Patents

Literature

43 results about "Subbase (pavement)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In highway engineering, subbase is the layer of aggregate material laid on the subgrade, on which the base course layer is located. It may be omitted when there will be only foot traffic on the pavement, but it is necessary for surfaces used by vehicles.

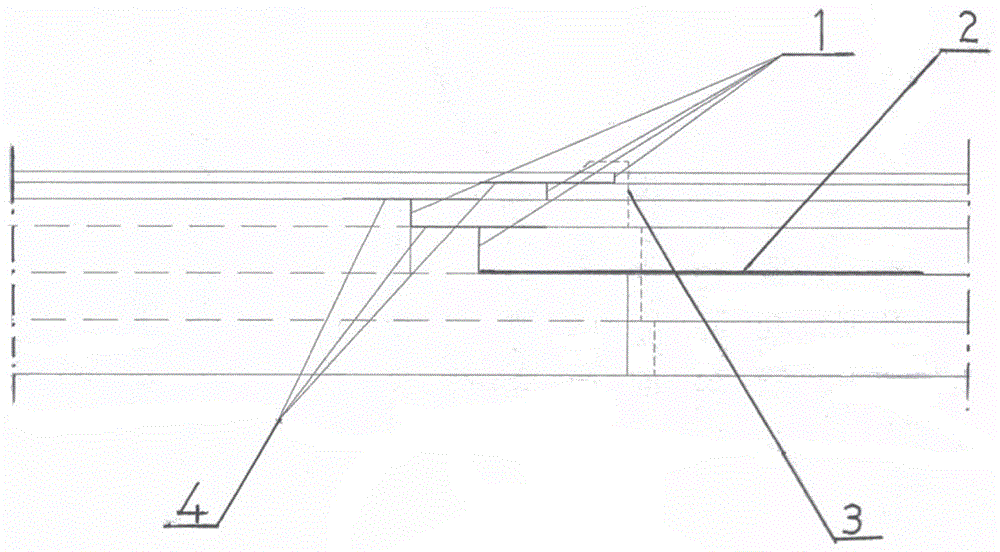

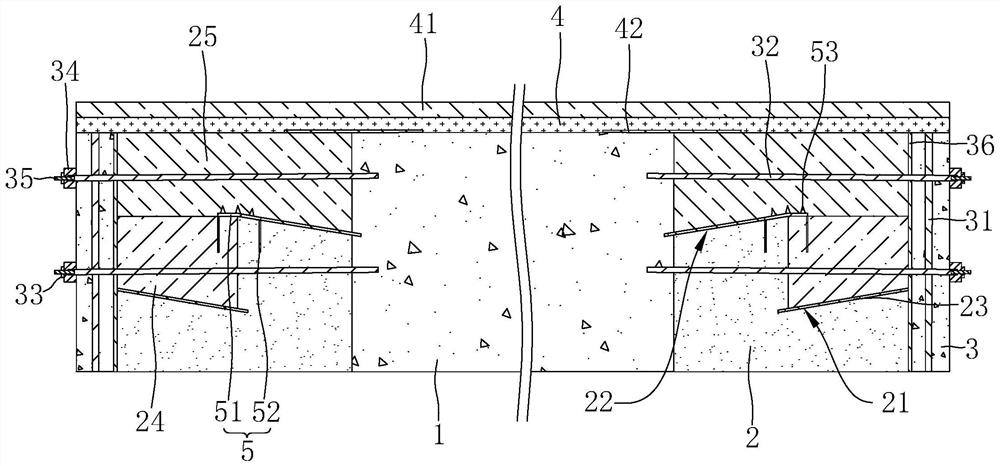

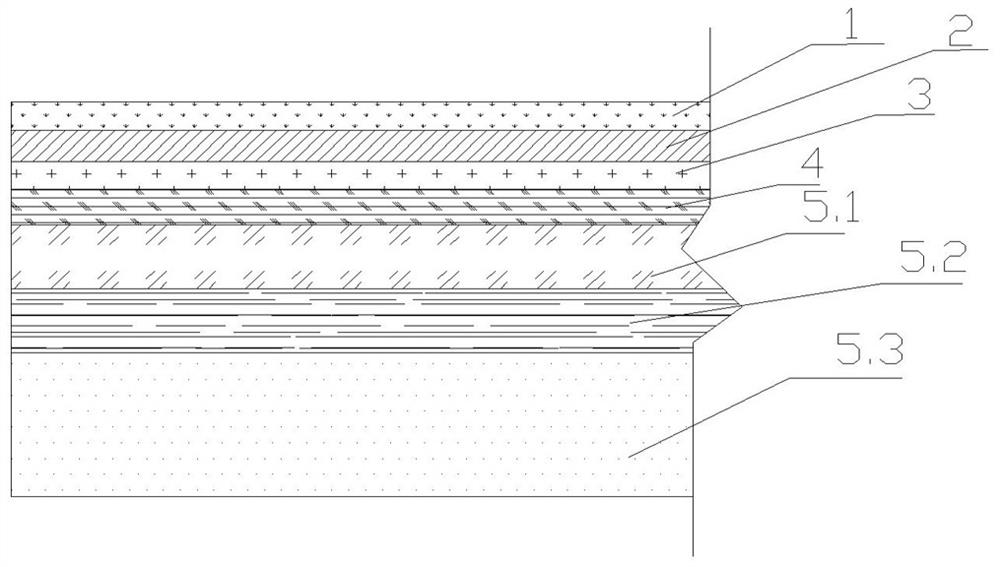

