Double-way controllable material returning valve for circulating fluidized bed boiler

A technology of circulating fluidized bed and return valve, which is applied in the direction of fluidized bed combustion equipment, fuel burning in a molten state, lighting and heating equipment, etc., and can solve problems such as uneven distribution of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

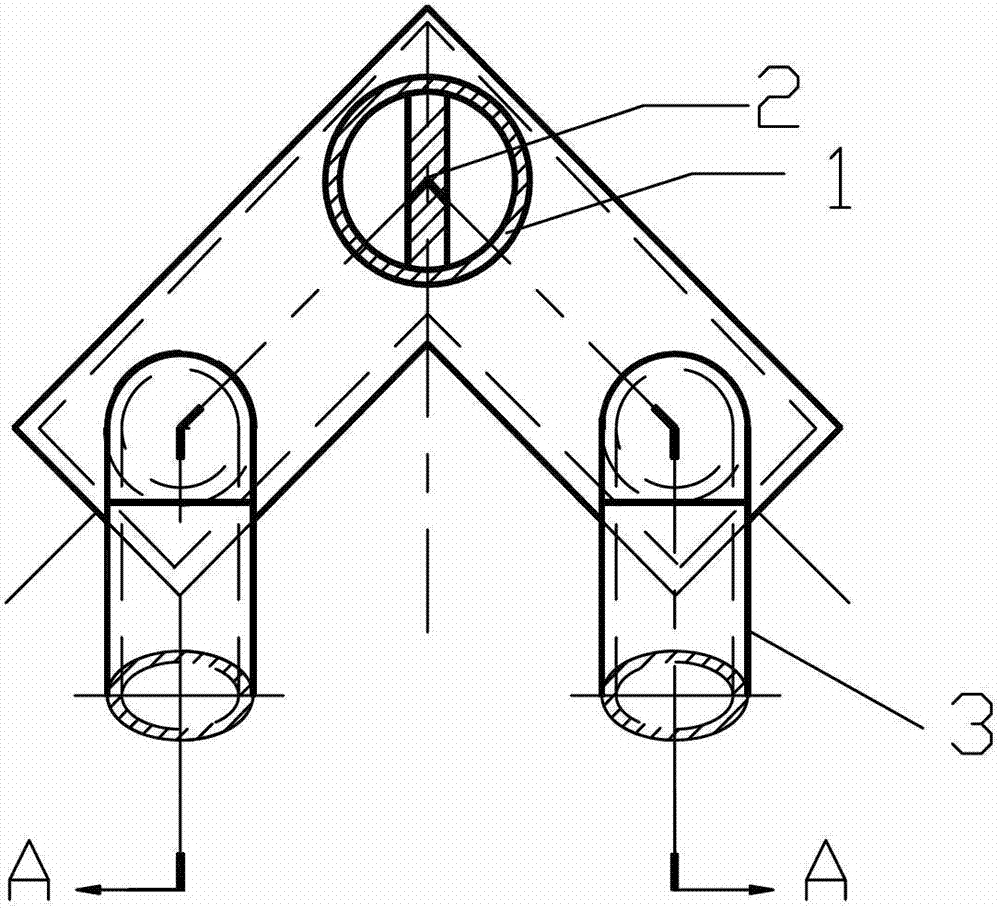

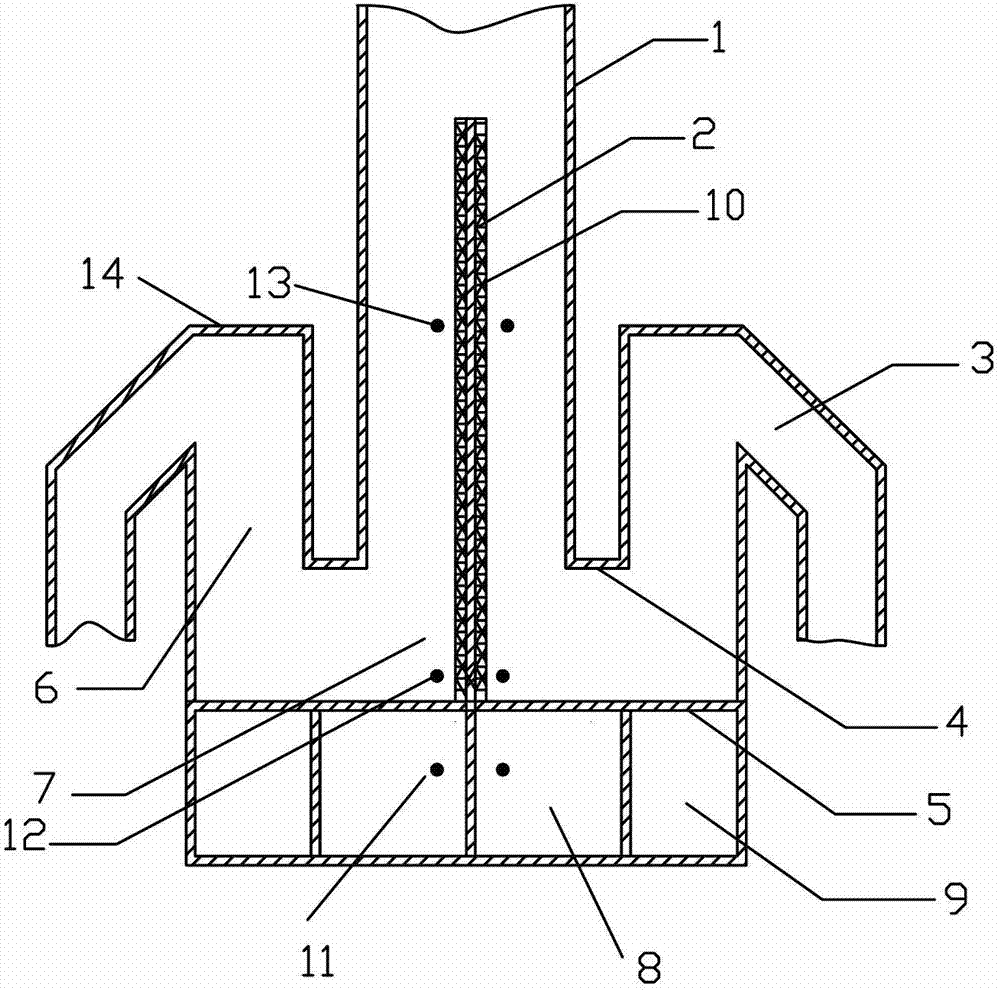

[0017] The structure, principle and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] The two-way controllable return valve includes a feed pipe, an air distribution device, and a moving packed bed 7 symmetrically arranged on both sides of the lower part of the feed pipe, a baffle section 4, a return bed 6 and a return pipe 3; The moving packed bed 7 and the return material bed 6 are connected through the baffle section 4, and the moving packed bed and the return material bed are respectively connected with the air chamber of the air distribution device; The pipe is divided into two parts, and the lower part of the dividing plate is connected with the air distribution plate 5 . The top of the dividing plate will be higher than the upper edge 14 of the air outlet of the return pipe, generally at least 0.2 meters higher.

[0019] The diameter of the feed pipe in this embodiment is 1300 mm. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com