Touch LCD screen

A liquid crystal display and touch-type technology, which is applied in static indicators, optics, instruments, etc., can solve the problems of high manufacturing cost, poor linearity and accuracy, and uneven resistance distribution of touch screens, so as to improve resolution and accuracy , uniform resistance distribution, and excellent semiconductor properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The touch-type liquid crystal display screen of the technical solution will be described in detail below in conjunction with the accompanying drawings.

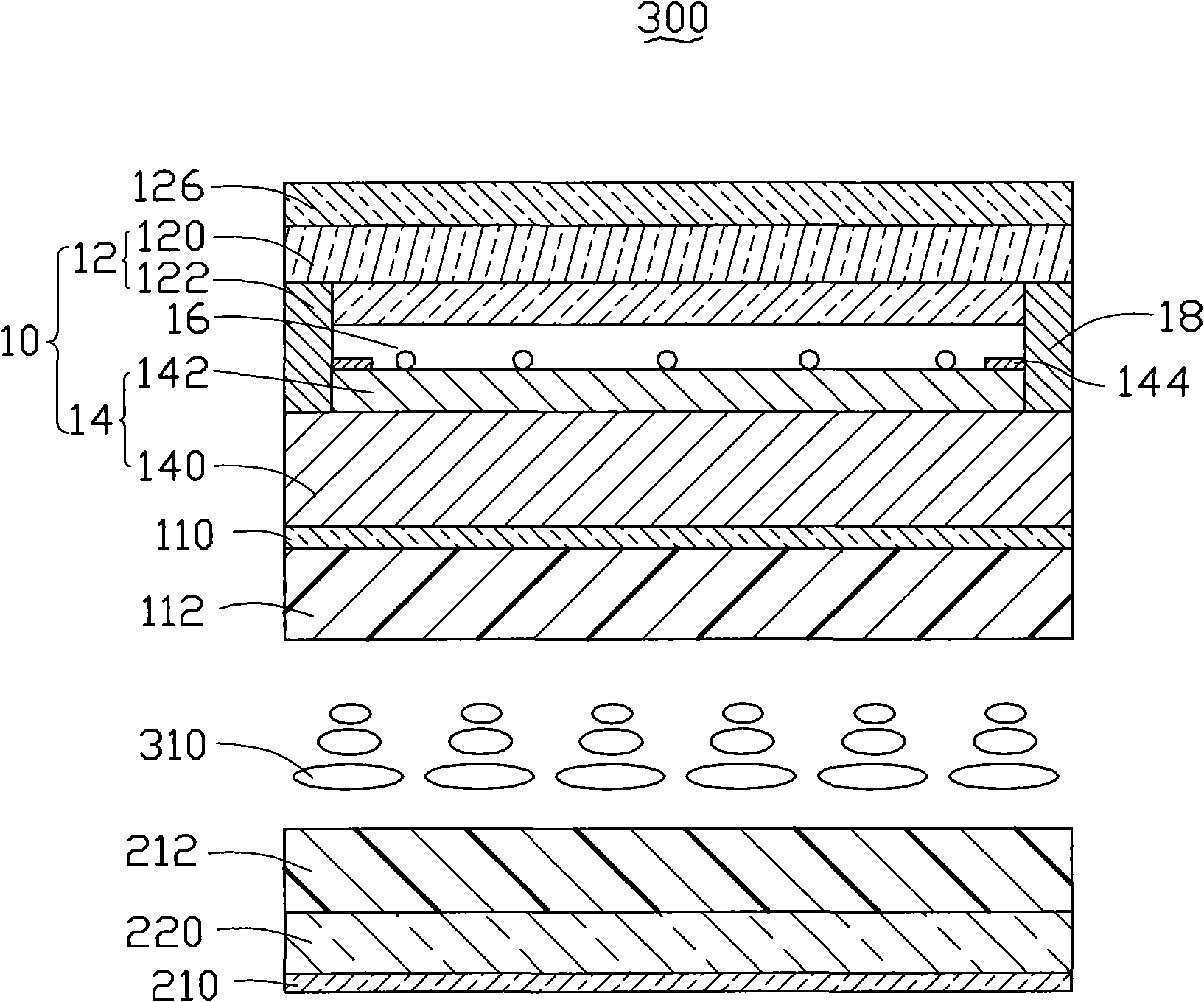

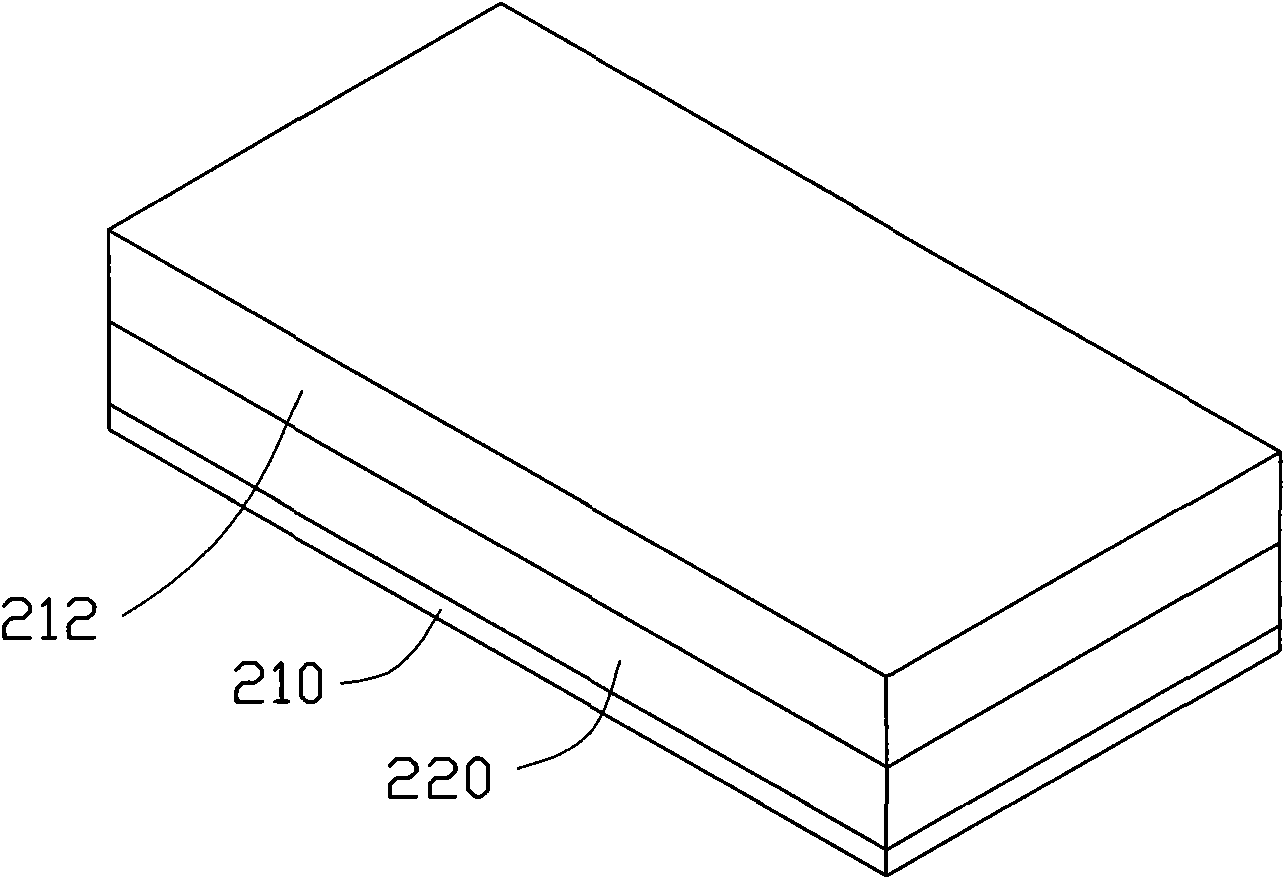

[0018] see figure 1 The embodiment of the technical solution provides a touch-type liquid crystal display 300, which includes an upper substrate 100, a lower substrate 200 opposite to the upper substrate 100, and a liquid crystal disposed between the upper substrate 100 and the lower substrate 200. Layer 310.

