Asphalt pavement reflection crack propagation simulation test device provided with middle layer

A technology of asphalt pavement and reflective cracks, which is applied in the direction of measuring devices, using repeated force/pulsation force to test the strength of materials, instruments, etc., can solve the problems of unstable test data, long test period, and many test consumables, and achieve test data Real and reliable, easy to operate and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

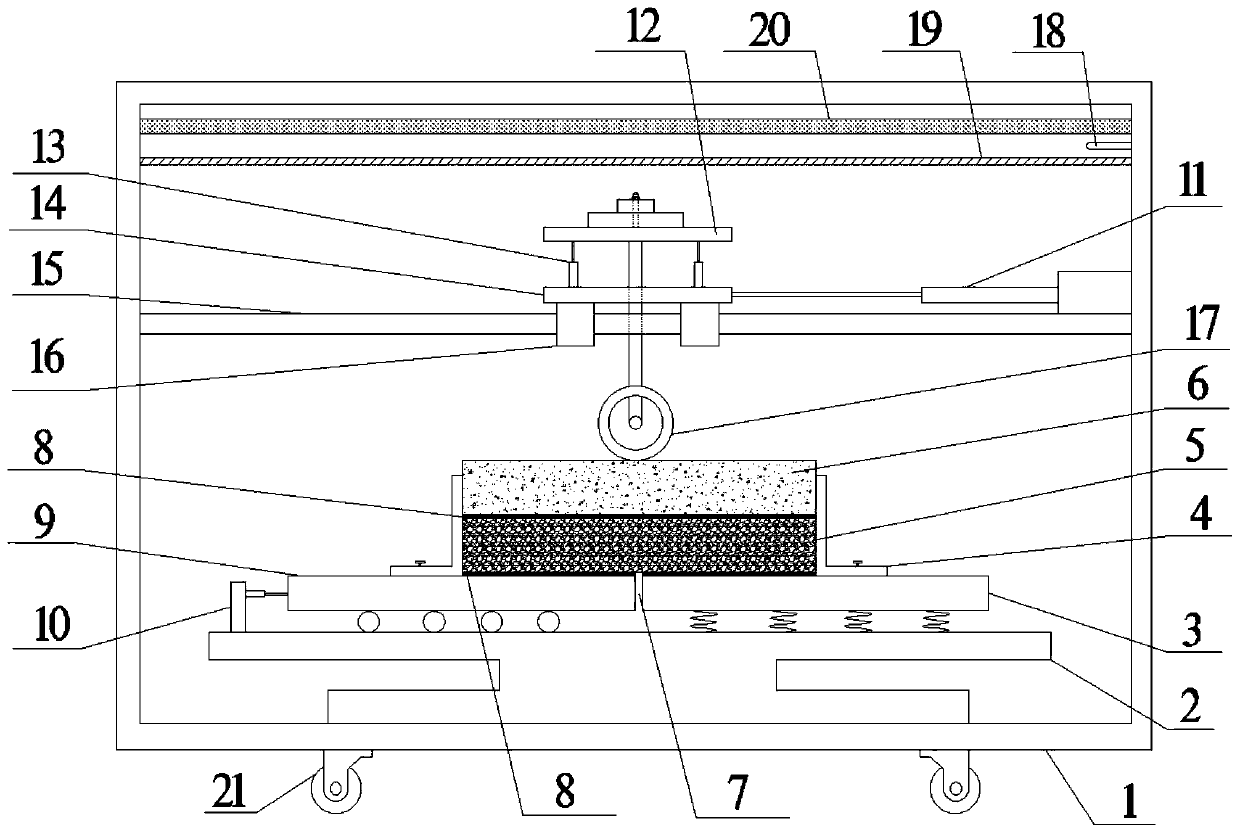