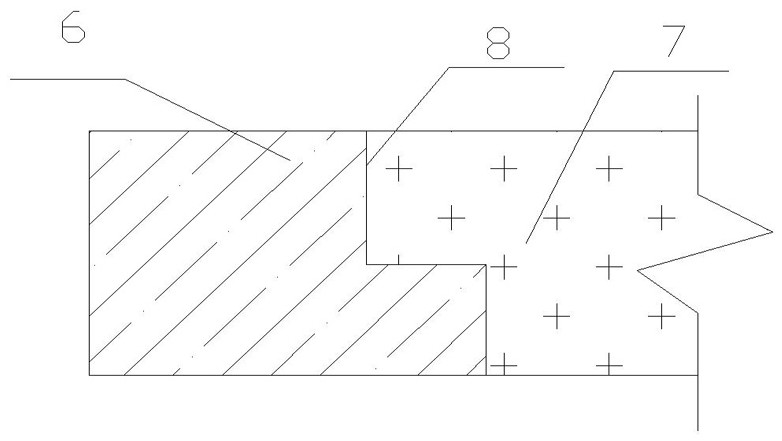

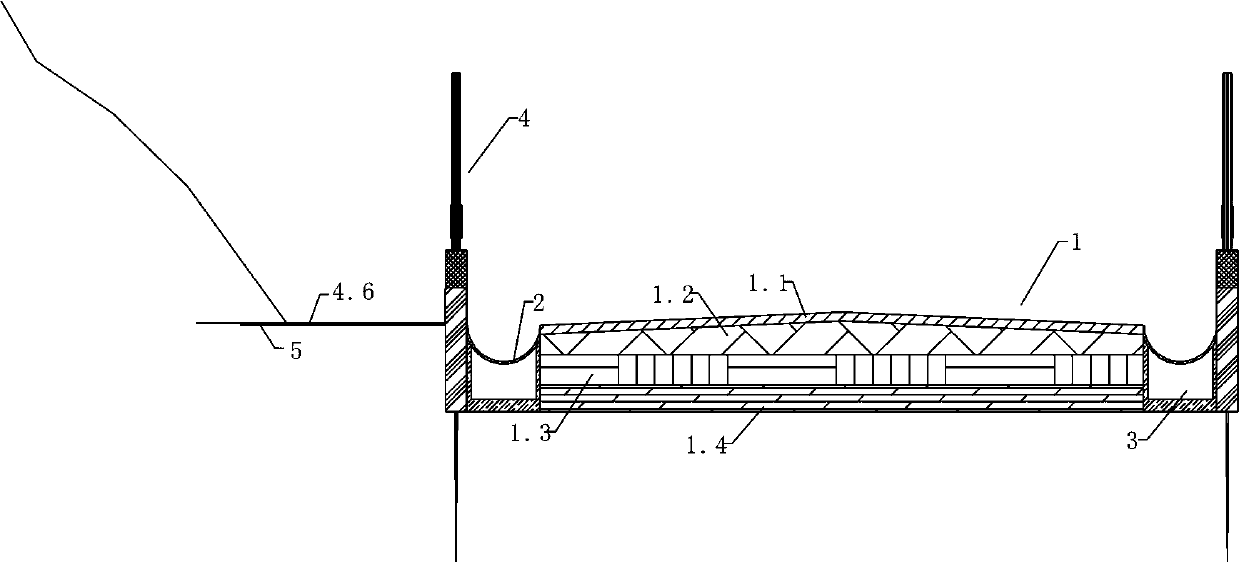

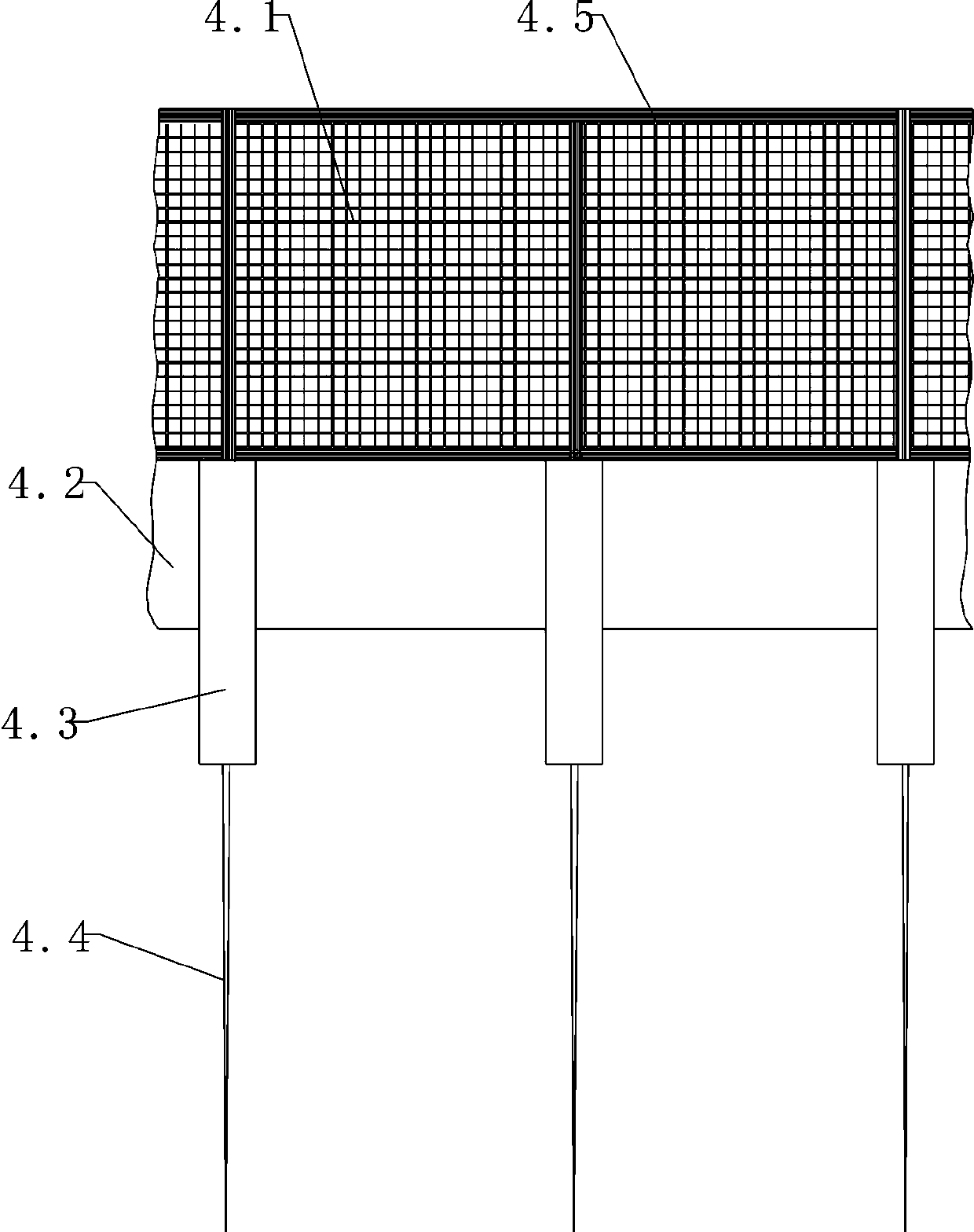

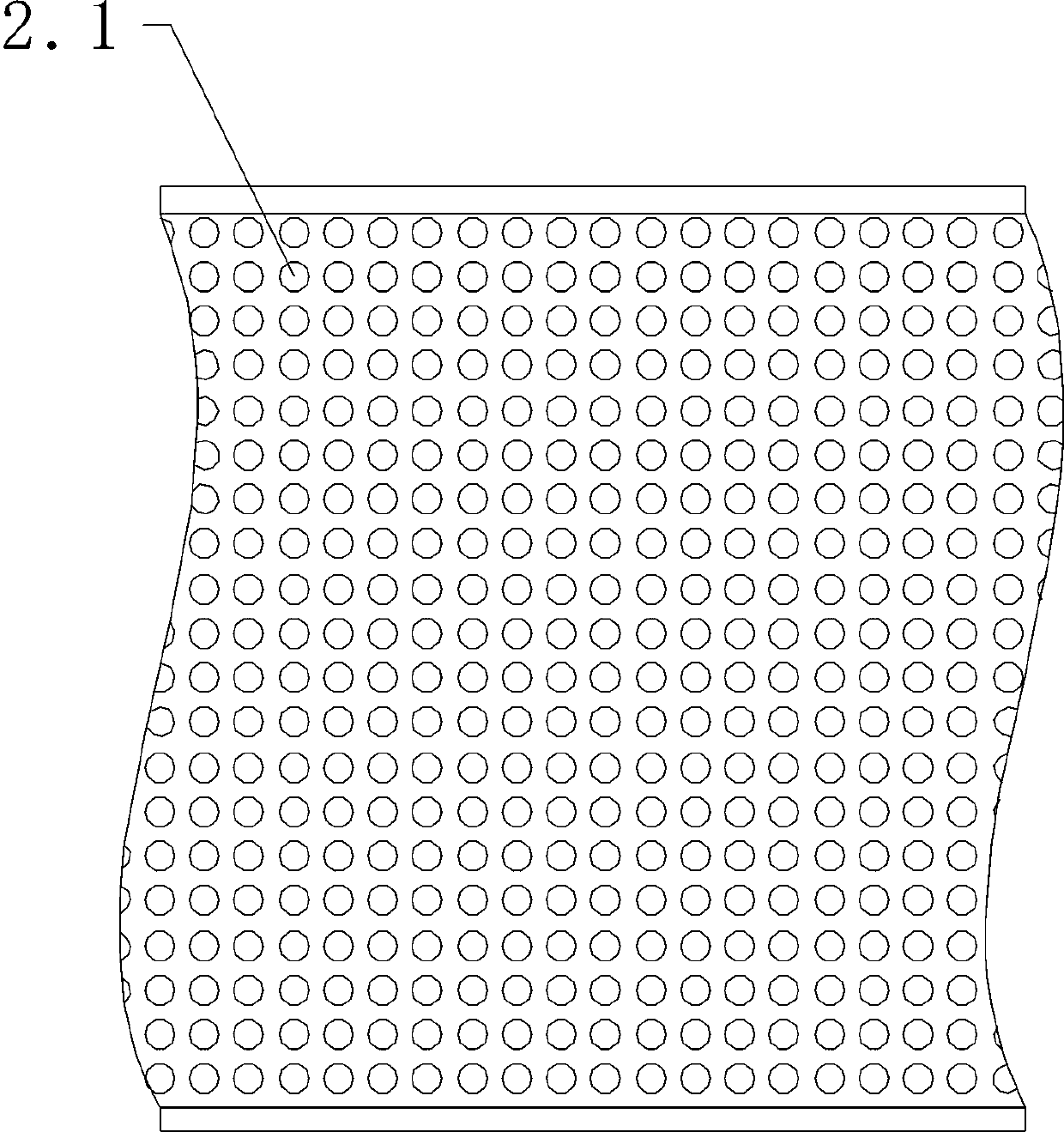

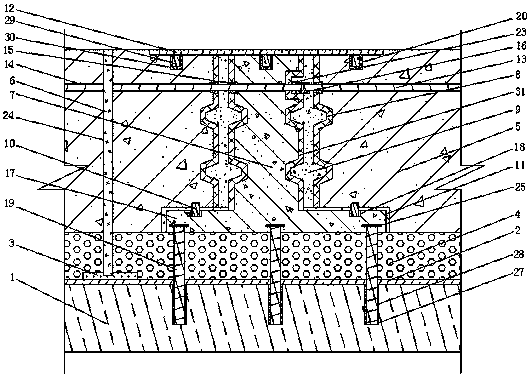

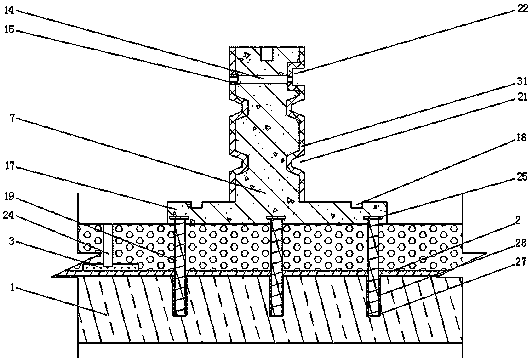

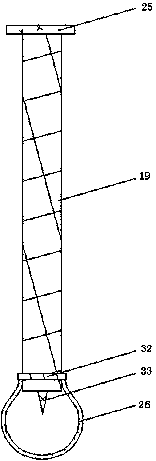

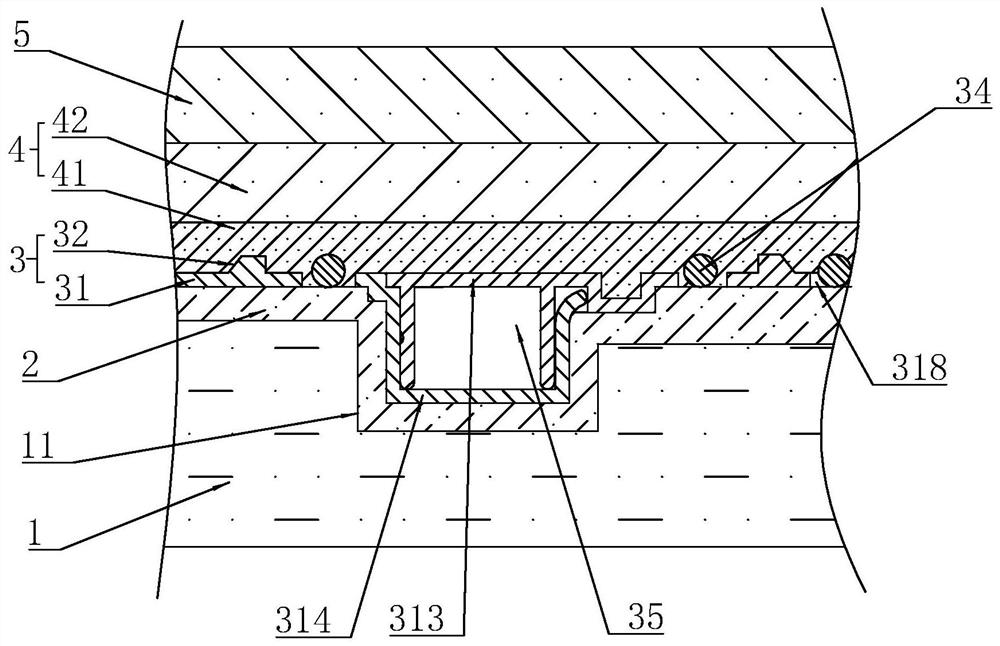

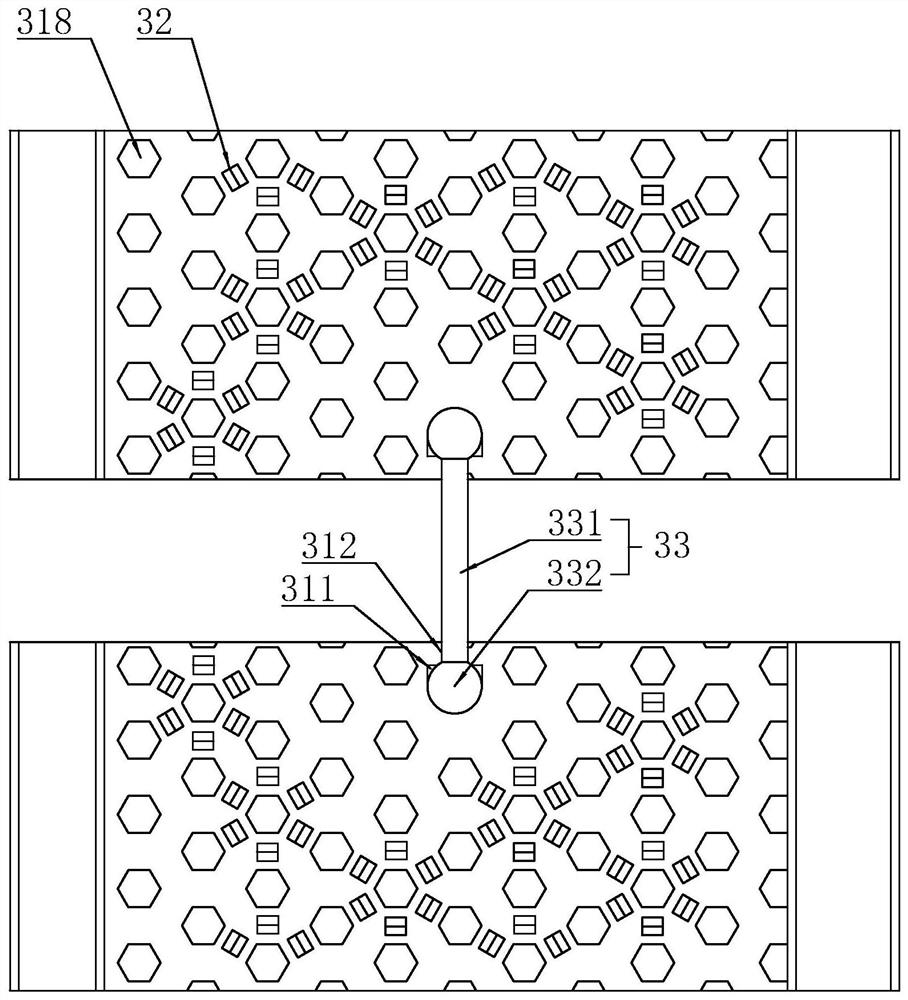

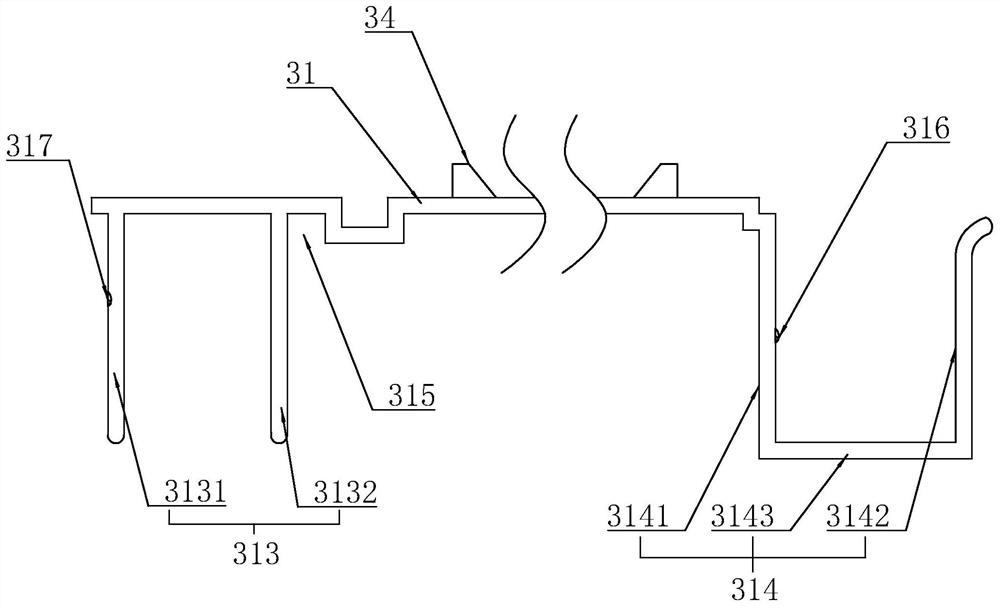

Splicing method and structure for new and old roads in reconstruction and extension of pavement

