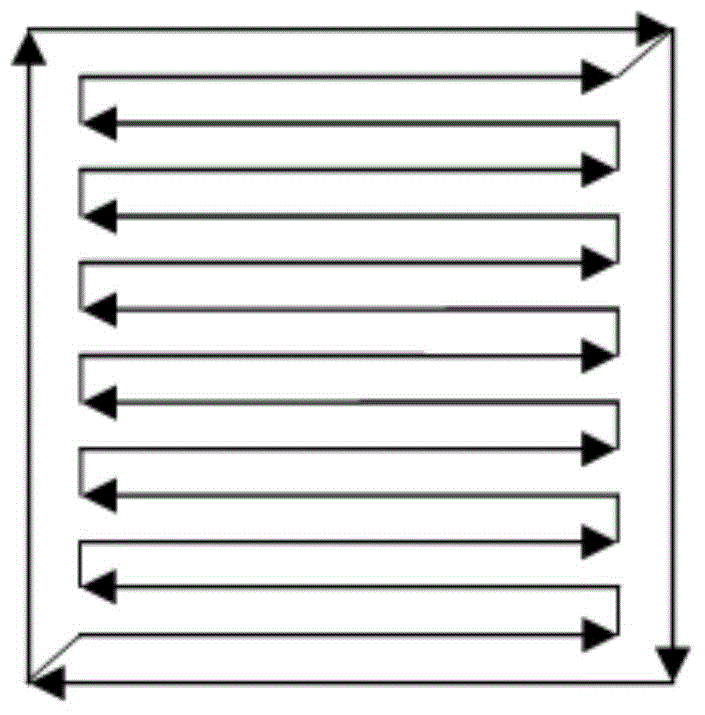

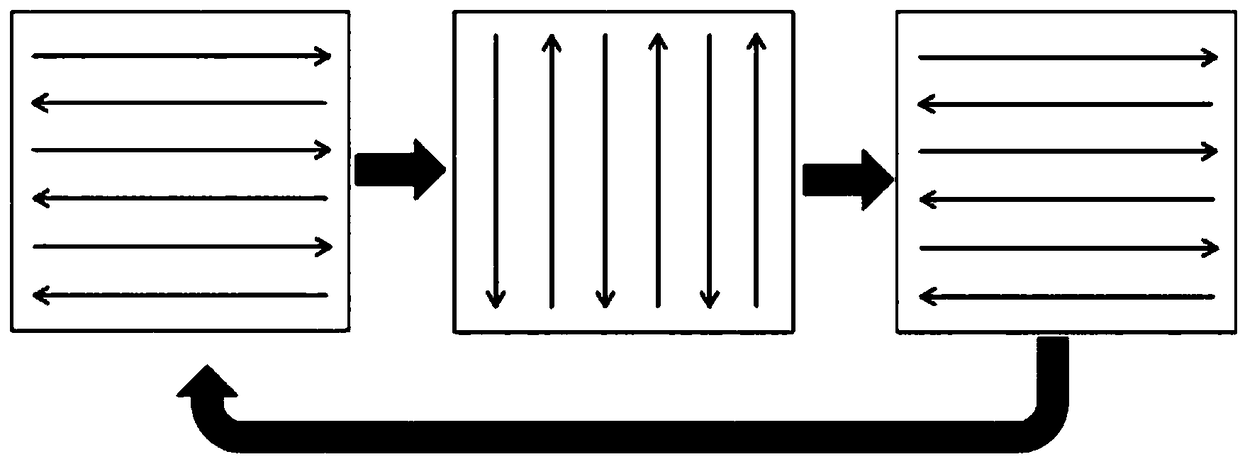

InactiveCN104785778AImplement defect controlControl internal defectsIncreasing energy efficiencyManufacturing technologyLaser scanning

The invention discloses a laser additive manufacturing technology of high-temperature alloy parts, and belongs to the technical field of laser additive manufacturing of metal powder. According to the invention, the technological parameter ranges of different high-temperature alloy materials are determined through basic technological experiments, and then additive manufacturing is carried out by adopting specific laser scanning paths and related internal defect control methods in the manufacturing process. The parts manufactured through the technology have the advantages that the forming efficiency is high, the cost is low, the internal quality is high, the automation degree is high and operation is easy. The high-temperature alloy parts capable of being applied industrially can be directly manufactured by adopting the technology, so that a new approach for manufacturing the high-temperature alloy parts is provided.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

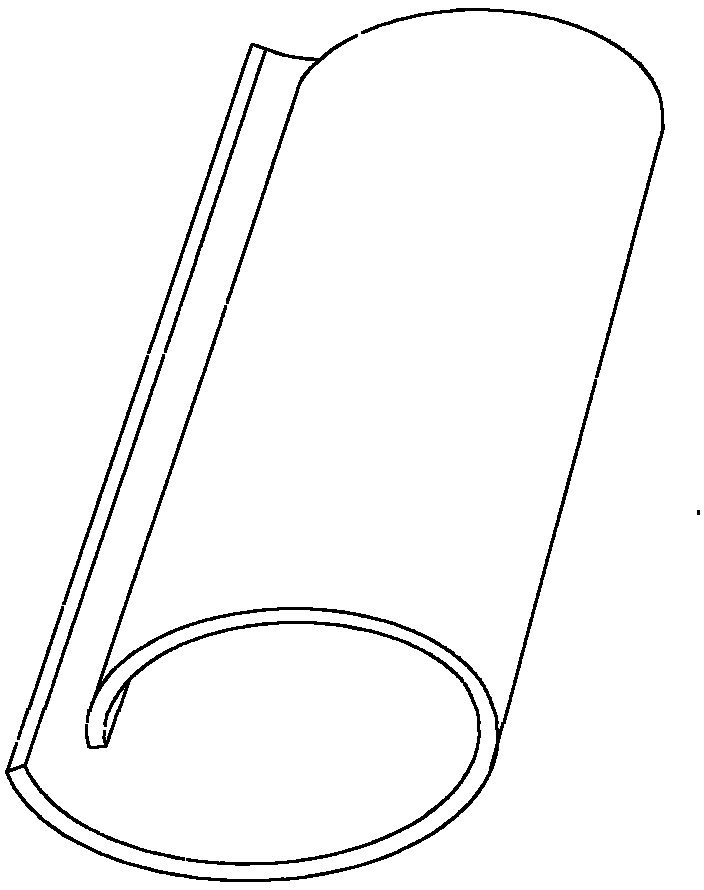

Preparation method of thin-wall tubular product of particle-reinforced aluminum-based composite material

ActiveCN101737574AReduce plasticityFix production issuesRigid pipesSolution treatmentRoom temperature

The invention relates to a preparation method of a thin-wall tubular product of a particle-reinforced aluminum-based composite material, which comprises the steps of: 1, preparing a tube blank by adopting a mixing and casting process and a powder metallurgy process; 2, homogenizing the tube blank, turning and stripping, carrying out a high-temperature compression deformation test to obtain a suitable processing deformation condition; 3, spinning the tube blank for finite element number value simulation, optimizing process parameters, and thermally spinning and warmly spinning; and 4, carrying out solution treatment on the obtained tubular product, and ageing after water hardening at room temperature. The tubular product prepared by the invention has larger diameter wall thickness ratio, smooth internal surface and outer surface without defects, uniform wall thickness and better interface combination between reinforced particles and a base body of the thin-wall tubular product. The method has short procedure, labor saving of the processing mode, energy saving and environmental protection, simple process, low raw material cost, suitability for large-scale production and better popularization value, and can be widely applied to the preparation of high-strength light tubular products in the fields of aerospace, vehicles, advanced weapons and the like.

Owner:有研金属复材技术有限公司

Laser melting deposition method of ceramic reinforced high-entropy alloy composite component

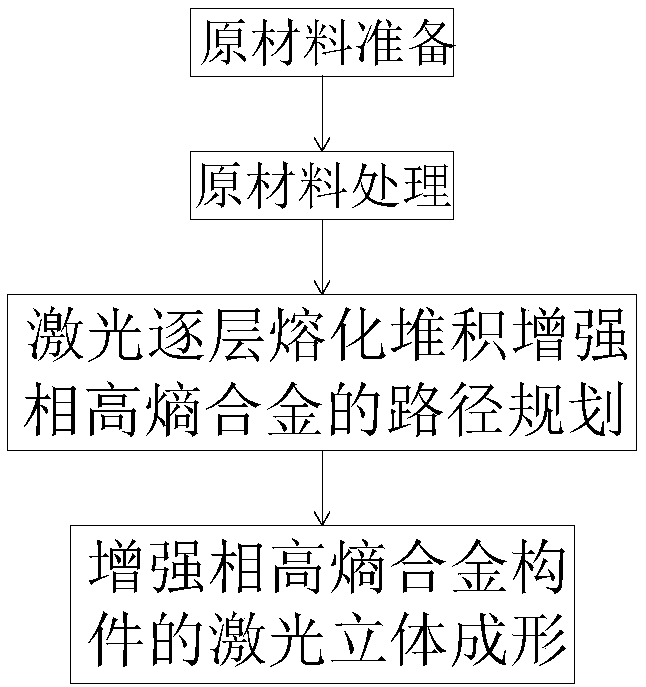

InactiveCN109290572AIncrease profitHigh forming precisionAdditive manufacturing apparatusIncreasing energy efficiencyHigh entropy alloysCeramic

The invention discloses a laser melting deposition method of a ceramic reinforced high-entropy alloy composite component. The method includes the following steps that (1) raw materials are prepared; (2) the raw materials are treated; (3) a path of a laser layer-by-layer melted accumulated reinforced phase high-entropy alloy is planned; and (4) a reinforced phase high-entropy alloy component is subjected to laser stereoscopic forming. The laser melting deposition technology is creatively applied to preparation of the ceramic reinforced high-entropy alloy composite component, process parametersof laser melting deposition of the ceramic reinforced high-entropy alloy composite component are explored, the restriction technical problem of laser melting deposition of the ceramic reinforced high-entropy alloy composite component is solved, and the method has great significance in research and application of the component.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