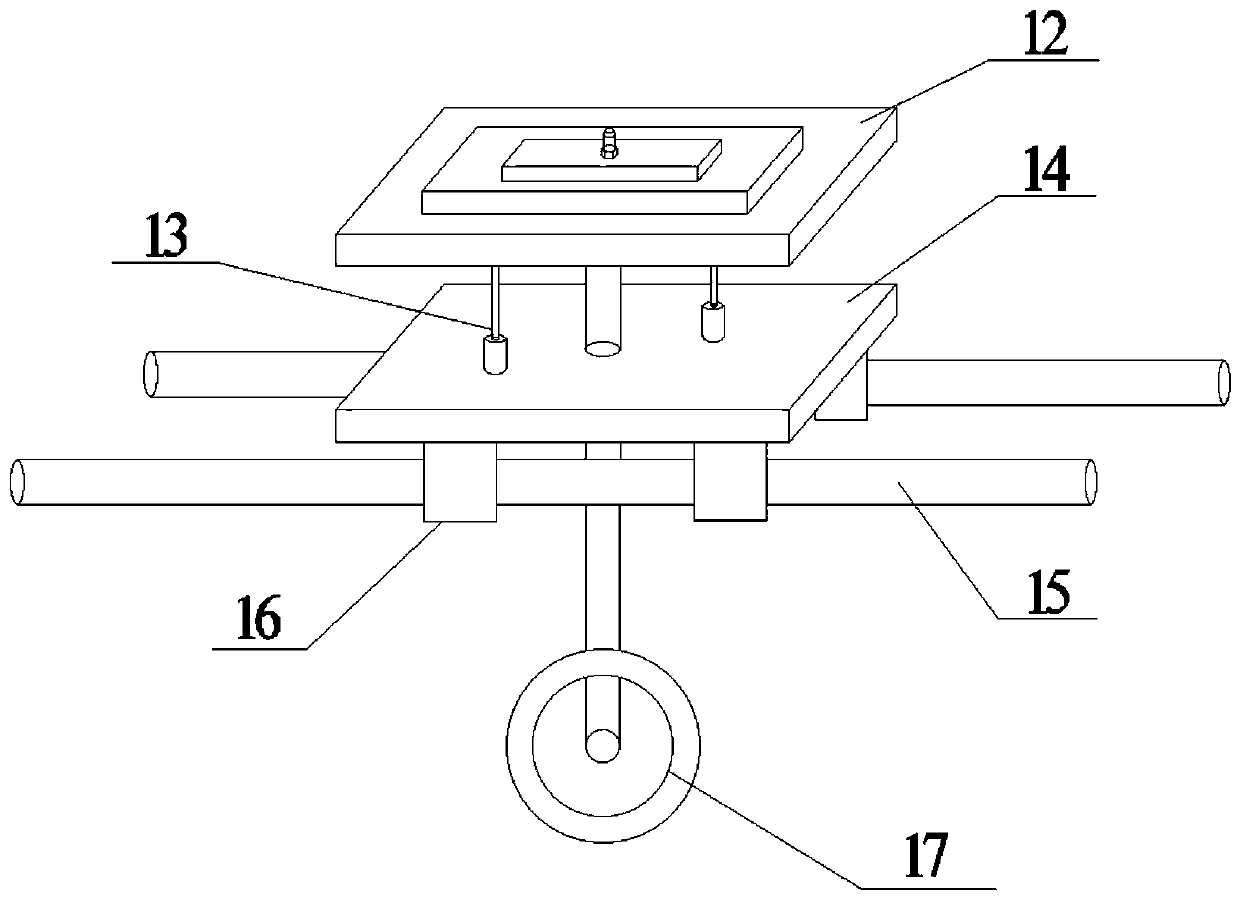

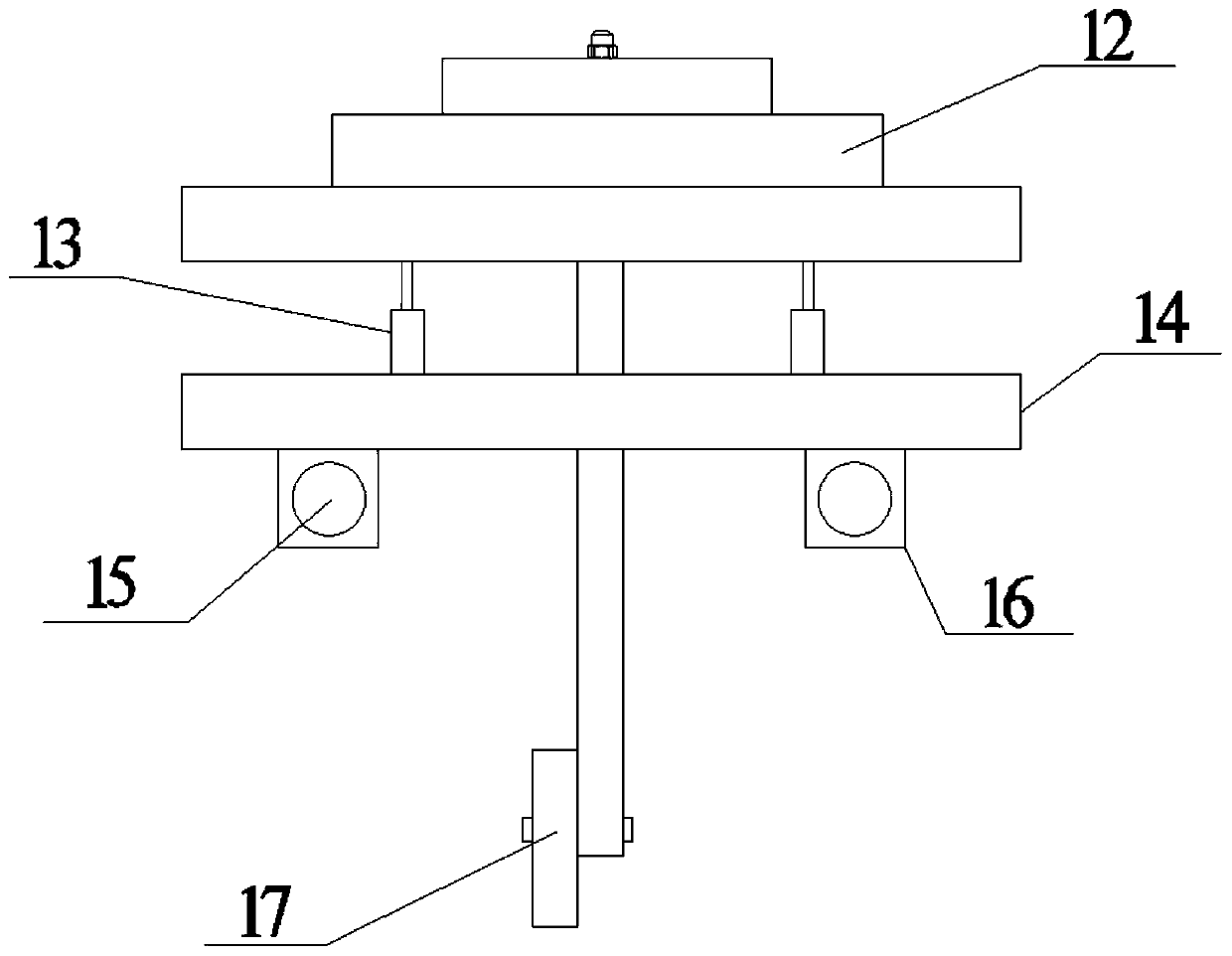

[0034] The present embodiment 1 is a kind of asphalt pavement reflective crack propagation simulation test device for setting the middle layer and setting the middle layer, such as figure 1 , figure 2 and image 3 As shown, it specifically includes an external chassis 1, an asphalt road simulation platform, a wheel-mounted device, and a temperature regulating device. The asphalt pavement simulation platform includes a base 2 connected to the bottom of the cabinet, on which a moving plate 9 and a settling plate 3 are installed, and a horizontal power device 10 is mounted on the moving plate. The wheel-mounted device comprises a rubber test wheel 17, a sliding device 16, a slide bar 15, a connection platform 14, a test wheel telescopic device 13, a loading test block 12, etc., on which a wheel-borne power unit 11 is connected. This device can not only simulate the temperature-type opening type reflection cracks from the horizontal direction, but also simulate the load-type sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com