ActiveCN105926406AImprove stitching qualityStrong shear resistanceIn situ pavingsPaving detailsCarrying capacityChipseal

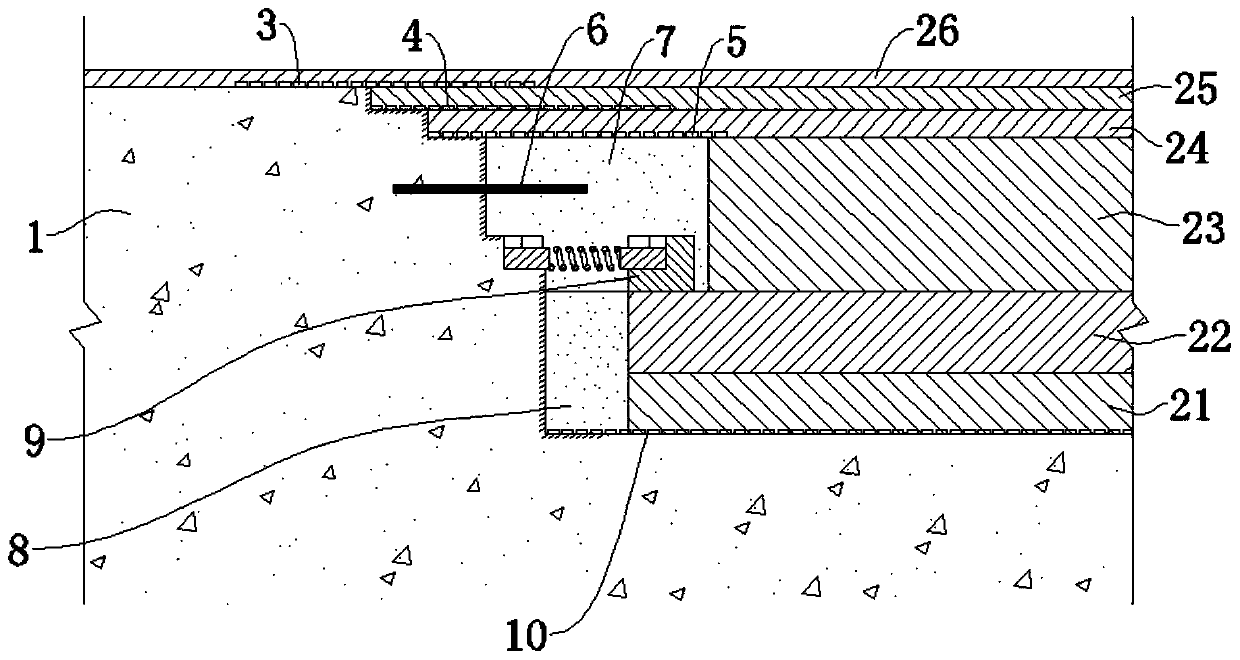

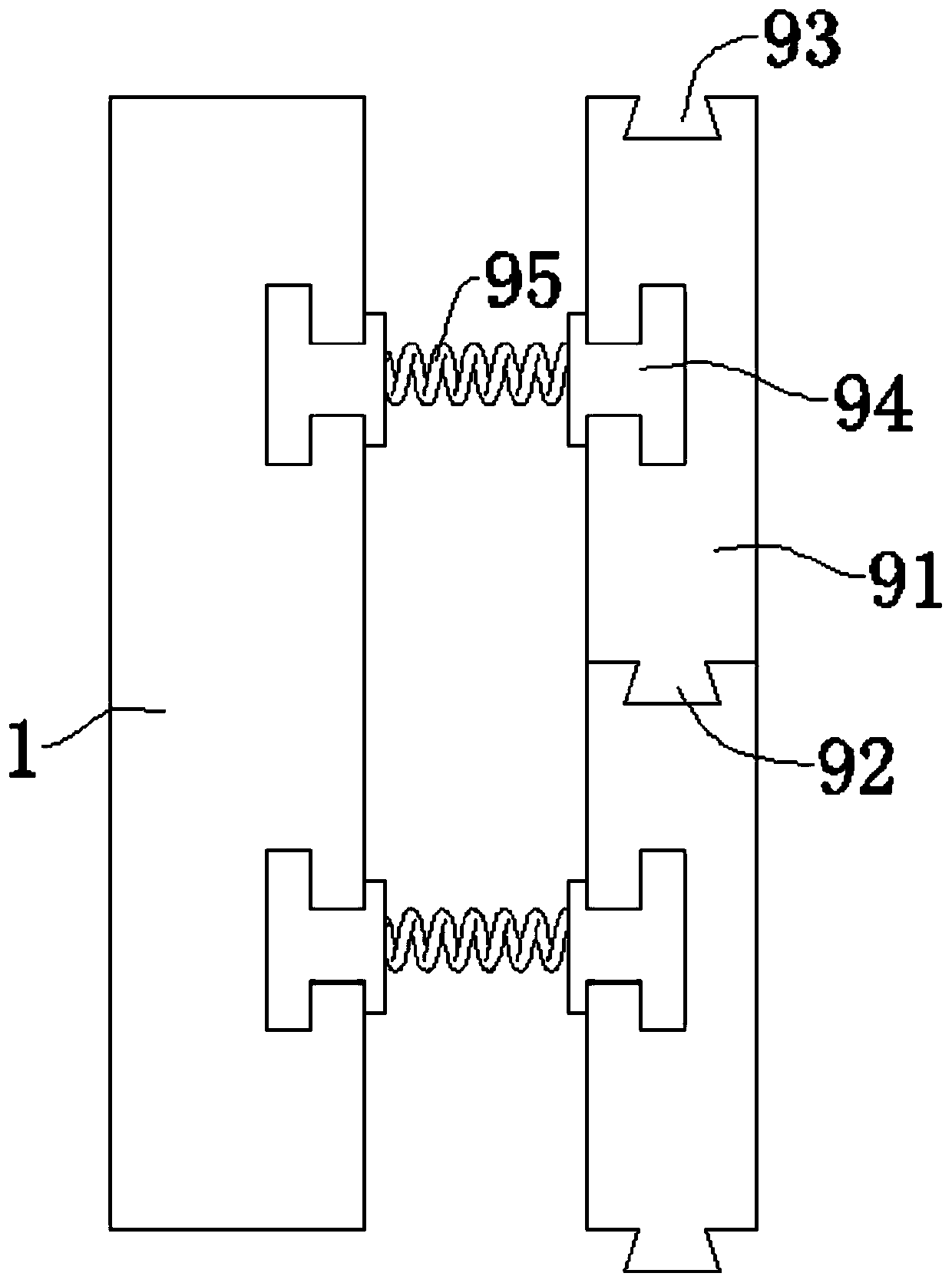

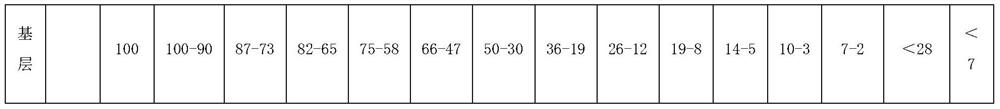

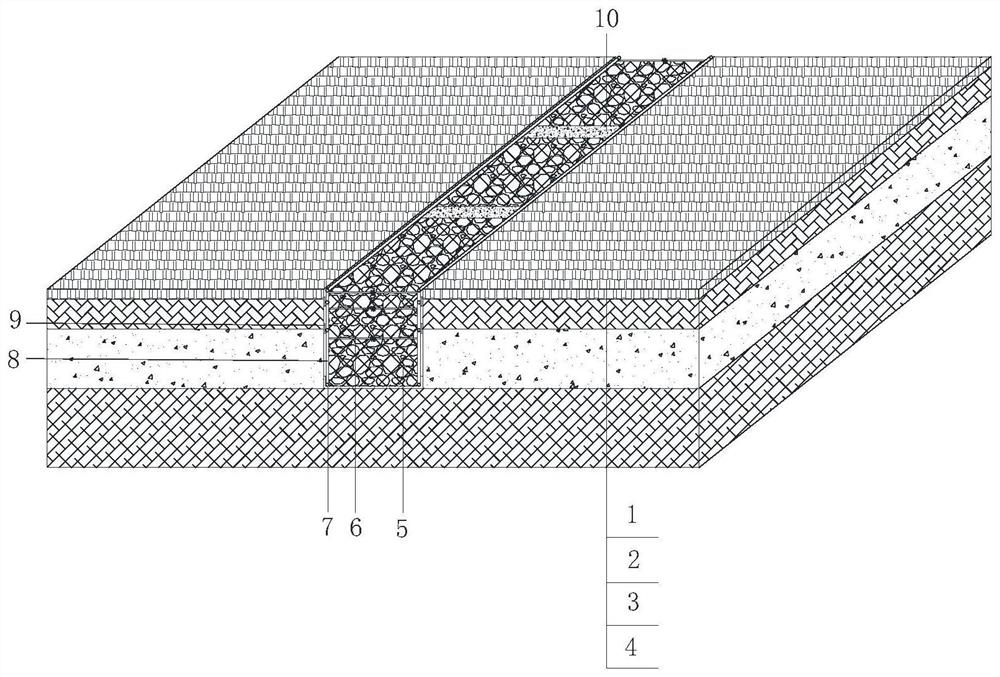

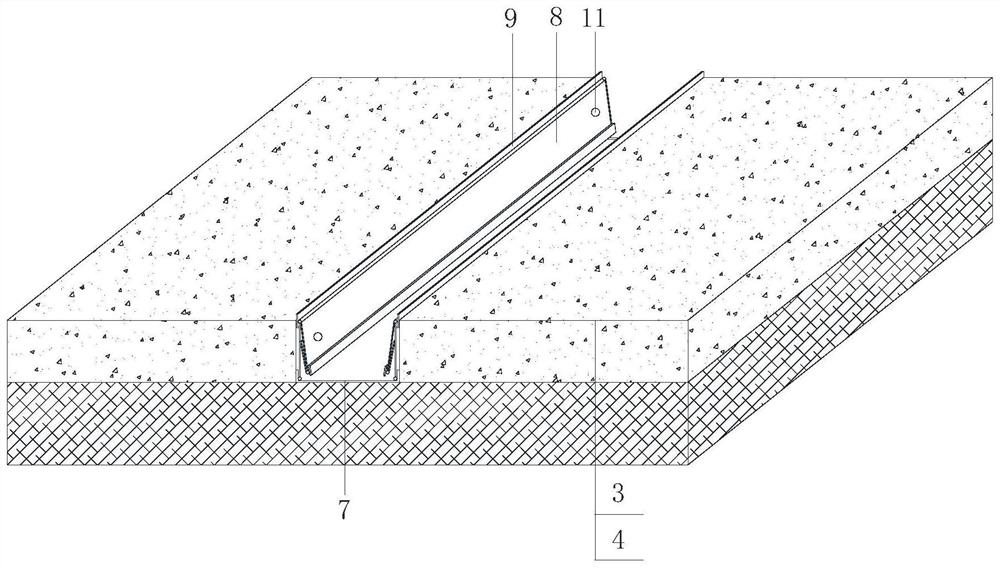

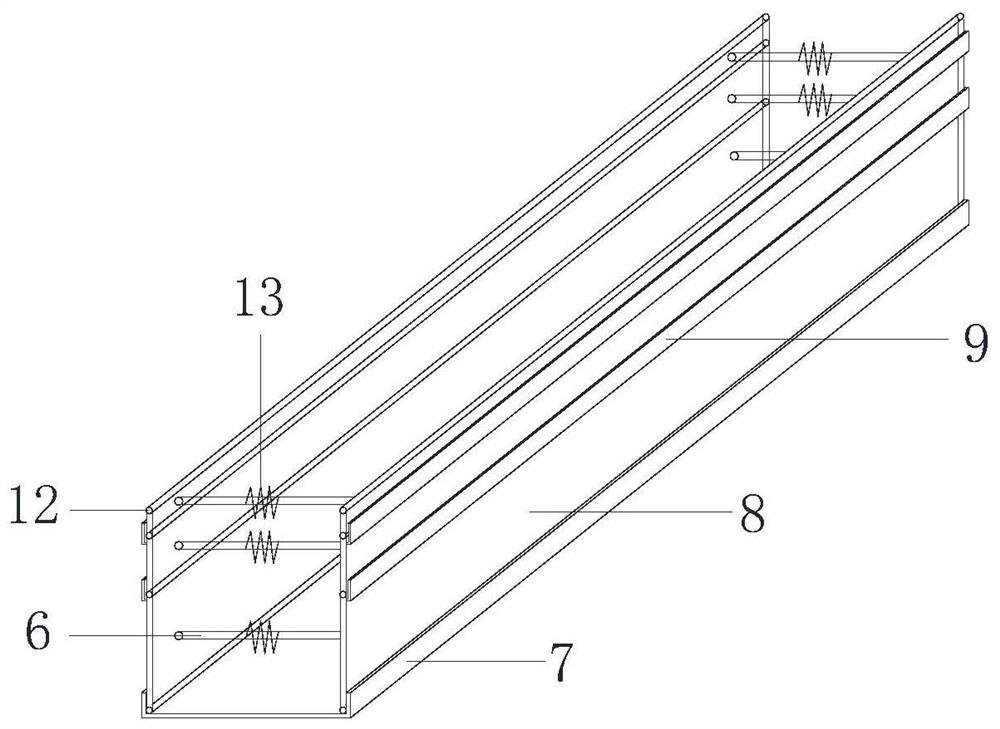

The invention relates to a splicing method and structure for new and old roads in reconstruction and extension of a pavement. The splicing parts of new and old roads and loading positions of vehicle wheels are staggerly arranged. The base layers and subbase layers of new and old roads are connected in a step manner, so a contact area of the roadbeds of the new and old roads is increased and frictional force at bonding sites is improved. Construction of pavement layers of the new and old roads is carried out in an inverse step manner, and the splicing parts of the pavement layers can be flexibly adjusted to favorable stress states through adjusting the width of step so as to be kept away from wheelmark zones. The thickness of a water-stop belt depends on the height of a longitudinal joint surface where the belt is located, so the functions of sealing and water stopping of the water-stop belt are realized. Ribbed reinforcement nets are laid at the splicing parts on the top of the subbase layers of cement stabilized macadam of the new road to improve the anti-shearing and anti-bending performance of the parts. The splicing method and structure provided by the invention can improve the splicing quality of new and old roads of a pavement reconstruction and extension project and carrying capacity and endurance of an integral pavement project; and the method and structure are simple, practicable, fast in construction speed, labor-saving, time-saving and good in construction quality and allows the pavement to have good anti-shearing and anti-bending performance.

