Full-automatic tunnel mist spraying trolley for second-lining concrete curing

A fully automatic concrete technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of on-site operation environment impact, concrete surface damage, water waste, etc., to avoid waste of water resources, improve strength and durability, The effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

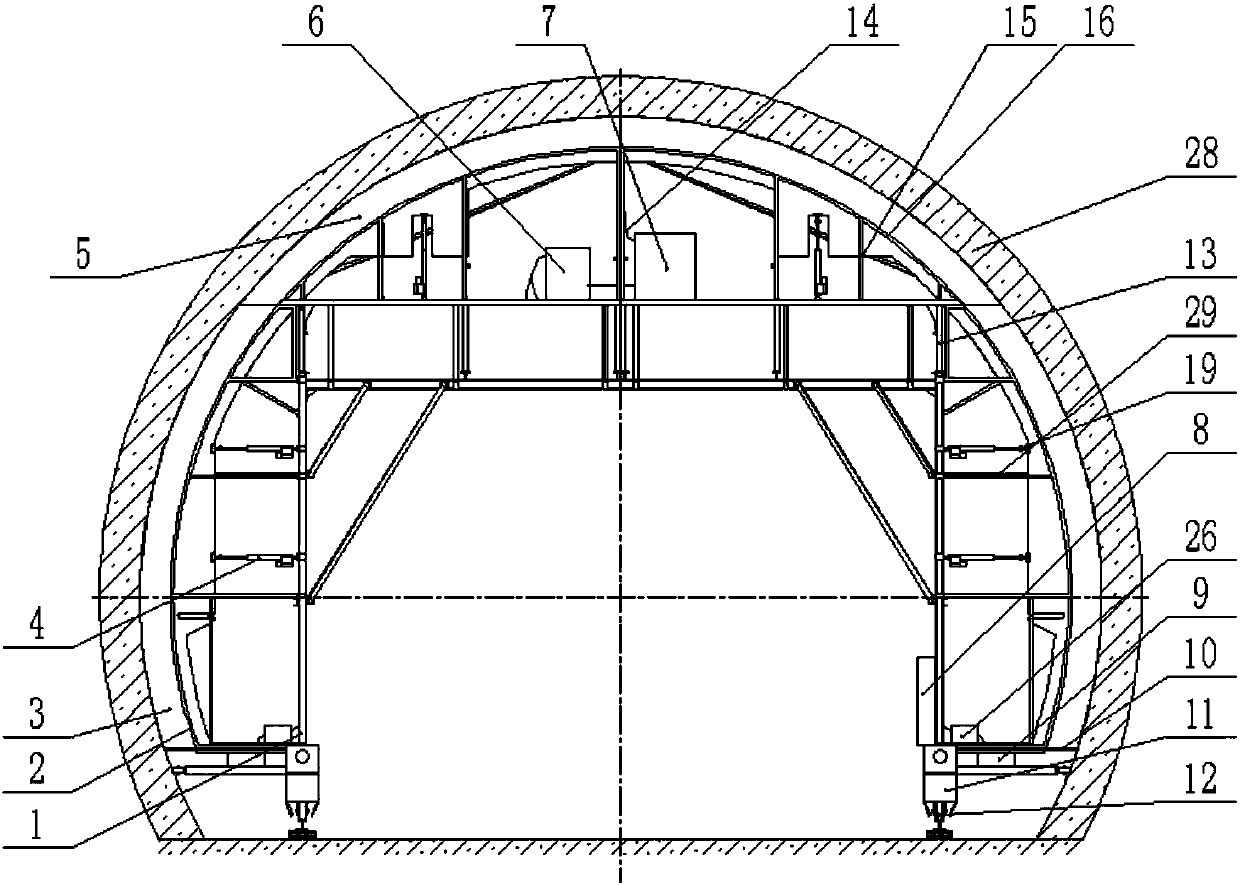

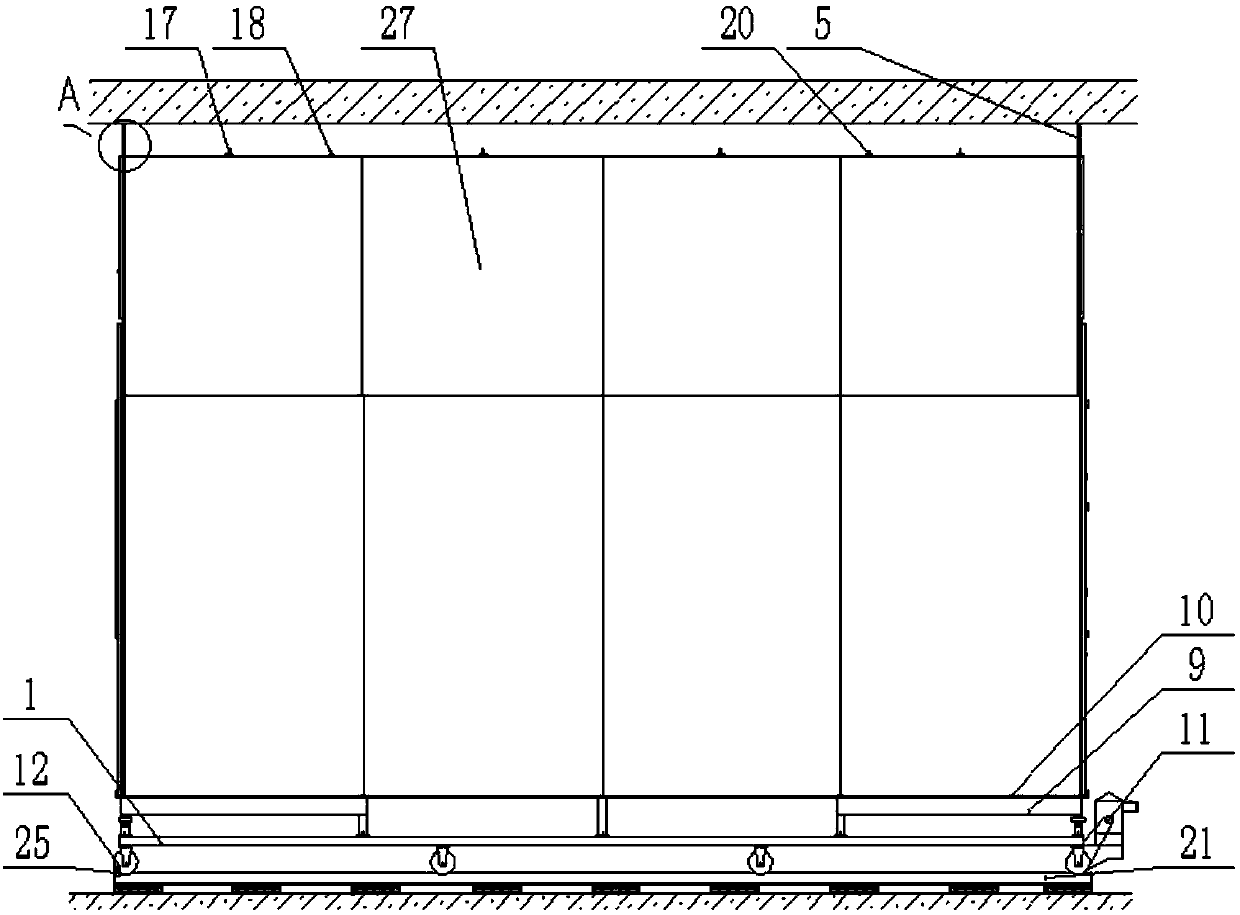

