Core filling composite thermal insulation block self-thermal insulation wall

A technology of composite thermal insulation and thermal insulation blocks, applied to walls, building materials, building components, etc., can solve the problems of falling off, poor thermal insulation, penetration, etc., and achieve the effect of increased strength, good thermal insulation effect and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

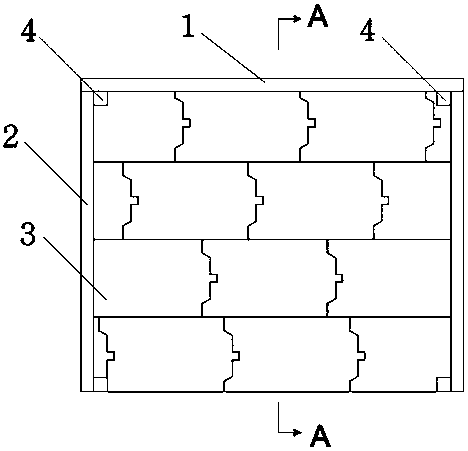

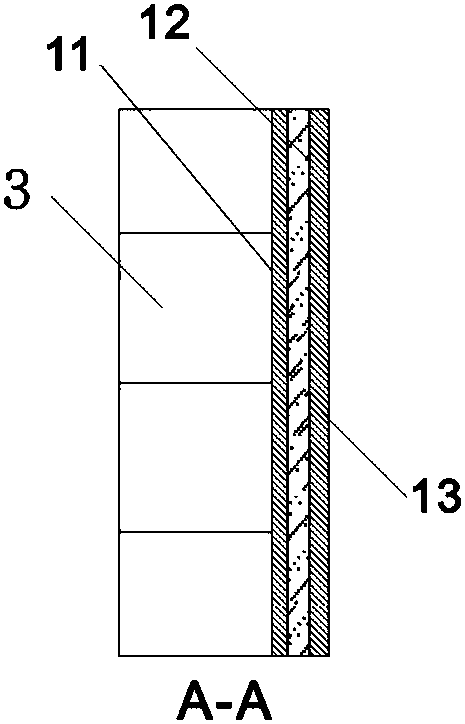

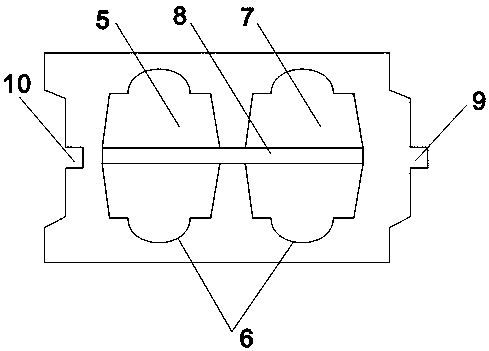

[0017] Such as figure 1 , 2 As shown in . and 3, a self-insulating wall of a core-filling composite thermal insulation block, including a horizontally arranged beam 1 and a vertically arranged column 2, is fixed at the junction of the beam 1 and the column 2 by connecting a steel block 4 at a corner, and the corner One end of the connecting steel block 4 is fixed to the beam 1, and the other end is fixed to the inner surface of the column 2. In the space formed by the beam 1 and the two columns 2, thermal insulation blocks 3 are arranged in dislocation rows. The thermal insulation blocks 3 are thermal insulation blocks with internal cavities 6. Bonded with the putty layer 12, the outer surface of the putty layer 12 is coated with a primer layer 13. When in use, the blocks are directly stacked in the space formed by the beams and columns to quickly form a wall with thermal insulation function, and the four corners of the wall are fixed by corner connecting steel blocks, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com