Patents

Literature

66results about How to "Reduce reflective cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel slag and rubber asphalt concrete and preparation method thereof

The invention provides a steel slag and rubber asphalt concrete and a preparation method thereof. In the concrete, the steel slag is selected as a coarse aggregate and rubber asphalt is selected as a binder, and the concrete further comprises a fine aggregate and a filler; the mineral aggregate of the asphalt mixture is graded to form a coarse aggregate gap gradation framework solid type; the ratio of the rubber asphalt to the mineral aggregate is comprehensively determined through a Marshall compacting experiment to determine the range via the volume parameter of a Marshall test piece and verification on the road properties such as high-temperature rutting resistance and water damage resistance; when the rubber asphalt and the mineral aggregate are mixed and stirred, the heating temperature of the rubber asphalt is 175-180 DEG C and the heating temperature of the mineral aggregate is 10-30 DEG C higher than that of the rubber asphalt; moreover, the dry mixing time of the mineral aggregate is 15-20 s and the wet mixing time of the mineral aggregate is 35-40 s; and the ex-factory temperature of the steel slag and rubber asphalt concrete formed after the mixing and the stirring is 175-185 DEG C. The invention replaces the mineral aggregate by the steel slag, and can recycle the waste materials, save the stone resources, and reduce the destruction from the stone mining to the environment.

Owner:RES INST OF HIGHWAY MIN OF COMM

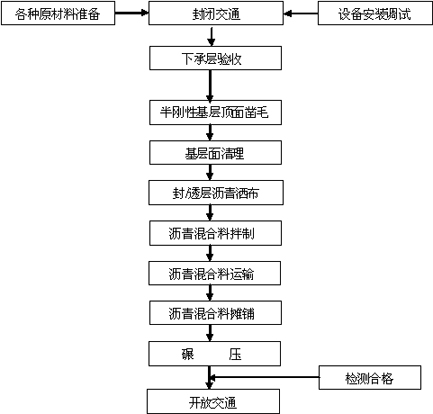

Hot-distribution rubber bituminous pavement and construction method thereof

InactiveCN101982610AImprove adhesionAvoid enteringIn situ pavingsSolid waste managementInter layerChipseal

The invention discloses hot-distribution rubber bituminous pavement and a construction method thereof. The construction method comprises the following steps: 1, cleaning a lower bearing layer; 2, preparing rubber asphalt; 3, distributing the rubber asphalt, namely, uniformly distributing a rubber asphalt layer on the lower bearing layer, wherein the distribution amount of the rubber asphalt is 2.2 to 2.6 kg / m<2>, and the distribution temperature is 180 to 190 DEG C; 4, distributing broken stone with an amount which is 60 to 70 percent based on the distribution area of the rubber asphalt, wherein the distribution temperature of the broken stone is not lower than 80 DEG C; and 5, rolling and forming, namely, rolling and forming a rubber asphalt waterproof adhesive layer by a rubber-tire pavement roller following a broken stone distribution vehicle, wherein the rubber-wire pavement roller rolls the pavement once to twice back and forth. The construction method of the invention can enhance the inter-layer adhesive performance, prevent water penetration, effectively absorb and eliminate inter-layer stress and reduce reflection cracks caused by the conventional bituminous pavement, and can be applied to the projects of building and rebuilding bituminous pavement, pavement of bituminous concrete bridge floor, bituminous overlaying of cement concrete pavement and the like.

Owner:BEIJING ROAD & BRIDGE CONSTR GROUP +2

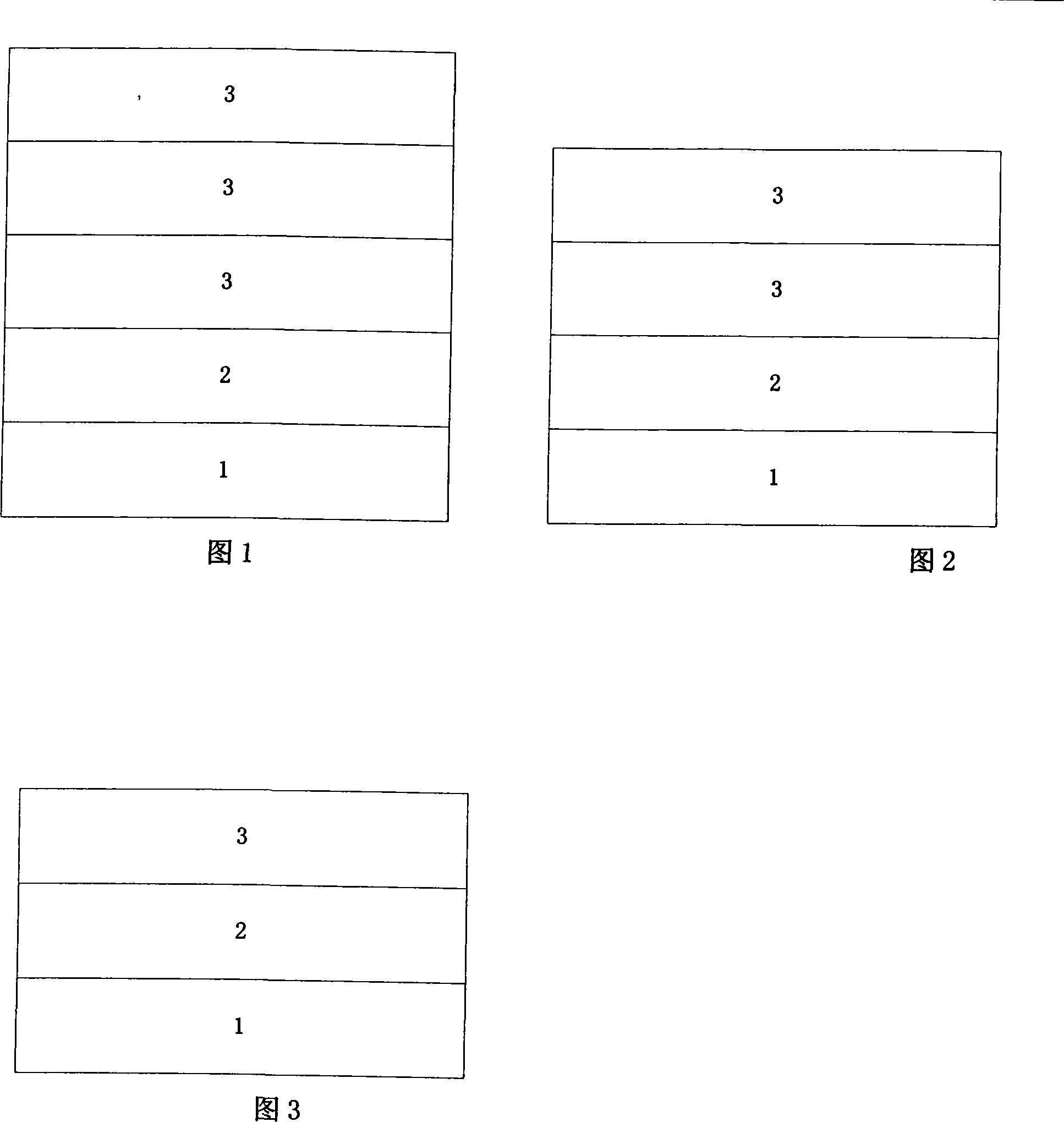

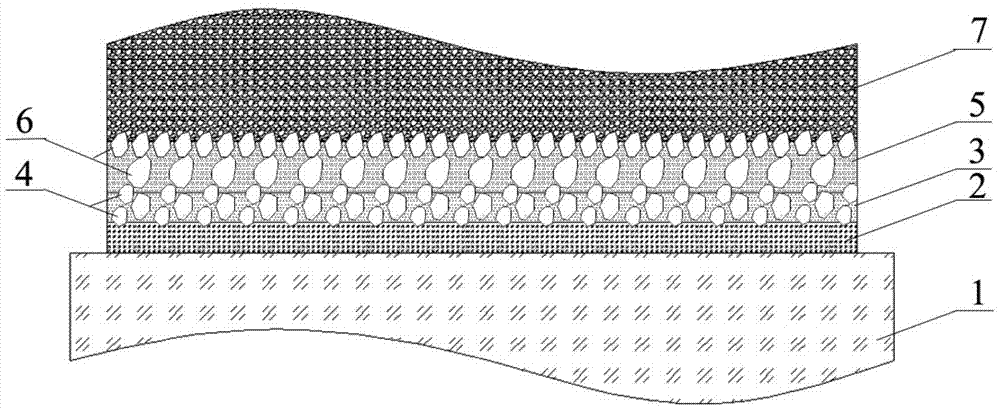

Large grain diameter water permeability asphalt mixture novel pavement structure and laying method thereof

InactiveCN101250845AImprove high temperature stabilityObvious resistance to permanent deformationIn situ pavingsMining engineeringRoad surface

The invention discloses a novel road surface structure with large particle diameter water permeability bitumen mixture and a method for laying thereof, which solves diseases such as problems of reflection crevice, pit groove and pump mud and the like which are brought from that current express-way only adopts a semi-rigid basal layer and a traditional bitumen layer, and has the advantages of simple structure, good water permeability, thereby being not easy to occur breakage of early water and being capable of efficiently increasing life time of the road surface and the like. The novel road surface structure comprises a basal layer which is consecutively provided with a large particle diameter water permeability bitumen mixture layer and at least a bitumen layer, wherein the large particle diameter water permeability bitumen mixture layer is made of one-stone coarse aggregates with the particle diameter of 25mm-62mm to form a frame and be mixed with a proper quantity of filling fine aggregates with the particle diameter of 0-4.75mm and bituminous cement to form the frame type bitumen mixture, and the thickness of each bitumen layer is not above the thickness of the large particle diameter water permeability bitumen mixture layer.

Owner:山东省交通厅公路局 +2

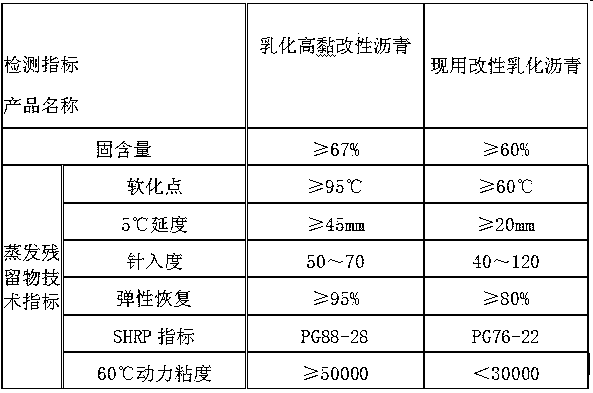

Operation method for confirming cold regeneration mix mixing proportion of emulsified asphalt

The invention relates to a working method for determining the combining ratios of cold recycled mixtures of emulsified asphalts and comprises the following aspects: (1) the performance evaluation of old asphalt mixtures; (2) the design of the combining ratio of cold recycled mixtures of the emulsified asphalts; (3) the performance tests of the performance of the cold recycled mixtures of the emulsified asphalts. The working method has the advantages of releasing the unavoidable reflective cracking problem of a semi-rigid base, improving the water temperature environment, reducing the tensile stress at the bottom of the semi-rigid base and prolonging the service life of the semi-rigid base asphalt pavement, thus providing effective measure of settlement for newly built pavements, more particularly for the maintenance and transformation of old roads; the working method can save a plurality of construction and maintenance funds as well as reducing the resource waste and environmental destruction.

