Honeycomb tendon drawing type anti-crack road surface

A tensile and honeycomb technology, applied in the field of urban transportation, can solve the problems of investing a lot of road maintenance fees, traffic jams in road maintenance projects, etc., and achieve the effects of long-lasting crack resistance, prolonged service life, and improved aging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

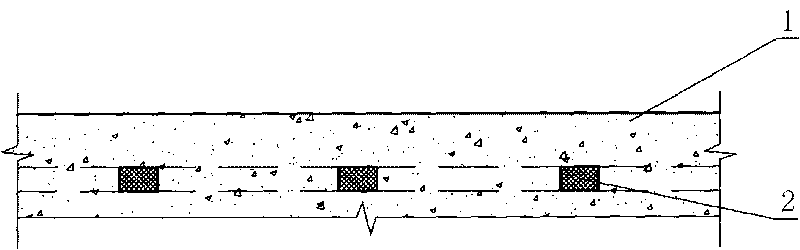

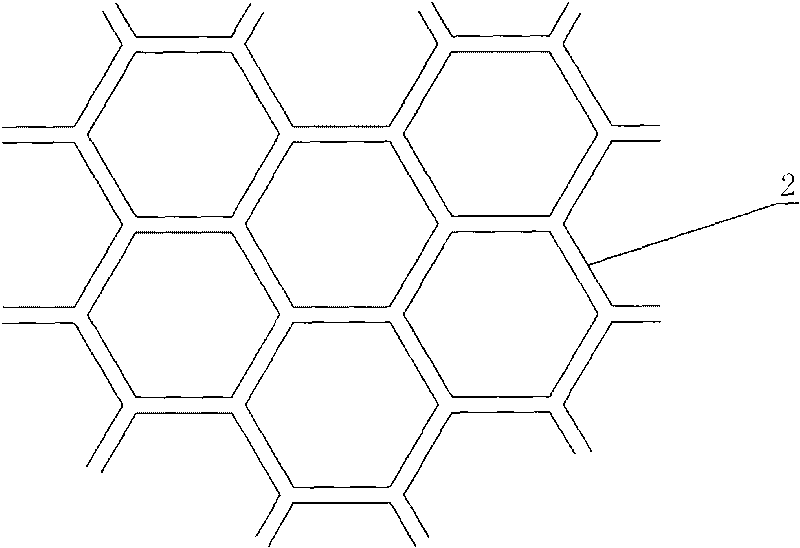

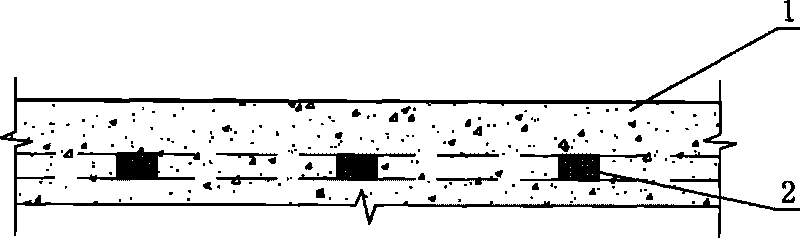

[0014] The tensile crack-resistant pavement with cellular reinforcement is composed of surface layer 1 and cellular reinforcement 2. Wherein, the material of surface layer 1 is dense asphalt concrete. The honeycomb reinforcement 2 is a network structure composed of a plurality of regular hexagonal frames with a circumscribed circle diameter of 60 mm. The cross-sectional area of the frame bars that constitute the regular hexagonal frame is 10mm 2 , The frame material is low-pressure polyethylene engineering plastics. The honeycomb reinforcement 2 is in the surface layer 1, and the upper surface of the honeycomb reinforcement 2 is 15mm away from the road surface behind the cover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com