Asphalt road

A kind of asphalt and road technology, applied in the direction of roads, roads, buildings, etc., can solve the problems that the rolling construction cannot be guaranteed, the construction quality is difficult to ensure, and the local compaction degree is insufficient, so that it is not easy to melt and flow, and the heat storage stability is good. , good anti-rutting and high-temperature cracking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

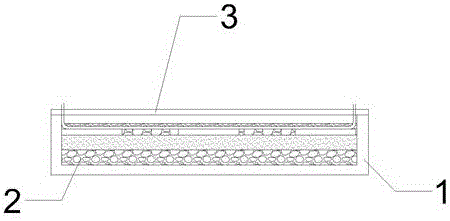

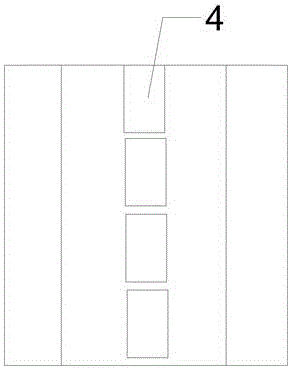

[0032] Such as figure 1 As shown, an asphalt road comprises a roadbed 1, a roadbed 2 and a road surface 3, the roadbed 2 is arranged in the roadbed 1, the roadbed has a horizontal layered structure, and the roadbed is respectively the first mix from bottom to top. A slag layer, a crushed stone layer, a second mixed slag layer and a concrete layer, the second mixed slag layer is provided with a geogrid and a low-voltage shielded wire inside; the middle part of the road surface 3 is provided with a number of solar photovoltaic modules 4 along the road extension direction , the solar photovoltaic module 4 is connected to the photovoltaic inverter through a low-voltage shielded wire. The thickness of the first mixed slag layer is 30cm, the thickness of the gravel layer is 20cm, the thickness of the second mixed slag layer is 8cm, and the thickness of the concrete layer is 25cm. The gravel particle size of the crushed stone layer is not greater than 5cm, the total amount of which ...

Embodiment 2

[0034] A method for laying asphalt roads, comprising the steps of:

[0035] Step 1. Surveying and alignment, including re-measurement of conductors, centerlines, benchmarking points, cross-section inspection and re-measurement. Before the start of construction, carry out construction lofting, and release the subgrade edge, groove, slope toe, side ditch protection slope, borrowing field, etc. The location shall be marked with its outline, and the trees, weeds, shrubs, etc. within the scope of the route land shall be cleared, and the roadbed shall be dug;

[0036]Step 2: fill the subgrade in horizontal layers, divide it into horizontal layers according to the full width of the cross section, and fill it up layer by layer. The first layer is filled with mixed slag with a thickness of 30cm, and the second layer is filled with gravel , the thickness of the filling is 20cm, the third layer is filled with mixed slag, and the thickness of the filling is 8cm; after the filling is compl...

Embodiment 3

[0041] The asphalt mixture consists of 78 parts by mass of modified asphalt, 51 parts of gravel, 24 parts of styrene-butadiene-styrene triblock copolymer, 20 parts of polylactic acid-butylene succinate-polylactic acid triblock Segment copolymer, 8 parts of potassium formate and 11 parts of lignin fibers, the structural formula of the polylactic acid-butylene succinate-polylactic acid triblock copolymer is

[0042] .

[0043] Wherein, the particle size of the crushed stone in the mixture is not greater than 3cm, and the total amount of the particle size less than 0.075mm does not exceed 7% of the total amount, the crushed stone does not contain impurities, and the crushed stone has a strength of not less than 15MP . The modified asphalt is composed of 50 parts by mass of liquefaction residue, 25 parts of crosslinking agent and 82 parts of base asphalt, and the crosslinking agent is benzaldehyde.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com