Owner:TIANJIN GUOSHENG CONSTR COST CONSULTATIVE

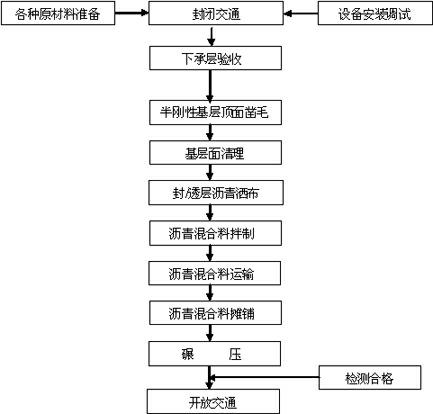

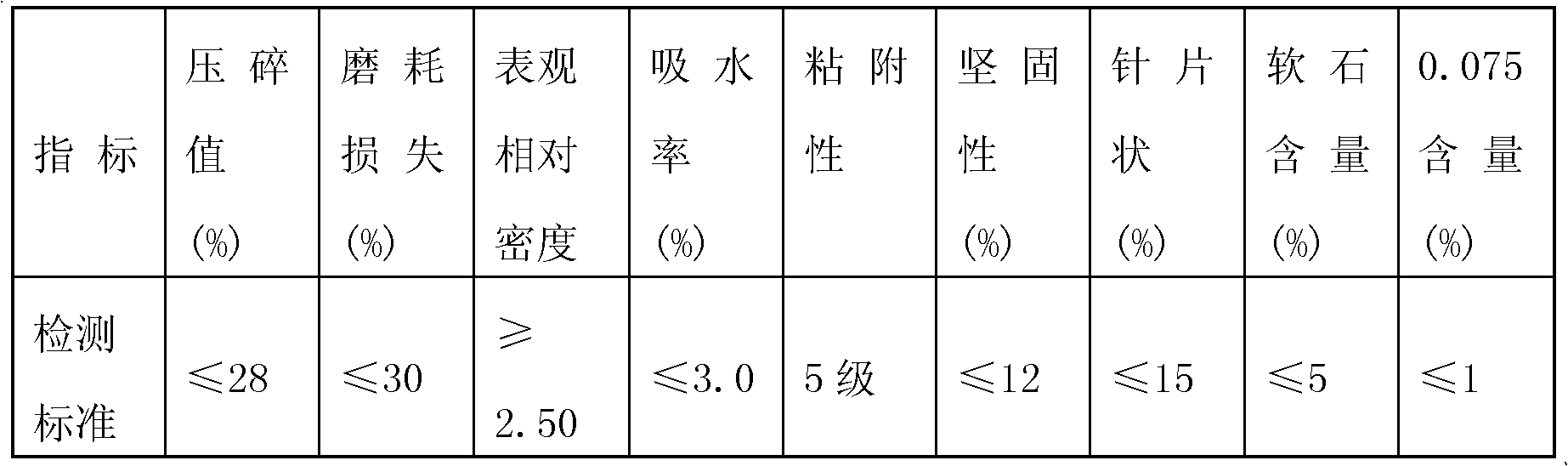

Asphalt-treated permeable-base (ATB) construction process

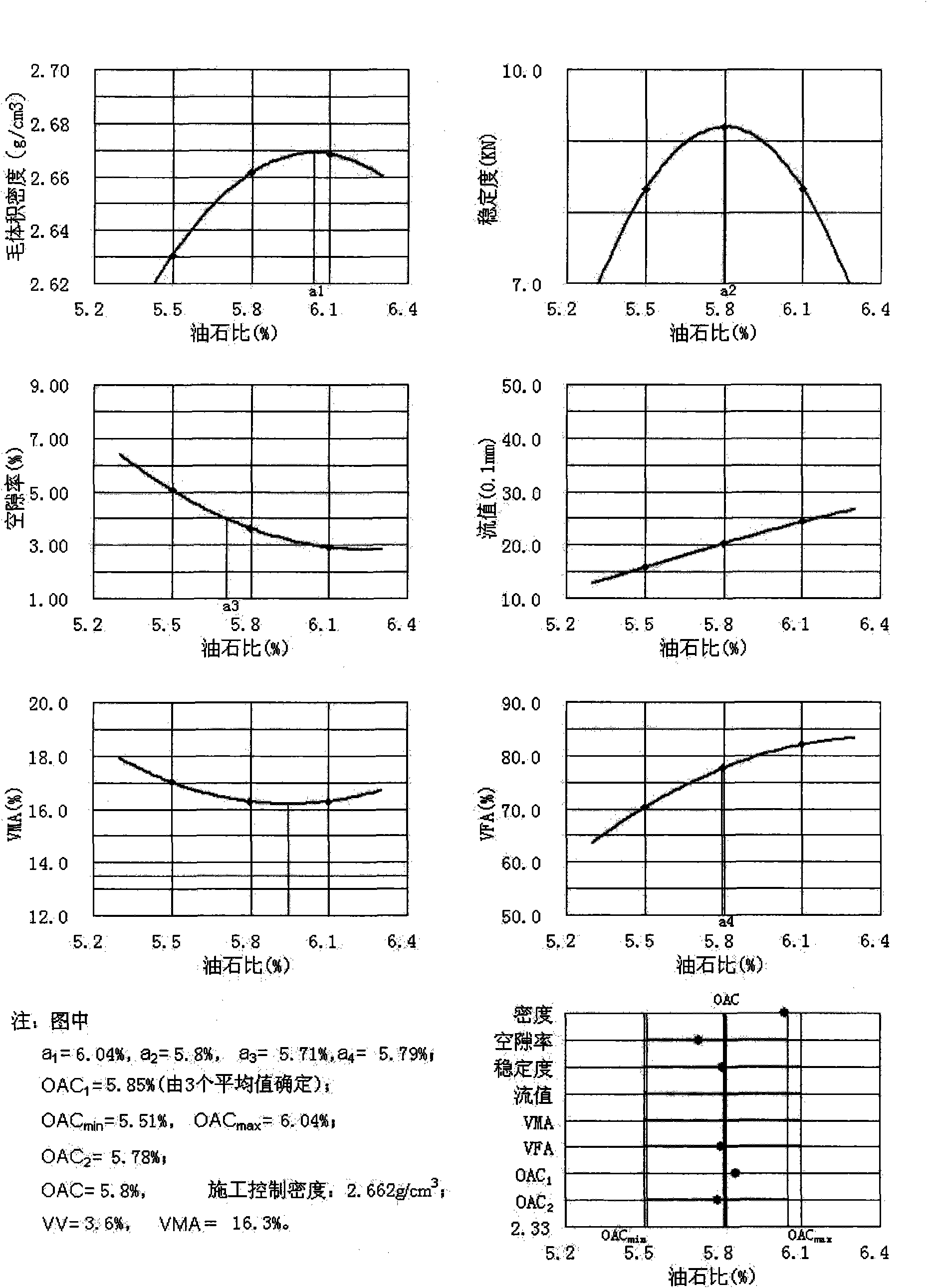

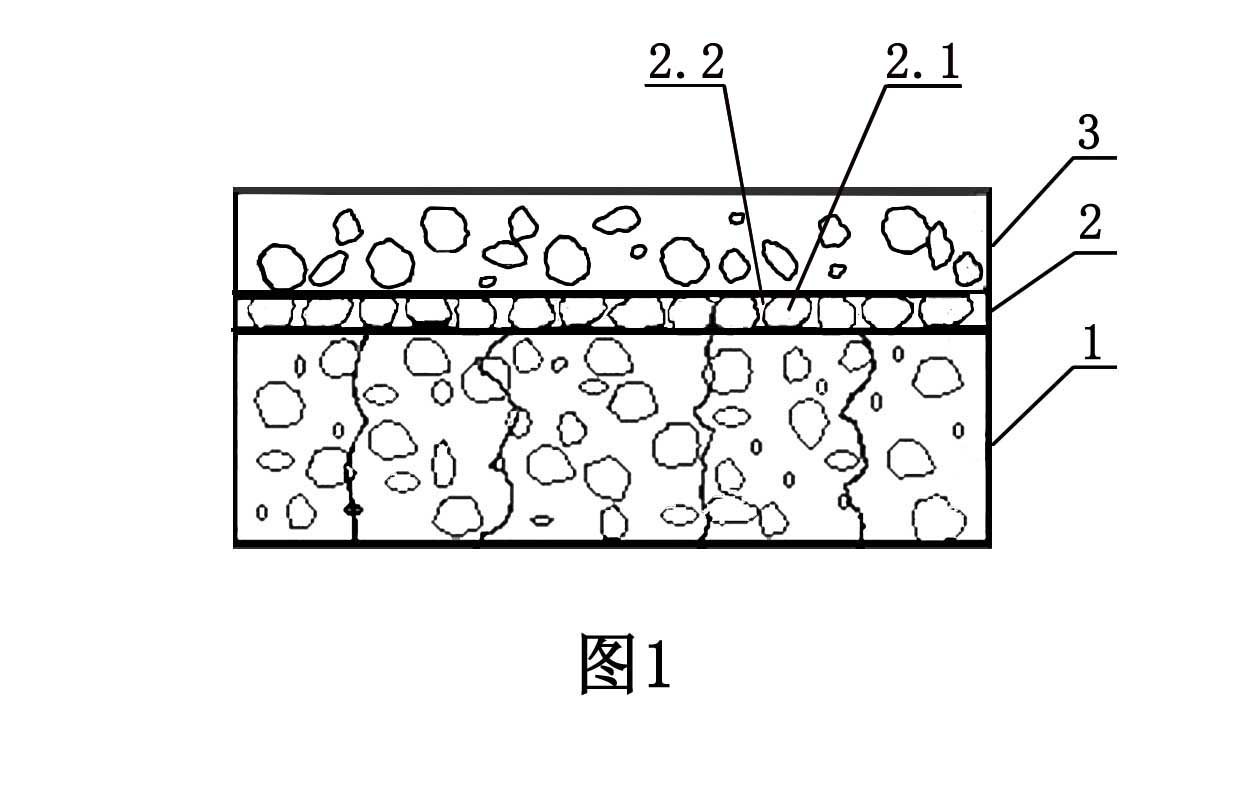

The invention relates to an asphalt-treated permeable-base (ATB) construction process. The ATB construction process is characterized in that: each raw material is obtained in a way that: coarse aggregate comprises crushed limestone produced by an impact crusher, fine aggregate comprises the crushed limestone with the particle sizes of less than 2.36mm, and a filler is produced by levigating hydrophobic stones such as highly-basic rocks and the like in limestone or magmatite; the asphalt distribution of a prime coat is 0.6 to 1.2 L / m<2>, and the asphalt distribution of a seal coat is 0.8 to 1.0 L / m<2>; when an asphalt mixture is mixed, asphalt is heated at the temperature of 155 to 165 DEG C, the mineral aggregate is heated at the temperature of 170 to 190 DEG C, the mixture is produced at the temperature of 155 to 170 DEG C, and reduction in the mixture storage temperature is not more than 10 DEG C; when the asphalt mixture is transported and charged, a vehicle is required to be moved forwards and backwards to realize balanced charging, and the temperature of the mixture is not lower than 150 DEG C when arriving at a pavement site; the temperature of an asphalt mixture paver screed is not lower than 80 DEG C, and the mixture is paved at the temperature of not lower than 140 DEG C at the pavement speed of 3 to 5 m / min; and rolling compaction is performed by three rolling compaction stages. The ATB construction process is simple and convenient to construct, and ensures relatively lower cost and high performance.

Owner:CCCC SHEC DONGMENG ENG CO LTD

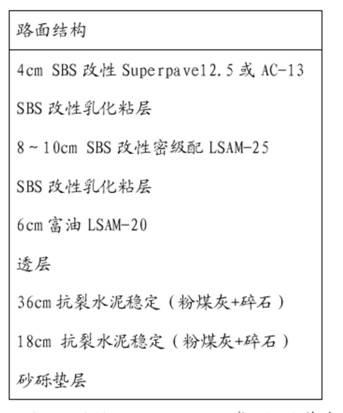

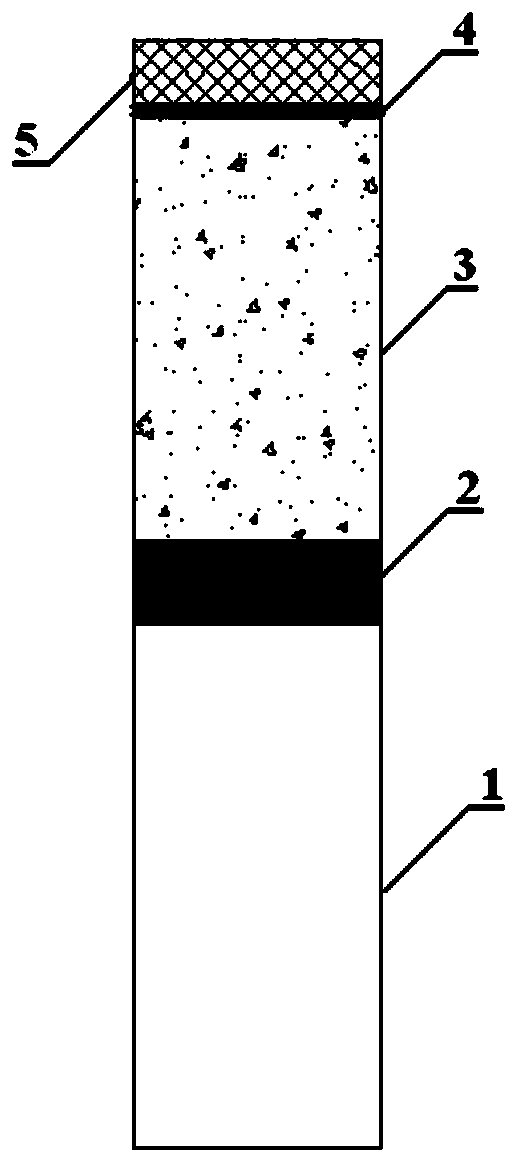

Structure of asphalt pavement applicable to very heavy traffic

InactiveCN102433815AIncreased durabilityReduce reflective cracksIn situ pavingsEngineeringStructural engineering

The invention discloses a structure of an asphalt pavement applicable to very heavy traffic. A wearing layer of the structure adopts 4cm of SBS (styrene butadiene styrene) modified Superpave 12.5 type or AC-13 type modified asphalt concrete; a middle layer of the structure adopts 8-10cm of SBS modified dense gradation LSAM (large stone asphalt mixture)-25; an anti-fatigue layer of the structure adopts 6cm of rich oil LSAM-20 asphalt concrete; a base layer of the structure adopts 36cm of anti-crack stabilized cement; and a subbase layer of the structure adopts treated original cement concrete pavement and treated original asphalt pavement or 18cm of anti-crack stabilized cement. The asphalt pavement structure resists the breaking such as penetrating, cracking, loosing, deforming and the like, resists high-temperature permanent deformation, resists fatigue loading damage, disperses the load, and slows down the reflection crack, so that the problems of rutting deformation resistance and the durability of the very heavy traffic asphalt pavement can be solved, and the service life of the asphalt pavement can be prolonged.

Owner:SHANXI PROVINCIAL RES INST OF COMM

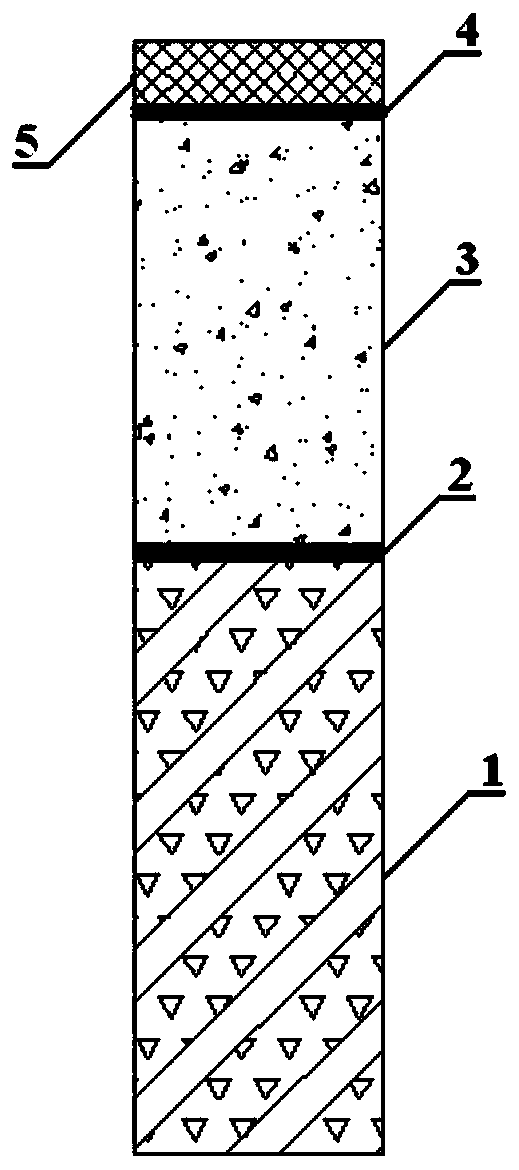

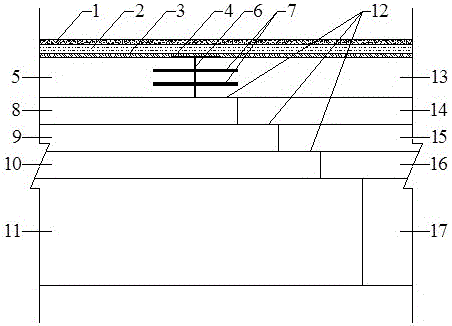

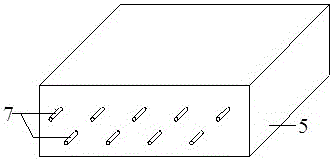

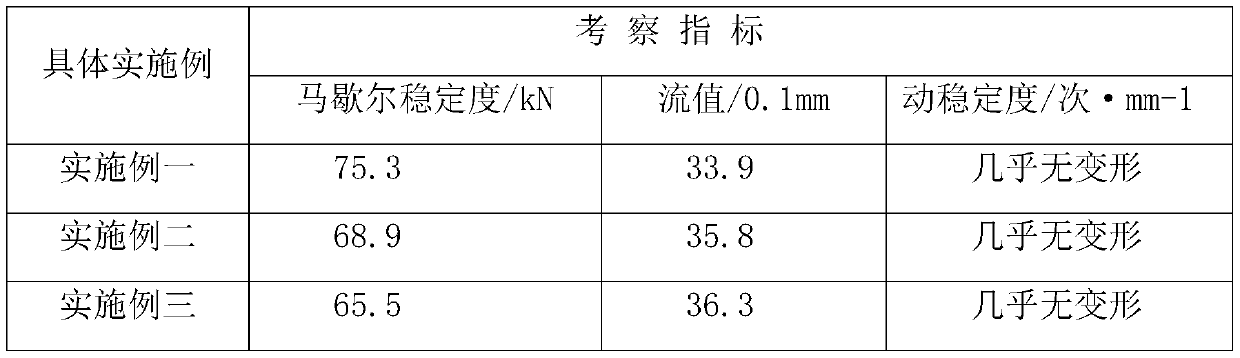

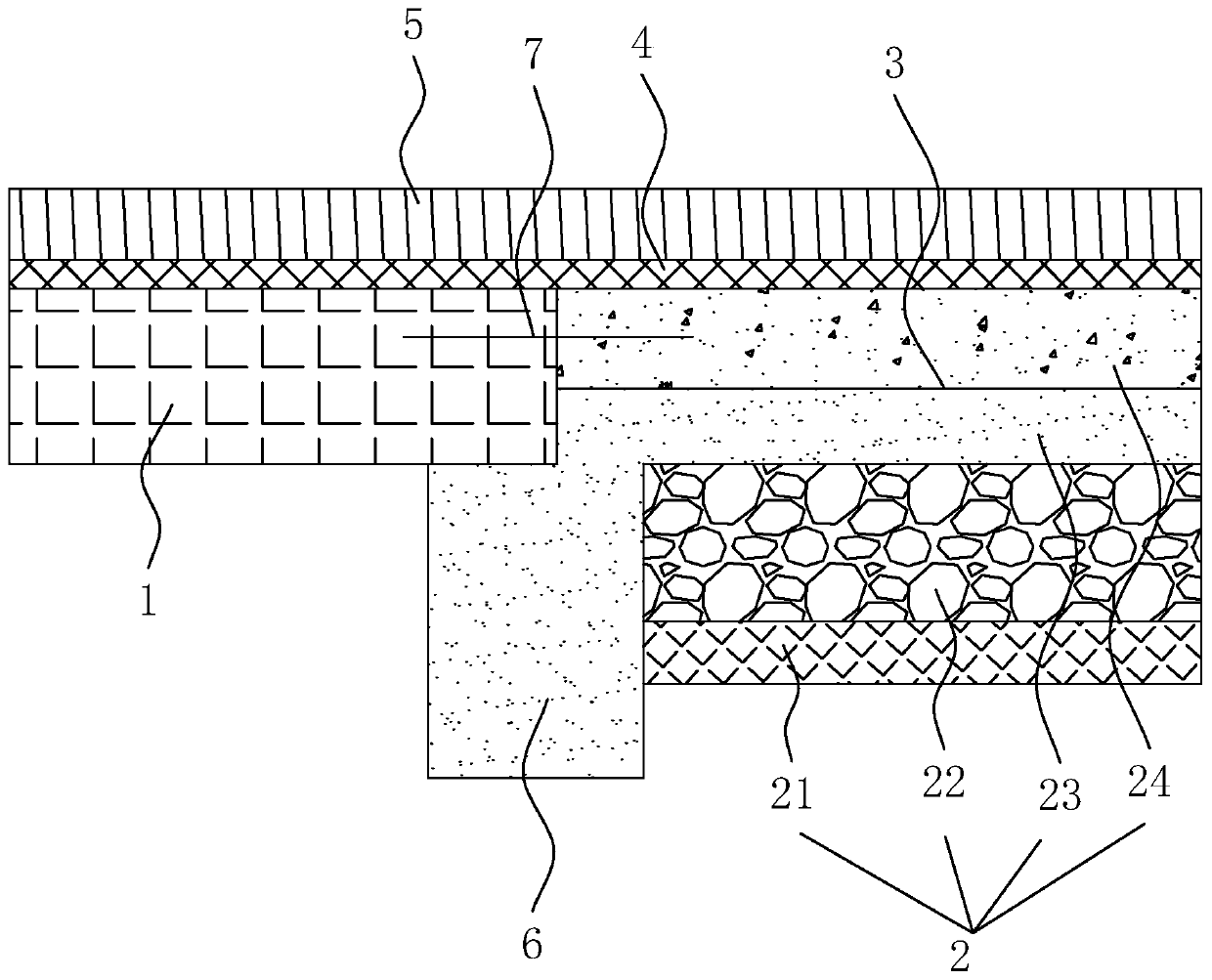

Composite fabricated cement concrete pavement structure and construction method thereof

