Foundation treatment method under dynamic load and static load mixing effect of equipment room

A technology of mixed action and foundation treatment, applied in infrastructure engineering, construction, etc., can solve problems such as subsidence and cracking of reinforced concrete floors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

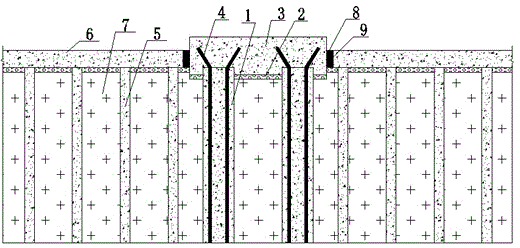

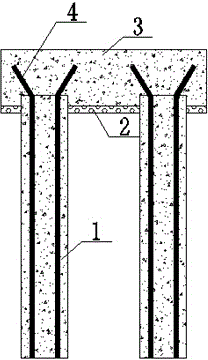

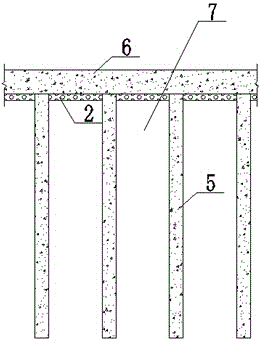

[0018] Such as figure 1 As shown, a foundation treatment method under the mixed action of dynamic load and static load in the equipment room, including the construction of artificial excavation pile 1, the construction of high-pressure rotary grouting pile 5, the construction of reinforced concrete cap 3, the construction of sand and gravel cushion 2, The construction of the reinforced concrete floor 6 and the treatment of the sealing ointment 9 are carried out according to the following steps: (1) Construction of the artificial hole-digging pile 1 in the dynamic load area, and the top area of the artificial hole-digging pile 1 is laid with a sandstone cushion layer 2 for construction. Reinforced concrete platform 3 supporting the equipment generating dynamic load;

[0019] (2) After the plain soil 7 is backfilled and compacted, the high-pressure jet-grouting pile 5 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com