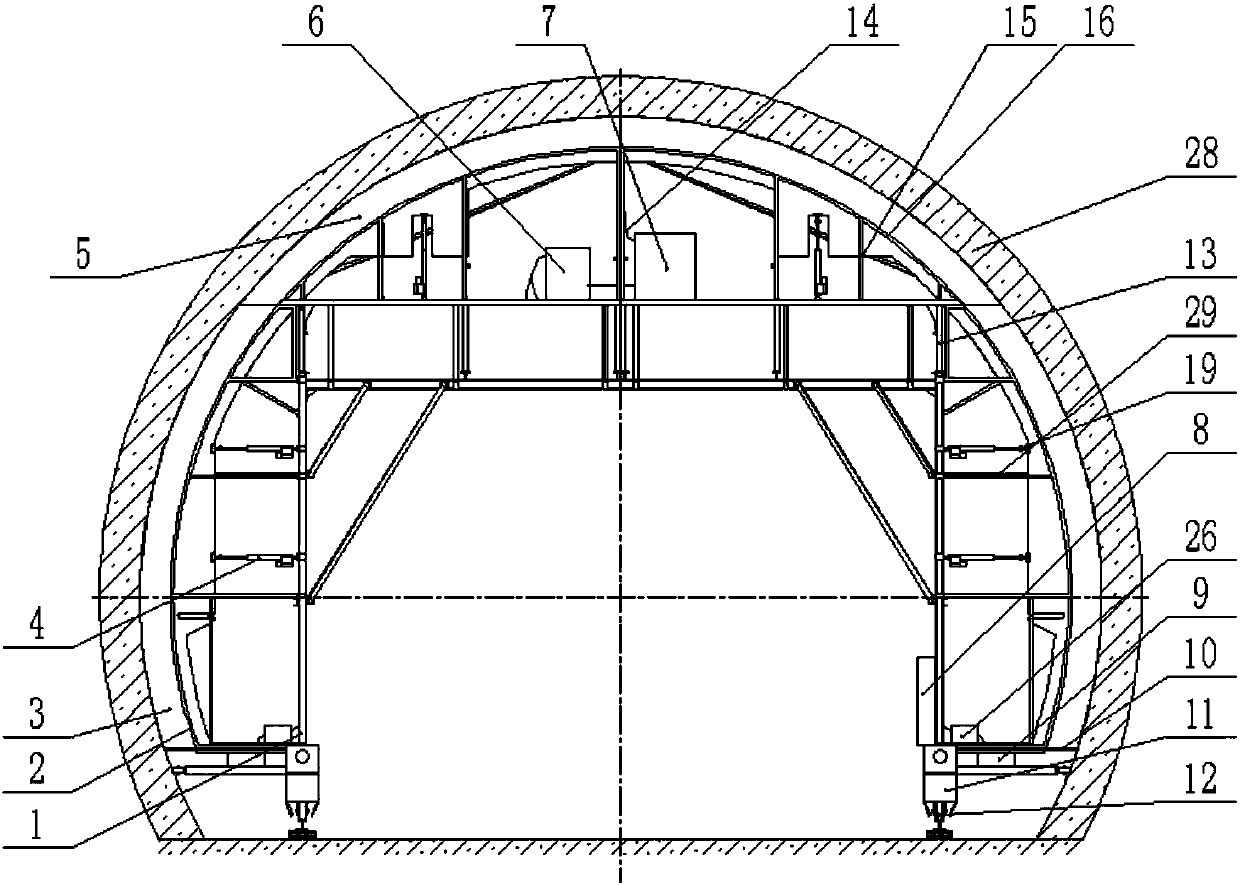

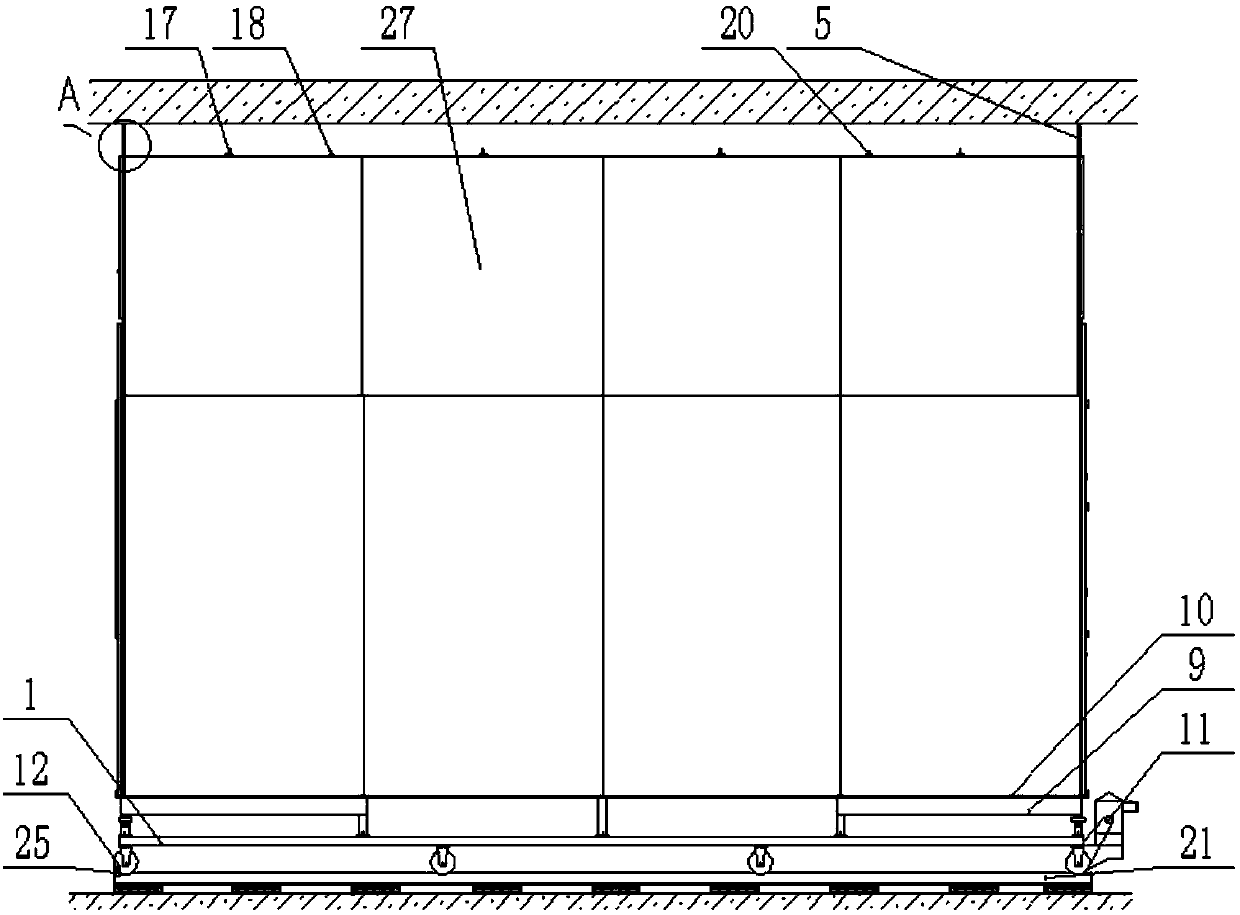

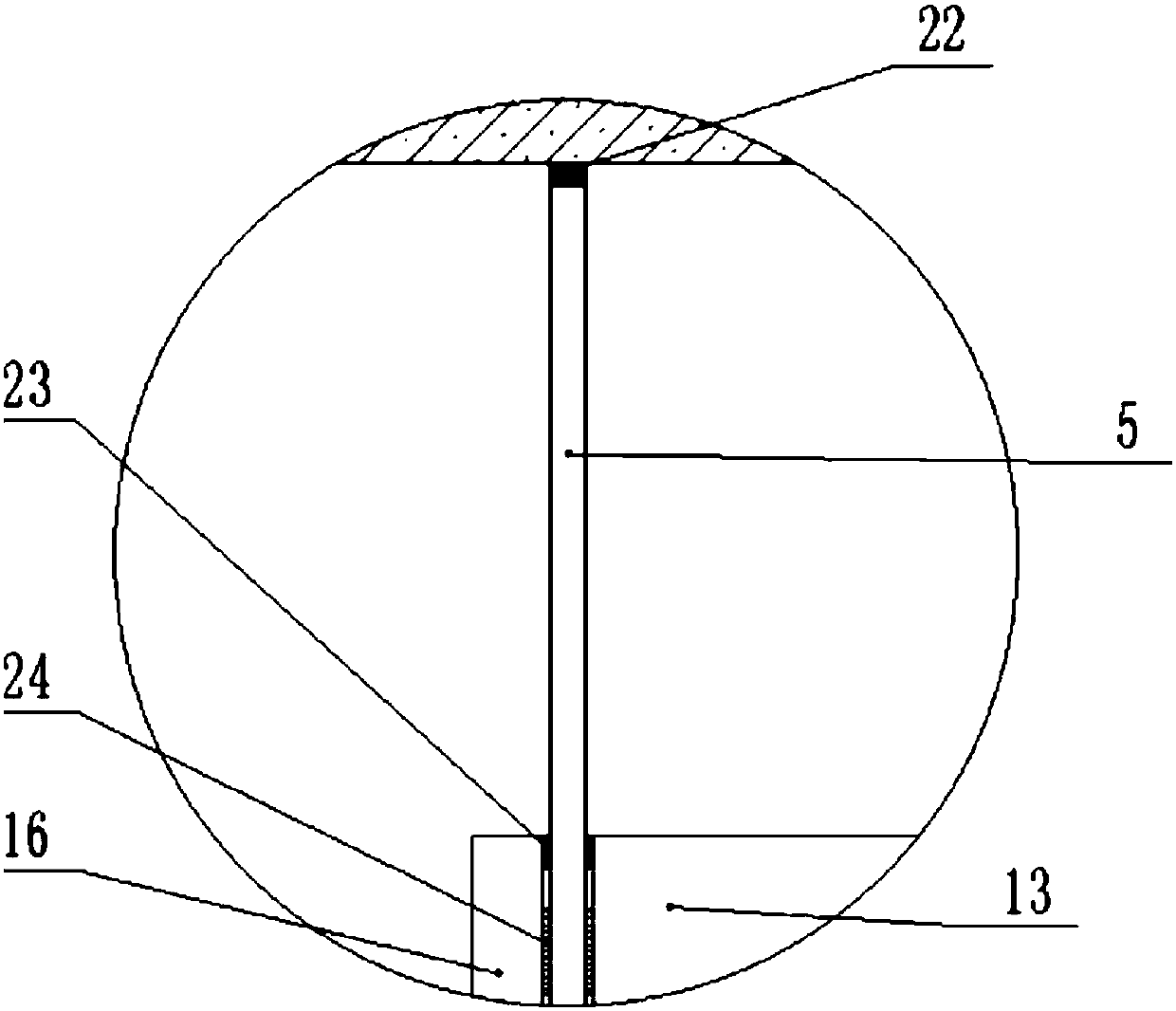

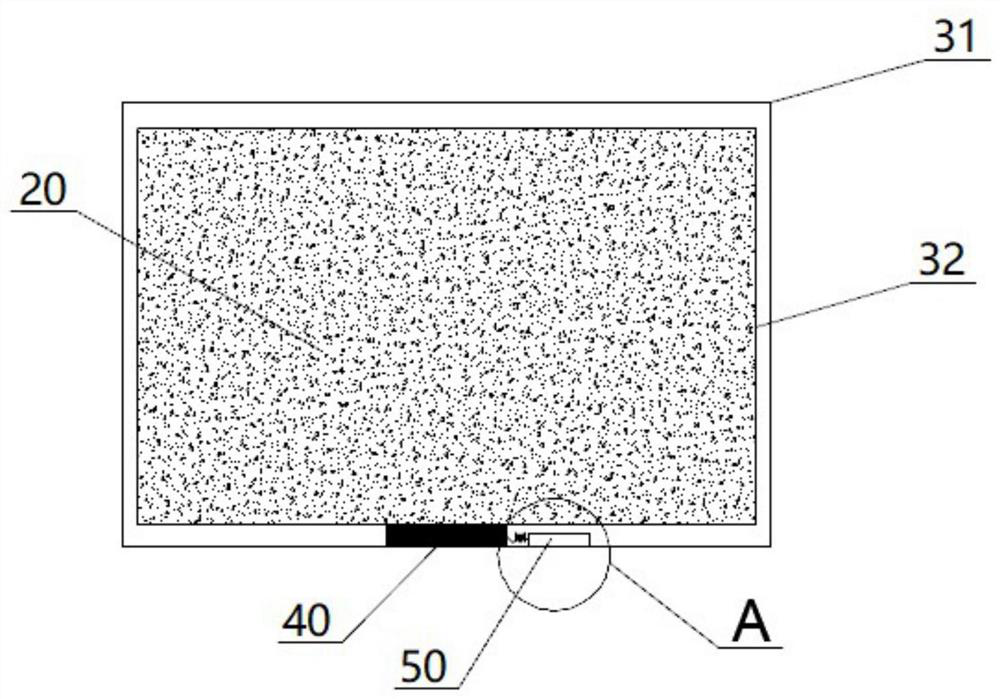

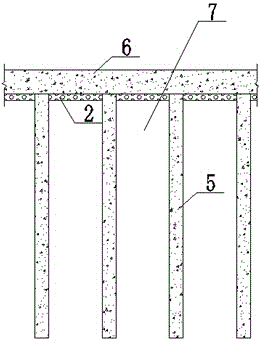

Full-automatic tunnel mist spraying trolley for second-lining concrete curing

PendingCN107559021ASolve the strength problemSolve problems such as crackingUnderground chambersTunnel liningWater storage tankEffusion

The invention discloses a full-automatic tunnel mist spraying trolley for second-lining concrete curing. Upper arched frames and side arched frames are arranged on the periphery of a main frame, the two sides of the lower portions of the two upper arched frames are each connected with the corresponding side arched frame. A trolley travelling mechanism is arranged at the lower end of the main frameand mainly comprises a track, travelling wheels, a stroke switch, a motor and a driving mechanism. The front radial end face and the rear radial end face of the trolley are each provided with a spokeplate telescopic mechanism, and the spoke plate telescopic mechanisms mainly comprise upper spoke plates, lower spoke plates, upper-lower spoke plate fixing frames, electric push rods, force sensors,guide wheels and self-lubricating plates. Curing automatic mist spraying mechanisms are arranged on the arched frames and mainly comprise water storage tanks, electric heating steam generators, nozzles, temperature sensors, humidity sensors and pipelines. A condensate accumulation and recovery mechanism is arranged on the lower portion of the main frame and mainly comprises a liquid accumulationtray, a liquid accumulation box, a water pump and a filter. The concrete surface is not damaged, the field operating environment is also not affected, and the temperature and humidity of second-liningconcrete during curing can be guaranteed.

Owner:YANSHAN UNIV

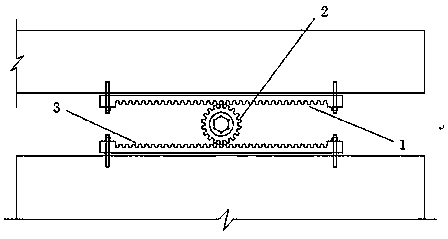

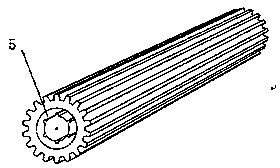

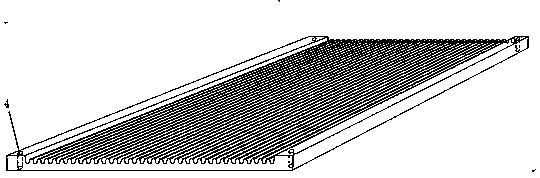

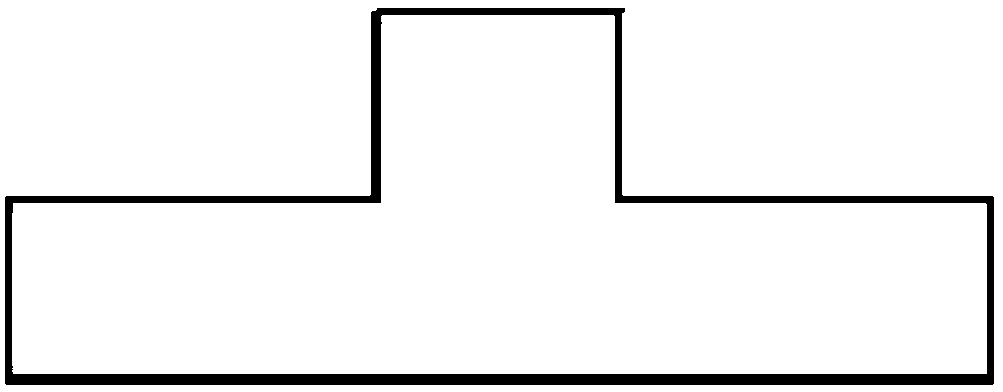

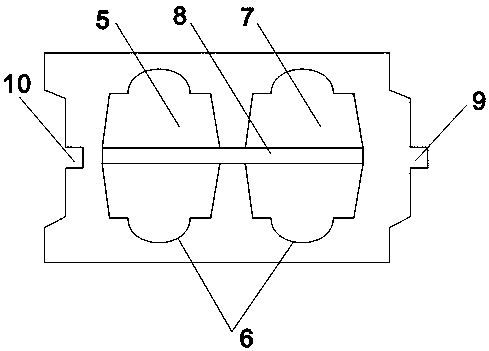

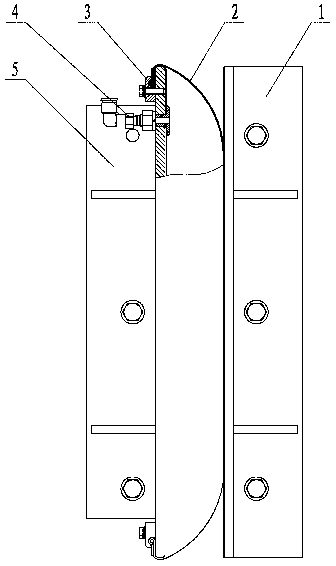

Adjustable bridge rail support

PendingCN107938503ASolve problems such as crackingSolve pressing problemsBridge structural detailsArchitectural engineeringBridge deck