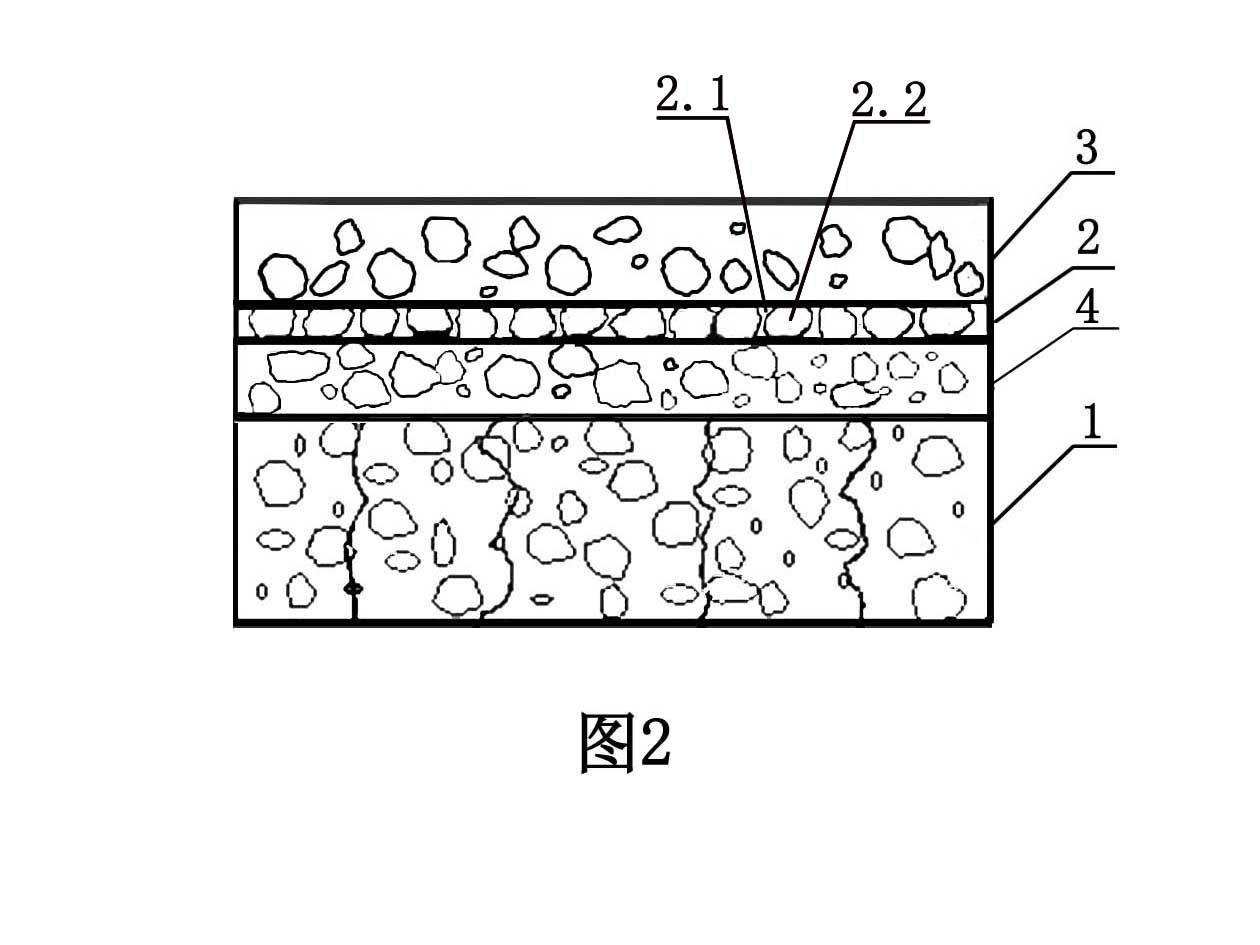

The invention provides a composite fabricated cement concrete pavement structure. The composite fabricated cement concrete pavement structure comprises a base layer, a leveling layer laid on the baselayer, a fabricated prefabricated concrete slab laid on the leveling layer, a rubber modified asphalt synchronous gravel sealing layer laid on the fabricated prefabricated concrete slab, and rubber modified asphalt concrete laid on the rubber modified asphalt synchronous gravel sealing layer. Compared with the prior art, the composite fabricated cement concrete pavement structure is formed by combining specific functional layers under specific connection relationship, the functional layers have good interaction, and the cooperation of layer structures is realized, so that the whole composite fabricated cement concrete pavement structure has high strength and good driving comfort, and reflective cracks and rutting can be reduced, and the service life of the pavement is prolonged. The experimental results show that the pavement damage index PCI of the composite fabricated cement concrete pavement structure is 92.3-95.5, and the pavement service condition is excellent.

Owner:CCCC THIRD HIGHWAY ENG

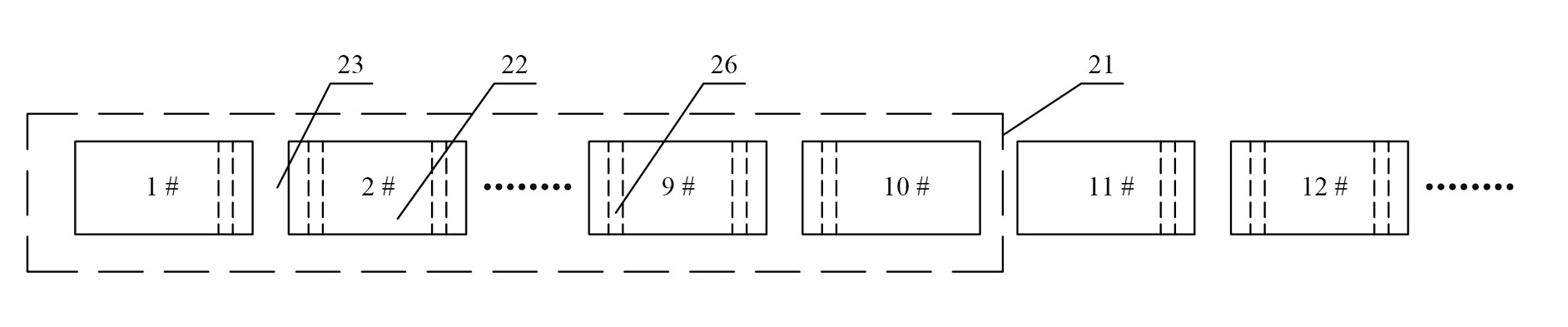

Composite pavement structure and construction method thereof

InactiveCN102031744AReduce reflection cracksGuaranteed road performance and service lifeIn situ pavingsSingle unit pavingsReflective crackCement mortar

The invention discloses a composite pavement structure and a construction method thereof. The composite pavement structure comprises an upper asphalt concrete finishing coat and a lower old cement concrete slab layer, wherein the slab layer comprises a plurality of old cement concrete slab connection groups; and each connection group is formed by connecting a plurality of old cement concrete slabs by means of connecting parts arranged at the joints of the old cement concrete slabs. The construction method of the composite pavement structure comprises the following steps: firstly determining the connection type in the road section to be reconstructed based on the plan; secondly determining the arrangement type of rake nails at the joints; thirdly drilling rake nail holes corresponding to the rake nails in terms of quantity and space on the edges of the old cement concrete slabs at the two sides of the joints; fourthly implanting the rake nails and pouring epoxy cement mortars into the rake nail holes to fix the rake nails; fifthly sprinkling water to cover the old cement concrete slabs to cure and form the old cement concrete slab layer; and finally paving the asphalt concrete finishing coat on the old cement concrete slab layer, thus obtaining the composite pavement structure. The composite pavement structure has the advantages of good economical efficiency, obvious reflection crack resistance effect, good road property, long service life and the like, and is convenient for construction.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

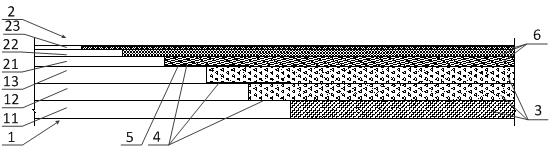

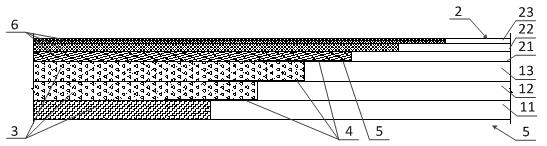

Pavement splicing method and structure for old cement concrete pavement reconstruction and expansion

ActiveCN106480799AGuaranteed normal operationEasy to handleIn situ pavingsPaving detailsSurface layerCrushed stone

The invention discloses a pavement splicing method and structure for old cement concrete pavement reconstruction and expansion. A cement concrete slab splicing seam is formed in a hard shoulder of an old cement concrete slab, steps are arranged on an old road upper base layer, an old road lower base layer and an old road cushion layer for transition, poor concrete is adopted for a new road upper base layer of an expansion part, and unscreened macadam is adopted for a road bed; a new cement concrete slab and the old cement concrete slab are connected by adopting double-layer reinforcing steel bars; a high-molecular polymer anti-cracking paste is firstly stuck to the cement concrete slab splicing seam, then an asphalt concrete anti-cracking leveling interlayer is paved, and a lower asphalt concrete surface layer and an upper asphalt concrete surface layer are finally paved sequentially, wherein the lower asphalt concrete surface layer is doped with 0.3% by mass of short-cut basalt fiber. According to the method and structure, the problem that the durability of existing old cement concrete pavement reconstruction and expansion engineering is insufficient can be effectively solved, and the important significant is achieved for promoting quicker and better development of transportation industry in China.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

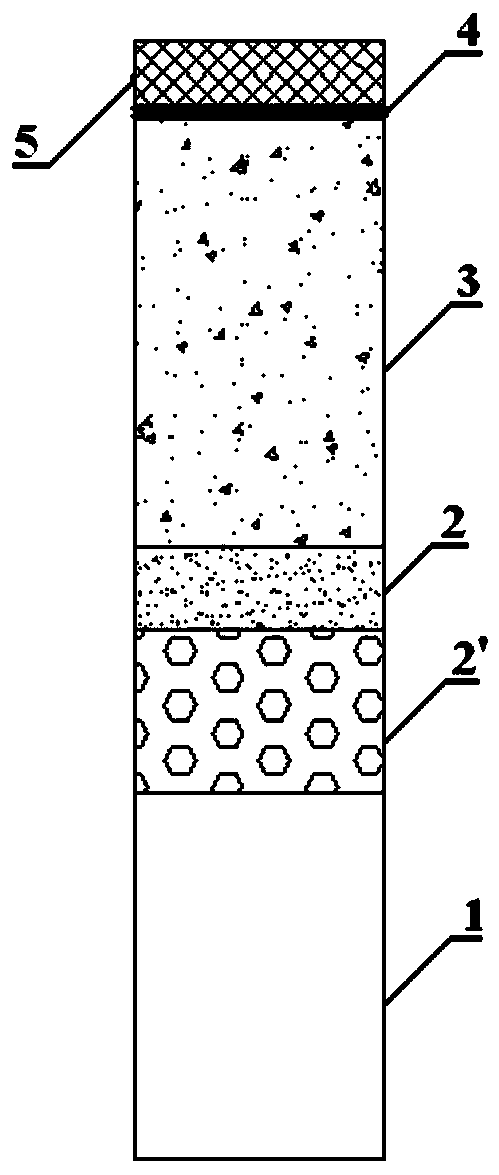

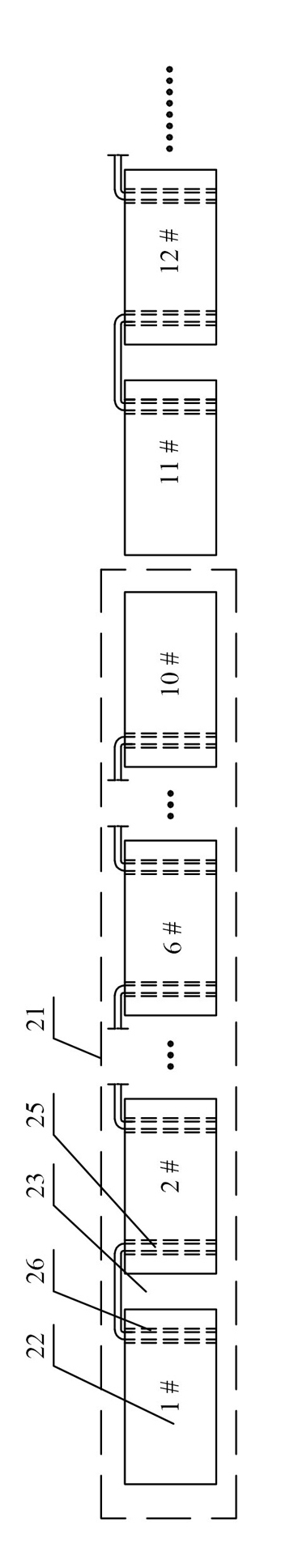

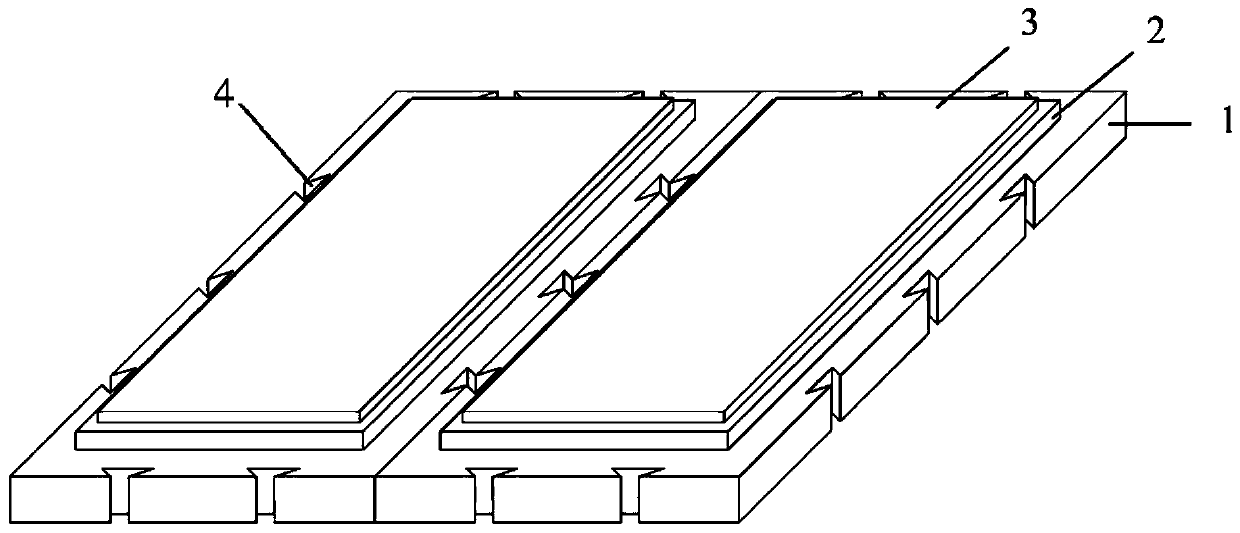

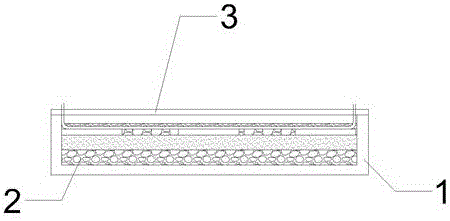

Continuous prefabricated asphalt pavement and construction method thereof

ActiveCN110863404AGuaranteed flatnessGuaranteed integrityIn situ pavingsSingle unit pavingsArchitectural engineeringBitumen emulsion

The invention discloses a continuous prefabricated asphalt pavement and a construction method thereof, and relates to a prefabricated asphalt pavement and an installation method thereof. The continuous prefabricated asphalt pavement and the construction method thereof aim to solve the problems that an existing prefabricated asphalt pavement slab is prone to generate a reflection crack and is low in construction efficiency. The prefabricated asphalt pavement is composed of a prefabricated asphalt pavement slab, an upper surface layer, a cushion layer and a soil foundation; and the prefabricatedasphalt pavement slab is arranged on the upper surface of the cushion layer, the upper surface layer is arranged on the upper surface of the prefabricated asphalt pavement slab and the upper surfacelayer and the prefabricated asphalt pavement slab are bonded through emulsified asphalt adhesive, and a gap between adjacent lower surface layers and a T-shaped joint between adjacent middle surface layers are filled with asphalt mixture. The method comprises the following steps of manufacturing prefabricated slab units and dual-tenon joint blocks in a prefabricated field, paving the soil foundation on a construction site, laying the cushion layer on the soil foundation, assembling the prefabricated asphalt pavement slab, and paving the upper surface layer. The continuous prefabricated asphaltpavement has good flatness, integrity and continuity, the reflection crack is reduced, the durability is good, and the construction period is short; and the continuous prefabricated asphalt pavementand the construction method thereof are suitable for asphalt pavement paving.

Owner:HARBIN INST OF TECH

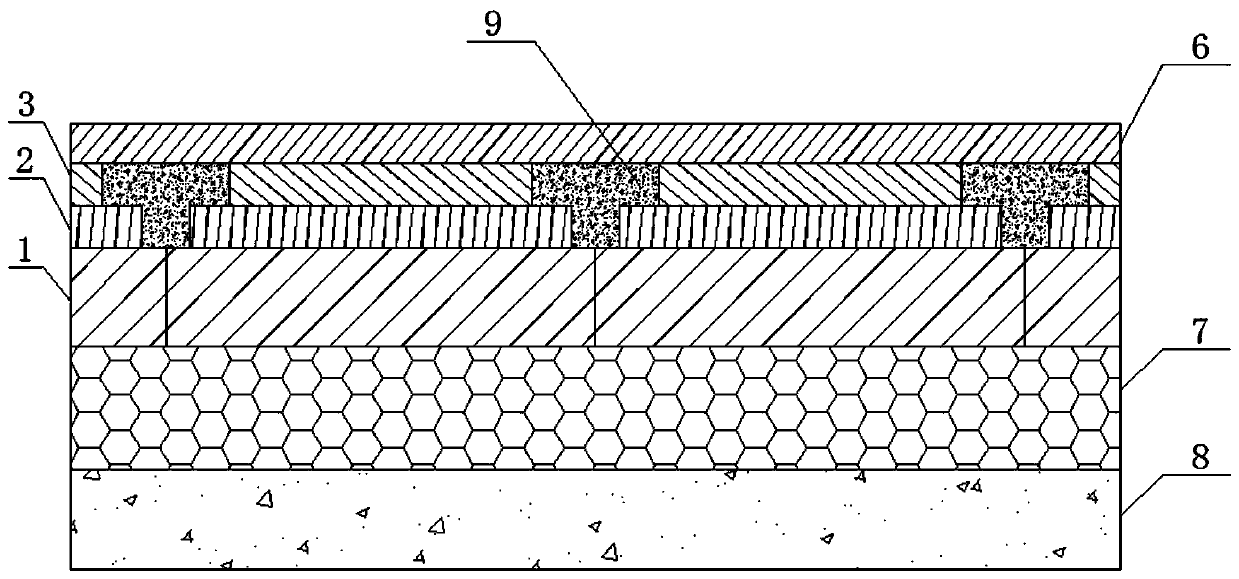

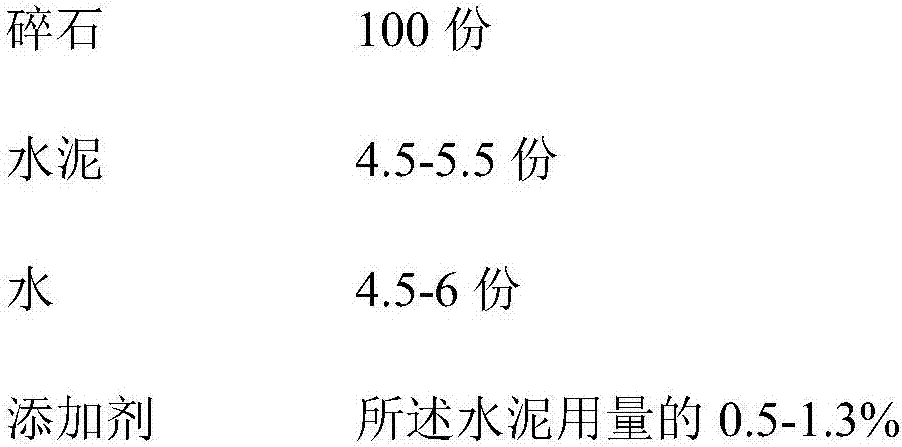

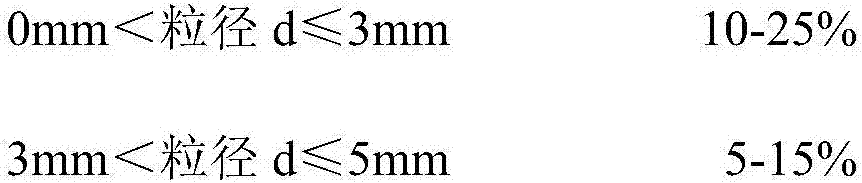

Water super-absorbing resin-based inner cured cement stabilized broken stone base material and preparation method thereof

The invention discloses a water super-absorbing resin-based inner cured cement stabilized broken stone base material. The material comprises, by weight, 100 parts of broken stones, 4.5 to 5.5 parts of cement and 4.5 to 6 parts of water and the additive use amount is 0.5 to 1.3% of the amount of the cement. The water super-absorbing resin is a water swelling-type polymer which contains strong hydrophilic groups such as a hydroxyl group and a carboxyl group and has a certain crosslinking degree. Through adsorption action, the water super-absorbing resin can store water and is uniformly distributed in the cement stabilized macadam mixture. In the latter period, under driving of humidity gradient difference, osmotic pressure and capillary interspace negative pressure in the mixture, the water super-absorbing resin releases pre-stored water to cure cement stabilized broken stones so that the problem that poor water supplement and maintenance in the cement stabilized broken stone cause shrinkage and reduce cracking resistance is solved, greatly improves cracking resistance of the cement stabilized broken stones, delays road surface base reflection cracking and improves road durability.

