Cement-stabilized anti-crack base newly-built pavement structure and construction method and application thereof

A technology for cement stabilization and pavement structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

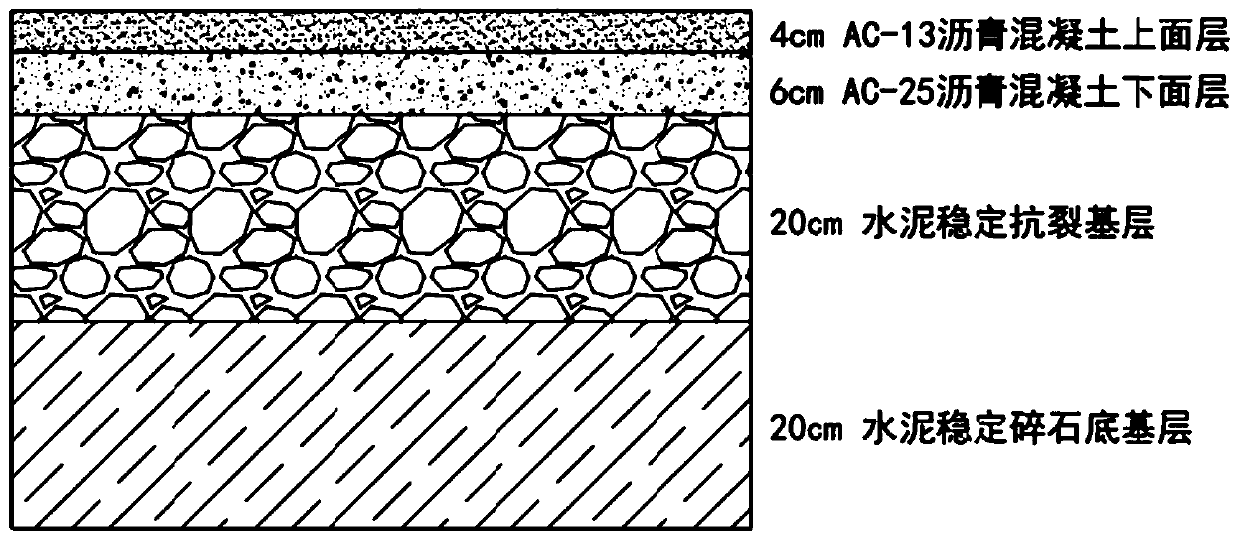

[0033] A cement-stabilized anti-crack base new pavement structure, which is applied to arterial highways with heavy traffic. The project is a new project, such as figure 1 Shown is the cross-sectional design drawing of the pavement structure of the newly-built scheme.

[0034] The pavement structure includes asphalt concrete upper layer, asphalt concrete lower layer, cement stabilized anti-crack base and cement stabilized subbase laid on the roadbed from top to bottom;

[0035]The cement-stabilized anti-cracking base is set above the cement-stabilized sub-base. The material of the cement-stabilized large-grained crushed stone base is crack-resistant cement-stabilized crushed stone mixture. In order to meet the needs of traffic volume, the thickness of this layer is set to 20cm. The main components of the anti-cracking cement-stabilized gravel mixture are cement, large-grained gravel and small-sized gravel, which play the roles of plate blocking, deformation absorption and stre...

Embodiment 2

[0046] Embodiment 2 has the same structure and construction method as Embodiment 1, except that:

[0047] The cement-stabilized anti-crack base material is set above the cement-stabilized sub-base as a crack-resistant cement-stabilized crushed stone mixture with a thickness of 15cm; the cement used in the cement-stabilized anti-crack base material is PC 32.5, and the dosage is 6.0%; the upper layer of asphalt concrete The designed gradation is AC-13, with a thickness of 6cm; the designed gradation of the lower layer of asphalt concrete is AC-25, with a thickness of 8cm; the cement-stabilized subbase is an ordinary water-stabilized subbase, with a thickness of 15cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com