Rock slope combined type protective structure and method

A technology for rock slopes and protective structures, which is applied in basic structure engineering, botanical equipment and methods, and excavation, etc., can solve the problems of large engineering volume and high cost, and achieve the purpose of reducing engineering cost, restoring ecological environment, and absorbing automobile exhaust gas. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

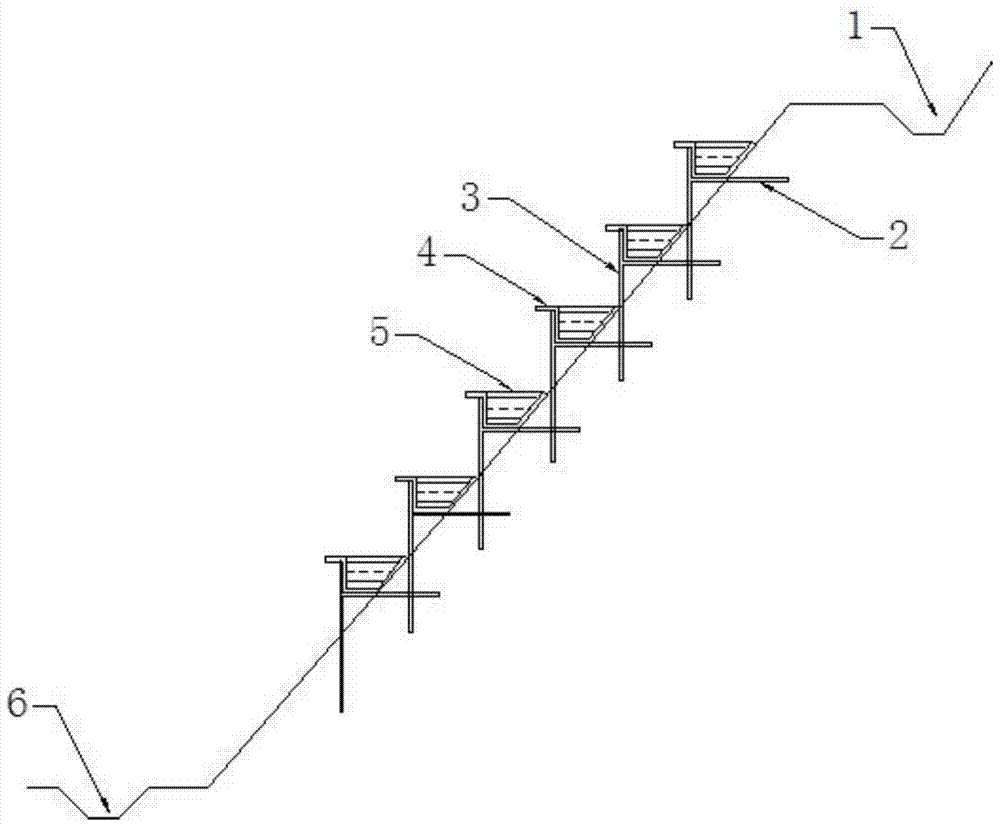

[0044] The method of the present invention is used to carry out composite protection on a rocky slope, the rocky slope is 43 meters long, 10.5 meters high, and the slope ratio is 1:1.2.

[0045] Excavate the slope, brush the slope, clean the surface of the slope, set up drainage and intercommunication ditches for the slope, set out lines, locate the nailing points on the slope, and mark them.

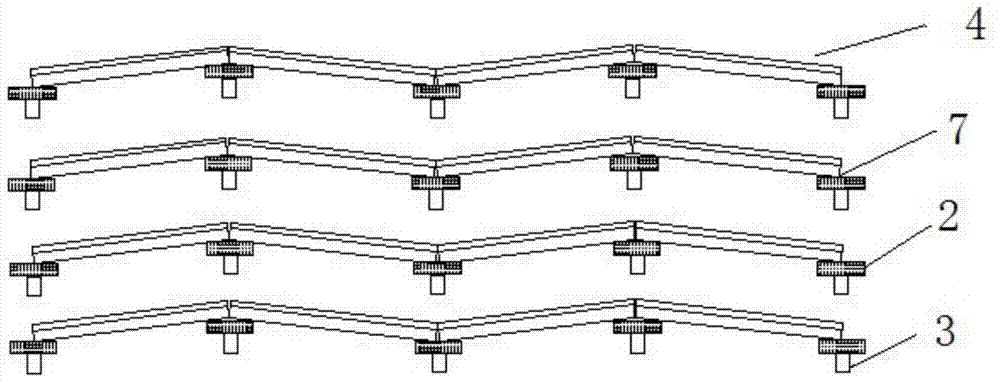

[0046] Drive horizontal soil nails and vertical soil nails into the slope along the horizontal direction and vertical direction respectively. The depth of entry into the slope is not less than 200cm. 10-15cm above the horizontal line. The distance between adjacent horizontal soil nails in each soil nailing unit row is 140cm, the height difference between adjacent horizontal soil nails in each soil nailing unit row is 15cm, and the distance between adjacent soil nailing unit rows is 115cm.

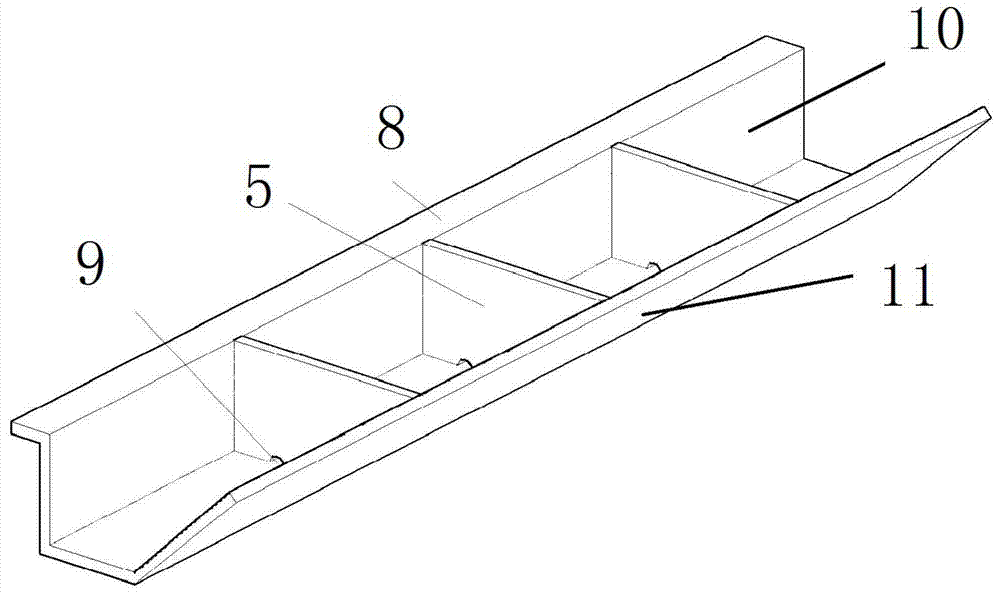

[0047] The height of the prefabricated groove is equal to the height from the top of the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com