Owner:JIANGSU SINOROAD ENG TECH RES INST CO LTD

Complex fiber roadbed thin felt

The present invention discloses a complex fiber roadbed thin felt, including 40% to 60% of glass fiber short cutting silk by weight, 20% to 40% of polyester fiber short cutting silk by weight, and 18% to 30% of organic binder. The complex fiber roadbed thin felt is made from the glass fiber short cutting silk, the polyester fiber short cutting silk and the organic binder through a wet process, thus the felt is integrated with the advantage of the glass fiber thin felt and the polyester fiber thin felt, has adequate intensity, good flexibility, uniform thickness, easy impregnation, and high collapse property; the complex fiber roadbed thin felt is not only suitable for wide temperature range, also has low expansion coefficient, good stability, strong capacity for penetrating bitumen; a structural layer is formed after absorbing a bituminous material, thus the felt has water-proof, heat-proof and corrosion-proof physical characteristics, and very good associativity and is not liable to separate. The felt is suitable for building and reconstructing an old cement concrete pavement asphalt pavement; the repair maintenance of asphalt pavement facial cleft.

Owner:樊福定

Multi-scale fiber reinforced cement stable gravel roadbase material

InactiveCN101660287AHigh tensile strengthImprove toughnessIn situ pavingsGlass fiberCrack resistance

The invention provides a multi-scale fiber reinforced cement stable gravel roadbase material doped with different-length fiber, such as micro-steel fiber and the like. The invention provides a methodwhich can better improve the performance of cement stable gravel roadbase material than flexible fiber and effectively improve the shrinkage crack resistance capability and mechanical property of theroadbase material. The multi-scale fiber reinforced cement stable gravel roadbase material of the invention comprises cement stable gravel and multi-scale fiber material, wherein, the multi-scale fiber material comprises micro-steel fiber and glass fiber, and the doping amount of the micro-steel fiber and the glass fiber is respectively 0.8-1.2kg / m<3>. The invention adopts multi-scale short fiber,has favorable mixture workability and even fiber dispersion and is easy to satisfy construction requirements; low fiber doping amount effectively lowers material cost; in the process of base materialcrack expansion, addition of short cut glass fiber causes to form a plurality of micro cracks, which further effectively improves impact resistance of the base material and increases crack energy.

Owner:CHONGQING UNIV

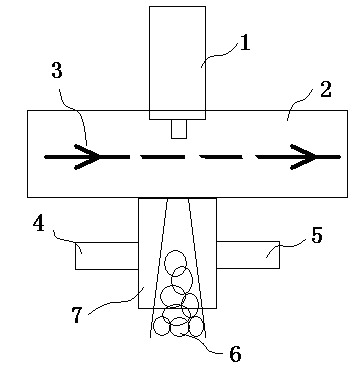

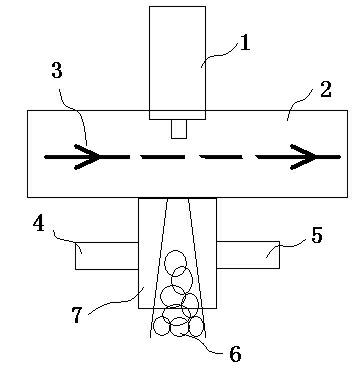

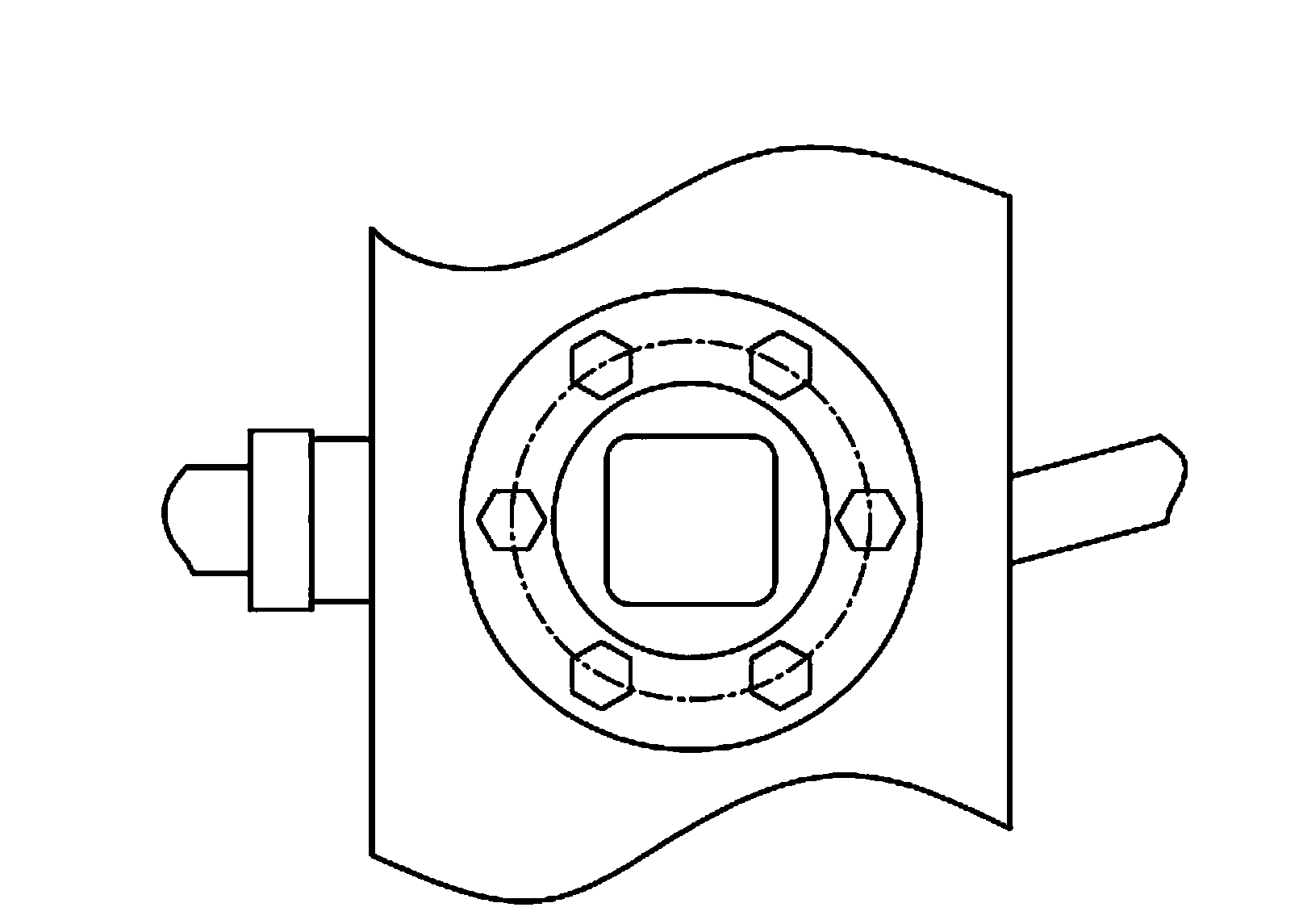

Cold regeneration device for foamed asphalt and base course construction process

The invention relates to a base course construction technology used when a freeway asphalt road surface is conserved and maintained, and in particular relates to a cold regeneration device for foamed asphalt and a base course construction process. The cold regeneration device for foamed asphalt is characterized by comprising a high-temperature shower nozzle, a hot asphalt pipeline and hot asphalt, wherein the hot asphalt enters another end from one end of the hot asphalt pipeline; the lower end in the middle of the hot asphalt pipeline is vertically connected with a foamed asphalt outlet pipeline, and the upper end in the middle of the hot asphalt pipeline is vertically connected with the high-temperature shower nozzle; one side of the upper end of the foamed asphalt outlet pipeline is provided with a water inlet, and the other end of the upper end of the foamed asphalt outlet pipeline is provided with a wind inlet; the water inlet is connected with an environmental water source, and the wind inlet is connected with a hot wind source; and high-temperature steam generated by the high-temperature shower nozzle acts on the asphalt in the hot asphalt pipeline. The cold regeneration base course construction process for the foamed asphalt is divided into four steps: preparing construction; implementing the engineering; checking and verifying the engineering; and putting into operation. The cold regeneration device for foamed asphalt and base course construction process provided by the invention have the advantages of small temperature control range and easily-controlled foaming effect, and are easy in operation.

Owner:CCCC SECOND HIGHWAY ENG CO LTD

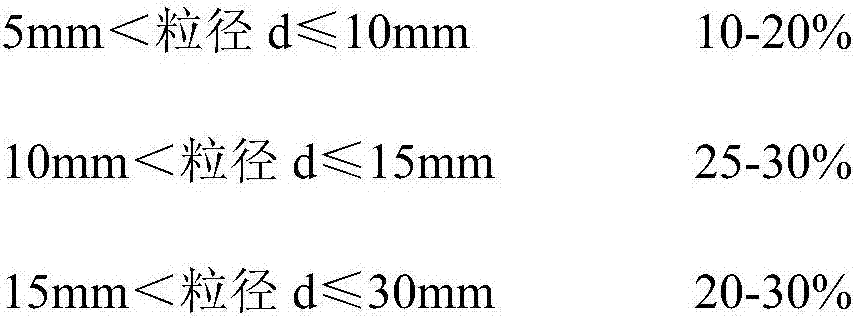

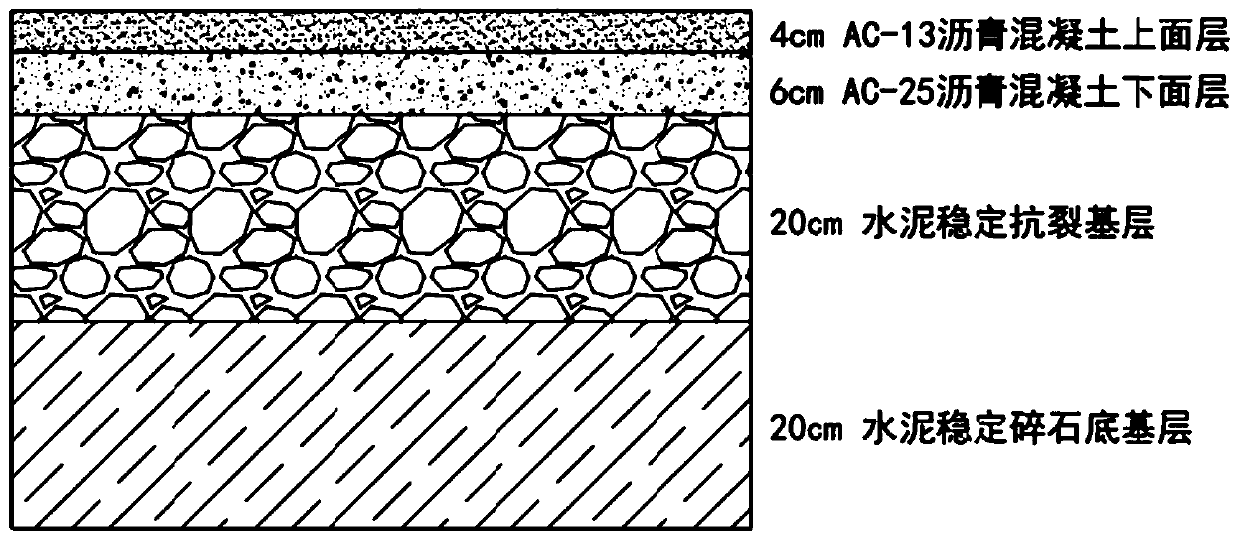

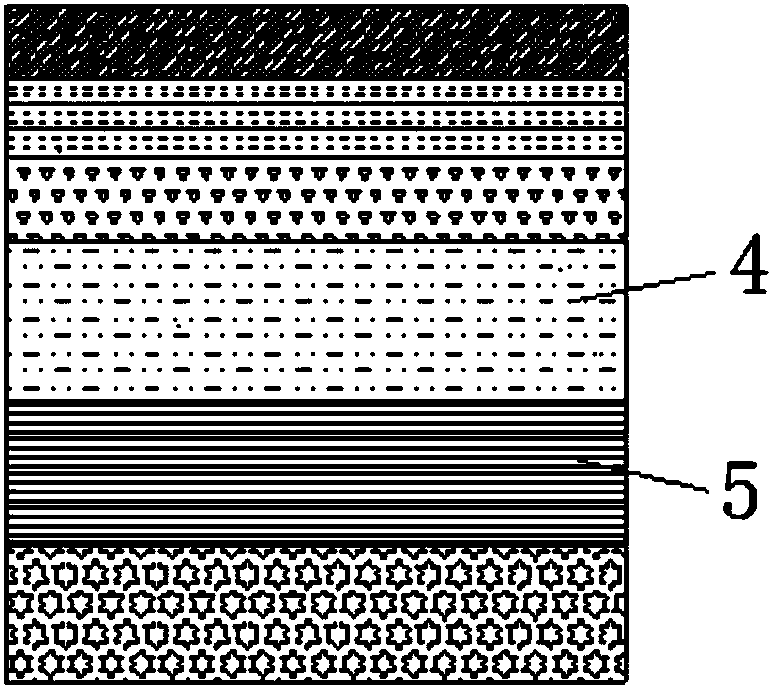

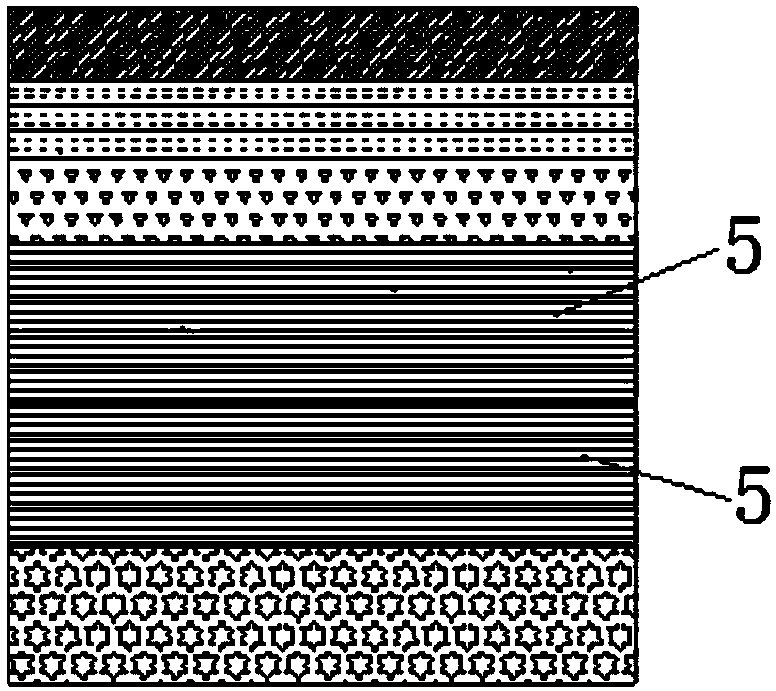

Cement-stabilized anti-crack base newly-built pavement structure and construction method and application thereof

ActiveCN111021178APrevent reflective cracksReduce reflective cracksIn situ pavingsReflective crackGeotechnical engineering

The invention discloses a cement-stabilized anti-crack base layer newly-built pavement structure and a construction method and application thereof. The pavement structure sequentially comprises an asphalt concrete upper surface layer, an asphalt concrete lower surface layer, a cement-stabilized anti-crack base layer and a cement-stabilized subbase layer from top to bottom, wherein the cement-stabilized anti-crack base layer is made of an anti-crack cement-stabilized macadam mixture and mainly comprises cement, large-particle macadam and small-size aggregate, the cement-stabilized anti-crack base layer adopts a road mixing construction mode after on-site layer paving, it is guaranteed that the large-particle macadam makes full contact to form main frameworks, and the small-size aggregate evenly fills gaps between the frameworks. According to the cement-stabilized anti-crack base layer newly-built pavement structure, reflection cracks of a semi-rigid base asphalt pavement structure are reduced, so that various disease problems caused by expansion and penetration of the reflection cracks of a traditional semi-rigid base asphalt pavement structure are solved, various diseases caused byexpansion and penetration of the reflection cracks of the pavement structure are reduced, and the purpose of prolonging the service life of the pavement structure is achieved.