Owner:NO 1 ENG CO LTD OF FHEC OF CCCC

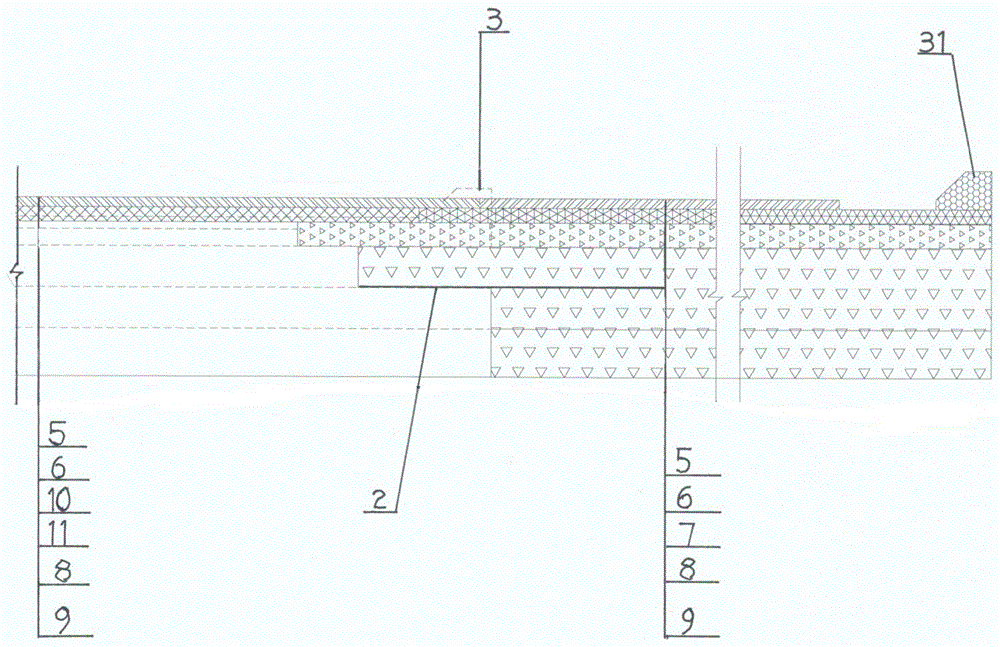

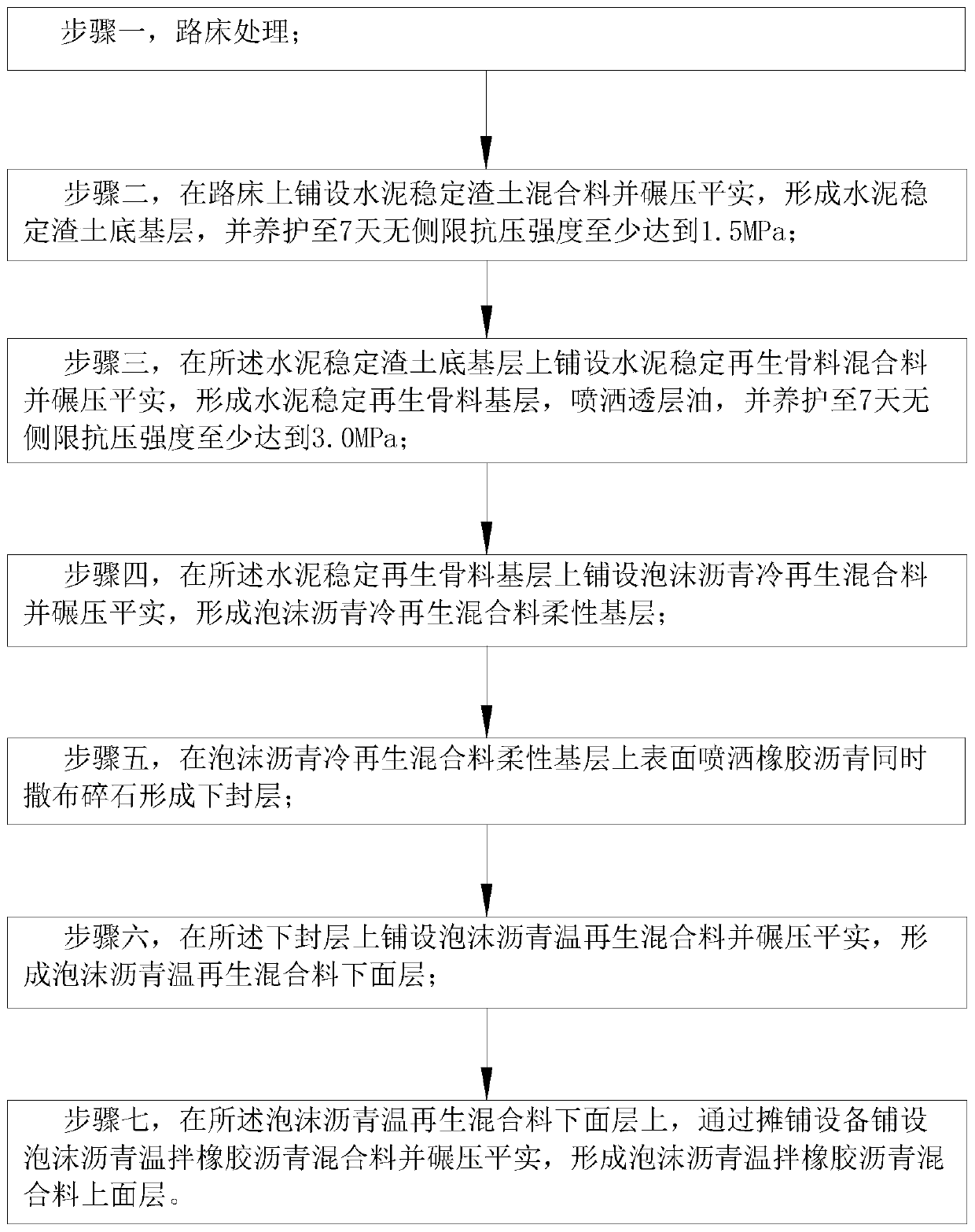

Recycled pavement structure and road construction process thereof

ActiveCN110607726AImprove durabilityReduce road construction costsIn situ pavingsClimate change adaptationRubberized asphaltPitch blende

The invention belongs to the technical field of road engineering and specifically relates to a recycled pavement structure and a road construction process thereof. The recycled pavement structure comprises base courses and surface courses. The base courses include the cement stabilized muck subbase course, the cement stabilized recycled aggregate base course and the foamed asphalt cold-recycled mixture flexible base course which are arranged from bottom to top. The surface courses include the warm-mixed recycled asphalt mixture lower surface course and the warm-mixed rubber asphalt mixture upper surface course. Through the recycled pavement structure, large-scale and high-value utilization of construction waste recycled materials can be realized, the recycling rate of construction waste reaches up to 95% or more, the utilization ratio of recycled aggregate can reach up to 100%, and the ratio of the recycled materials in an overall pavement structure can reach up to 80%-90%. Comprehensive recycling on solid waste such as construction waste is realized, and the requirements of relevant specifications are met. There is no need to conduct degrading utilization on the recycled aggregate. The effects of energy conservation and emission reduction are achieved. The environment is protected. Exploitation and consumption of new aggregated rocks can be reduced. The construction funds canbe saved.

