Enhanced hydroxypropyl cellulose microporous film and preparation method thereof

A technology of hydroxypropyl cellulose and microporous membranes, which is applied in the field of microporous membranes, can solve the problems of microporous membranes such as unstable mechanical properties and dimensions, easy shrinkage, and rupture, and achieve improved mechanical properties, dimensional stability, and process No pollution, improved toughness and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

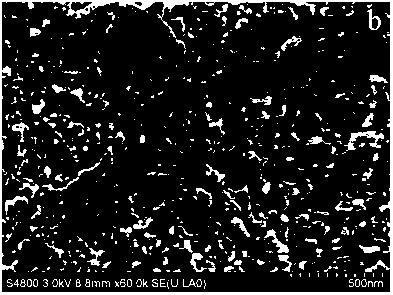

[0032] The above-mentioned treatment of the reinforced hydroxypropyl cellulose microporous membrane is the same as that of the comparative example. After drying at room temperature, put the membrane into the refrigerator and freeze it at -20°C for 24 hours, then take it out and dry it in the air. The microporous membrane has a micropore diameter of about 150nm and a tensile strength of 24MPa. See Figure 3 for cross-sectional photos.

Embodiment 2

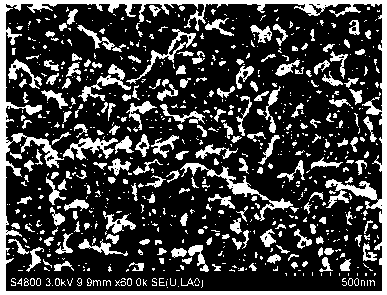

[0034] The above-mentioned treatment of the reinforced hydroxypropyl cellulose microporous membrane is the same as that of the comparative example, after being cross-linked and plasticized, steamed at normal pressure for 2 hours, and then dried at room temperature. The microporous membrane has a micropore diameter of about 50nm and a tensile strength of 20MPa. The cross-sectional photos are shown in Figure 2.

Embodiment 3

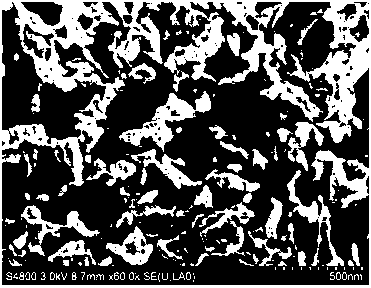

[0036] The above-mentioned treatment of the reinforced hydroxypropyl cellulose microporous membrane is the same as that of the comparative example. After the cross-linking and plasticizing treatment, it is steamed at normal pressure for 2 hours, dried at room temperature for 2 hours, and the membrane is placed in the refrigerator and frozen at -20°C for 24 hours. , remove to dry. The microporous membrane has a micropore diameter of about 80nm and a tensile strength of 20MPa. The cross-sectional photos are shown in Figure 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com