The invention discloses an adjustable bridge rail support comprising an upper rail board and a lower rail board which performs mechanical transmission with the upper rail board via a gear shaft. The steel-concrete composite structure bridge support of the present invention effectively solves the problems of existing steel-concrete composite structure bridge bearings under external load, falling off of roof, overrun of vertical displacement, and limited angle of rotation at locals of girders so that the stress of the steel-concrete composite structure is uneven, and the technical problems suchas fatigue, cracking, and the like of the bridge deck pavement are prone to occur.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

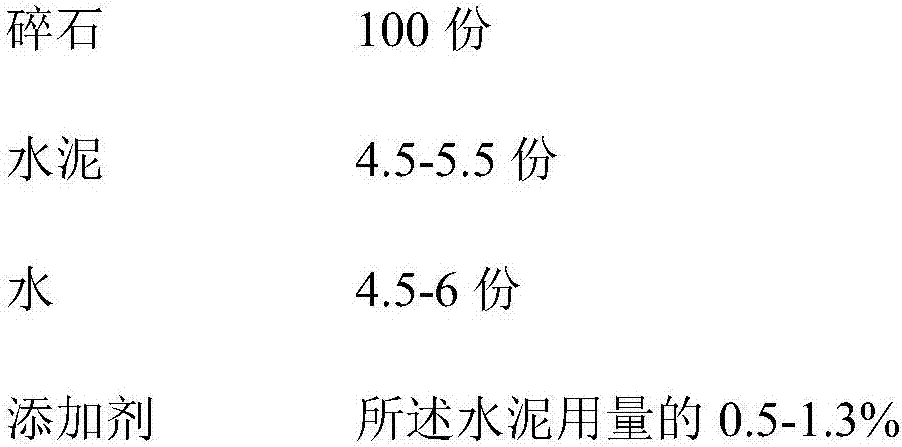

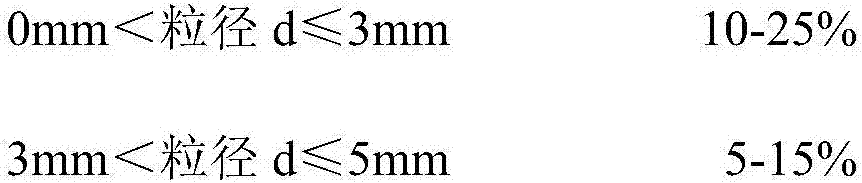

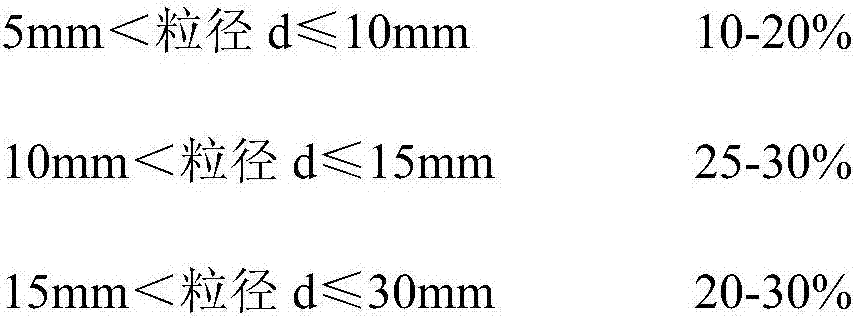

Water super-absorbing resin-based inner cured cement stabilized broken stone base material and preparation method thereof

The invention discloses a water super-absorbing resin-based inner cured cement stabilized broken stone base material. The material comprises, by weight, 100 parts of broken stones, 4.5 to 5.5 parts of cement and 4.5 to 6 parts of water and the additive use amount is 0.5 to 1.3% of the amount of the cement. The water super-absorbing resin is a water swelling-type polymer which contains strong hydrophilic groups such as a hydroxyl group and a carboxyl group and has a certain crosslinking degree. Through adsorption action, the water super-absorbing resin can store water and is uniformly distributed in the cement stabilized macadam mixture. In the latter period, under driving of humidity gradient difference, osmotic pressure and capillary interspace negative pressure in the mixture, the water super-absorbing resin releases pre-stored water to cure cement stabilized broken stones so that the problem that poor water supplement and maintenance in the cement stabilized broken stone cause shrinkage and reduce cracking resistance is solved, greatly improves cracking resistance of the cement stabilized broken stones, delays road surface base reflection cracking and improves road durability.

Owner:JIANGSU SINOROAD ENG TECH RES INST CO LTD

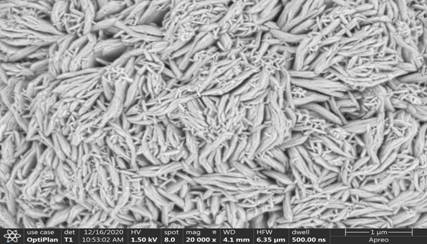

Enhanced hydroxypropyl cellulose microporous film and preparation method thereof

The invention discloses an enhanced hydroxypropyl cellulose microporous film and a preparation method thereof. The preparation method comprises the following steps: dissolving hydroxypropyl cellulose into an alkaline water-soluble solvent system subjected to precooling treatment to obtain a hydroxypropyl cellulose solution; causing the obtain solution to form a film through tape casting, and solidifying in an acid coagulation bath; carrying out cross-linking and plasticizing processing after water washing, and continuing to water vapor boiling under atmospheric pressure or freezing or water vapor boiling under the atmospheric pressure and then freezing; and drying in the air to obtain the enhanced hydroxypropyl cellulose microporous film. The hydroxypropyl content of the hydroxypropyl cellulose is 2-20 percent by weight. The toughness, the tensile strength and the air and water permeability of the film are improved, and the biodegradable homogeneous microporous film is obtained. The microporous film can be widely applied to the film separation process and can be used as packaging films, film electrodes or biomedical materials.

Owner:SUZHOU UNIV +1

Injection molding method of large metal piece

ActiveCN106735170AIncrease profitLower requirementTransportation and packagingMetal-working apparatusInjection molding machineMetal

The invention discloses an injection (MIM) molding method of a large metal piece. The method comprises such steps as sintering raw material pretreatment, raw material coating, feeding granulation, mold design, injection molding, degreasing, splicing and sintering. The method solves such problems as cracking and bubbling caused by incomplete degreasing in manufacturing of the large metal piece by a traditional MIM method, and prevents potential safety hazards in production when improving the quality of the large metal piece.

Owner:PINGXIANG GREENLONG IND

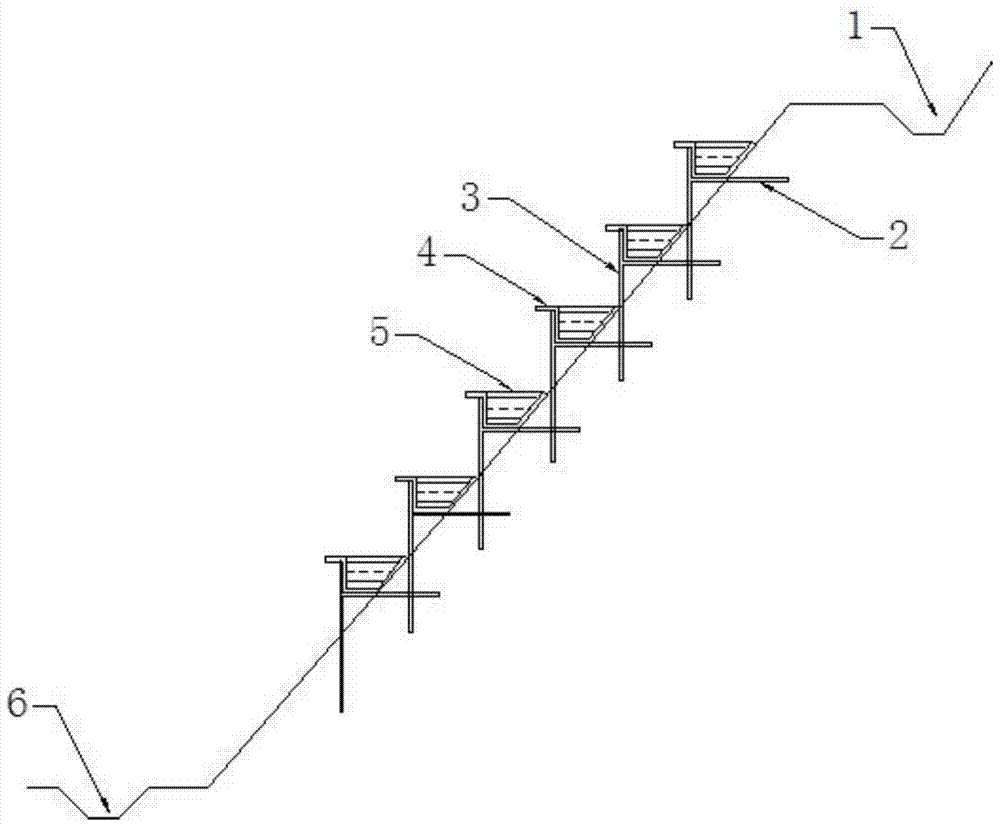

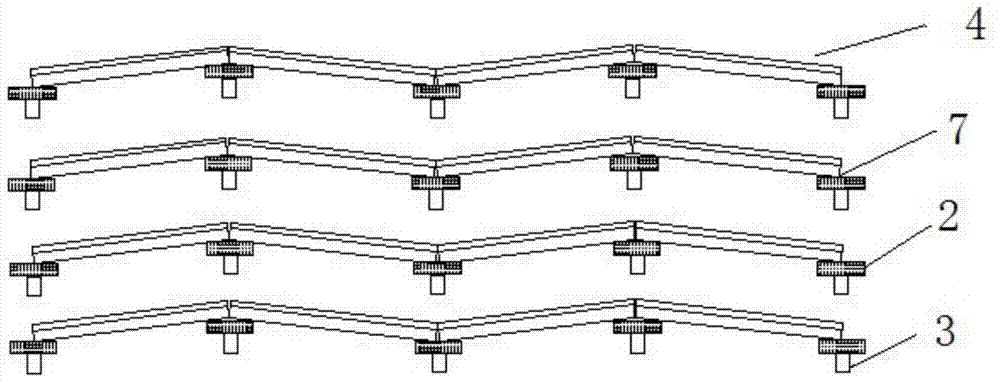

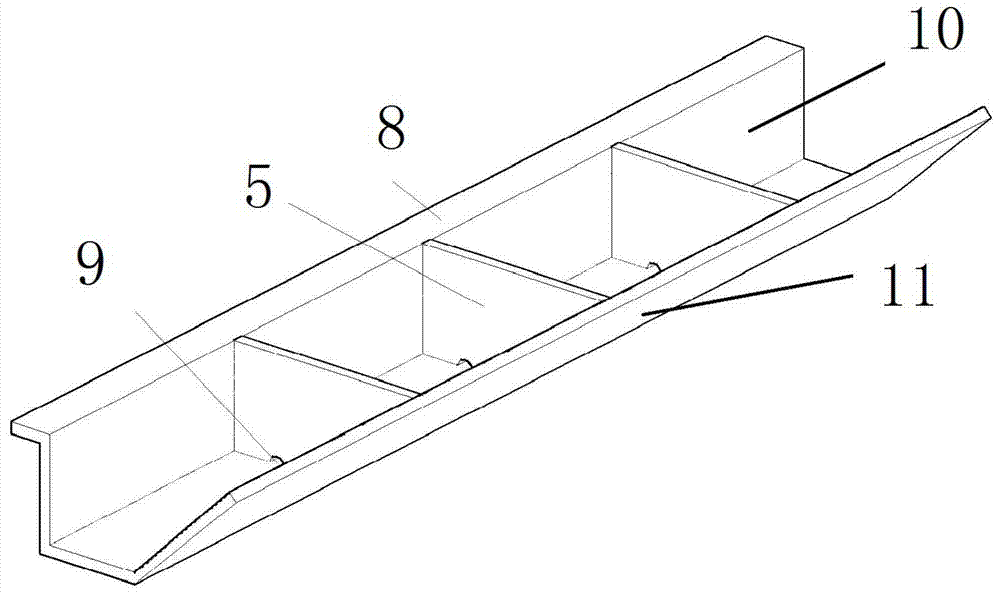

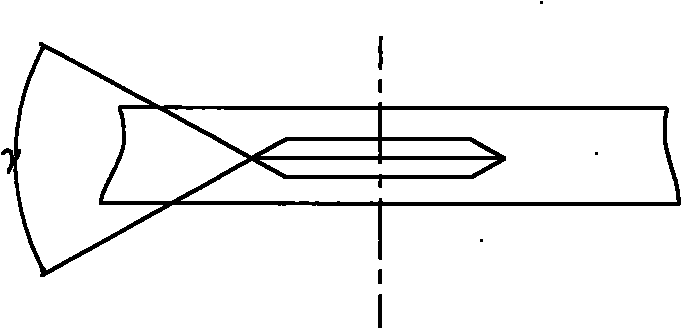

Rock slope combined type protective structure and method

InactiveCN104294829ALow costSolve problems such as crackingExcavationsReceptacle cultivationSoil nailingSoil science

The invention discloses a rock slope combined type protective structure and method. The protective structure comprises prefabricated grooves and multiple soil nailing unit rows. Each soil nailing unit row is composed of soil nailing units which are driven into a slope and arranged in a staggered mode high and low. Each soil nailing unit is composed of a horizontal soil nail and a vertical soil nail which are perpendicular to each other. One end of each horizontal soil nail is fixed to the corresponding vertical soil nail, each horizontal soil nail is driven into the slope in the horizontal direction, each vertical soil nail is driven into the slope in the vertical direction, and the top end of each vertical soil nail is higher than the horizontal line where the corresponding horizontal soil nail is located. The angle between a plane formed by the horizontal soil nails of the adjacent soil nailing units in each soil nailing unit row and the horizontal plane ranges from 4 degrees to 7 degrees and the prefabricated grooves are formed in the horizontal soil nails of the adjacent soil nailing units in the soil nailing unit rows. According to the structure and method, construction is convenient and rapid, the engineering manufacturing cost can be remarkably reduced, and the structure and method are suitable for protection of the rock slope generated in the manual digging process in traffic civil engineering.