Owner:沧州市市政工程股份有限公司

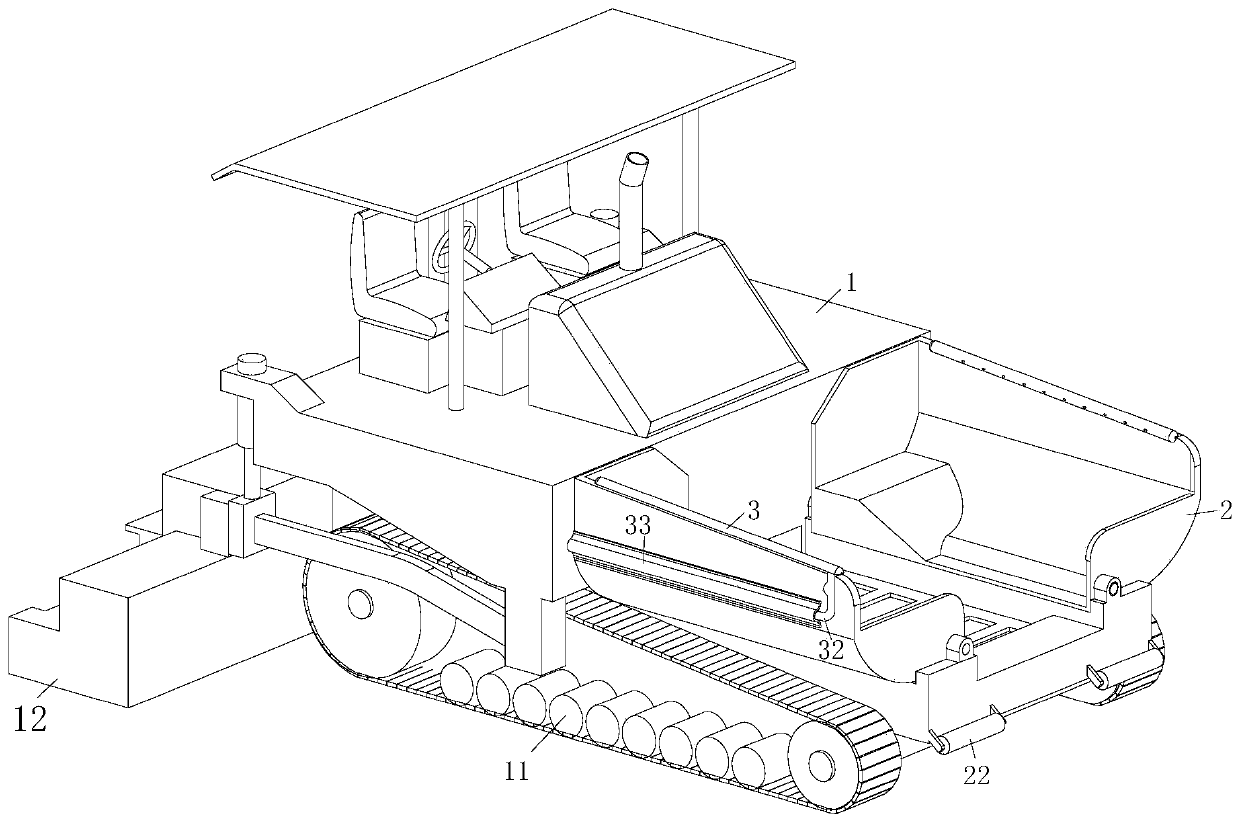

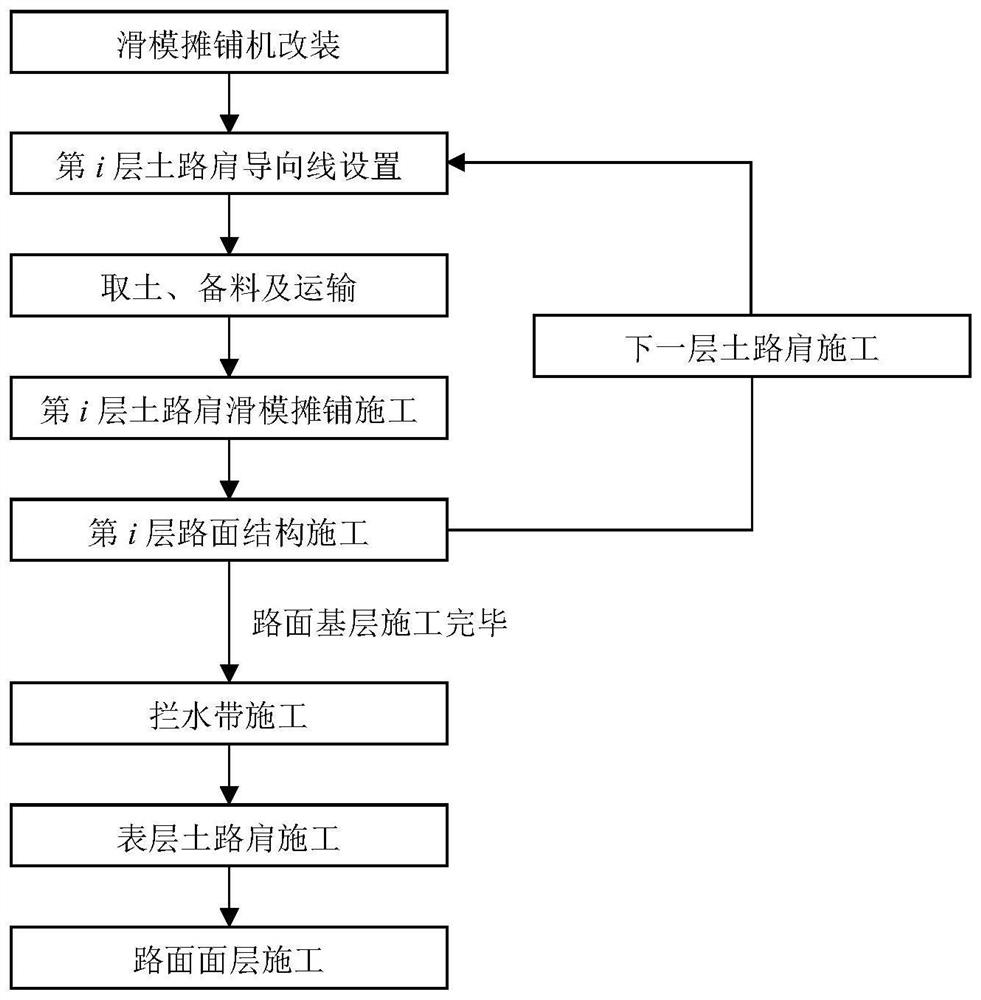

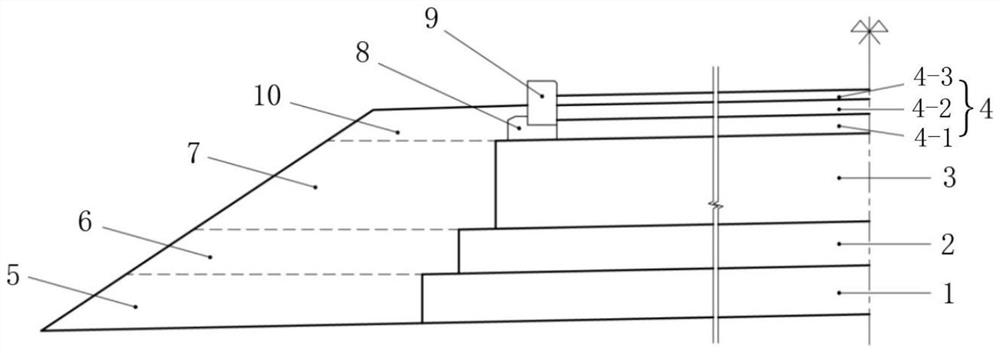

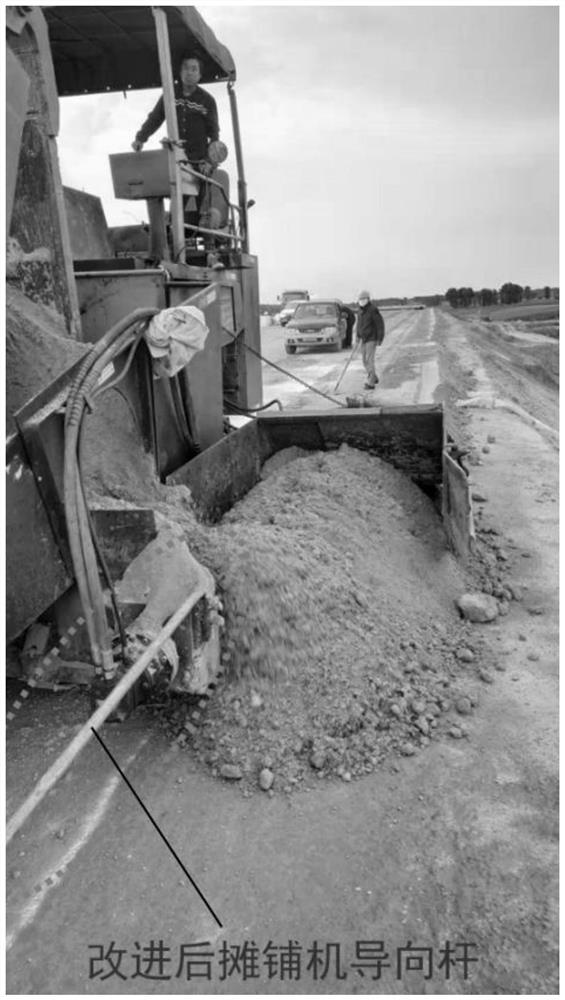

Layered slip form paving construction method for earth shoulder of road

InactiveCN113047137AGuaranteed compactnessRealize eternal unionRoads maintainenceStructural engineeringRoad surface

A disclosed layered slip-form paving construction method for an earth shoulder of a road comprises the following steps: a first earth shoulder layer is constructed on the top surface of a roadbed by adopting slip-form paving, and a pavement cushion layer is constructed by taking the first earth shoulder layer as a side form; a second earth shoulder layer is constructed on the first earth shoulder layer and the pavement cushion layer in a slip form paving mode, and a pavement subbase layer is constructed on the pavement cushion layer with the second earth shoulder layer as a side form; a third earth shoulder layer is constructed on the second earth shoulder layer and the pavement subbase layer in a slip form paving mode, and the pavement base layer is constructed on the pavement subbase layer with the third earth shoulder layer as a side form; and a water retaining belt base and a water retaining belt are constructed on the pavement base layer, a fourth earth shoulder layer is constructed in the outer sides of the water retaining belt base and the water retaining belt in a hilling manner, and a pavement surface layer is constructed on the pavement base layer by taking the water retaining belt base, the water retaining belt and the fourth earth shoulder layer as side molds. The soil shoulder constructed through the layered slip form paving construction method is good in overall compactness, the long-term stability of a side slope is good, a side form does not need to be arranged during pavement structure layer construction, and the construction progress is accelerated.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

Highway engineering new and old pavement splicing structure and construction method thereof

PendingCN111576127AReduce load capacityReduce uniformityPaving reinforcementsIn situ pavingsArchitectural engineeringRoad surface