Owner:SOUTHEAST UNIV

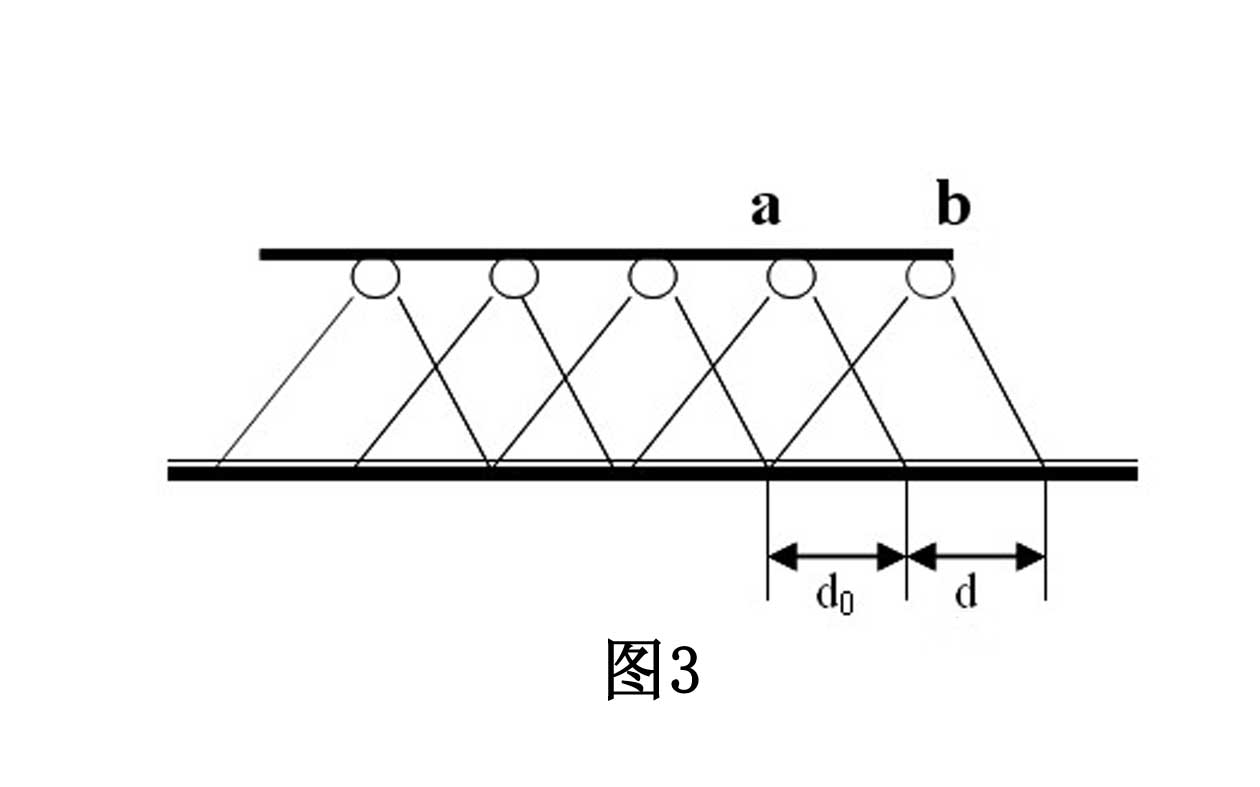

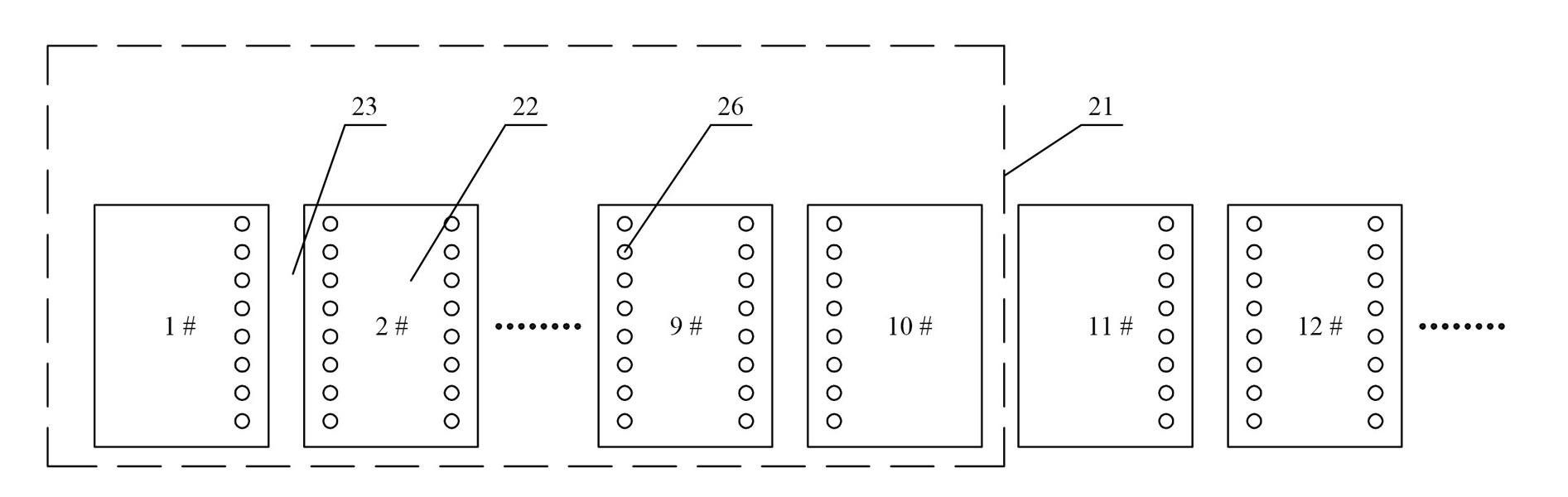

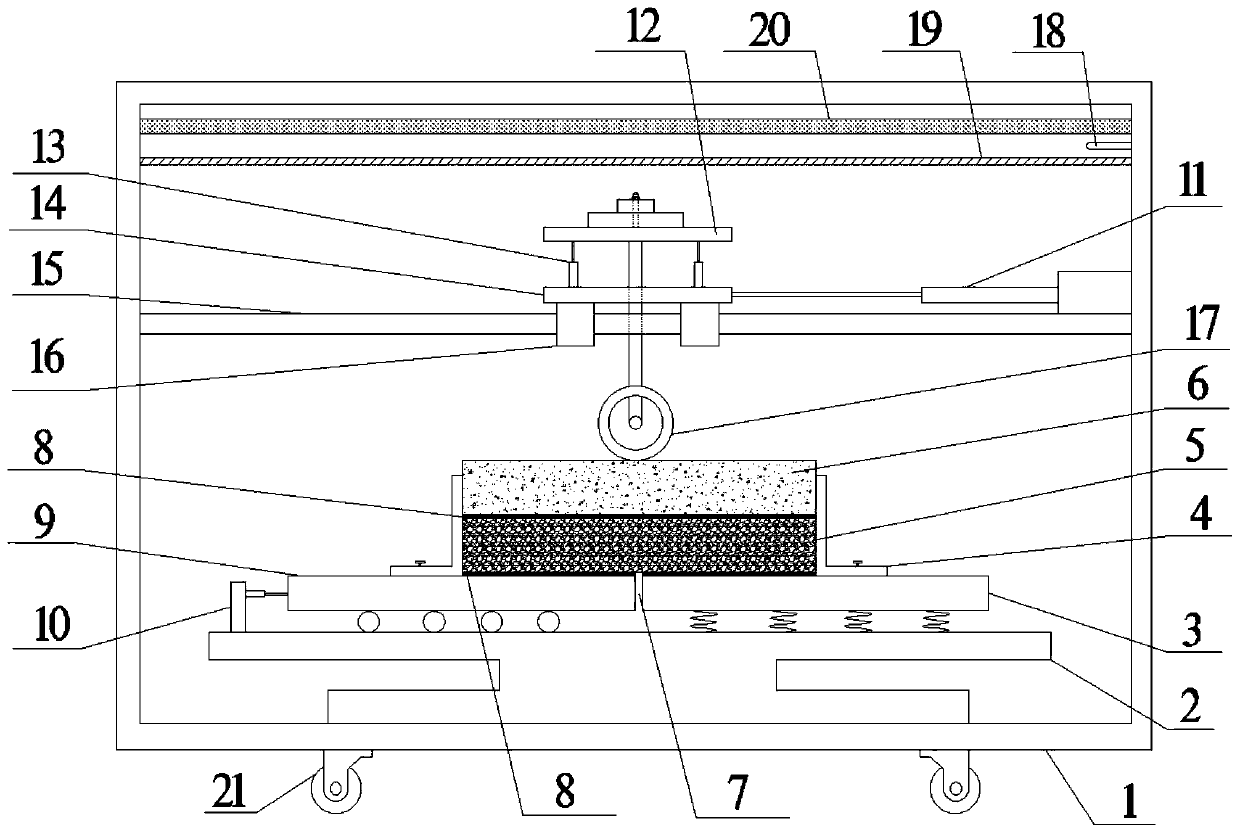

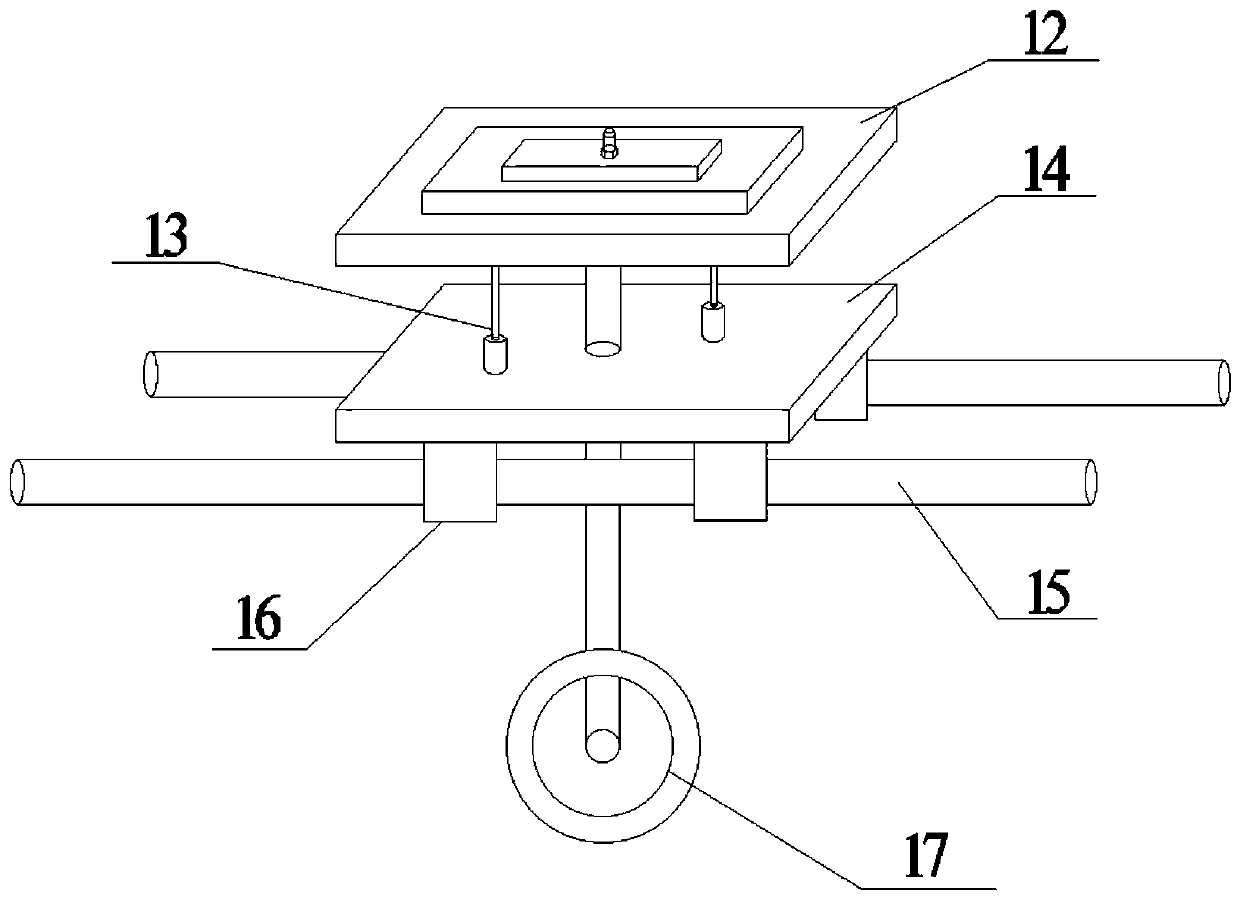

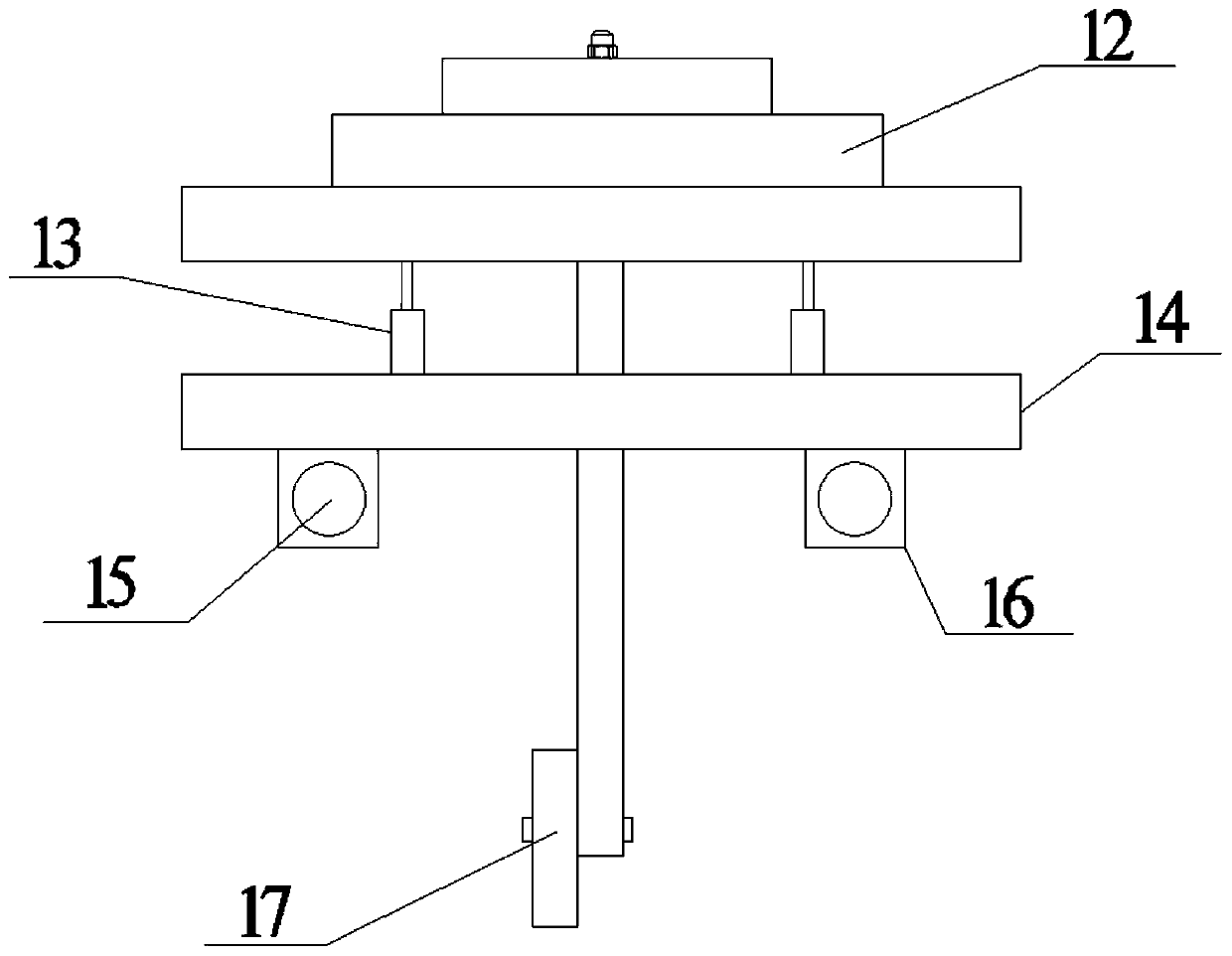

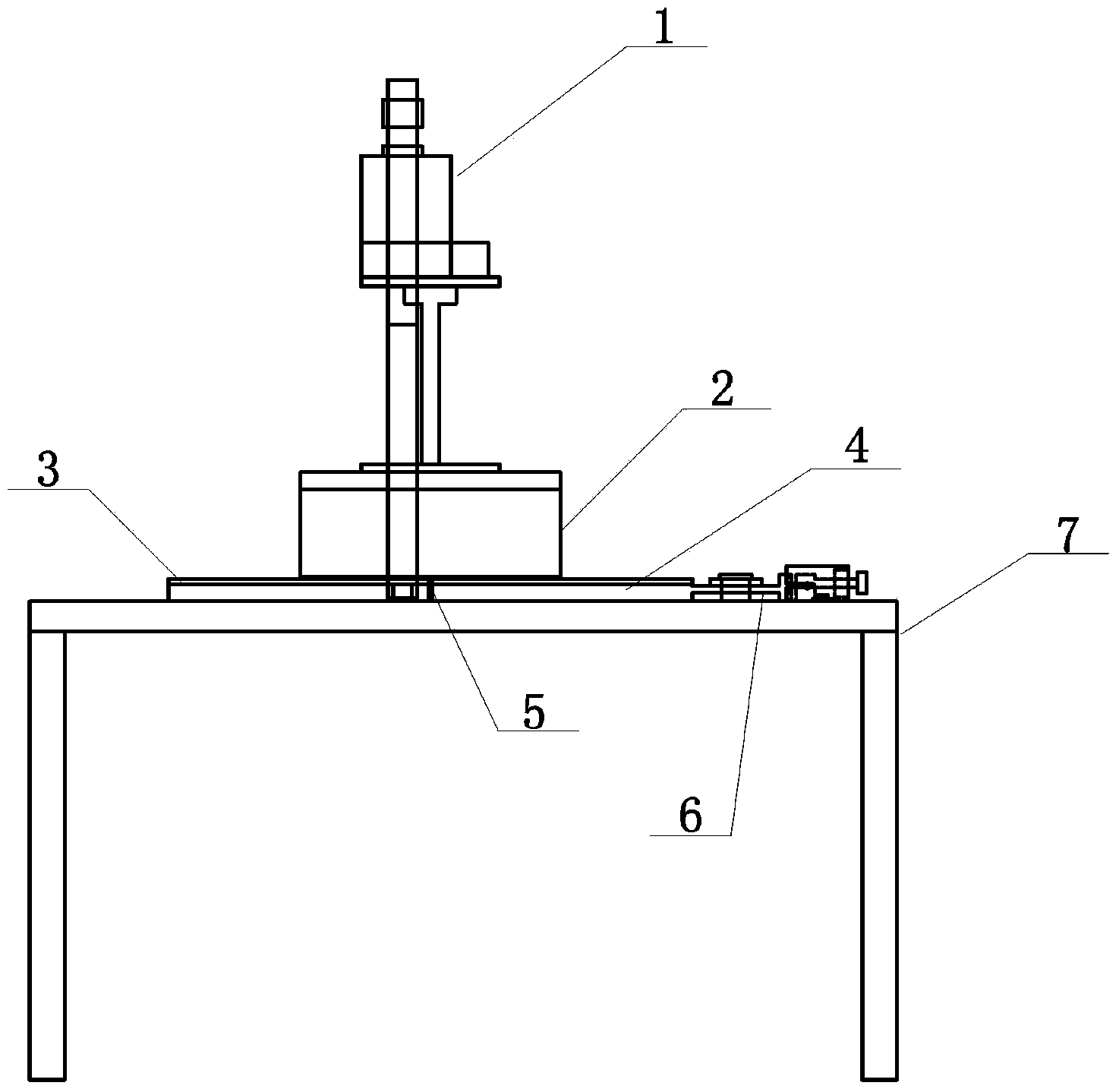

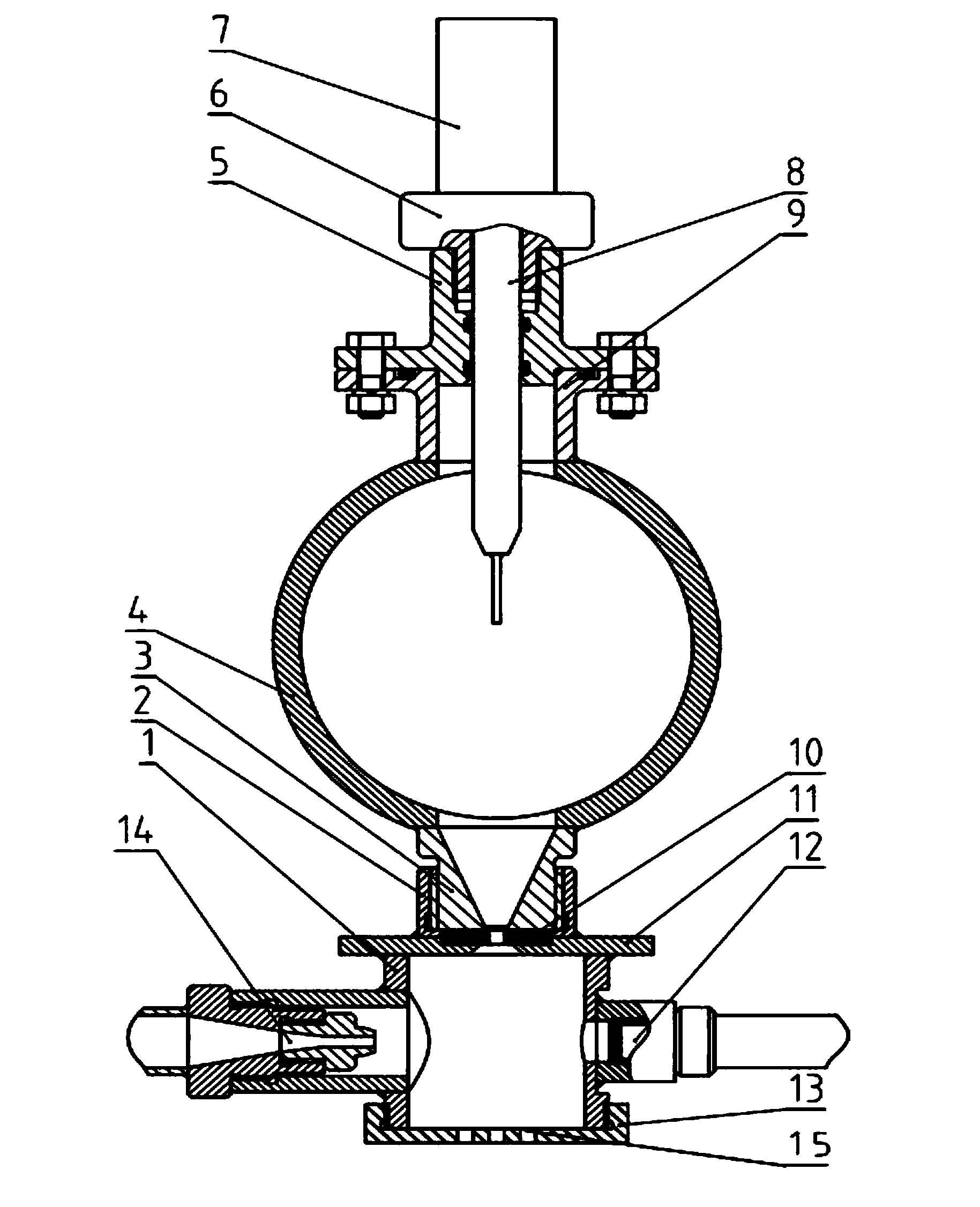

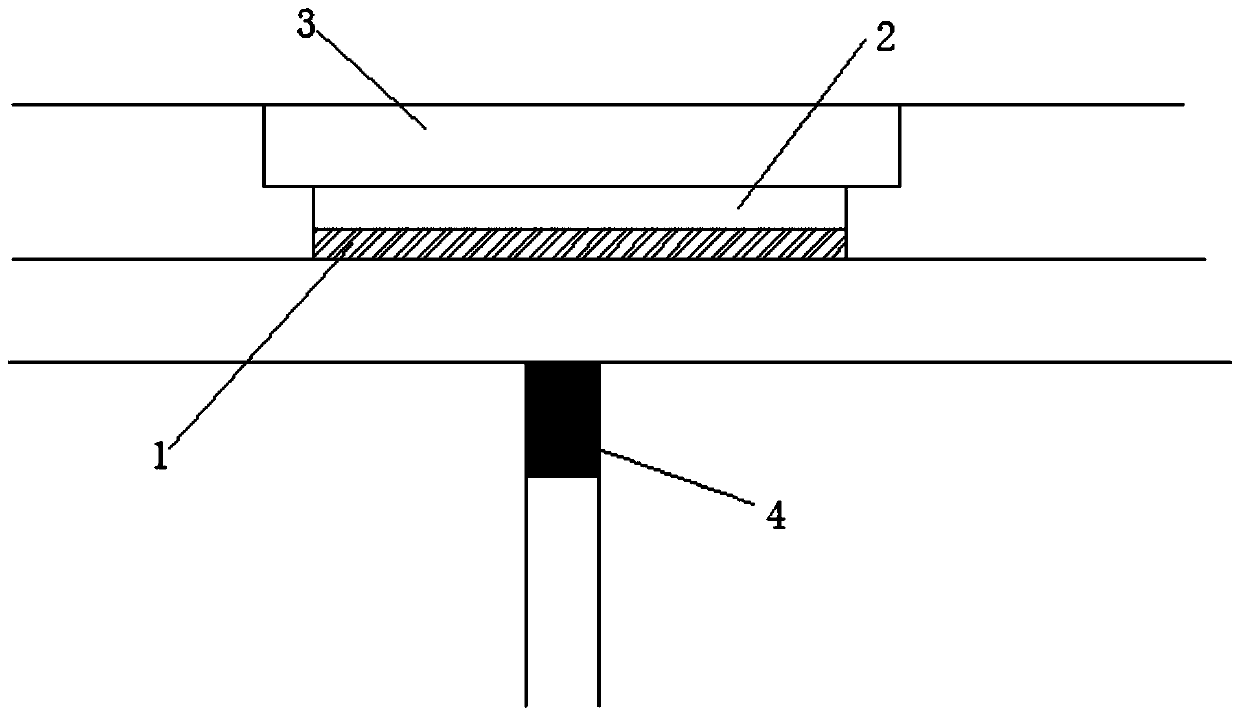

Asphalt pavement reflection crack propagation simulation test device provided with middle layer

PendingCN111579400AReduce reflective cracksExtended service lifeMaterial strength using repeated/pulsating forcesRoad surfaceReflective crack

The invention discloses an asphalt pavement reflection crack propagation simulation test device provided with a middle layer. The asphalt pavement reflection crack propagation simulation test device comprises a case, an asphalt pavement simulation platform, a wheel load device and a temperature adjusting device. The asphalt pavement simulation platform comprises a base, a movable plate and a settlement plate are installed on the base, and a horizontal power device is installed on the movable plate. The wheel load device comprises a test wheel, a sliding device, a sliding rod, a connecting platform, a test wheel telescopic device, a loading test block and the like. The wheel load device is connected with the wheel load power device. According to the invention, a temperature type (open type)reflection crack is simulated in the horizontal direction; a load type (shearing type) reflection crack is simulated in the vertical direction; generation and expansion of actual reflection cracks ofthe semi-rigid base asphalt pavement are truly and closely simulated, the anti-cracking effects of different asphalt pavement intermediate layer materials are analyzed and compared, the types of theintermediate layer materials are reasonably selected, and the method has important significance in delaying the reflection cracks of the asphalt pavement and prolonging the service life of the pavement.