Owner:CHONGQING COMM CONSTR GRP

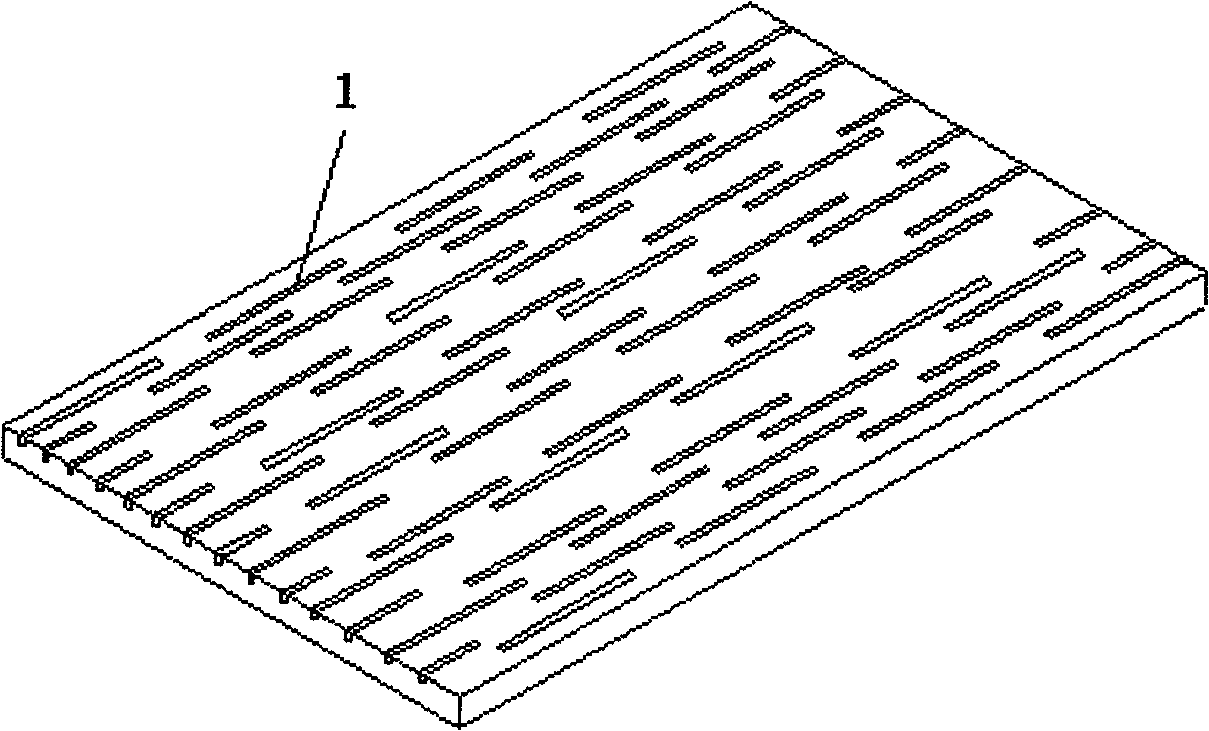

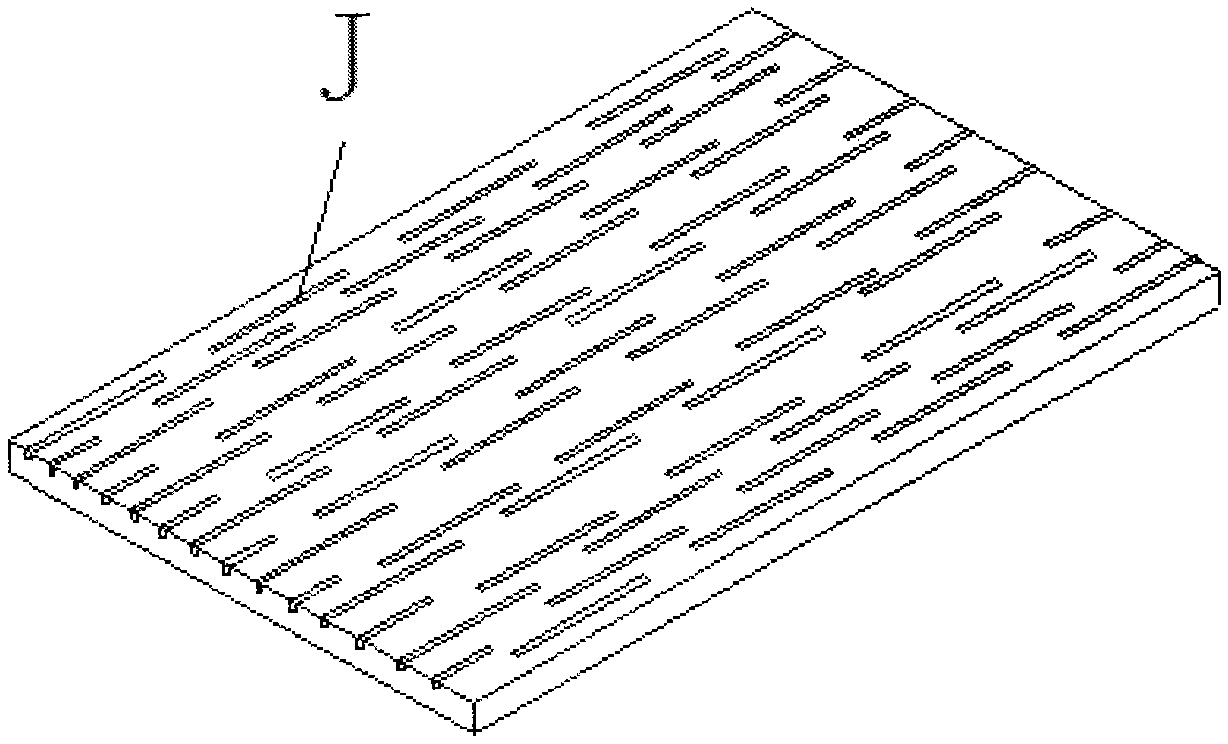

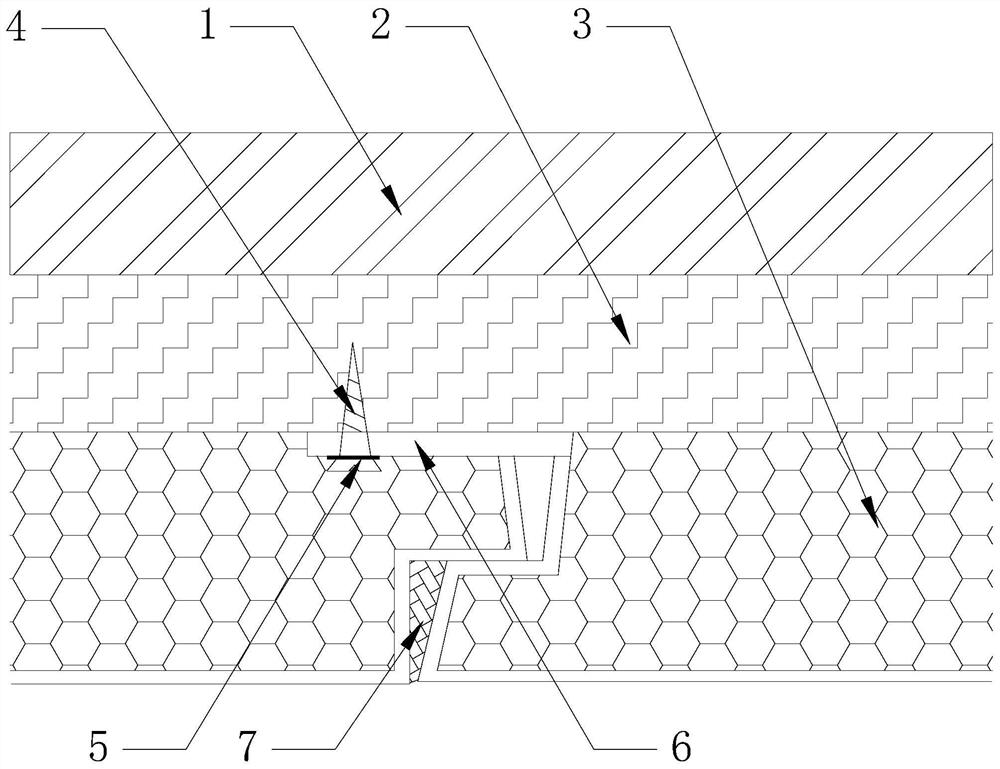

Method for flattening and drying rotary cut veneer

ActiveCN103522375ASolve the deformationSolve problems such as crackingOther plywood/veneer working apparatusPlywood pressesPulp and paper industryLine segment

The invention discloses a method for flattening and drying a rotary cut veneer. The method for flattening and drying the rotary cut veneer includes the following steps of rotary cutting of the veneer, grooving of a loose face of the veneer and drying and shaping by a hot press. A series of line-segment-shaped wedge-shaped grooves are formed in the loose face of the rotary cut veneer through wedge-shaped teeth of a flattening roller of a flattening machine and the veneer is flattened. The hot press is used for carrying out drying and shaping on the flattened veneer and the problems of deformation, cracking and the like of the rotary cut veneer can be effectively solved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