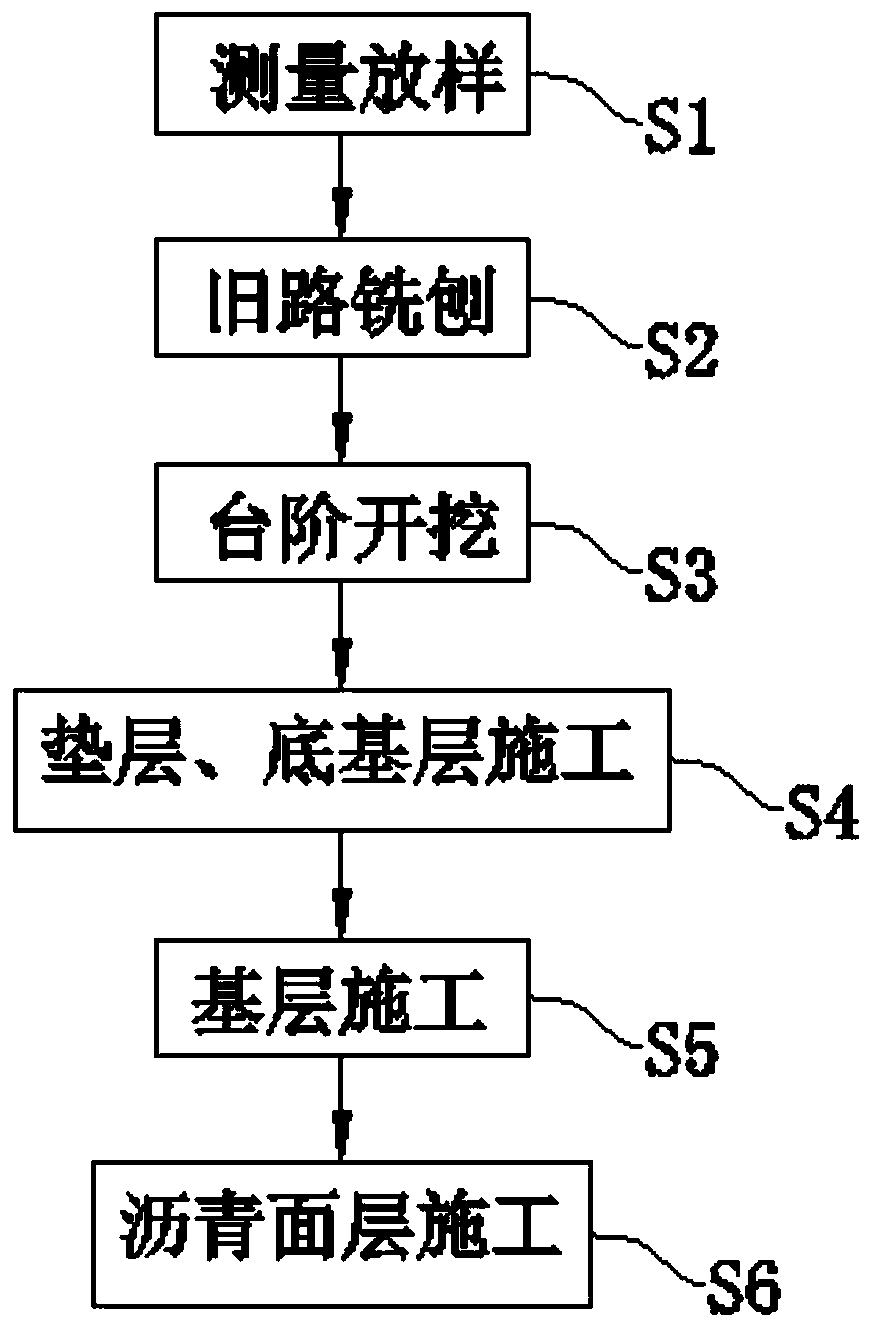

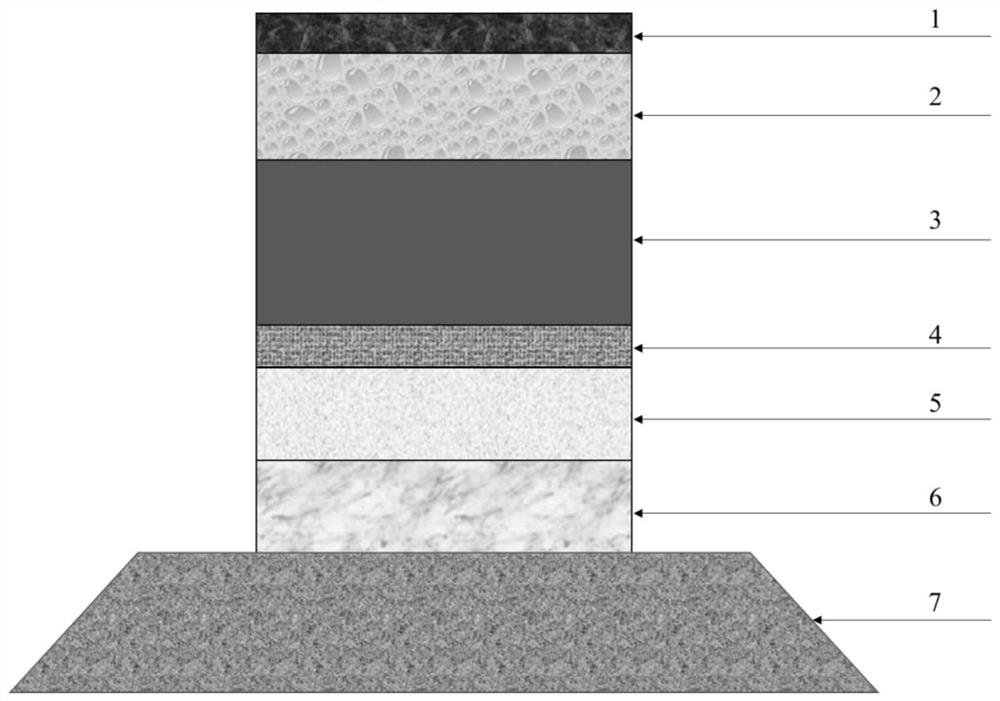

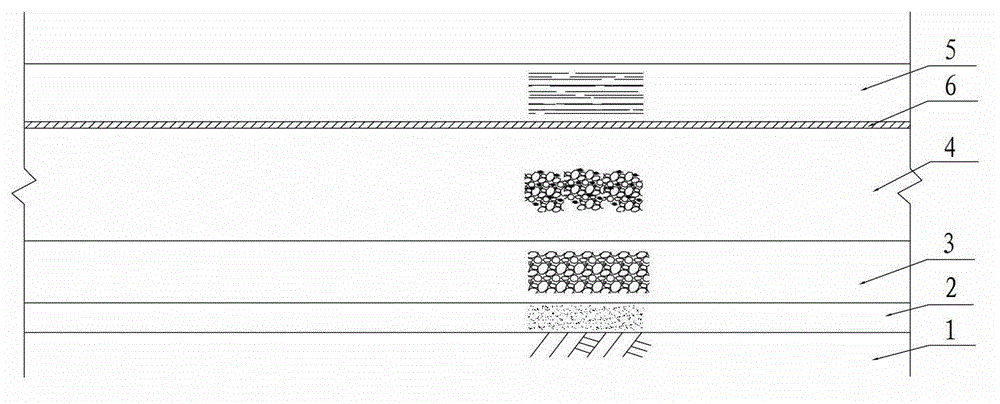

The invention discloses a highway engineering new and old pavement splicing structure and a construction method thereof, and belongs to the field of highway reconstruction and extension projects. Thenew and old pavement splicing structure comprises an original pavement and a new pavement, the new pavement sequentially comprises a cushion layer, a subbase layer, a base layer, a lower surface layer, a middle surface layer and an upper surface layer from bottom to top, and the upper surface layer is laid at the top of the middle surface layer and the top of the original pavement; non-fine macroporous concrete drainage belts are arranged at the splicing parts of the cushion layer and the subbase layer and the original pavement, and a cast-in-place concrete layer is arranged at the splicing part of the base layer and the original pavement; and reinforcing steel bars and reinforcing pieces are arranged between the cast-in-place concrete layer and the original pavement. The construction method of the new and old pavement splicing structure comprises the following steps of: S1, surveying and setting out; S2, milling an old road; S3, excavating steps; S4, constructing the cushion layer andthe subbase layer; S5, constructing the base layer; and S6, constructing an asphalt surface layer. The phenomena of deformation and differential settlement at the joint of new and old pavements are reduced, the common quality problem of longitudinal reflection cracks of the pavement is reduced, and the service life of the pavement is prolonged.

Owner:湖南交通国际经济工程合作有限公司

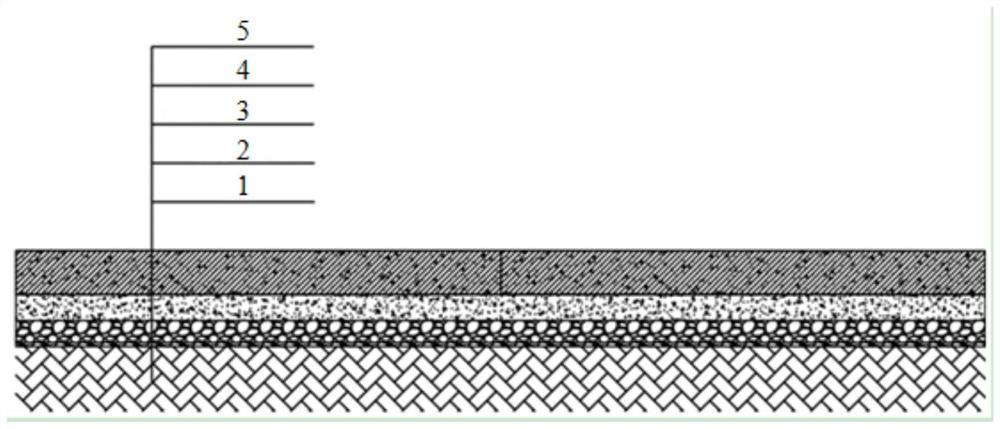

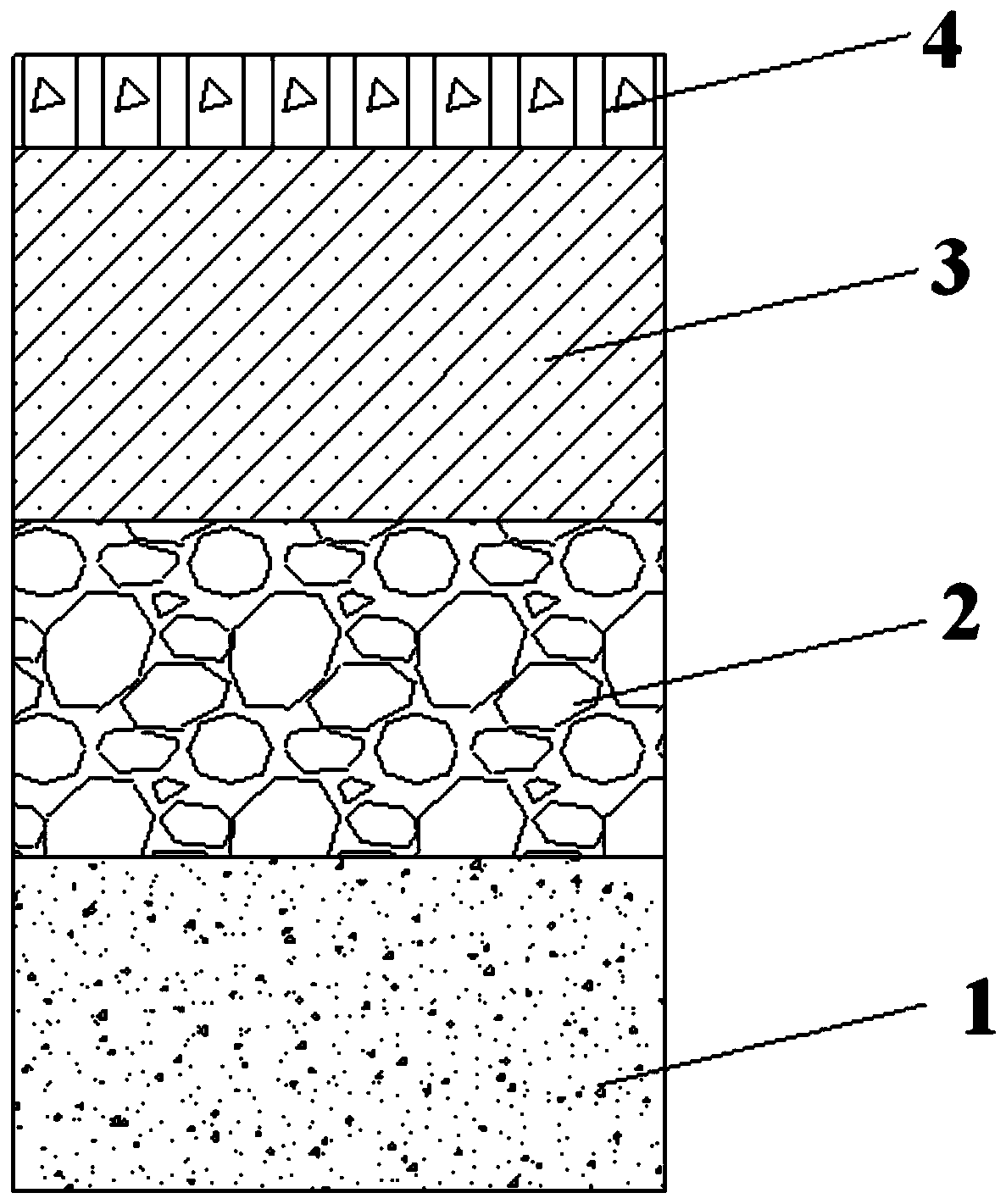

Long-service-life flexible base asphalt pavement structure

ActiveCN112376349AGuaranteed service lifeImproves rutting resistanceIn situ pavingsCrushed stoneStructural engineering