[0019] The liquid crystal layer 310 includes a plurality of long rod-shaped liquid crystal molecules. The liquid crystal material of the liquid crystal layer 310 is a commonly used liquid crystal material in the prior art. The thickness of the liquid crystal layer 310 is 1-50 microns. In this embodiment, the thickness of the liquid crystal layer 310 is 5 microns.

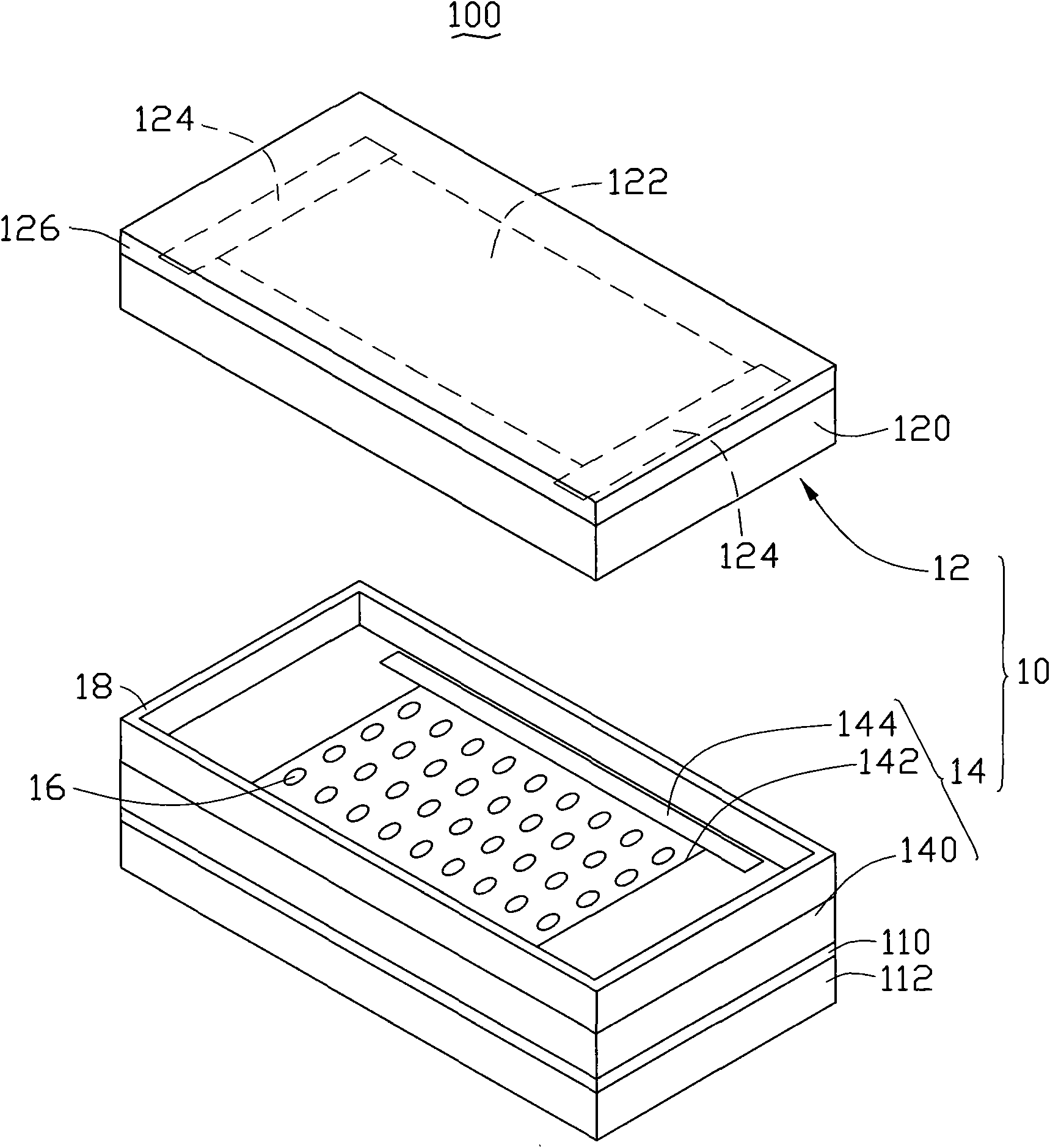

[0020] see figure 2 , the upper substrate 100 sequentially includes a touch screen 10 , a first polarizing layer 110 and a first alignment layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com