Owner:POWERCHINA CHENGDU ENG

Emulsified bitumen concrete steady porcelain granule road surface base layer material and road surface base layer construction method thereof

InactiveCN101349037AReduce ruttingReduce reflective cracksIn situ pavingsCrushed stoneExpanded clay aggregate

The invention discloses an emulsified asphalt-cement stabilized porcelain granule base course material which eliminates waste and has good performance. Porcelain granules are utilized to substitute broken stones to prepare the base course material, the base course material mainly comprises cement, emulsified asphalt, the porcelain granules, stone chips and water, and further the porcelain granules are sintered porcelain granules produced by pelleting and roasting the waste. The base course material reduces rigidity, contributes to the reduction of ruts and reflective cracks on a road surface, improves the structural performance of the road surface, and has good impermeability, antifreezing performance and durability as well as convenient construction. The invention also provides a construction method for the emulsified asphalt-cement stabilized porcelain granule base course.

Owner:CHONGQING UNIV

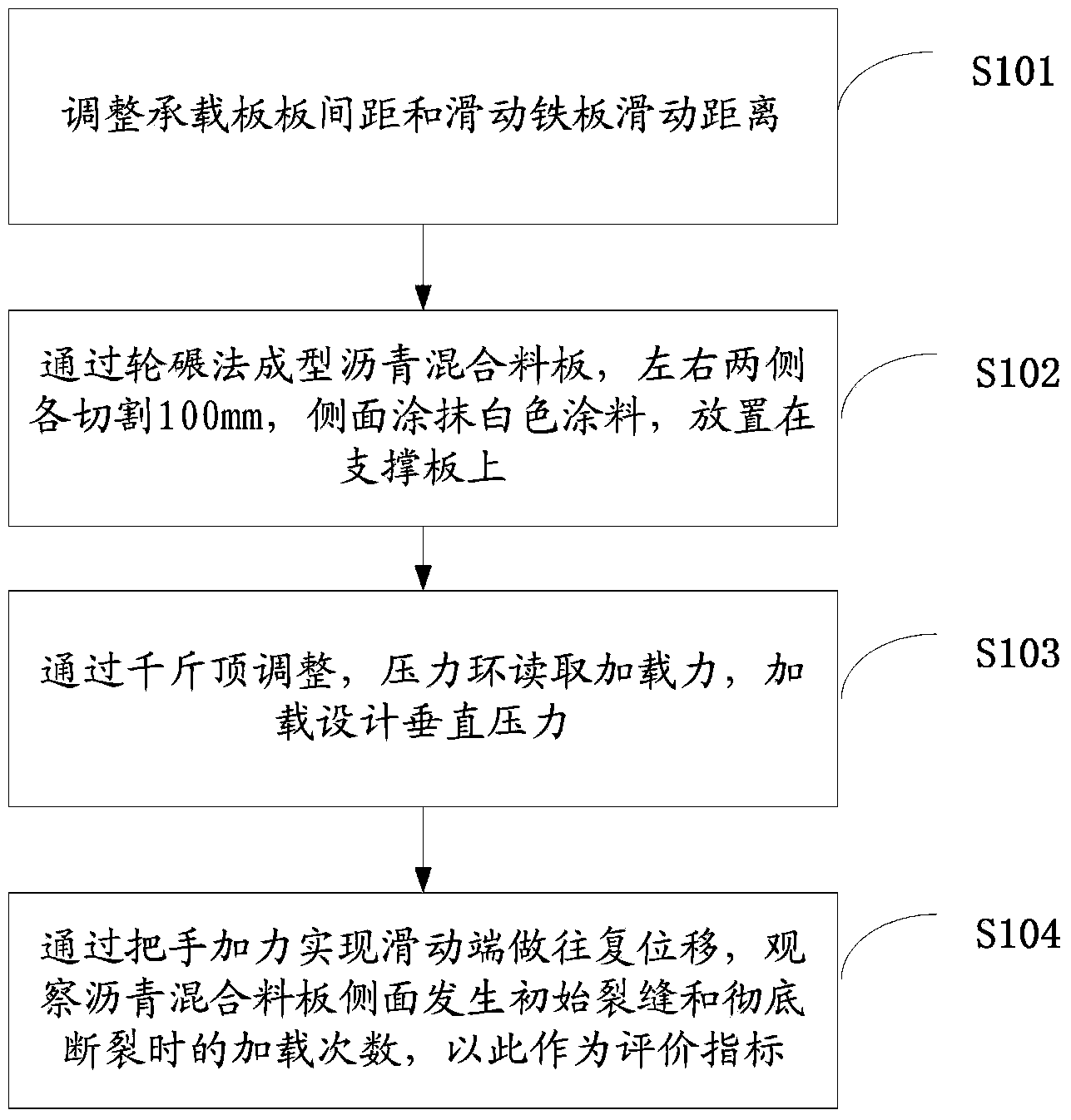

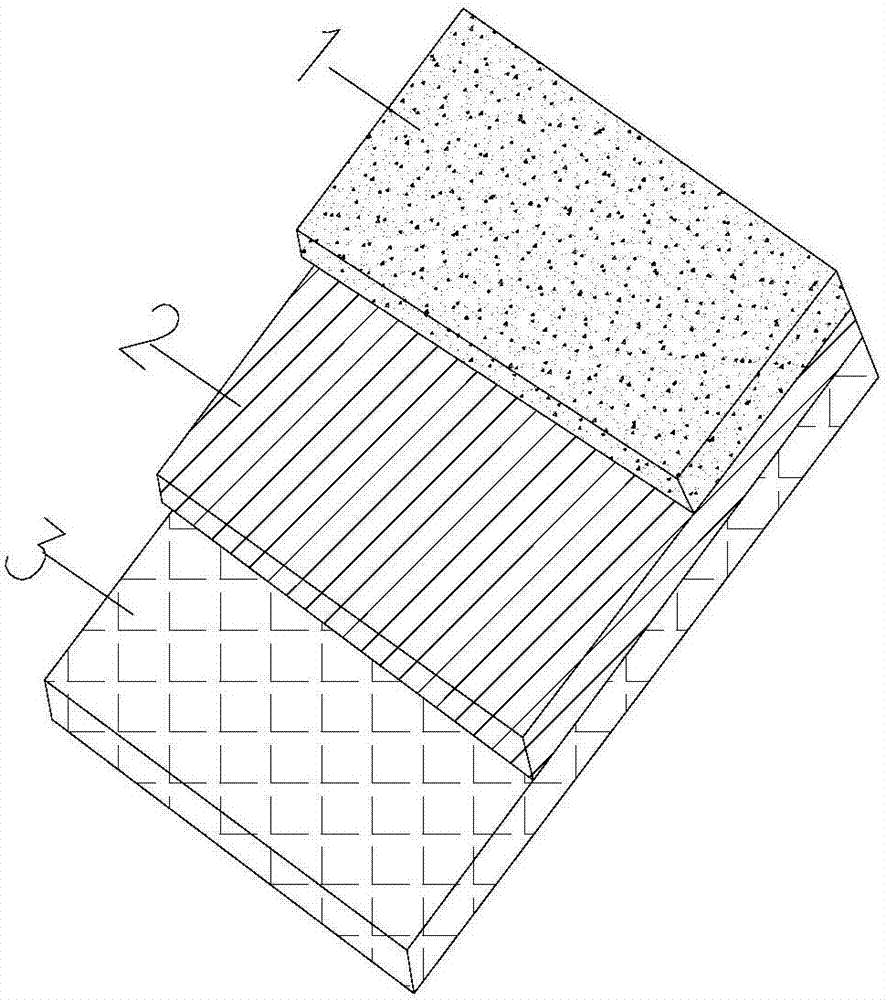

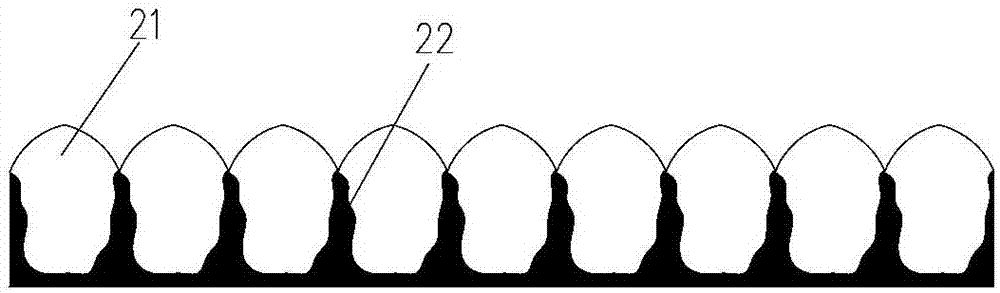

Evaluation device and method for reflection crack resistance of asphalt mixture

InactiveCN103969138AReduce reflective cracksExtended service lifeMaterial strength using repeated/pulsating forcesCrack resistanceEngineering

