Safety coating, electrode plate, preparation method of electrode plate and lithium ion battery

An electrode pole piece, safe technology, applied in the direction of secondary batteries, battery electrodes, battery components, etc., can solve the problems of poor safety performance of lithium-ion batteries, achieve excellent thermal stability, high electrochemical stability, guarantee Safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] 3. A method for preparing an electrode pole piece, comprising the following steps:

[0044] Prepare the safety coating slurry, mix and stir the polymer, lithium salt, toughener, inorganic filler and plasticizer to obtain the safety coating slurry; it can be mixed by high-speed dispersion and stirring to obtain a uniform safety coating slurry;

[0045] Prepare pole piece main body;

[0046] Cold pressing; then coating the safety coating slurry on at least one side of the pole piece main body;

[0047] The preparation of the electrode pole piece is completed.

[0048] Further, the preparation method of the pole piece main body is as follows: firstly prepare the active material slurry, then apply the active material slurry on at least one side of the current collector, and dry to obtain the pole piece main body with the active material layer. Wherein, the safety coating slurry is coated on the side of the active material layer away from the current collector and / or on t...

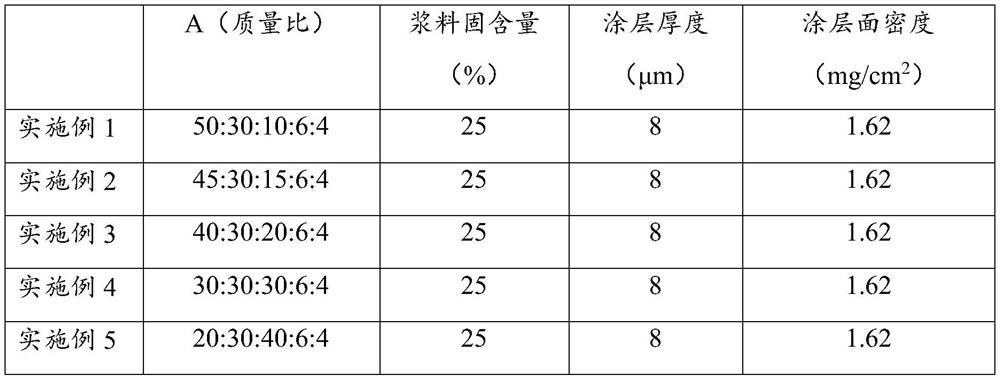

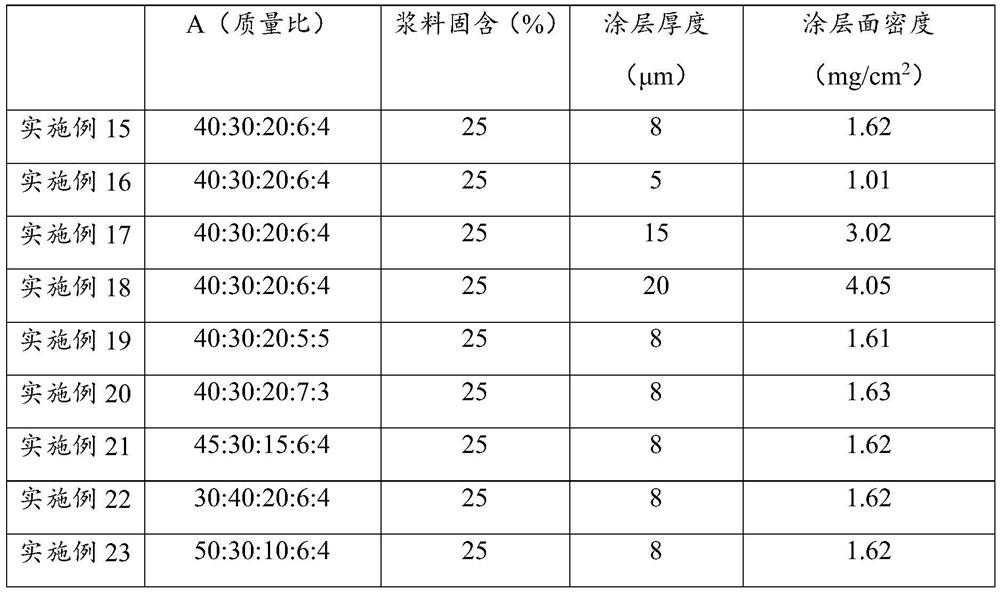

Embodiment 1

[0056] A lithium-ion battery includes a positive electrode sheet, a negative electrode sheet, a diaphragm spaced between the positive electrode sheet and the negative electrode sheet, and an electrolyte; wherein, the safety coating is coated on the negative electrode sheet.

