Warp knitting machine

A warp knitting machine and actuator technology, applied in the field of warp knitting machines, can solve problems such as the quality reduction of knitted fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

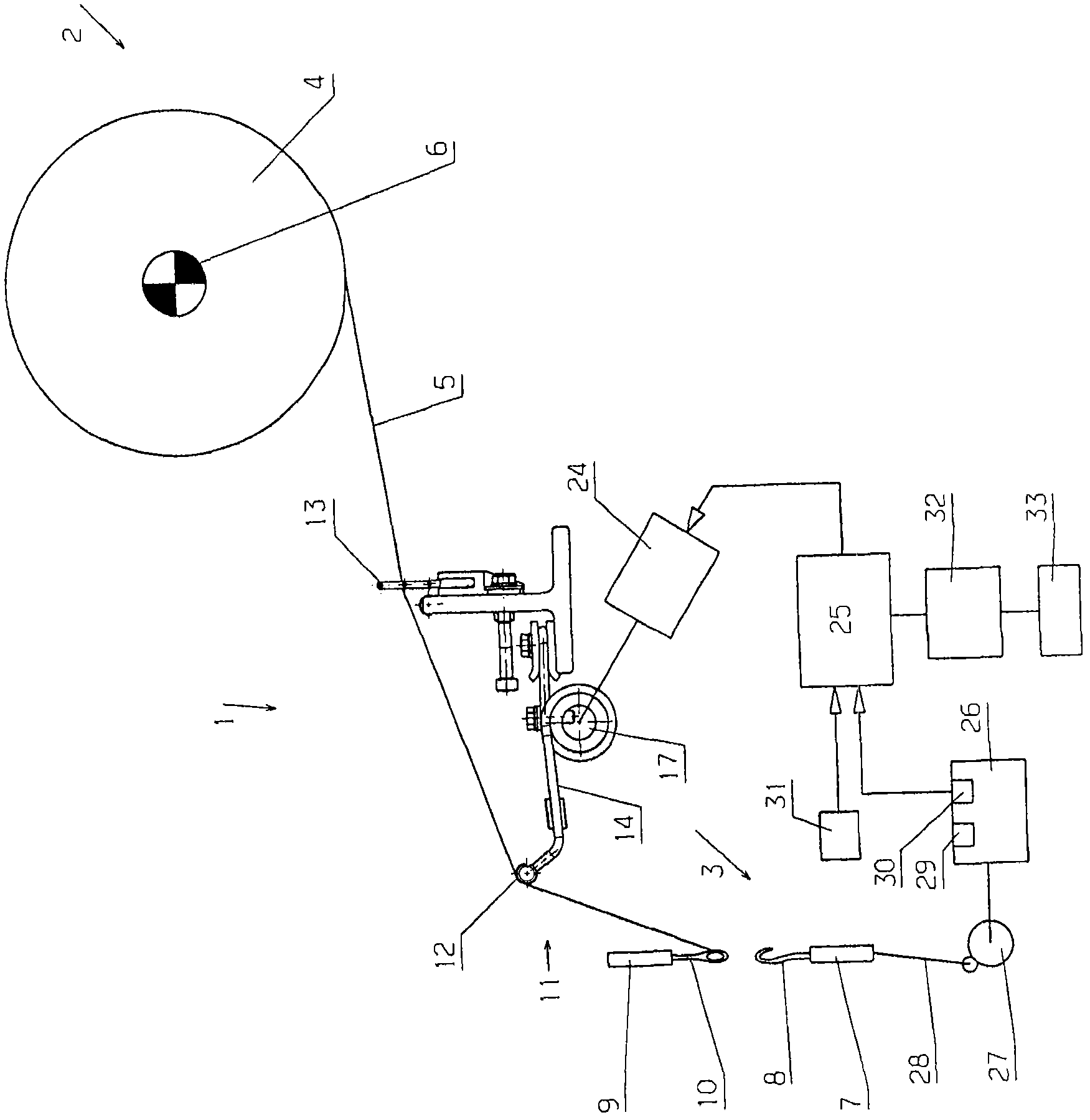

[0025] figure 1 A warp knitting machine 1 with a thread feeding area 2 and a knitting area 3 is shown very schematically. In this case, a warp beam 4 is arranged in the thread feeding area 2 , which provides the yarn sheets. The yarn sheet has a plurality of threads 5 arranged side by side, one of which can be seen in the figure. Other lines follow it perpendicular to the drawing plane.

[0026] The warp beam 4 is driven by the drive 6 in such a way that the wire 5 is fed at a constant speed.

[0027] The knitting area 3 shown here in a very simplified manner has a needle bar 7 on which a plurality of knitting needles 8 are arranged. The knitting needles 8 are arranged one after the other perpendicular to the drawing plane, so that only one knitting needle 8 is visible. Furthermore, the knitting area 3 has a bar 9 on which a plurality of eye needles 10 are arranged. The other eye pins are located perpendicular to the drawing plane. Each thread 5 is guided through an eye ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com