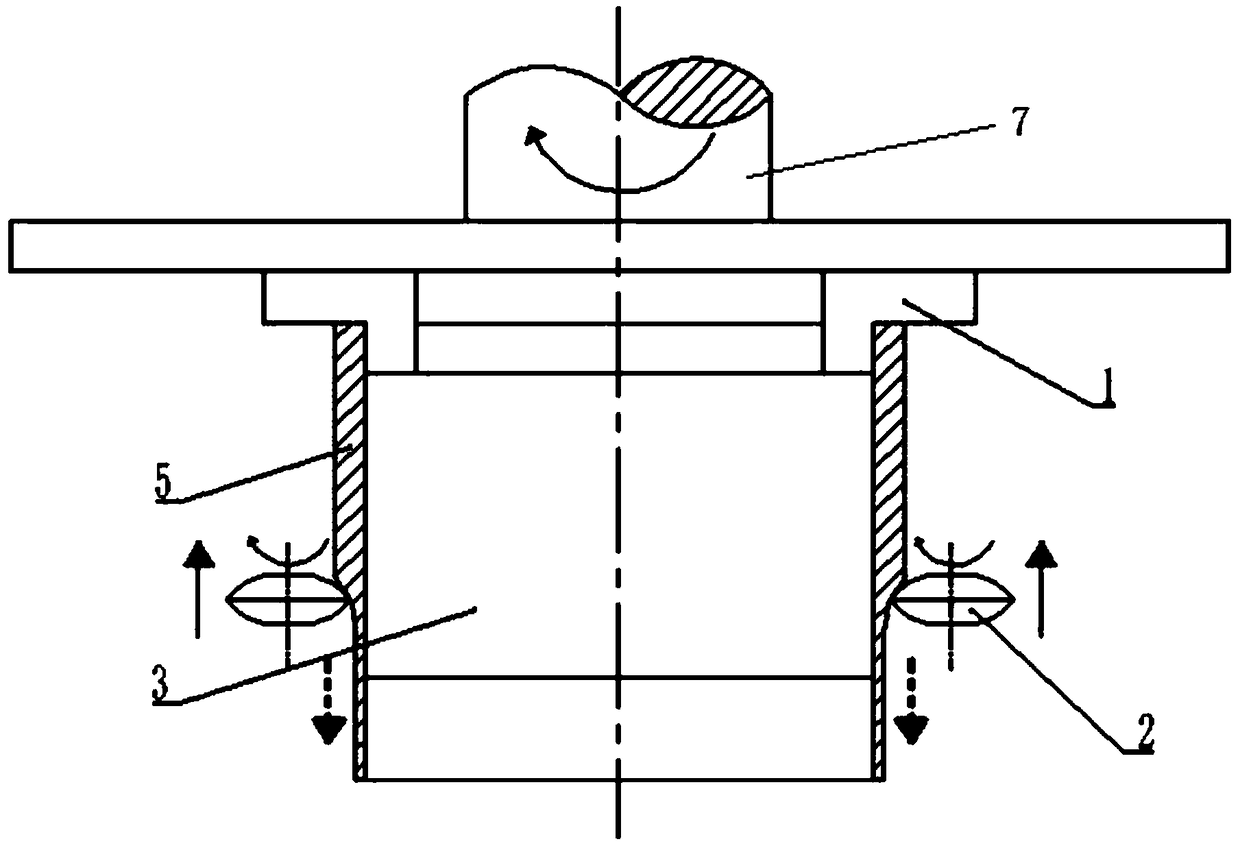

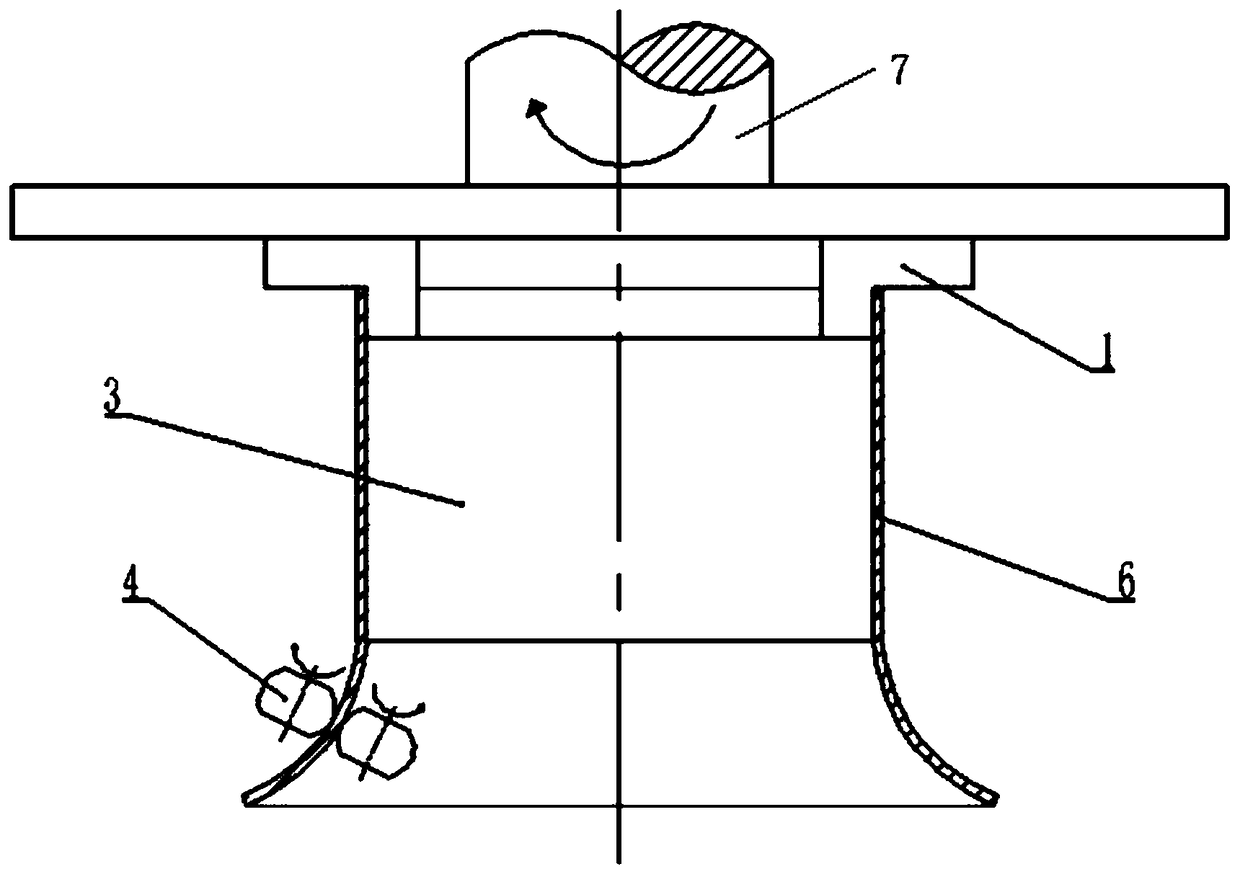

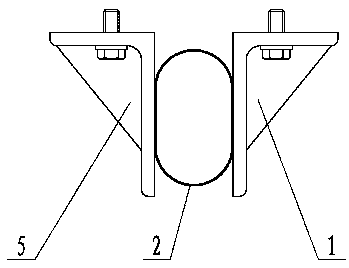

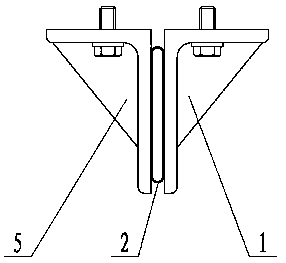

Compound forming method of flow spinning and double-roller clamping spinning

The invention provides a compound forming method of flow spinning and double-roller clamping spinning. The compound forming method of flow spinning and double-roller clamping spinning comprises the steps that firstly a thick wall seamless tube blank is clamped on a main shaft through an internal expansion type clamping device, and a core could is mounted in the thick wall seamless tube blank; thenrotating speed of the main shaft is set, and the thick wall seamless tube blank is rotated with the main shaft driven by the internal expansion type clamping device; counterflow spinning is carried out by adopting a spinning roller for flow spinning from the end, away from the internal expansion type clamping device, of the thick wall seamless tube blank, and a seamless thin walled cylinder pieceblank is formed; the spinning roller for flow spinning is replaced to a spinning roller for double-roller clamping spinning, double-roller clamping spinning forming is carried out on the seamless thin walled cylinder piece blank clamped by the spinning roller for double-roller clamping spinning, and a complex flange hook face is formed; and finally the core mould is taken out, clamping force of the internal expansion type clamping device is removed, and a well formed thin walled rotational part with the complex flange hook face is obtained. The compound forming method of flow spinning and double-roller clamping spinning has the advantages of flow spinning forming and double-roller clamping spinning forming, forming is in the same device at a time is achieved, and forming precision and production efficiency are obviously improved.

Owner:XI AN JIAOTONG UNIV

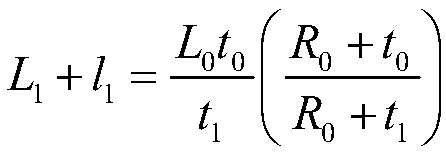

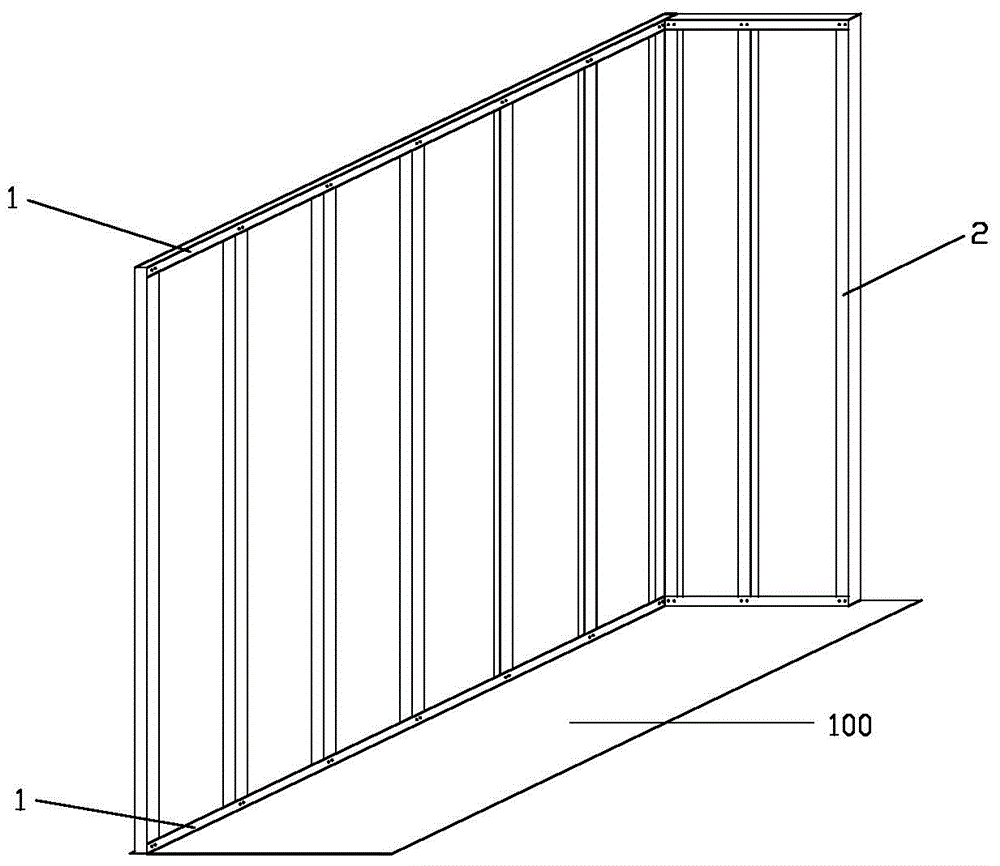

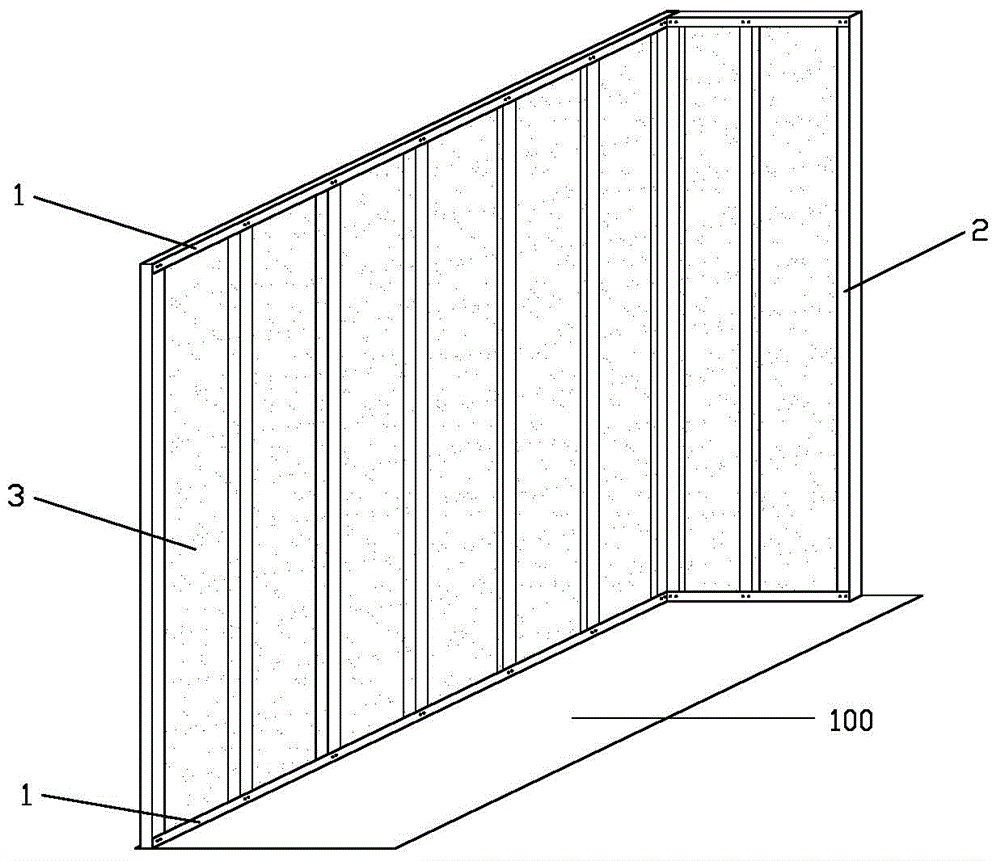

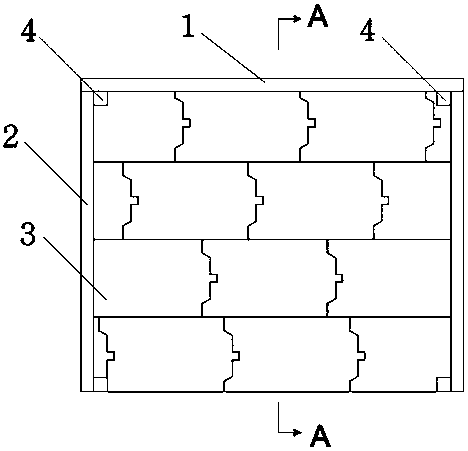

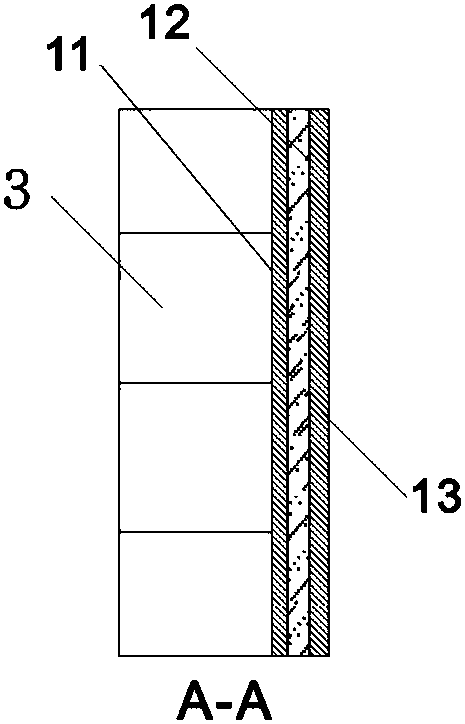

Indoor seamlessly-spliced secondary light partition wall system and rapid construction method of partition wall

The invention discloses an indoor seamlessly-spliced secondary light partition wall system. The indoor seamlessly-spliced secondary light partition wall system comprises a keel frame and dampproof membrane layers. The keel frame comprises joint keels and vertical keels perpendicularly connected with the joint keels. The dampproof membrane layers are attached to the two side faces of the keel frame. The top and the bottom of each dampproof membrane layer are horizontally provided with horizontal keels respectively. Apex-angle keel bars and foot-margin keel bars are arranged on the top horizontal keels and the bottom horizontal keels respectively. Multiple seamlessly-spliced wall plates are horizontally inserted in grooves of the apex-angle keel bars and the foot-margin keel bars. The apex-angle keel bars and the foot-margin keel bars are buckled to apex-angle lines and bed plates respectively. The invention further discloses a rapid construction method of the indoor seamlessly-spliced secondary light partition wall. By means of the light partition wall system and the partition wall rapid construction method, the problems that a light partition wall for indoor secondary construction is difficult to connect, fix, construct and the like are solved, the installed partition wall is firm, vertically smooth and free of cracks, the requirements for seismic resistance and use functions can be met, the construction process is simplified, and the soundproof performance and fireproof performance are improved.