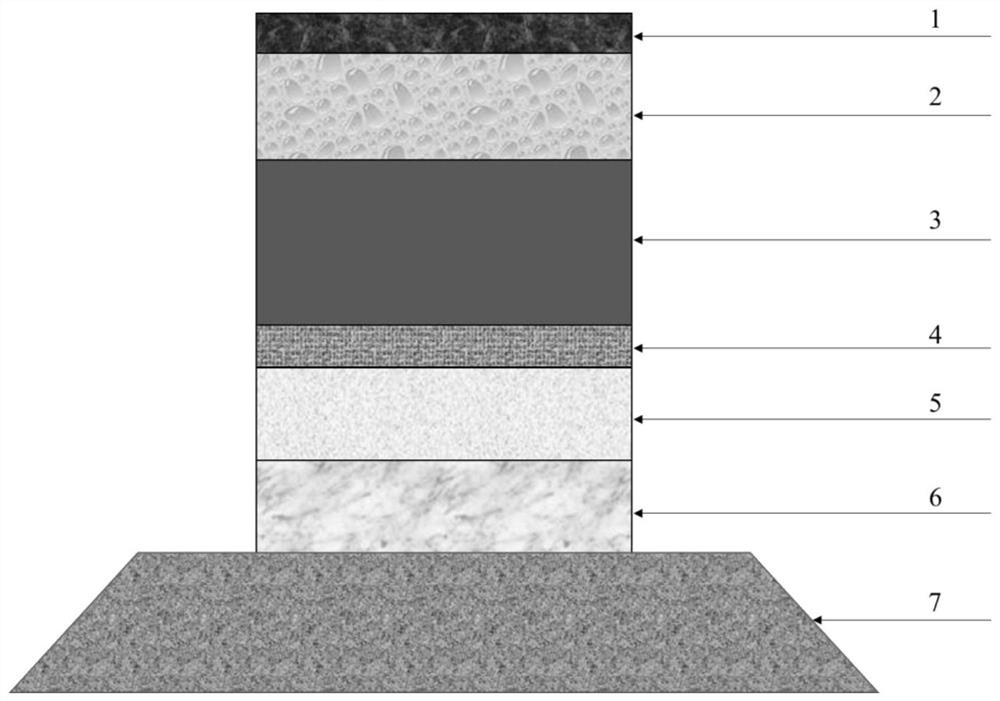

The invention discloses a long-service-life flexible base asphalt pavement structure, and belongs to the technical field of pavement structures. The pavement structure sequentially comprises, from topto bottom: an asphalt concrete upper surface layer with a thickness of 3-6 cm; a high-modulus anti-rutting asphalt concrete middle surface layer with a thickness of 6-12 cm; a high-modulus asphalt concrete lower surface layer with a thickness of 8-16 cm; an anti-fatigue asphalt concrete layer with a thickness of 4-6 cm; a graded broken stone base layer with a thickness of 10-16 cm; a reinforced graded broken stone subbase layer with a thickness of 12-18 cm; a roadbed improvement soil layer. According to the long-service-life flexible base asphalt pavement structure, the defect of inherent reflection cracks existing all the time is overcome, the consumption of non-renewable resource gravel aggregate is reduced from the perspectives of environment and resources, and the problem that the service life design and the service state evaluation of an asphalt pavement are not clear is solved.

Owner:SOUTHEAST UNIV

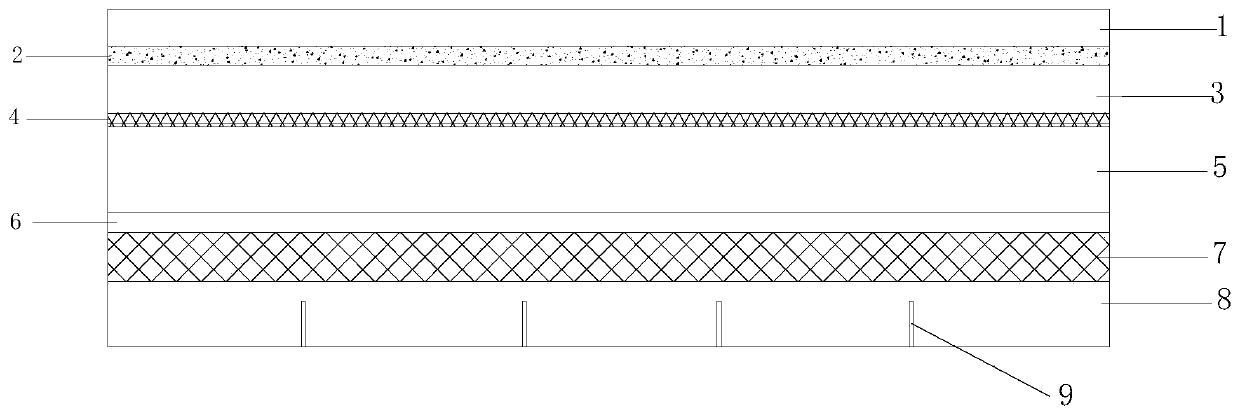

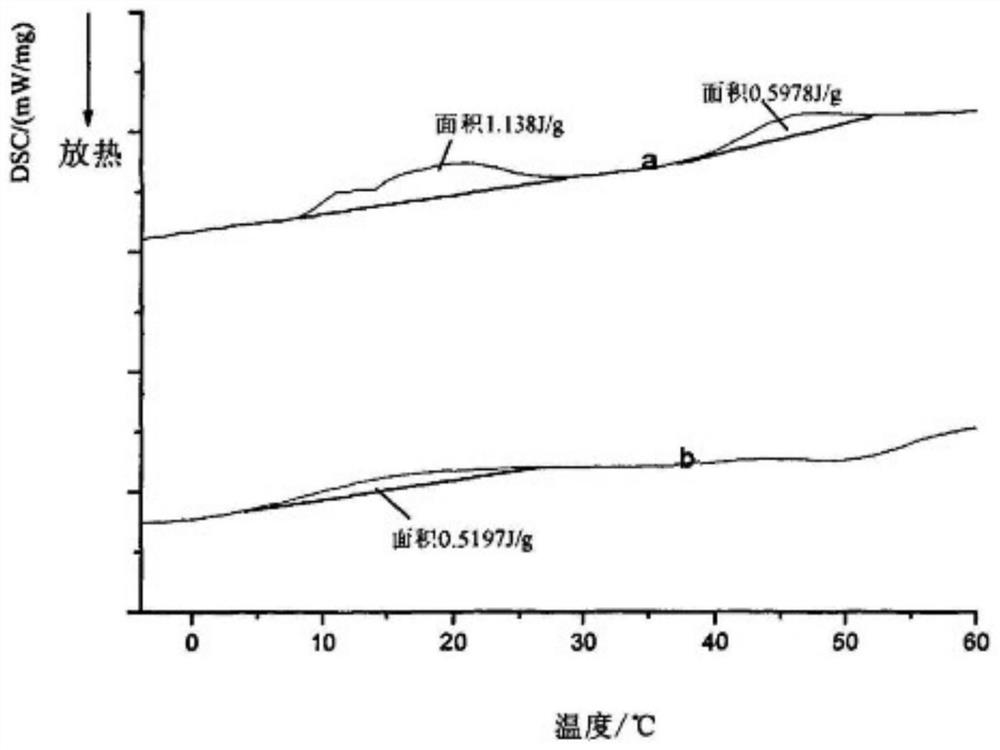

Road structure of urban intersection, bus station and bus lane

PendingCN111118999AMitigate the impact on driving safetyImproves rutting resistanceIn situ pavingsClimate change adaptationFiberWaste rubber

The invention discloses a road structure of an urban intersection, a bus station and a bus lane. The road structure comprises a surface layer, a middle surface layer, a lower surface layer, a base layer and a sub-base layer from top to bottom, a rubber asphalt stress absorption layer is arranged between the lower surface layer and the base layer, and the surface layer is composed of a semi-flexible material SFA13 sprayed with a stone exposing agent of 4-6 cm; the middle surface layer is formed by a semi-flexible material SFA16 doped with a phase change energy storage material of 6-8cm; the lower surface layer is made of an EME20 high-modulus asphalt mixture of which the thickness is 8-10cm; the base layer is composed of C-B-1 cement stabilized graded broken stones or gravels doped with bagasse fibers, waste rubber powder and water-absorbent resin sodium polyacrylate of 18-20cm, and the subbase layer is composed of 15-18cm fabricated regular hexagonal prism-shaped porous cement concrete. By integrating and optimizing the pavement structure, the water stability, the crack resistance and the durability of the road structure are improved, the rut resistance, the skid resistance and thefatigue resistance of the pavement are improved, the urban heat island effect is relieved to a certain extent, and the recycling of wastes is realized.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