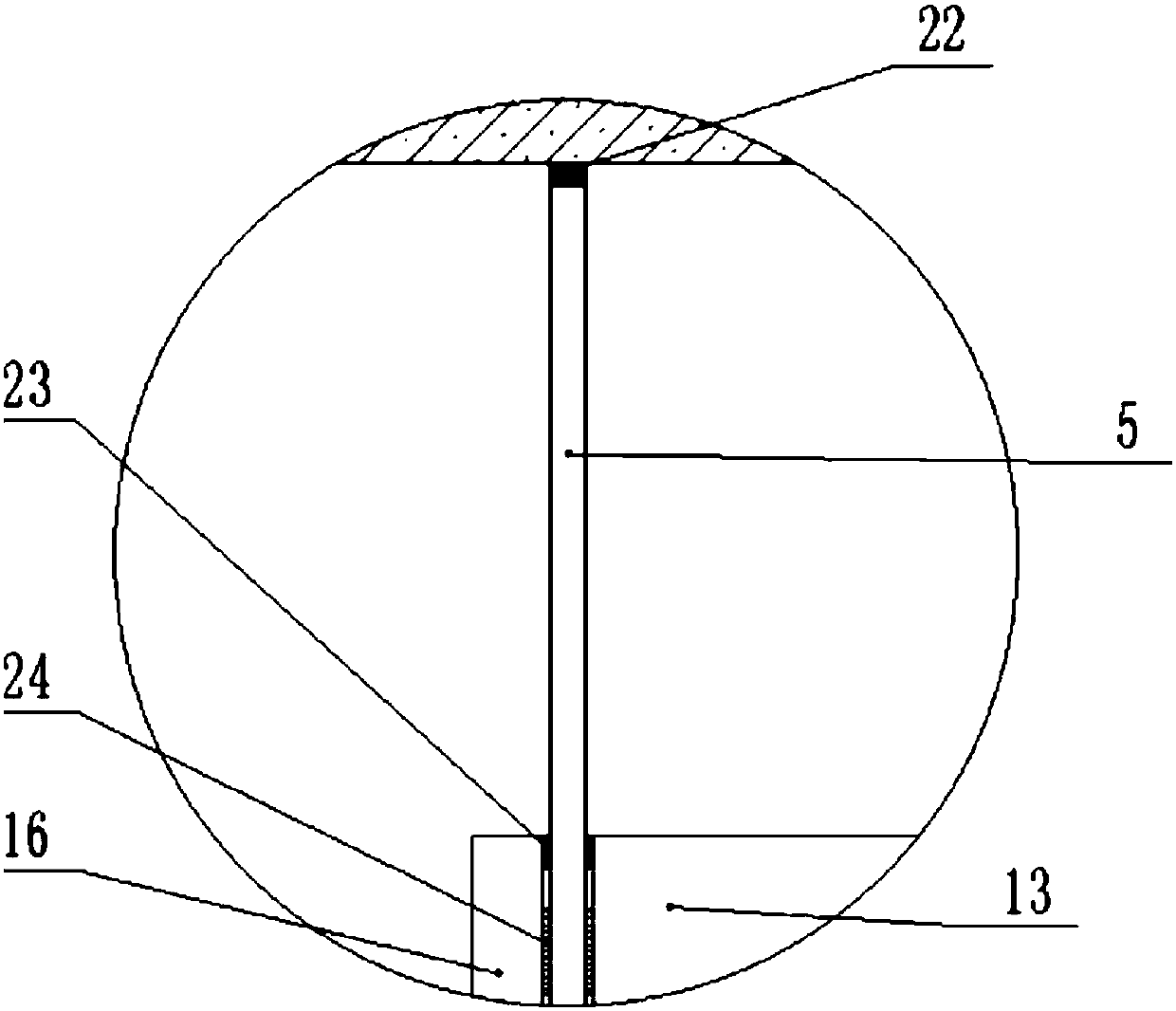

[0026] exist figure 1 with figure 2 In the schematic diagram of the front view of a fully automatic second-lined tunnel concrete maintenance spray trolley in use, the main frame is a door-shaped frame 1 with a certain length, width and height made of high-strength steel, and the upper frame and a stiffener is provided between the two side frames, such as Figure 4 As shown, the upper frame and the two side frames are intermittently provided with several arches that are as long as the connecting part and are curved toward the outside of the second-lined concrete. The arches are also frames made of high-strength steel. The adjacent arch frames are connected by bolts and the connection gap is filled with elastic sealing strips. The upper arch frame 13 that is located on the upper frame consists of 2 sections such as Figure 5 The arch frame sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com