Large-diameter proportional pneumatic valve directly driven by alternating-current servo motor

An AC servo motor, large-diameter technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of high cost, low action sensitivity, inability to realize output flow and pressure adjustment, etc., to improve dynamic performance, The effect of high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings.

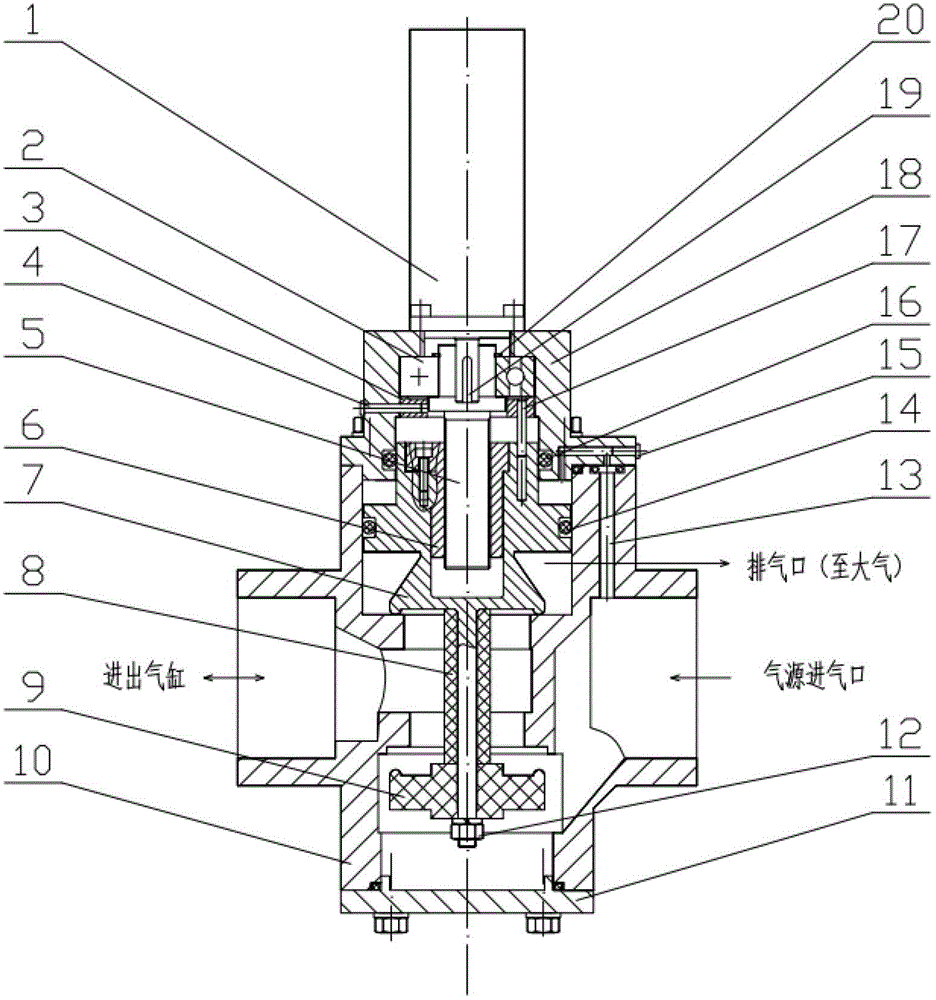

[0014] As shown in the accompanying drawings, an AC servo motor direct-drive large-diameter proportional pneumatic valve includes an AC servo motor 1, and the AC servo motor 1 is fixed on the upper end surface of the upper end cover 18 by screws, and the upper end cover 18 and the lower end cover 11 are passed through respectively. The screw is fixed to the valve body 10 and sealed by a sealing ring. The rolling bearing 2 and the sleeve 3 are installed inside the upper end cover 18. The sleeve 3 is provided with two symmetrical holes in the radial and axial directions respectively, and is inserted through the upper end cover. The pin 4 in the radial hole is fixed, the outer ring of the rolling bearing 2 is positioned by the upper end cover 18 and the sleeve 3, and the inner ring is positioned by the spring retaining ring 20 installed on the ball screw 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com