Owner:TIANJIN DAYIN BUILDING MATERIAL CO LTD

Copper embedded block heat radiation substrate and manufacturing method therefor

The invention discloses a copper embedded block heat radiation substrate comprising a substrate body, wherein the substrate body is provided with a copper embedded block via groove, a heat radiation copper block is arranged in the copper embedded block via groove, and a surface of the heat radiation copper block is level with a surface of the heat radiation substrate. The heat radiation copper block is arranged in the substrate, a top face and a bottom face of the heat radiation copper block are exposed from an outer part of the substrate, and the heat radiation substrate is enabled to have adouble face heat radiation structure; compared with a conventional copper embedded block PCB board only capable of single surface heat radiation, the copper embedded block heat radiation substrate disclosed in the invention is advantaged by improved heat radiation efficiency. The invention also discloses a manufacturing method for the copper embedded block heat radiation substrate; a two time etching method is adopted for manufacturing the heat radiation copper block of which double surfaces are exposed, size precision of the heat radiation copper block is improved in such a processing mannerthat a bottom part heat radiation copper block is manufactured after pressing operation, and copper blocks are bonded together via two time pressing operation; a problem that the copper blocks are prone to deviating, loosening, cracking and the like; copper block processing efficiency and quality stability can be improved.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

Method for monitoring crack defects in heavy load runway girder

ActiveCN106568841AResolve detectionCan't solveAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringHeavy load

The invention discloses a method for monitoring crack defects in a heavy load runway girder. According to the method, electromagnetic ultrasonic surface wave probes that satisfy the sensitivity requirement are chosen and oppositely / parallelly arranged on the arc parts of the runway girder web in the column shoulder beam; the plug ends of the cables of the probes are connected to an electromagnetic ultrasonic data collecting instrument so as to perform onsite echo data collection; the change of echo is observed, when the structural echo of the arc surface of the runway girder web just disappears, the position of the acoustic beam angle of the probes is taken as the position for fixing the probes; after the probes are fixed, the waveform data of each probe is collected and observed at regular intervals and compared; when obviously abnormal echoes are found, a reliable method is adopted to confirm the property of the echoes, the extension situation of the abnormal echoes of crack defects is determined through regularly collected echo data so as to judge whether the runway girder is cracked or not. The defects of conventional detection modes are overcome by the provided method, through the prediction, the safety hazards can be found in time, and the great loss of accidents is avoided.

Owner:SHANGHAI JINYI INSPECTION TECH

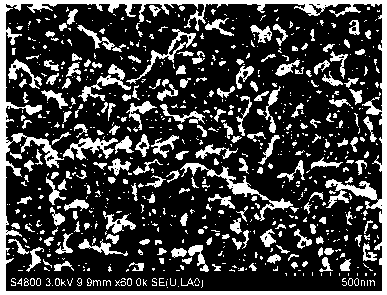

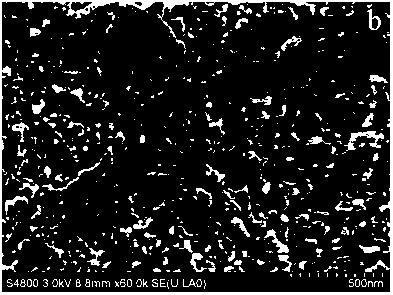

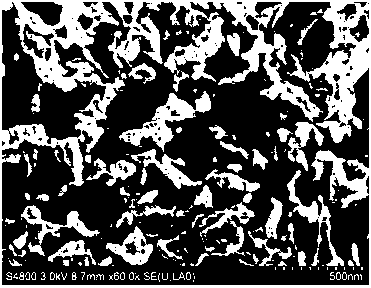

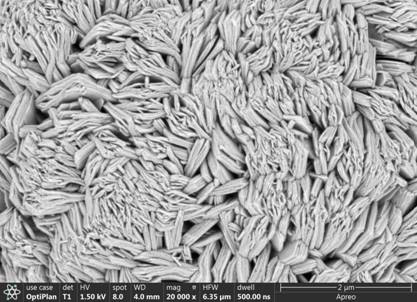

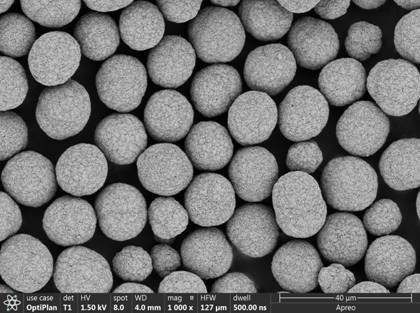

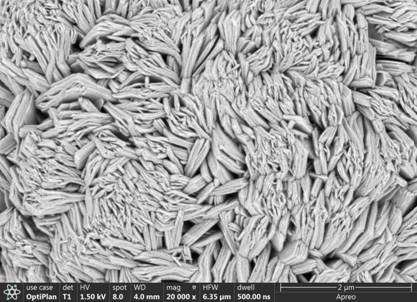

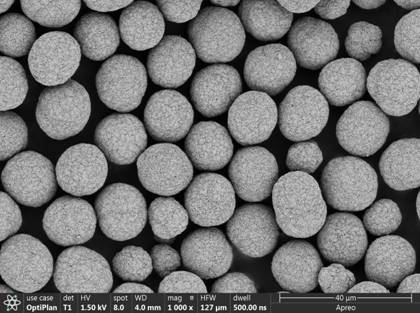

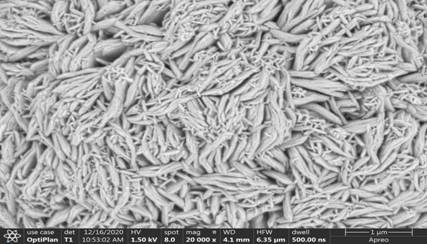

Nickel-cobalt binary precursor and preparation method thereof

ActiveCN113526573ASolve problems such as crackingSolve crackingCell electrodesSecondary cellsChemistryNickel

The invention provides a nickel-cobalt binary precursor and a preparation method thereof. According to the invention, a batch-type process is adopted, and the nickel-cobalt binary precursor which is free of surface cracks, large in particle size and high in sphericity degree is synthesized in two stages through a hydroxide co-deposition method. The pH value of the system is continuously increased along with the increase of the particle size in the growth stage of the precursor, so that two primary particles with different sizes grow on the surfaces of the secondary particles, and the cracking phenomenon caused by uneven stress between the primary particles is solved. The method provided by the invention has no additional cost, the prepared nickel-cobalt binary precursor D50 is 15-20 microns, the tap density is 1.9-2.2 g / cm<3>, the specific surface area is 6-12 m<2> / g, the product physical index is excellent, the consistency is high, the technological process is stable, and the precursor material is an excellent nickel-cobalt-aluminum positive electrode precursor material.

Owner:JINCHI ENERGY MATERIALS CO LTD +2

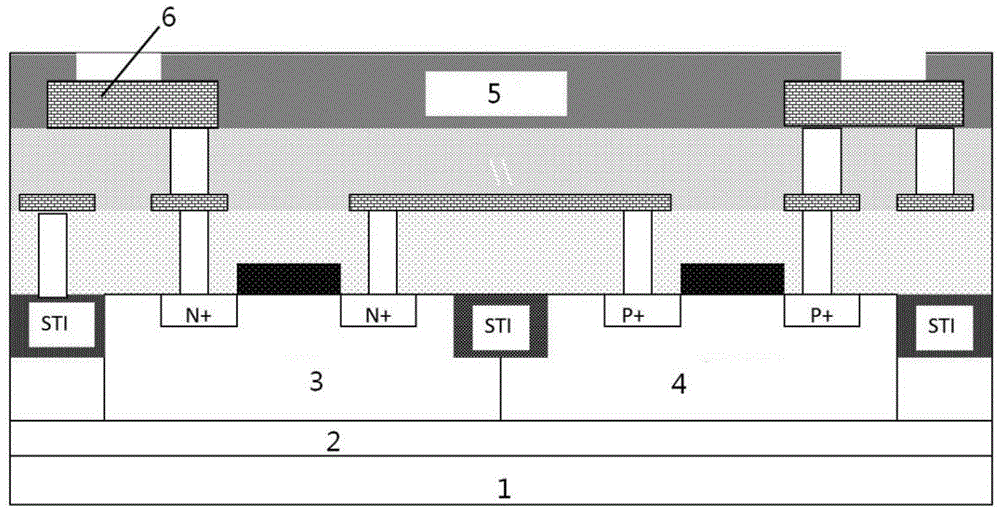

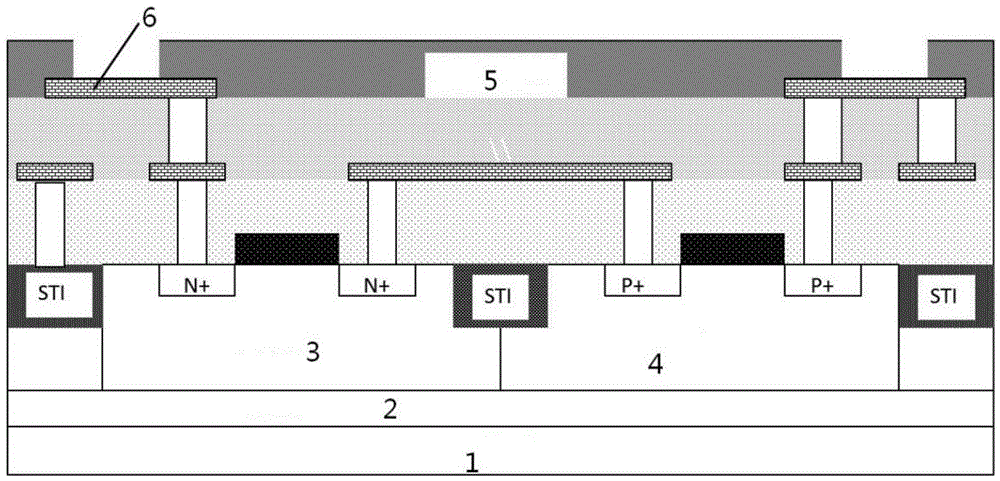

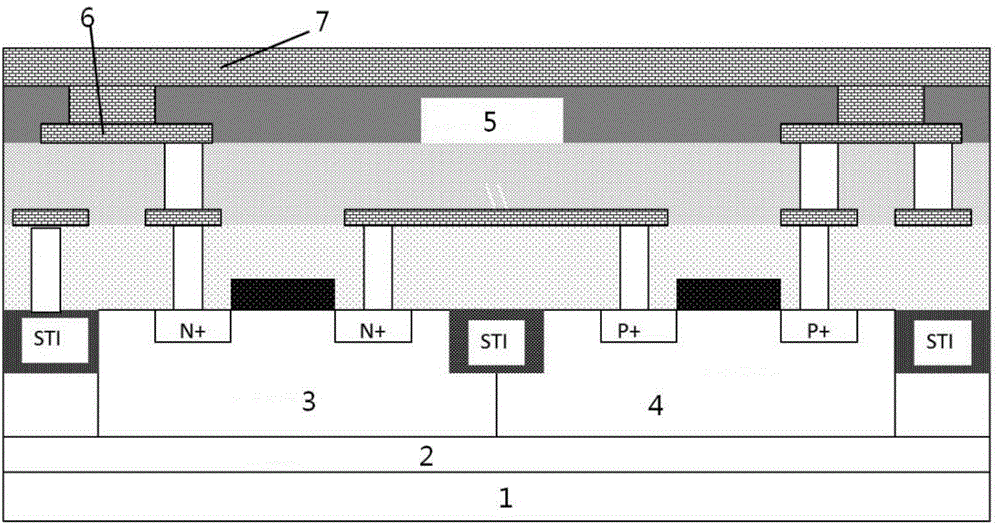

Integrated circuit packaging method

InactiveCN104659024ASolve metal crackingDoes not affect routing densitySolid-state devicesSemiconductor/solid-state device manufacturingMethod selectionWire bonding

The invention discloses an integrated circuit packaging method which comprises the following steps: step 1, thinner top metal is deposited, and a passivation layer PAD window is defined and opened through photoetching after the passivation layer is formed; step 2, a metal layer is deposited again; and step 3, metal except the PAD window on the passivation layer is removed. The metal strength in a PAD area is reinforced selectively, and the metal on other wired areas is kept thinner, so that the problem of cracking of metal in the PAD area due to packing wire bonding stress is solved under the condition that the wiring density is not influenced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Method for preparing sintered water-permeable brick by utilizing ceramic roller waste and municipal sludge

InactiveCN110183209AReduce manufacturing costRealize resource utilizationCeramic materials productionCeramicwareMaterials preparationMicrowave

The invention discloses a method for preparing a sintered water-permeable brick by utilizing ceramic roller waste and municipal sludge. The sintered water-permeable brick comprises the following raw materials, in parts by weight: 35-45 parts of the ceramic roller waste, 20-30 parts of the urban sludge, 5-10 parts of feldspar, 8-12 parts of water glass, and 12-18 parts of water. The preparation method comprises the steps of material preparation, mixing, ageing, molding, microwave drying and firing. The method provided by the invention realizes the resource utilization of the solid waste, reduces the production costs of the water-permeable brick, and has the advantages of a simple preparation process, high production efficiency, environmental protection and energy saving.

