Nickel-cobalt binary precursor and preparation method thereof

A precursor, nickel-cobalt technology, applied in the direction of chemical instruments and methods, nickel compounds, electrical components, etc., can solve the problems of unspecified product characteristics, low solid content, etc., and achieve the effect of good consistency and high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

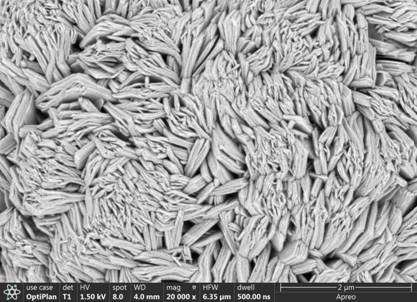

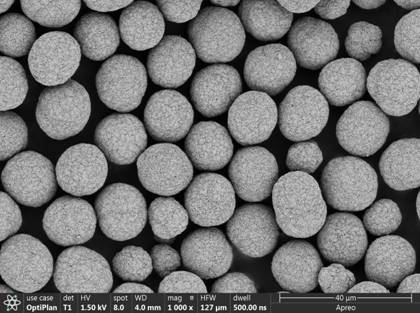

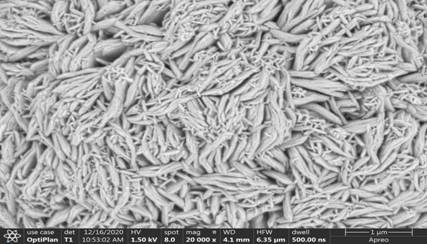

Image

Examples

Embodiment 1

[0037] This embodiment includes the following steps:

[0038] (1) According to the molecular formula Ni 0.9 co 0.1 (OH) 2 Prepare a nickel-cobalt mixed metal salt solution with a total metal ion concentration of 2mol / L; prepare a 10mol / L sodium hydroxide solution; prepare a 11mol / L ammonia solution.

[0039](2) Add 200L of pure water to a 300L volume reactor, control the temperature at 65°C, control the stirring speed at 750rpm, pass in sodium hydroxide solution to adjust the pH value to 11.50±0.05, and continuously feed nitrogen into the reactor . Into the bottom liquid of the reaction kettle, flow into the nickel-cobalt mixed metal salt solution, sodium hydroxide solution and ammonia solution in the step (1), wherein the flow rate of the nickel-cobalt mixed metal salt solution is 120ml / min, and adjust the hydrogen oxidation after the reaction starts. Sodium solution flow rate, stabilize the pH value in the reactor to 10.6±0.05, control the ammonium ion concentration in ...

Embodiment 2

[0045] This embodiment includes the following steps:

[0046] (1) According to the molecular formula Ni 0.8 co 0.2 (OH) 2 Prepare 1.2mol / L nickel-cobalt mixed metal salt solution; prepare 5mol / L sodium hydroxide solution; prepare 6mol / L ammonia solution;

[0047] (2) Add 200L of pure water to a 300L reactor, control the temperature at 55°C, control the stirring speed at 550rpm, pass in sodium hydroxide solution to adjust the pH value to 11.10±0.05, and continuously feed nitrogen into the reactor . The nickel-cobalt mixed metal salt solution, sodium hydroxide solution and ammonia solution prepared in step (1) are flowed into the bottom liquid of the reaction kettle concurrently, wherein the flow rate of the nickel-cobalt mixed metal salt solution is 120ml / min, and the hydrogen is adjusted after the reaction starts. Sodium oxide solution flow, stabilize the pH value of the reaction system to 10.10±0.1, control the concentration of ammonium ions in the reaction system to abou...

Embodiment 3

[0052] This embodiment includes the following specific steps:

[0053] (1) According to the molecular formula Ni 0.97 co 0.03 (OH) 2 Prepare a nickel-cobalt mixed metal salt solution with a total metal ion concentration of 2.2mol / L; prepare an 8mol / L sodium hydroxide solution; prepare a 12mol / L ammonia solution;

[0054] (2) Add 200L of pure water to a 300L reactor, control the temperature at 75°C, control the stirring speed at 650rpm, pass in sodium hydroxide solution to adjust the pH value to 11.90±0.05, and continuously feed nitrogen into the reactor . The nickel-cobalt mixed metal salt solution, sodium hydroxide solution and ammonia solution prepared in step (1) are flowed into the bottom liquid of the reaction kettle concurrently, wherein the flow rate of the nickel-cobalt mixed metal salt solution is 120ml / min, and the hydrogen is adjusted after the reaction starts. The flow rate of sodium oxide solution is used to stabilize the pH value of the reaction system to 10....

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com