[0057] (1) Preparation of positive electrode sheet

[0058] Mix NCM811 positive electrode active material, conductive agent superconducting carbon and carbon tubes, and binder polyvinylidene fluoride in a mass ratio of 96:2:0.5:1.5 to make positive electrode slurry, and coat the positive electrode slurry on the current collector aluminum foil On one surface of the aluminum foil, after drying and winding at 120°C, the positive electrode slurry is coated and dried on the other side of the aluminum foil according to the above method, and then the prepared aluminum foil is double-sided coated with the positive electrode active material layer. cold pressing;

[0059] Carry out edge trimming, cutting into piec...

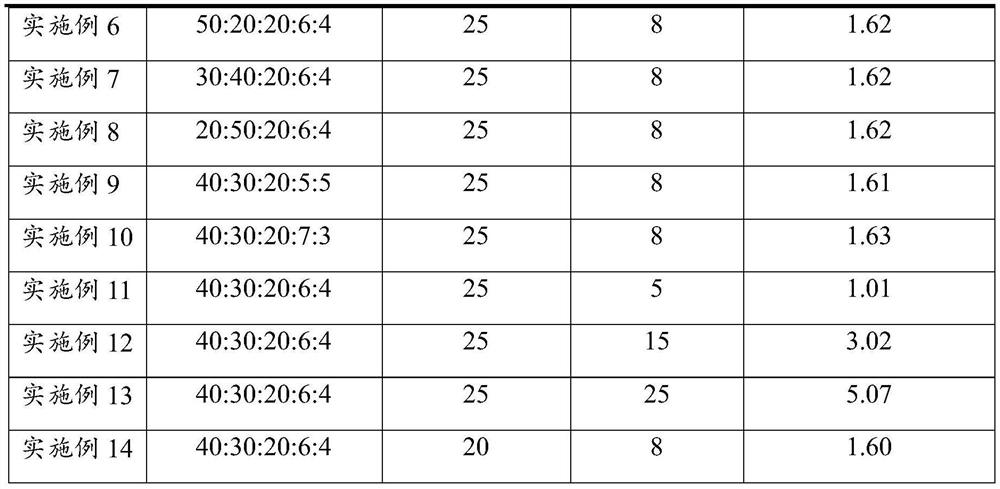

Embodiment 2

[0070] The difference from Example 1 is the preparation of the negative electrode sheet.

[0071] Preparation of negative electrode sheet:

[0072] The silicon carbon negative electrode active material, the conductive agent superconducting carbon, the thickener sodium carboxymethyl cellulose, and the binder styrene-butadiene rubber are made into a negative electrode slurry at a mass ratio of 96:1.5:1.0:1.5, and coated on the current collector After the copper foil is dried and rolled at 105°C, the negative electrode slurry is coated and dried on the other side of the copper foil according to the above method, and then the prepared copper foil is coated with a negative electrode active material layer on both sides. cold pressing;

[0073] Preparation of safety coating: polyvinylidene fluoride-hexafluoropropylene, lithium bistrifluoromethanesulfonimide, polyvinyl acetate, lithium lanthanum zirconium tantalum oxide and ethylene carbonate in a ratio of 45:30:15:6: The mass ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com