Owner:SHANDONG UNIV OF TECH

Welding optimization process for steel casting of oil pumping unit

InactiveCN102500963ASolve processingAddressing unresolved bad casting organizationWelding/cutting auxillary devicesAuxillary welding devicesStress relievingMachining process

The invention discloses a welding optimization process for a steel casting of an oil pumping unit, relating to the technical filed of a machining process for parts of the oil pumping unit of an oil well. The welding optimization process comprises the following steps of: (1), putting a steel casting workpiece to be welded in a furnace for preheating; (2), welding the preheated steel casting workpiece for fixing; and (3), putting the welded steel casting workpiece in the furnace till the steel casting workpiece is cooled. The preheating temperature in the step (1) is 330-380 DEG C. According to the invention, an optimization process is adopted for carrying out welding, such that the stress is removed, the compositional variation is reduced, the welding position is hard to break, and the service life of a load bearing member of the oil pumping unit is prolonged.

Owner:江苏明宇石油机械有限公司

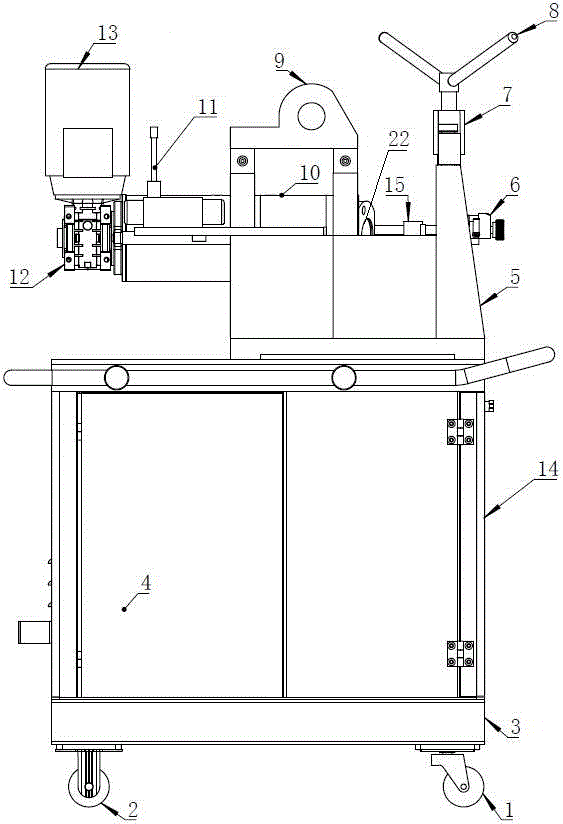

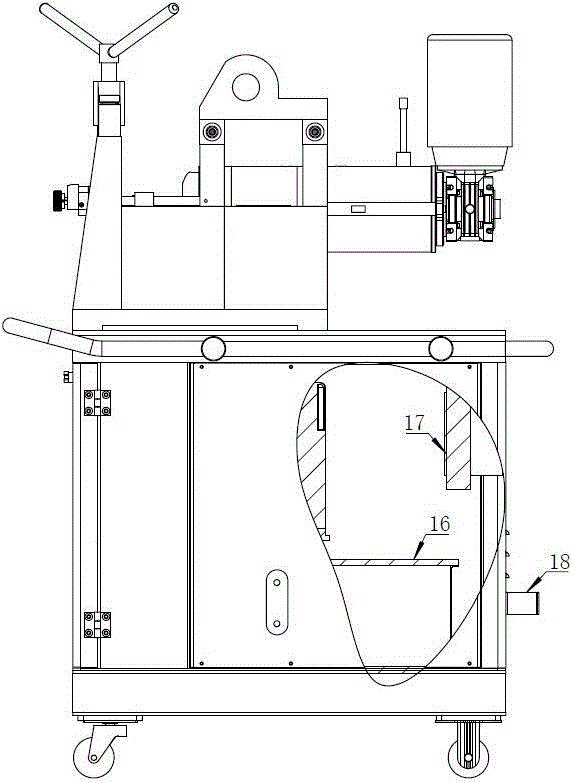

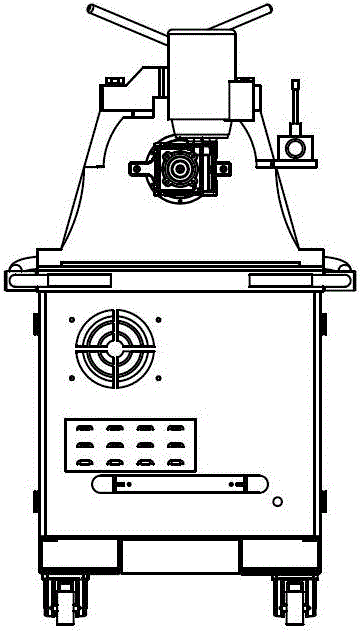

Electric spin-flaring equipment

InactiveCN105903828ASolve problems such as crackingSimple and flexible structureDisplay deviceEngineering

The invention relates to electric spin-flaring equipment. The electric spin-flaring equipment comprises a box. A casting base is arranged at the upper end of the box. An oil cylinder is arranged in the middle of the casting base in the length direction. A cylinder rod end of the oil cylinder is connected with a vertical motor through a speed reducer. A multi-way valve is arranged on one side of the casting base. A displayer and a limiting plate are arranged on the other side of the casting base. A lifting lug is fixedly connected to the middle position, in the length direction, of the casting base. A protruding part is arranged at the other end, opposite to the motor, of the casting base. A casting cover is arranged at the top of the protruding part. A turning piece is connected to the casting cover in a screwed mode through threads. The lower end of the turning piece is fixedly connected with a pressing block. A separation plate clamp is arranged at the lower end of the pressing block. A pipe cavity is formed in the separation plate clamp. By the adoption of the equipment, the problems that nonuniformity is likely to be caused during steel pipe flaring and cracks are caused during flaring of steel pipes made of different materials can be solved; and in addition, the structure is flexible, an ordinary welding way can be replaced, the sealing effect is good, and the production efficiency is high.

Owner:苏州巴茨流体动力技术有限公司

Tunnel water seepage early warning device and tunnel water seepage monitoring and processing method

PendingCN113931697ASolve the rustSolve problems such as tunnel lining crackingMining devicesUnderground chambersSoil scienceDisplay device

The invention discloses a tunnel water seepage early warning device and a tunnel water seepage monitoring processing method. The tunnel water seepage early warning device comprises a plurality of water seepage monitoring devices and a monitoring display device, and the plurality of water seepage monitoring devices are sequentially buried in a soil layer on the periphery of a tunnel at intervals along the extension direction of the tunnel; the water seepage monitoring device comprises a water seepage monitoring box filled with sample soil and is used for filtering water seepage in an external soil layer and enabling the water seepage to permeate into the sample soil. and a real-time detector for detecting the weight of the sample soil in real time is arranged in the water seepage monitoring box, the real-time detector is connected with a signal processing device, and the signal processing device is connected with a monitoring display device in a wireless or wired mode. The signal processing device converts the received sample soil weight signal into a sample soil moisture content signal and then transmits the sample soil moisture content signal to the monitoring display device, and the monitoring display device draws a moisture content curve of the moisture content changing along with the mounting position according to the sample soil moisture content signal and compares the moisture content curve with a preset moisture content allowable peak value line in the monitoring display device for early warning, and therefore, remote monitoring personnel can timely judge the water seepage condition of the tunnel for corresponding treatment.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD +1

Repair method of existing building wall thermal insulation system

ActiveCN111852067ASolve empty drumSolve crackingCovering/liningsClimate change adaptationThermal insulationKeel

The invention relates to a repair method of an existing building wall thermal insulation system. The thermal insulation decoration system comprises a keel and metal outer wall decoration plates whichare arranged outside a base layer wall. The repair method comprises the steps of keel design, base layer treatment, keel laying, metal outer wall decoration plate laying and local cavity-free treatment. Through the combination of the metal outer wall decoration plate, an anchoring part and the keel, the thermal insulation system is integrally suspended on an existing wall, and procedures such as shoveling, layer-by-layer grouting are not needed, the construction steps are simple, the influence of existing thermal insulation system defects is avoided, and the applicability is high; according todifferent heights and body type characteristics of existing buildings, the keel material and density are designed, the fixing points of the metal outer wall decoration plates and the keel are increased, combined with the tongue-and-groove design of metal outer wall decoration plates and the local cavity-free treatment, the outward pulling force of negative wind pressure on the thermal insulationsystem can be born, and the load requirement is achieved; and the effect of ventilation and waterproofing is realized by combining the local cavity structure design, and the problems such as wall hollowing, cracking caused by water seepage are fundamentally solved.

Owner:CHANGZHOU ARCHITECTUAL RES INST GRP CO LTD +3

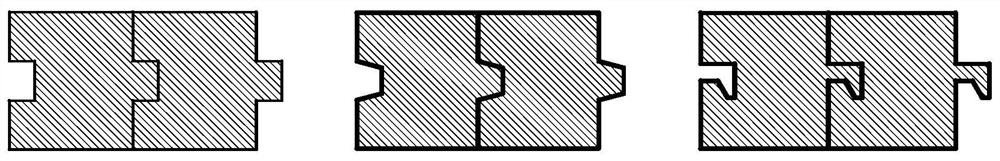

Combined external wall thermal insulation board, processing equipment and processing method

ActiveCN111576653AReduce mistakesReduce large gapsLiquid surface applicatorsHeat proofingPhysicsEngineering

The invention relates to a combined external wall thermal insulation board, which comprises an external wall main thermal insulation board, a matching thermal insulation board and rotating columns. The right end of the external wall main thermal insulation board is uniformly provided with matching grooves from top to bottom. Rotating columns are arranged between the inner walls of the upper and lower ends of the matching grooves, and matching blocks are uniformly arranged from top to bottom on the left end of the matching thermal insulation board. The matching blocks are connected to the rotating columns through bearings. The matching grooves and the matching blocks are arranged at intervals. An installation process of the combined external wall thermal insulation board relates to specialprocessing equipment for the above-mentioned combined thermal insulation board. The special processing equipment for the combined thermal insulation board comprises a base, a fixing unit and a gluingunit. The joint of the combined thermal insulation board is sealed through a sealant, and at the same time, the sealing shape conforms to the shape of a wall corner. The gap between the thermal insulation board and the wall corner is reduced to make no moving space is allowed when the thermal insulation board is stressed, and the problem of the external surface cracking caused by the easy movementof the thermal insulation board is solved.

Owner:湖南兴发保温材料有限公司

Core filling composite thermal insulation block self-thermal insulation wall

InactiveCN109838013AImprove insulation effectLight in massConstruction materialWallsThermal insulationEngineering

The invention discloses a core filling composite thermal insulation block self-thermal insulation wall. The wall includes a crossbeam in horizontal arrangement and columns in vertical arrangement; thermal insulation blocks are arranged in the space formed by the crossbeam and the two columns in rows through a dislocation manner; the thermal insulation blocks have left and right internal cavities;the left and right internal cavities are filled with thermal insulation rock wool boards, and communicate with each other through isolation bridges in horizontal arrangement; the outer surfaces of thethermal insulation blocks are bonded with a putty layer through masonry mortar; and the outer surface of the putty layer is coated with a primer layer. The mass of the whole wall can be lighter through core filling processing in the internal cavities; the intensity of the whole wall can be enhanced by using the isolation bridges to connect the internal cavities, so that good thermal insulation effects of the whole wall can be achieved; and through the arrangement of putty and primer on the thermal insulation blocks in advance, the problems of easy hollowing and cracking of traditional self-thermal insulation walls can be effectively solved.

Owner:成都科弗科技有限公司

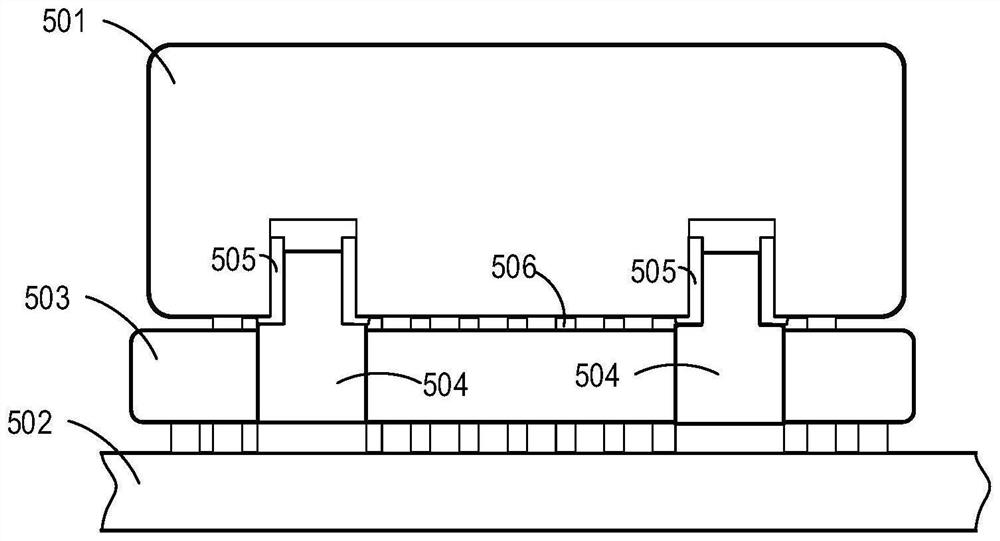

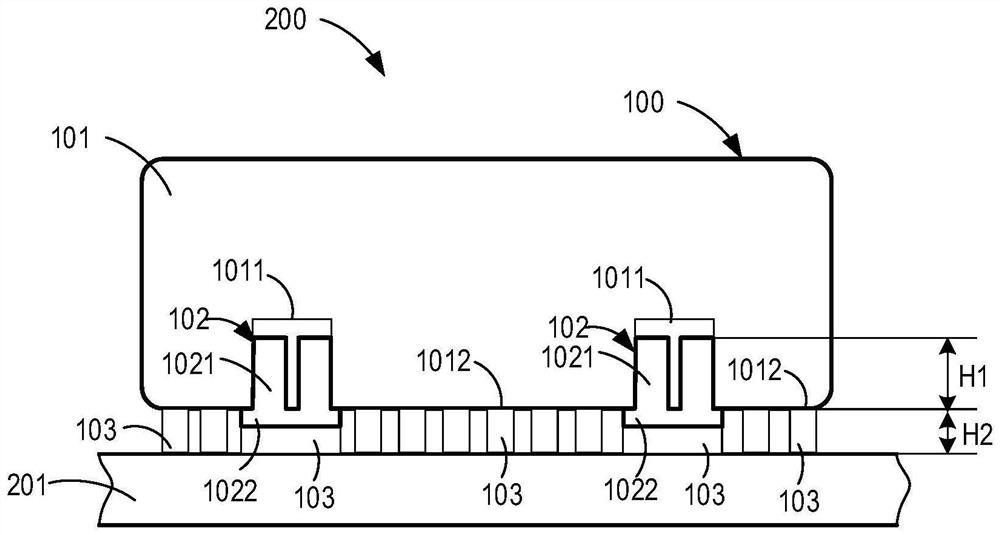

Dielectric filter and electronic equipment

PendingCN114464971AImprove reliabilityMiniaturizationPrinted circuit assemblingWaveguide type devicesDielectricMiniaturization

The embodiment of the invention provides a dielectric filter and electronic equipment. The dielectric filter includes a filtering portion made of a high dielectric material and having a plurality of coupling holes disposed at predetermined positions of an interface surface and a ground port; each input and output pin comprises a coupling part and an interface part, the coupling parts are in press fit with the corresponding coupling holes in an interference fit mode, and the grounding ports and the interface parts are coupled to a circuit board of the electronic equipment through solder. The input and output pins are in press fit with the coupling holes in an interference fit manner, so that a carrier plate does not need to be used for indirectly assembling the filtering part on the circuit board of the electronic equipment, the miniaturization and the light weight of the electronic equipment are effectively promoted, and the cost can be further reduced.

