Factory-prefabricated self-adhesive pavement sticker and preparation and construction method thereof

A factory prefabricated, self-adhesive technology, applied to roads, roads, pavement details, etc., can solve the problems of complex operation of the treatment plan, long time of closed traffic, and inability to corrective pre-maintenance of the entire road surface, achieving significant social benefits and economics Efficiency, long service life, and rapid opening to traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A factory-prefabricated self-adhesive pavement sticker includes: release paper layer, self-adhesive adhesive layer, anti-crack cloth layer, lower adhesive material layer, aggregate layer and upper adhesive material layer; upper adhesive material layer and lower adhesive layer The binder layer wraps the aggregate layer.

[0029] in,

[0030] The release paper layer is made of double-sided release paper.

[0031] The self-adhesive adhesive layer is formed by spraying a self-adhesive adhesive, and the self-adhesive adhesive used in this embodiment is composed of 60 parts of base asphalt, 3 terpene resins, 18 phenolic resins, 1 part of polysulfide resin, 2 parts of SIS, 10 parts of SBS, 3 parts It is compounded from 1 part aromatic oil and 2 parts plasticizer.

[0032] The anti-crack cloth layer is made of polyester fiber anti-crack cloth.

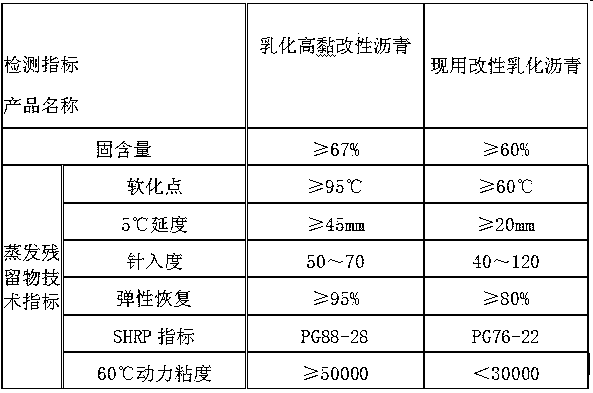

[0033] Both the upper binder layer and the lower binder layer are paved with emulsified high-viscosity modified asphalt. The emuls...

Embodiment 2

[0051] A factory-prefabricated self-adhesive pavement sticker includes: release paper layer, self-adhesive adhesive layer, anti-crack cloth layer, lower adhesive material layer, aggregate layer and upper adhesive material layer; upper adhesive material layer and lower adhesive layer The binder layer wraps the aggregate layer.

[0052] in,

[0053] The release paper layer is made of single-sided release paper.

[0054] The self-adhesive adhesive layer is formed by spraying the self-adhesive adhesive, and the self-adhesive adhesive used in the present embodiment consists of 55 parts of matrix pitch, 2 terpene resins, 16 phenolic resins, 2 parts of polysulfide resin, 3 parts of SIS, 11 parts of SBS, 4 parts It is compounded from 1 part aromatic oil and 2 parts plasticizer.

[0055] The anti-crack cloth layer is made of polyester fiberglass anti-crack cloth.

[0056] Both the upper binder course and the lower binder course are laid with commercially available modified asphalt. ...

Embodiment 3

[0070] A factory-prefabricated self-adhesive pavement sticker includes: release paper layer, self-adhesive adhesive layer, anti-crack cloth layer, lower adhesive material layer, aggregate layer and upper adhesive material layer; upper adhesive material layer and lower adhesive layer The binder layer wraps the aggregate layer.

[0071] in,

[0072] The release paper layer is made of single-sided release paper.

[0073] The self-adhesive adhesive layer is formed by spraying the self-adhesive adhesive, and the self-adhesive adhesive used in the present embodiment consists of 65 parts of matrix pitch, 1 terpene resin, 20 phenolic resin, 1 part of polysulfide resin, 4 parts of SIS, 9 parts of SBS, 3 parts It is compounded from 1 part aromatic oil and 2 parts plasticizer.

[0074] The anti-crack cloth layer is laid by carbon fiber anti-crack cloth.

[0075] Both the upper binder layer and the lower binder layer are laid by commercially available polyurethane.

[0076] The aggreg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com