Aerodynamic high pressure model flexible opening system

An aerodynamic and model technology, applied in the direction of unloading devices, manufacturing tools, etc., can solve the problems of blank body cracking, high labor intensity of operators, and low production efficiency, so as to solve the problems of blank body cracking, get rid of labor intensity, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

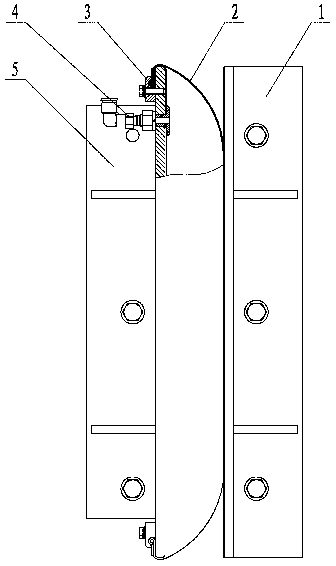

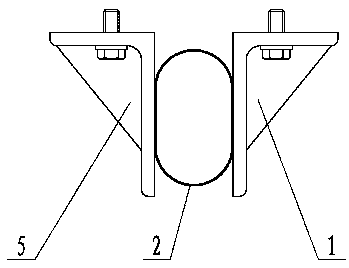

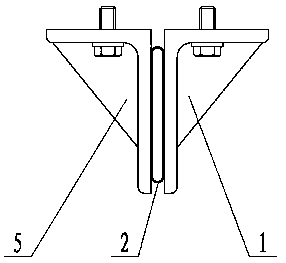

[0023] See attached Figure 1-7 , the aerodynamic high-pressure model flexible opening system disclosed in the present invention includes multiple sets of opening devices distributed on both sides of the production line, each group of opening devices includes a mold opening mechanism and a pneumatic mechanism, and the air belt top in each group of opening devices The seat and the air belt mounting seat are oppositely installed on the sides of two adjacent molding machine models, and there is a safety gap between the air belt top seat and the air belt mounting seat. Molded belt. A group of mold opening devices are respectively installed on both sides of each molding machine model, and the two groups of mold opening devices move synchronously.

[0024] The mold opening mechanism includes a mold opening air belt, an air belt top seat, an air belt mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com