Water super-absorbing resin-based inner cured cement stabilized broken stone base material and preparation method thereof

A technology of cement-stabilized gravel and superabsorbent resin, which is applied in the field of road materials to reduce the number of times of watering and maintenance, promote the development of strength, and improve the durability of road surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

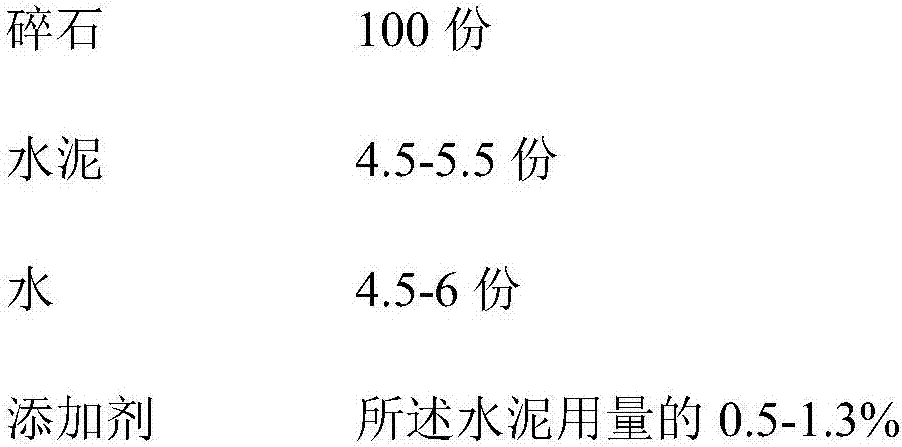

[0027] The invention provides a cement-stabilized crushed stone base material based on superabsorbent resin for internal curing and a preparation method thereof, comprising the following components in parts by weight:

[0028]

[0029] Additives include superabsorbent resin additives.

[0030] Further, the superabsorbent resin is carboxymethyl fiber, hydroxyethyl cellulose, polyacrylic acid, polyvinyl alcohol, polyoxyethylene, cellulose grafted acrylamide, cellulose grafted acrylic, fiber Any one of the grafted acrylonitriles. The particle size of the superabsorbent resin is 100-200 mesh, and the water absorption ratio is 15-50. In addition, in order to improve the distribution uniformity of the superabsorbent resin in the mixture and ensure the effect of superabsorbent treatment for internal health, the additives also include dispersants. The dispersants are ethylene-acrylic acid copolymers, calcium stearate, and aliphatic amides. any of the. The use of the dispersant c...

Embodiment 1

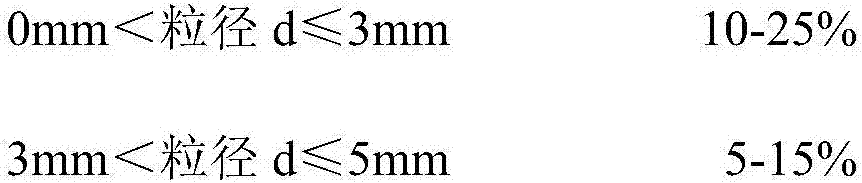

[0040] 100 parts of gravel, 4.5 parts of cement, super absorbent resin is polyacrylic acid, the particle size is 200 mesh, the water absorption rate is 30.5, the dosage is 1.3% of the amount of cement, and the water consumption is 4.5 parts. In addition, the gradation of gravel As shown in the table below:

[0041] Table 1 Gradation table of Example 1 crushed stone

[0042] Gravel particle size / mm

0~3

3~5

5~10

10~15

15~30

Amount / %

25

15

10

30

20

[0043] It is prepared according to the following steps: firstly, the above components are weighed in parts by weight, the superabsorbent resin is premixed with cement, and the mixture is fully stirred evenly.

[0044] The two-layer continuous paving process is used for construction operations. Since the superabsorbent resin can release water, the number of watering and health maintenance can be reduced.

Embodiment 2

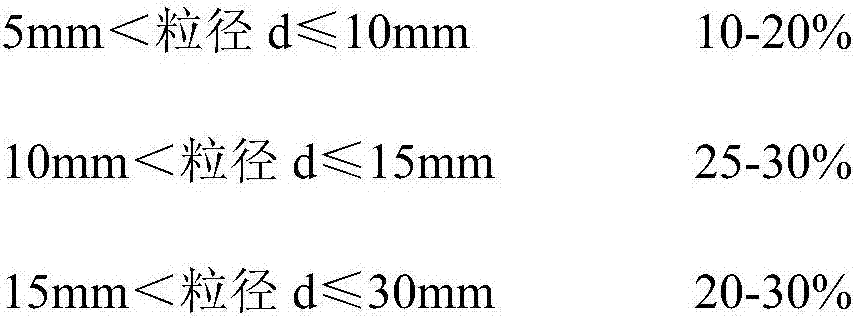

[0046]100 parts of gravel, 5.5 parts of cement, superabsorbent resin is carboxymethyl cellulose, particle size is 150 mesh, water absorption rate is 22.1, the dosage is 0.8% of cement consumption, water consumption is 5.0 parts, stearic acid Calcium dispersant, the dosage is 0.05% of the cement dosage, and the gradation of crushed stone is shown in the table below:

[0047] Table 2 Gradation table of embodiment 2 crushed stone

[0048] Gravel particle size / mm

0~3

3~5

5~10

10~15

15~30

Amount / %

10

15

20

25

30

[0049] It is prepared according to the following steps: firstly weigh the above components by weight, add the superabsorbent resin into the crushed stone at a rate of 135g / h and pre-mix evenly, add other components and fully stir evenly.

[0050] The two-layer continuous paving process is used for construction operations. Since the superabsorbent resin can release water, the number of watering and health maintenance can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com