The invention discloses an evaluation device and method for reflection crack resistance of an asphalt mixture. The evaluation device comprises a vertical loading device, a fixed plate, a sliding plate, a horizontal sliding device and a workbench; the fixed plate and the sliding plate are mounted on the workbench; the horizontal sliding device is mounted on the workbench and connected to the sliding plate; the vertical loading device is vertically mounted on the workbench and is positioned above a bearing plate; a test piece is placed on the fixed plate and the sliding plate, and below the vertical loading device. Through the adoption of the evaluation device and method, the number of reflection cracks in an asphalt pavement is reduced, the service life of the asphalt pavement is prolonged, and the evaluation device and method are of great significance.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Interlayer structure construction method of asphalt pavement

The invention discloses an interlayer structure construction method of an asphalt pavement. The interlayer structure construction method includes the following steps of cleaning an under bearing layer of the pavement; sprinkling rubber asphalt; sprinkling rubbles; and rolling into the shape. The interlayer structure construction method of the asphalt pavement has the advantages of being high in bonding strength between layers, good in water tightness, excellent in anti-shearing performance, deferring reflection cracks, convenient to construct, low in comprehensive cost and the like. By adoption of the interlayer structure construction method of the asphalt pavement, construction work can be done without closing to traffic or closing to traffic for a short term, therefore, the interlayer structure construction method of the asphalt pavement can not only be suitable for a bonding layer between asphalt surfaces of newly-built roads, but also particularly suitable for repairing and maintaining projects for asphalt surfaces of urban roads.

Owner:北京特希达交通勘察设计院有限公司

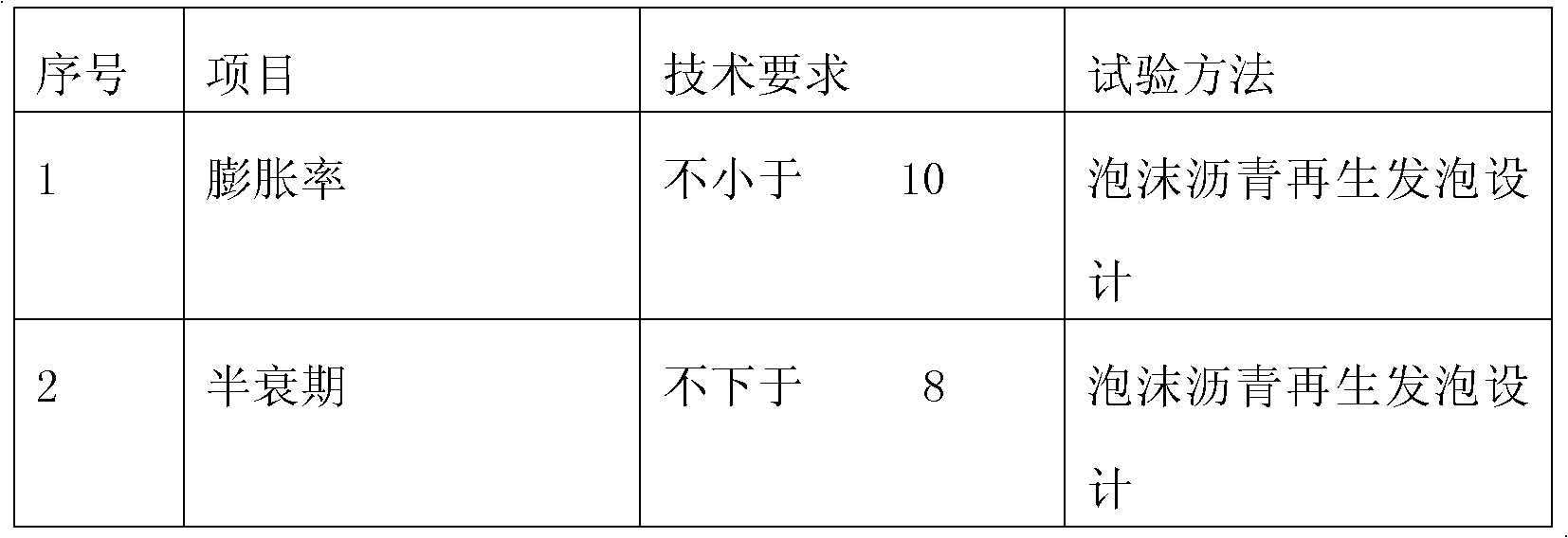

Efficient foamed asphalt foaming device

The invention discloses a foamed asphalt foaming device, belonging to the technical field of road construction equipment. The foaming device is structurally composed of an asphalt pipe, an asphalt spraying switch, a foaming cavity, a water atomization nozzle and a compressed air nozzle, wherein the asphalt spraying switch is driven by an air cylinder, the tail part of a piston rod of the air cylinder is of a needle-like structure, is matched with an asphalt spraying inlet, and has a self-cleaning effect; the center of an asphalt pore plate at the upper end of the foaming cavity is provided with the asphalt spraying inlet, the center of a bearing plate at the lower end of the foaming cavity is provided with an asphalt spraying outlet which is designed in a porous mode, and the asphalt pore plate and the bearing plate can be replaced so as to adjust the spraying pressure and flow rate of asphalt. The device is applicable to the forming of various types of asphalt, and has a self-cleaning effect to eliminate jams; due to the porous design of the asphalt spraying outlet, the half-life period and expansion rate of foamed asphalt are increased, and the quality of asphalt foaming is improved. The device is suitable for industrial production and experimental investigations and has the characteristics of flexibility, simplicity in manufacturing, high practicability, low cost, and the like.

Owner:TONGJI UNIV

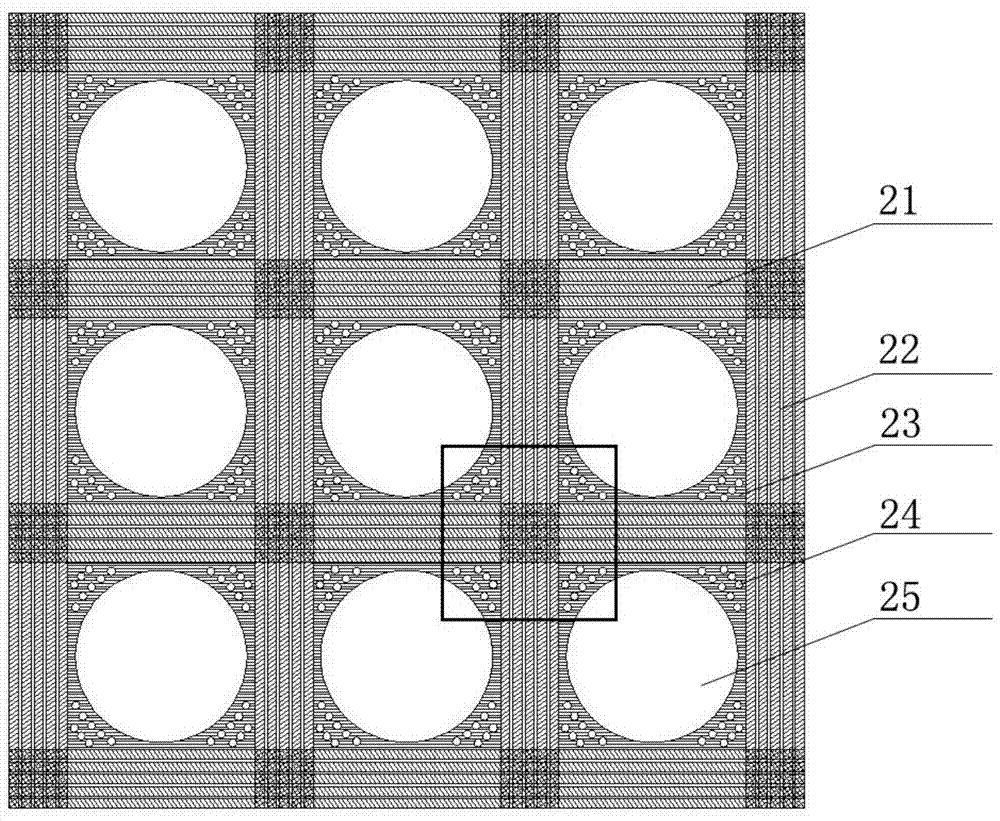

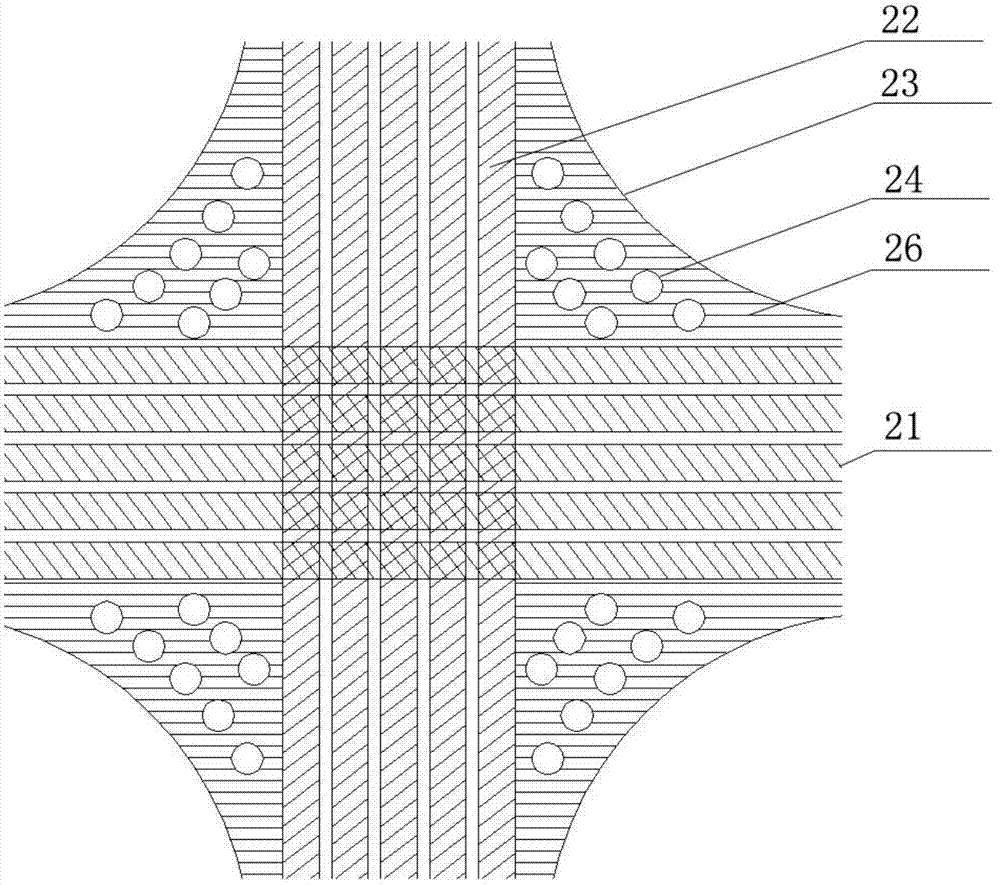

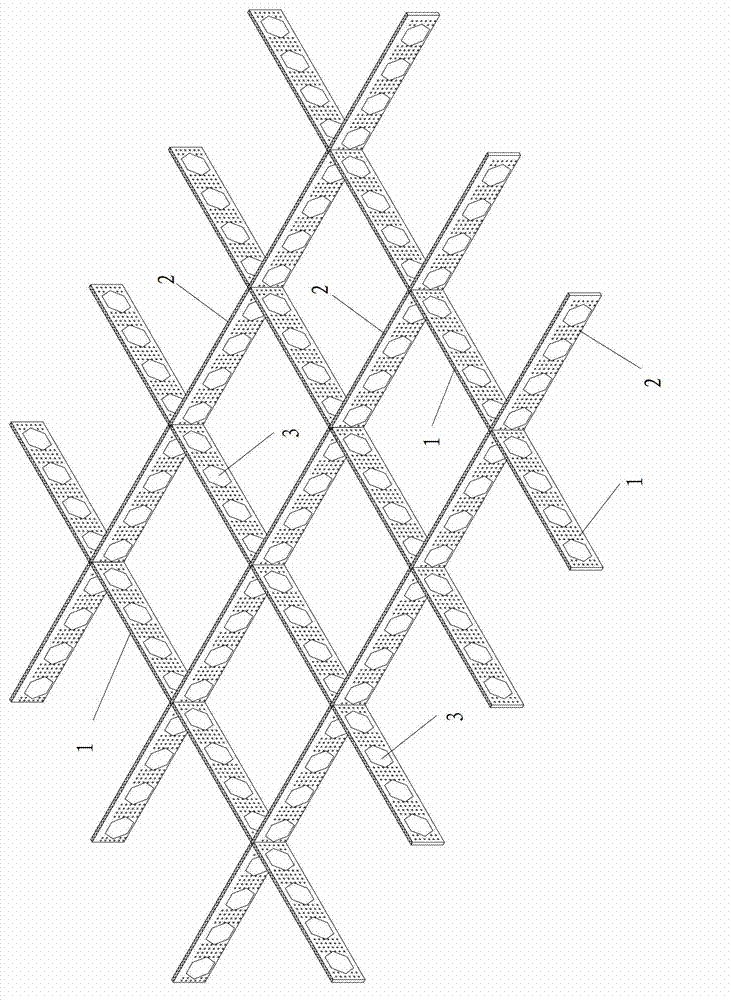

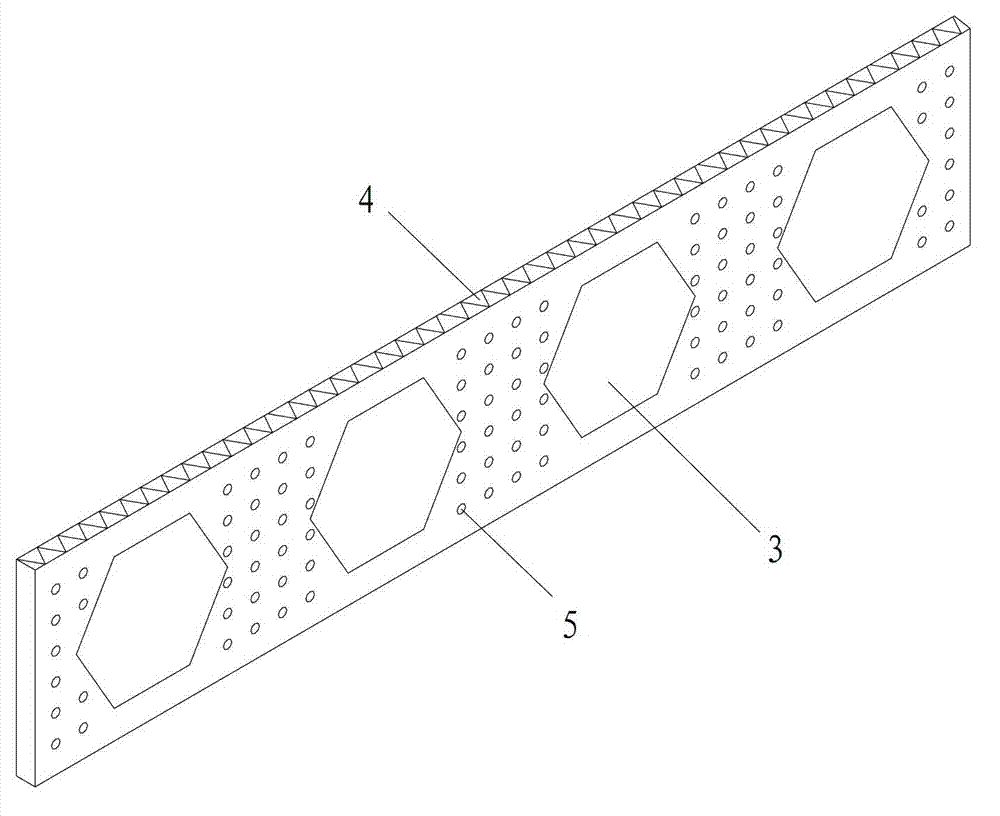

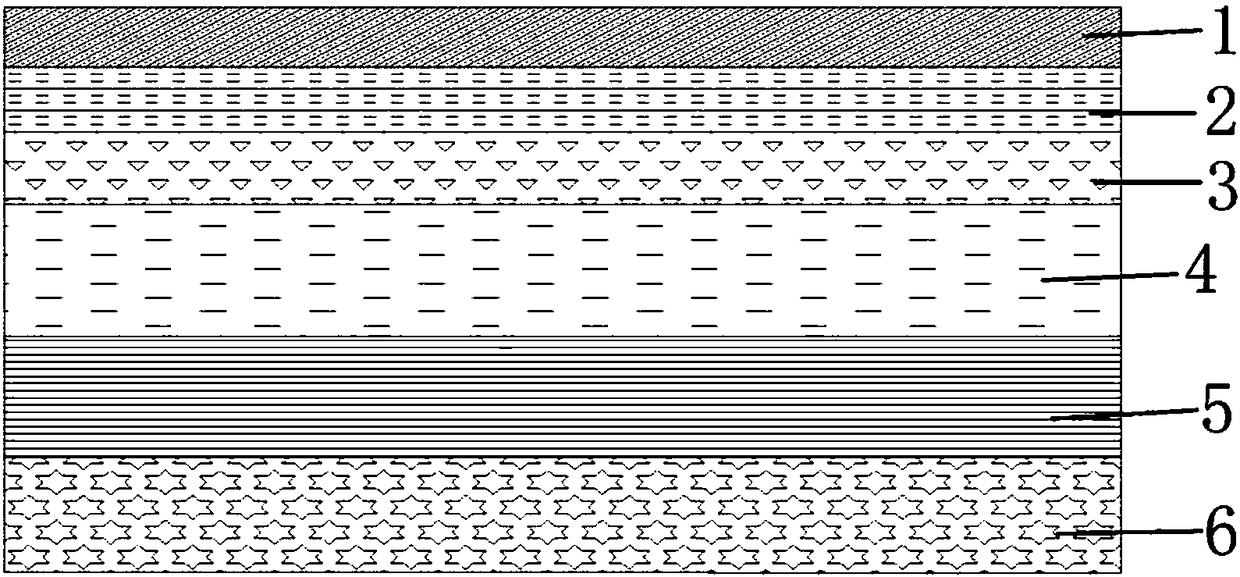

Ultrathin composite structure layer for preventing reflection cracks and preparation method of ultrathin composite structure layer