Owner:HUAWEI TECH CO LTD

Nickel-cobalt binary precursor and preparation method thereof

ActiveCN113526573BSolve problems such as crackingSolve crackingCell electrodesSecondary cellsCobaltLarge particle

The invention provides a nickel-cobalt binary precursor and a preparation method thereof. The invention adopts a batch process, and synthesizes a nickel-cobalt binary precursor with no surface cracks, large particle size and high sphericity in two stages through a hydroxide co-deposition method. In the growth stage of the precursor, the pH value of the system is continuously increased with the increase of the particle size, so that two primary particles of different sizes grow on the surface of the secondary particles, which solves the cracking phenomenon between the primary particles due to uneven stress. The method described in the present invention has no additional cost, and the D50 of the nickel-cobalt binary precursor produced is 15-20 μm, the tap density is 1.9-2.2 g / cm³, the specific surface area is 6-12 m² / g, and the physical properties of the product are excellent , with high consistency and stable process, it is an excellent nickel-cobalt-aluminum cathode precursor material.

Owner:JINCHI ENERGY MATERIALS CO LTD +2

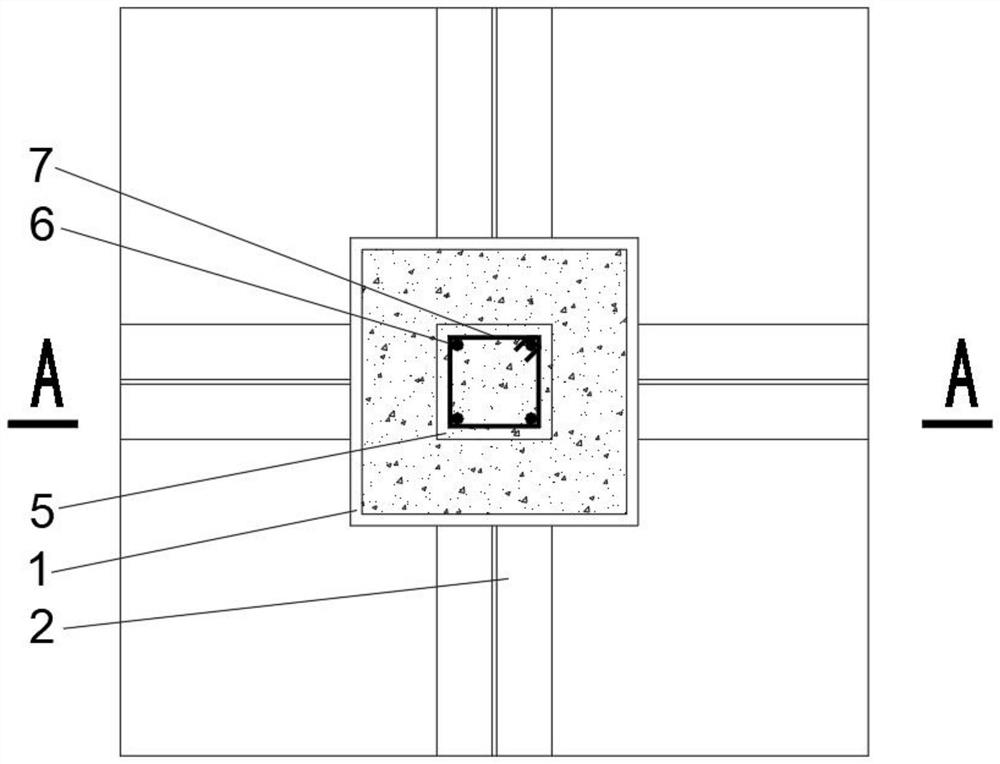

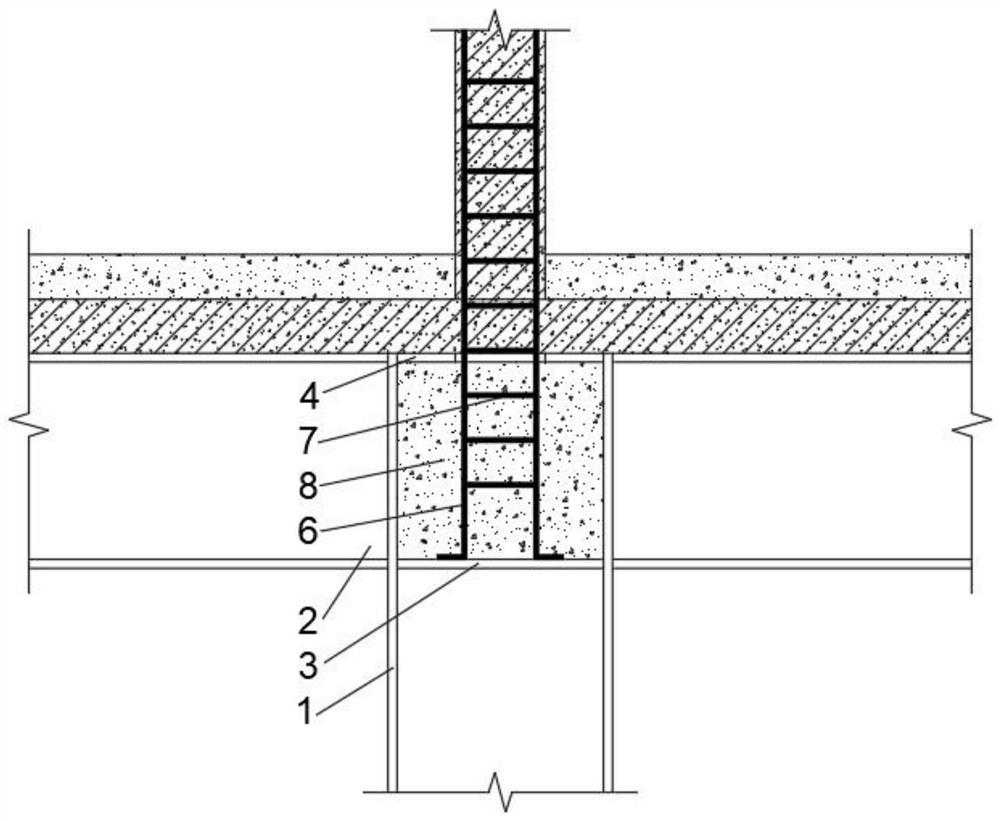

Steel structure column-to-concrete column building node structure and construction method

PendingCN114775810ASolve condensationSolve problems such as crackingStrutsBuilding material handlingSteel frameHeat conservation

The invention discloses a steel structure column-to-concrete column building joint structure and a construction method. The steel structure column-to-concrete column building joint structure comprises a steel frame column, and the steel frame column is used for being connected with frame beams forming a building joint; the steel frame column is divided into a steel frame column upper section and a steel frame column lower section through the inner partition plate II; the top of the steel frame column upper section is sealed through the inner partition plate I; a pouring gate is formed in the inner partition plate I, and the steel reinforcement cage is fixed to the inner partition plate II in the mode that the steel reinforcement cage is arranged on the pouring gate in a penetrating mode; the functions of heat preservation, protection, low carbon and energy conservation of the building can be realized; the problems of dewing, cracking and the like caused by the fact that the junction of steel and concrete is easily affected by temperature are solved.

Owner:CISDI ENG CO LTD

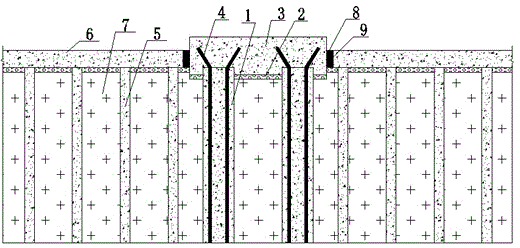

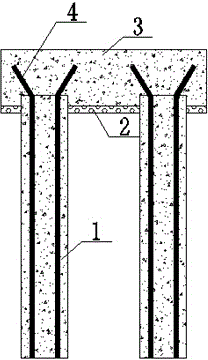

Foundation treatment method under dynamic load and static load mixing effect of equipment room

ActiveCN104947704ASolve local subsidenceSolve problems such as crackingFoundation engineeringReinforced concreteLoad generation

The invention relates to a foundation treatment method under the dynamic load and static load mixing effect of an equipment room, and relates to the technical field of building engineering construction. The method comprises the following steps that (1), manual hole digging piles are constructed on a dynamic load area, and a reinforced concrete bearing platform used for supporting dynamic load generation equipment is constructed after a gravel cushion layer is laid in the top area of the manual hole digging piles; (2), high-pressure jet grouting piles are constructed in a static load area, and a reinforced concrete terrace used for supporting static load generation equipment is constructed after a gravel cushion layer is laid in the top area of the high-pressure jet grouting piles; (3), dividing joints are cut at the connection positions of the reinforced concrete bearing platform and the reinforced concrete terrace and are filled with sealing factice. By means of the foundation treatment method, the manual hole digging piles are adopted for supporting the reinforced concrete bearing platform in the dynamic load area for foundation treatment, and the high-pressure jet grouting piles are adopted for supporting the reinforced concrete terrace in the static load area for foundation treatment, so that the problems that the reinforced concrete terrace is locally sunken, cracks and the like when the equipment room is used later are avoided.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU +3

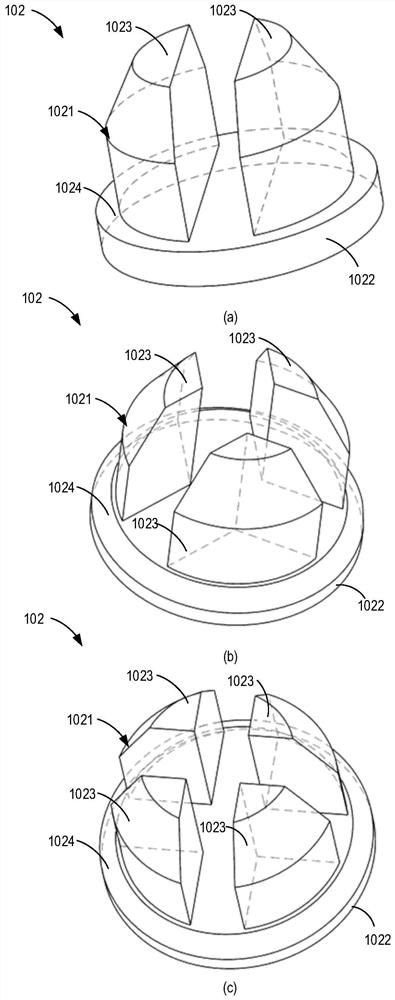

Aerodynamic high pressure model flexible opening system

ActiveCN105818257BShorter molding cycle timesSolve problems such as crackingDischarging arrangementProduction lineEngineering

A system for opening a high-pressure model with aerodynamic force comprises multiple groups of opening devices distributed on the two sides of a production line. Each group of opening device comprises a mold opening mechanism and a pneumatic mechanism. Air belt jacking seats and air belt mounting seats, which are made of angle steel, are arranged oppositely. Mold opening air belts are arranged between the air belt jacking seats and the air belt mounting seats. The upper end openings and the lower end openings of the mold opening air belts are overturned to the outer sides of the air belt mounting seats, and are fixed through sealed pressing plates. Ends of air belt suction nozzles pass through the air belt mounting seats and are communicated with the inner parts of the mold opening air belts. The other ends of the air belt suction nozzles are communicated with air distribution pipes. The air distribution pipes are connected with compressed air sources. Air inlet control valves are arranged on the air distribution pipes. Through the adoption of the system, the synchronous automatic opening of models can be realized, the manual opening labor intensity is reduced, the mold opening clearances are made of be uniform and consistent, the production efficiency is improved, the green body forming cycle period is shortened, the operation action is stable and gentle, and the problem of green body cracking in mold opening is solved.

Owner:TANGSHAN HEXIANG INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com