Efficient foamed asphalt foaming device

A foamed asphalt and foaming device technology, which is applied to the foaming device field of foamed asphalt, can solve the problems of low structural adaptability of the asphalt foaming device, unsatisfactory foaming effect, and the influence of continued use of equipment, and achieves good fatigue resistance. Features, energy saving, maintenance time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

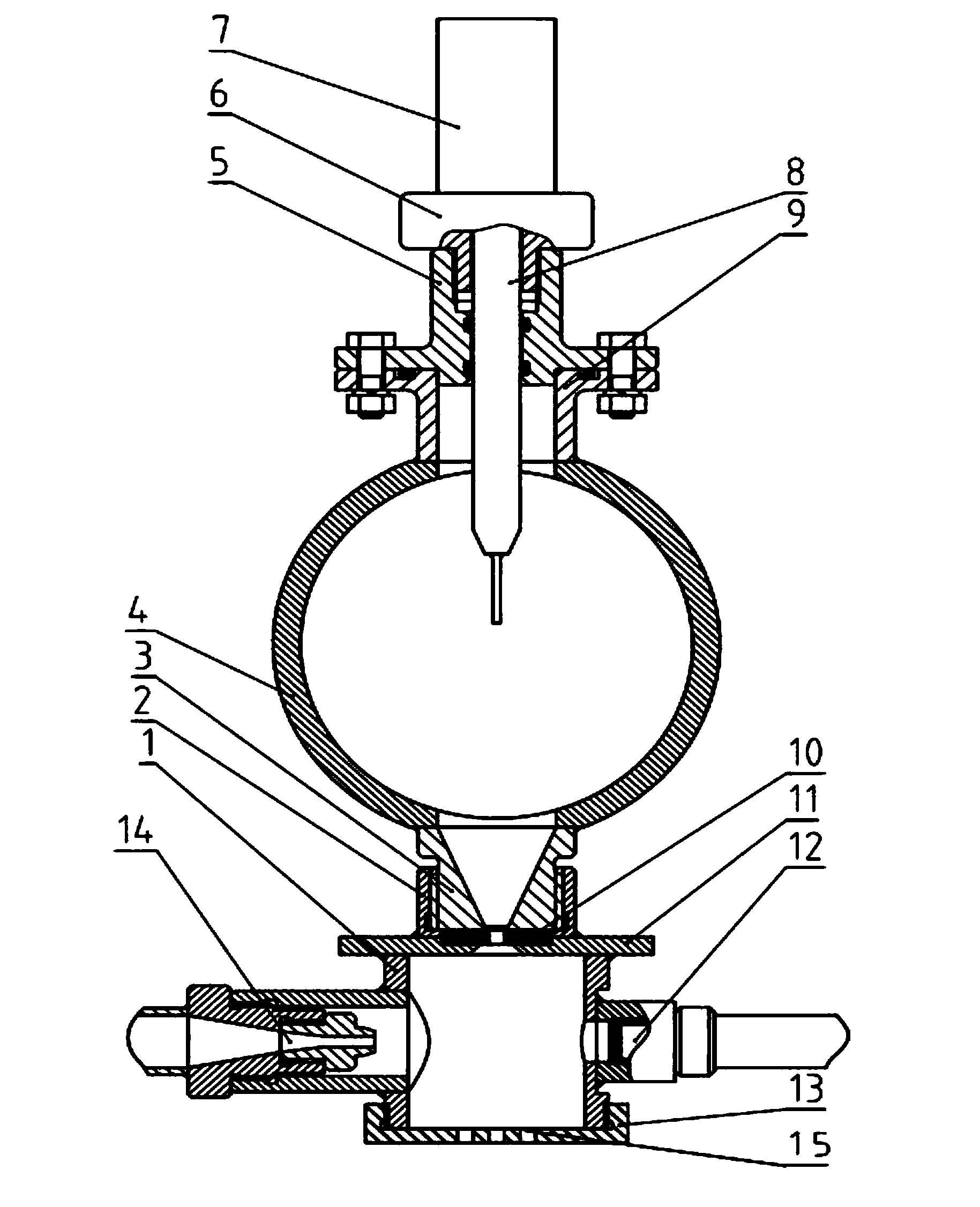

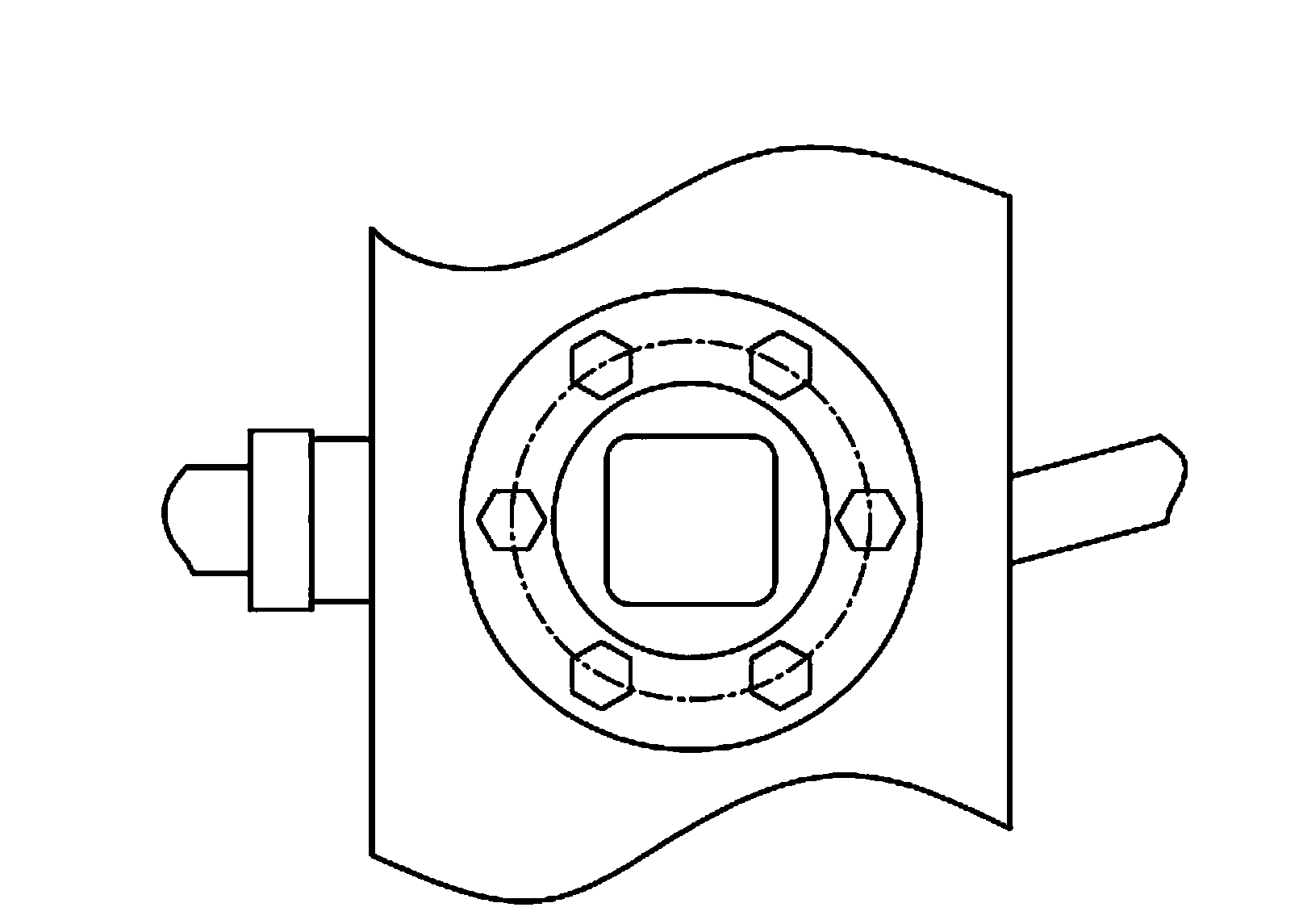

[0022] Such as figure 1 As shown, the asphalt foaming device is mainly composed of a cylinder 7, an asphalt pipeline 4, a foaming chamber main body 1, a compressed air nozzle 12, a water atomizing nozzle 14, a foaming chamber pressure plate 13 and an outlet. The cylinder 7 is located above the asphalt pipeline 4, and controls the on-off of the asphalt injected into the foaming chamber in the pipeline. The foaming chamber 1 is located below the asphalt pipeline 4, and the two sides of the foaming chamber 1 are respectively equipped with water atomizing nozzles 14 and compressed air nozzles 12. The upper end of the foaming chamber 1 is the asphalt injection inlet, and the lower end is the asphalt injection outlet.

[0023] The cylinder 7 drives the cylinder piston rod 8, and the cylinder 7 is installed on the sealing end cover welded with the as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com