ActiveCN104499399AHigh tensile strengthEnhanced resistance to peelingIn situ pavingsEpoxyLower grade

The invention discloses an ultrathin composite structure layer for preventing reflection cracks and a preparation method of the ultrathin composite structure layer. The ultrathin composite structure layer comprises an anti-sliding high-strength geogrid layer, a lower toughening type epoxy asphalt layer, a lower graded macadam layer, an upper reinforced type epoxy asphalt layer and an upper graded macadam layer which are arranged on a cement pavement from bottom to top in sequence. The composite structure layer disclosed by the invention is a complex and solid interlocking system which is excellent in anti-pull, anti-shearing, adhesive and waterproof property, has very good tensile, anti-shearing and stress absorption functions when strain is relatively small, is capable of effectively reducing reflection cracks of an additionally paved asphalt concrete layer on the cement pavement and effectively reducing the self-weight, and is relatively low in thickness, good in stability, high in anti-sliding property and relatively long in service life, the preparation method of the composite structure layer is high in mechanical degree and high in feasibility, and the additionally paved asphalt concrete layer can be directly constructed on the prepared ultrathin composite structure layer.

Owner:SOUTHEAST UNIV

Factory-prefabricated self-adhesive pavement sticker and preparation and construction method thereof

InactiveCN109056453AReduce driving noiseHigh breaking strengthPaving detailsHighway maintenanceReflective crack

The invention discloses a factory-prefabricated self-adhesive pavement sticker, a preparation method and a construction method, belonging to the technical field of highway maintenance. The invention comprises an isolation paper layer, a self-adhesive adhesive layer, an anti-cracking cloth layer, a lower binder layer, an aggregate layer and an upper binder layer. 15 DEG C pull-out test>= 0. 5MPa;The binder completely covers the aggregate and forms a continuous bonding material layer to ensure that the water permeability coefficient is 0; Multi-texture surface structure and surface protectivefilm ensure the anti-slip coefficient BPN >= 55 and the driving noise is low; The longitudinal and transverse fracture strength is high, and the reflection crack is delayed. The pavement sticker of the invention is directly applied to the tortoise-shaped cracks of the local pavement network which needs to be repaired or the whole pavement is corrected and pre-cured, is convenient to use, can quickly open the traffic, has long service life, and has remarkable social and economic benefits.

Owner:SHANDONG DASHAN ROAD & BRIDGE ENG

Large-particle-size asphalt concrete construction process

ActiveCN113235349AImprove high temperature stabilityFast constructionIn situ pavingsSolid waste managementArchitectural engineeringEconomic benefits

A large-particle-size asphalt concrete construction process comprises the following steps: A, preparing a pavement base layer before construction; B, mixing 75-80 parts by weight of concrete materials composed of aggregate, 30-35 parts by weight of auxiliary materials and 10-15 parts by weight of asphalt; C, paving the asphalt concrete on site; D, compacting the asphalt concrete to form a large-particle-size asphalt concrete layer; and E, curing the pavement. According to the construction process, the engineering construction speed is increased, the equipment investment is reduced, the traffic closing time can be greatly shortened in an overhaul and reconstruction project, and the social and economic benefits are remarkable. The large-particle-size asphalt concrete pavement paved after construction can resist large plasticity and shear deformation and bear heavy traffic, has good rut resistance, improves the high-temperature stability of the asphalt pavement, and shows very obvious permanent deformation resistance compared with the traditional asphalt concrete.

Owner:河南中交路通工程监理咨询有限公司

Asphalt pavement structure for urban tunnel deformation seam and paving method thereof

InactiveCN110284390AImprove waterproof performanceImprove adhesionIn situ pavingsRoads maintainenceSurface layerRoad surface

The invention discloses an asphalt pavement structure for an urban tunnel deformation seam and a paving method thereof. The asphalt pavement structure for the deformation seam comprises a stress absorbing layer, an upper asphalt concrete surface layer and an upper asphalt concrete surface layer which are arranged from bottom to top, wherein the stress absorbing layer is manufactured through normal-temperature thermoset modified asphalt adhering material; and the upper asphalt concrete surface layer and the lower asphalt concrete surface layer are paved through normal-temperature type thermoset modified asphalt mixtures of different formulas. With the adoption of the deformation seam pavement paving structure, the reflection crack resisting performance and the flexibility of the deformation seam pavement structure are obviously improved, the water sealing performance of paving is ensured, the normal-temperature construction of an asphalt pavement is achieved, and the construction energy is extremely reduced; and reliable basis is supplied to rapid repairing of the tunnel deformation seam asphalt pavement.

Owner:南京城建隧桥智慧管理有限公司

Old concrete pavement widening transformation method

InactiveCN110965415AEnhanced connectivityGuarantee the overall forcePaving reinforcementsStructural engineeringArchitectural engineering

The invention discloses an old concrete pavement widening transformation method which comprises the following steps: step 1, construction preparation: widening pavement foundation treatment; step 2, excavating a sleeper beam groove of an old pavement, and pouring concrete on a sleeper beam and a lower layer of a broadened pavement; step 3, horizontally planting steel bars on the old pavement, andpouring concrete on the upper layer of the widened pavement; step 4, optimizing construction; wherein a sleeper beam groove in a second step is located under an old road surface, the sleeper beam groove and lower-layer concrete of the broadened road surface are integrally poured when sleeper beam concrete is poured, and the upper surface of upper-layer concrete of the broadened road surface is flush with the upper surface of the old road surface. Concrete sleeper beams are poured below a pavement structure layer of a longitudinal connection part of a new road and an old road and are combined with longitudinal side edge embedded steel bars of the old road. Compared with a traditional step excavation method, the method has the advantages that the connectivity of the widened base layer and the old road is improved, the overall stress of the reconstructed and expanded road surface is ensured, and the differential settlement of the road surface is reduced.

Owner:福建誉洲建设有限公司

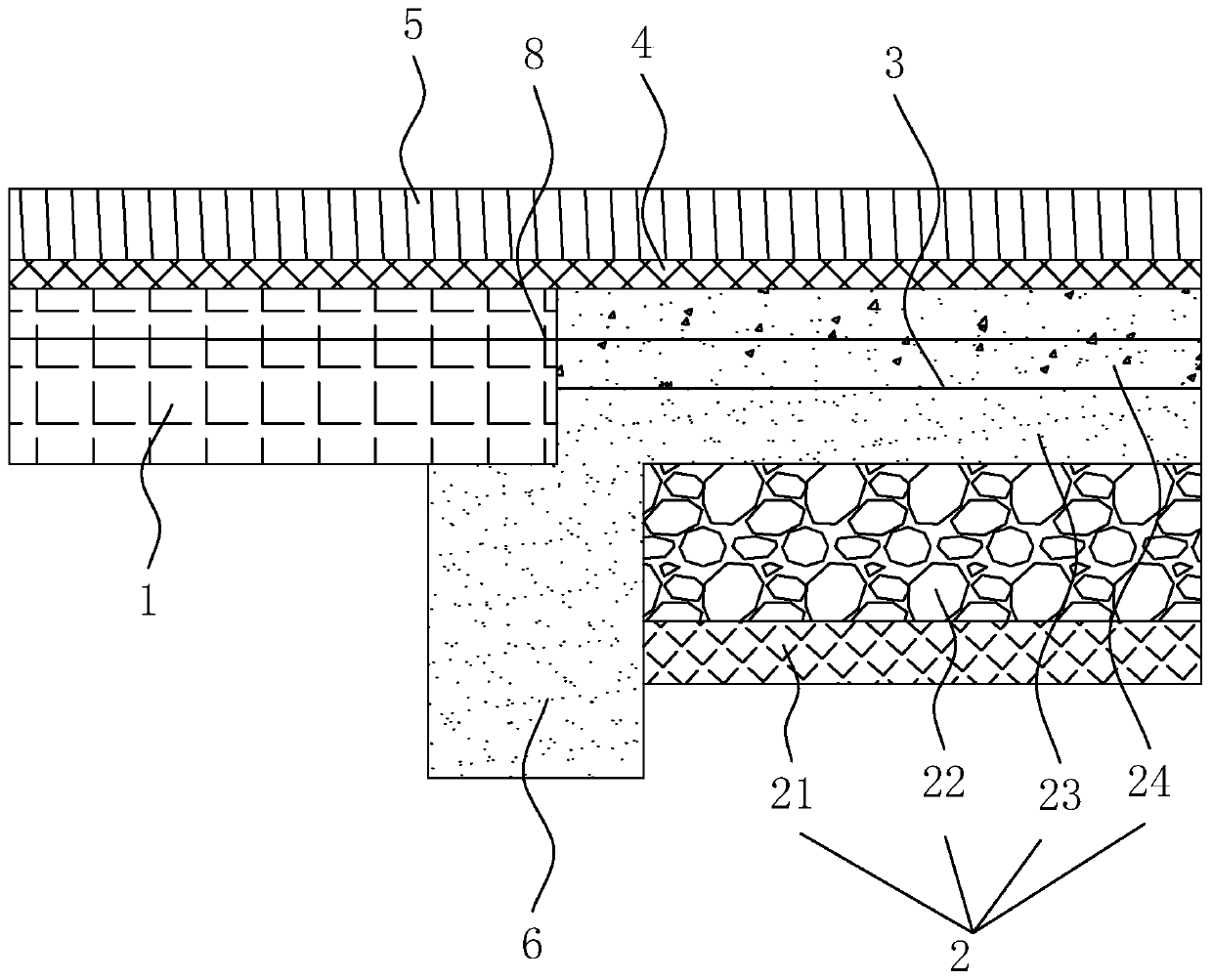

Multifunctional three-dimensional grid for asphalt mixture

The invention discloses a multifunctional three-dimensional grid for an asphalt mixture. The multifunctional three-dimensional grid is formed by splicing a plurality of three-dimensional grid units arranged on the same plane; the three-dimensional grid units are square grids; each square grid comprises a plurality of transverse support plates arranged in parallel and a plurality of longitudinal straight plates arranged in parallel; the transverse support plates and the longitudinal straight plates are vertically arranged and are arranged on the same plane; the height of each transverse plate is the same as that of each longitudinal straight plate; the plurality of longitudinal straight plates are arranged on the plurality of transverse support plates from left to right; each of the longitudinal straight plates is fixedly connected with the plurality of transverse support plates respectively; one or more rows of through holes are formed in the transverse support plates and the longitudinal straight plates; and each row of through holes comprises a plurality of through holes from front to back. The multifunctional three-dimensional grid has a simple structure, and is reasonable in design, relatively low in input cost, good in application effect, and convenient to construct, wherein the bearing capacity, the high-temperature stability and the integrity of asphalt roads can be effectively improved.

Owner:CHANGAN UNIV

Road pavement maintenance construction method

The invention discloses a road pavement maintenance construction method. The method includes the following steps that (1) a pavement is checked by a constructor, and damaged places and the damage condition of the pavement are recorded; (2) the damaged pavement is milled and planed to form milled and planed grooves, surrounding loose footstones are shoveled away, the depth of each milled and planedgroove ranges from 15 mm to 22 mm, and then the milled and planed grooves are cleaned; (3) the damaged places of the pavement are heated to 180 DEG C to 200 DEG C through microwaves, moisture and airin cracks in the milled and planed grooves overflow, and the pavement is fully dried through a steam pressure pump; (4) the cracks in the milled and planed grooves are plugged through needle-injectedsealant; (5) the surfaces of the milled and planed grooves are paved with bituminous concrete at a constant speed, the pavement is leveled and compacted in a vibrating compacting or static pressure compacting mode, and therefore the first-layer pavement is obtained. The road pavement maintenance construction method has the beneficial effects of being short in maintenance construction time, good in pavement anti-seepage performance, high in pavement levelness and the like.

Owner:ANHUI XINRUI HEAVY IND

Pavement structure of rubber powder modified cement stabilized macadam mixture base course and proposing method of pavement structure

PendingCN108316085AImprove structural performanceEasy to makeIn situ pavingsSurface layerPolymer science

The invention relates to a pavement structure of a rubber powder modified cement stabilized macadam mixture base course. The pavement structure comprises a bituminous concrete pavement surface layer,a cement stabilized macadam mixture base course, a graded broken stone subbase and a rubber powder modified cement stabilized macadam mixture base course, wherein the thickness of the rubber powder cement stabilized macadam mixture base course is 20 to 22cm, and the modulus of the rubber powder cement stabilized macadam mixture base course is 800 to 1000MPa; the thickness of the cement stabilizedmacadam mixture base course is 18 to 20cm, the modulus of the cement stabilized macadam mixture base course is 1300 to 2000MPa, and the thickness of the bituminous concrete pavement surface layer is 12 to 25cm. The pavement structure of the rubber powder modified cement stabilized macadam mixture base course, disclosed by the invention, has positive social and economic significance for delaying the appearance of pavement reflective cracks under heavy load traffic and prolonging the service life of the pavement.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Asphalt road

InactiveCN106223150AImprove flatnessTightness of compactionIn situ pavingsTemporary pavingsLow voltageSlag

The invention discloses an asphalt road, and belongs to the field of roads. The asphalt road comprises a roadbed, a subgrade and a road surface. The subgrade is arranged in the roadbed and is provided with a horizontal layered structure. The subgrade is provided with a first mixed slag layer, a rubble layer, a second mixed slag layer and a concrete layer from bottom to top, and a geogrid and low-voltage shielded wires are arranged in the second mixed slag layer. A plurality of solar photovoltaic modules are arranged in the middle of the road surface in the road extension direction, and the solar photovoltaic modules are connected with a photovoltaic inverter through the low-voltage shielded wires. The asphalt road has the characteristics of being high in flatness, capable of avoiding the circumstances of insufficient partial compaction degrees, serious temperature segregation and the like, good in road surface temperature sensing property, good in elasticity and ageing-resistant performance, not prone to melting or flowing at high temperatures, good in toughness and not likely to be cracked at low temperatures, capable of meeting the using requirements of high-grade roads, and capable of fully utilizing high temperatures of the road surface to conduct solar power generation.

Owner:江西省地质工程集团有限公司

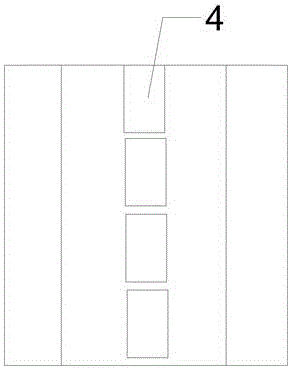

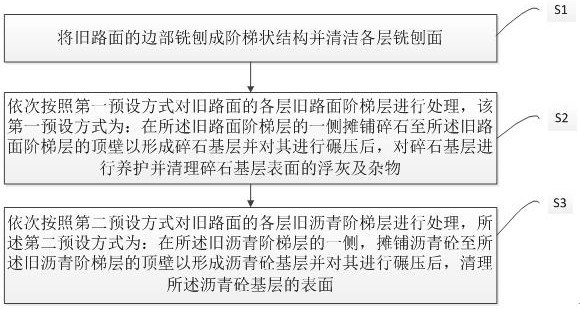

Municipal road reconstruction engineering asphalt pavement lap joint construction method and lap joint structure

InactiveCN111778802AIncrease widthImprove overall throughputIn situ pavingsLap jointReflective crack

The invention provides a municipal road reconstruction engineering asphalt pavement lap joint construction method and a lap joint structure. The lap joint construction method comprises the following steps that the edge of an old road surface is milled into a stepped structure, and all layers of milled surfaces are cleaned; all old pavement step layers of the old pavement are sequentially treated according to a first preset mode, and the first preset mode comprises the steps that gravels are laid on one sides of the old pavement step layers to form gravel base layers, after the gravel base layers are rolled, the gravel base layers are maintained, and floating ash and impurities on the surfaces of the gravel base layers are removed; the old asphalt step layers of the current asphalt pavementare sequentially treated according to a second preset mode, and the second preset mode comprises the steps that asphalt concrete is laid on one sides of the old asphalt step layers to form an asphaltconcrete base layer, the asphalt concrete base layer is rolled, and then the surface of the asphalt concrete base layer is cleaned. According to the invention, the new and old asphalt pavement structures are combined and broadened, so that differential settlement and reflection cracks at the joint of the new and old asphalt pavement structures are reduced.

Owner:CHINA MCC20 GRP CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com