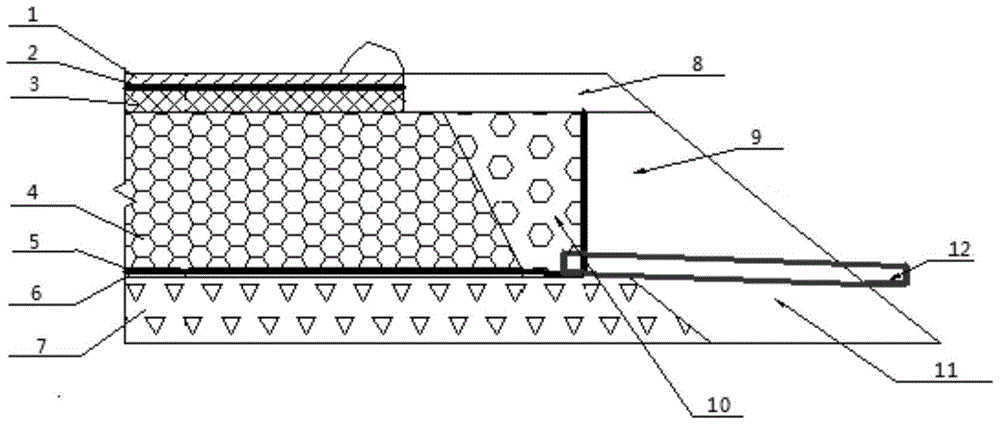

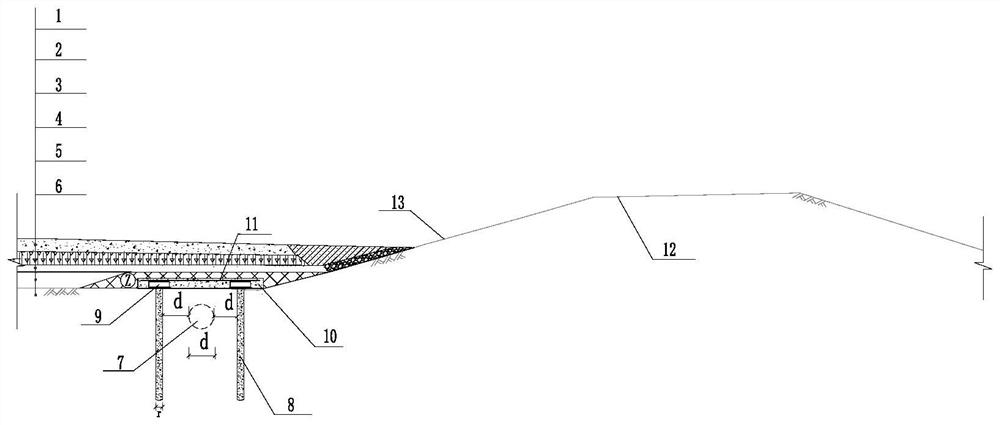

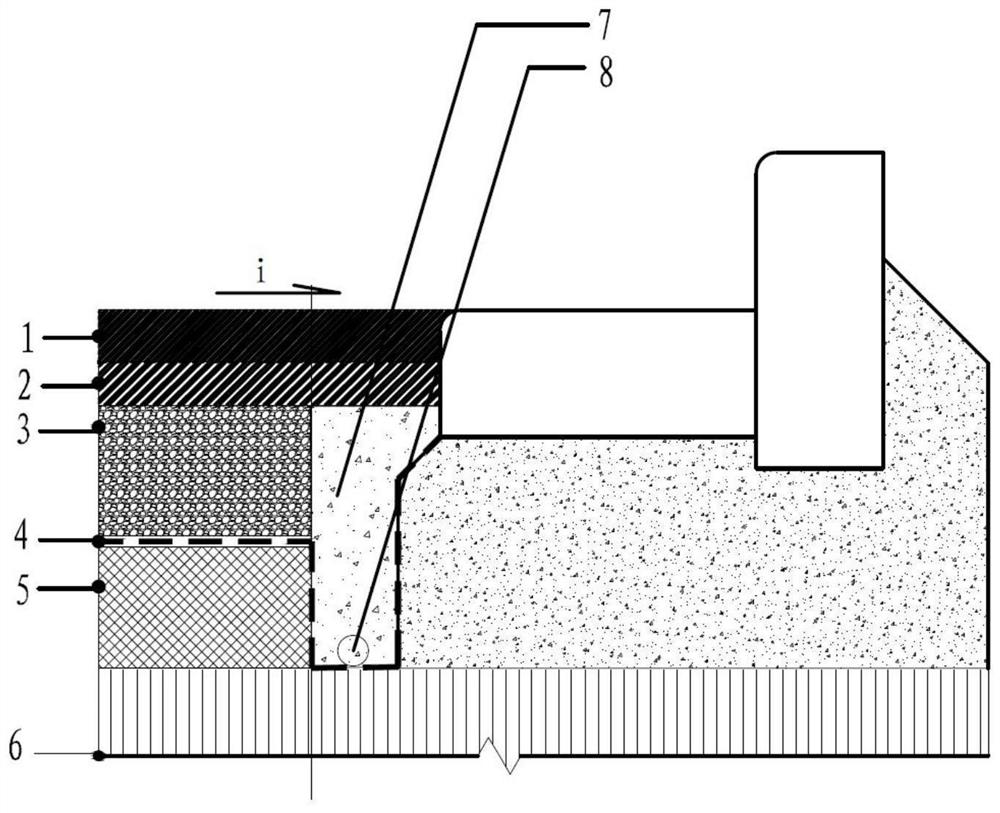

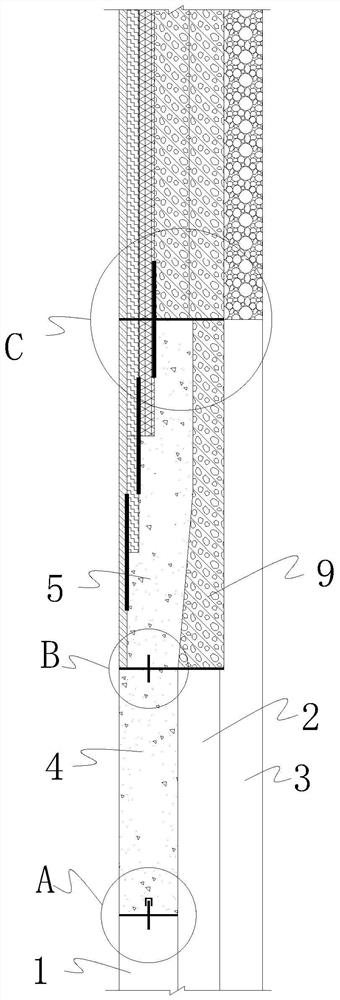

A pavement structure internal drainage system capable of eliminating water seepage from the pavement surface

InactiveCN104480829BExtended service lifePrecise positioningIn situ pavingsPaving gutters/kerbsCrushed stoneStructural engineering

Owner:CHANGAN UNIV

Highway pavement structure and construction method thereof

ActiveCN112921738AImprove pressure bearing capacityImprove crack resistancePaving reinforcementsIn situ pavingsRoad surfaceRebar

The invention discloses a highway pavement structure and a construction method thereof. The highway pavement structure comprises a gravel leveling layer, a cement stabilized soil subbase layer arranged on the upper surface of the gravel leveling layer, an anti-collapse net rack, a cement stabilized macadam base layer, a concrete cushion layer, an epoxy asphalt layer; the anti-collapse net rack is arranged in the cement stabilized soil subbase layer and is fixedly connected with the cement stabilized soil subbase layer; the cement stabilized macadam base layer is arranged on the upper surface of the cement stabilized soil subbase layer; the concrete cushion layer is arranged on the upper surface of the cement stabilized macadam base layer; and the epoxy asphalt layer is arranged on the upper surface of the concrete cushion layer. The vertical load is converted into part of horizontal thrust through a steel bar wave-shaped grating net, the pressure bearing capacity of the highway pavement is improved, and thus the problems that a surface layer structure of an existing highway pavement structure is single, the bearing capacity of the surface layer structure mainly depends on the quality of materials, and the structure for improving the strength is not provided are effectively solved.

Owner:李现伟

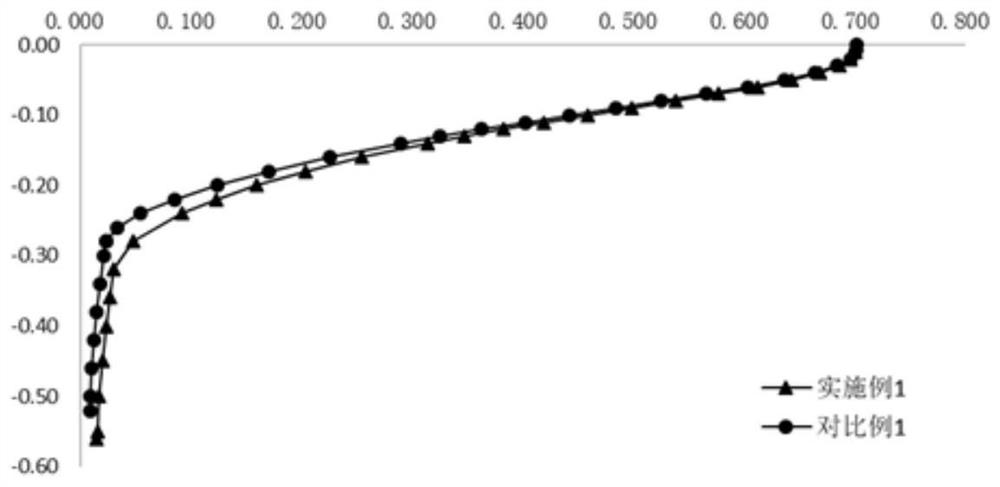

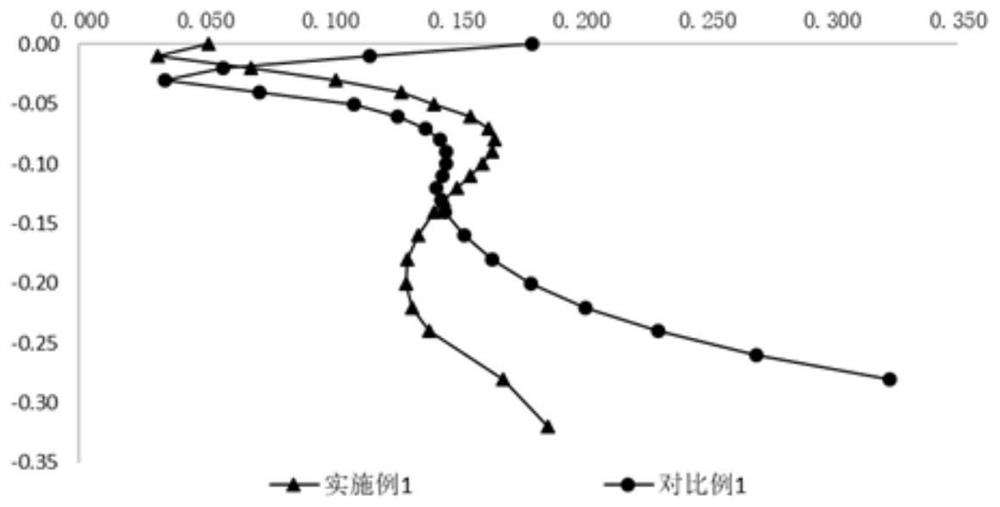

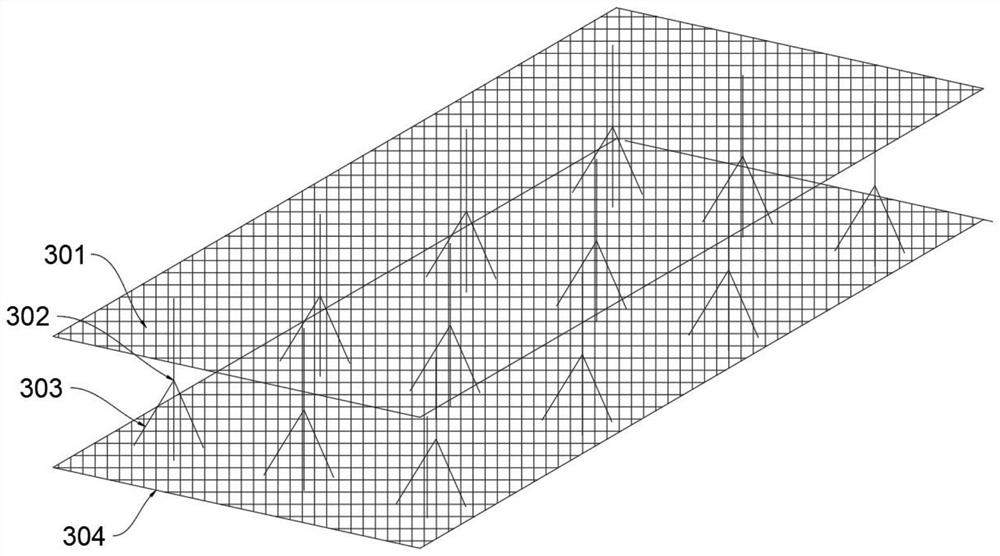

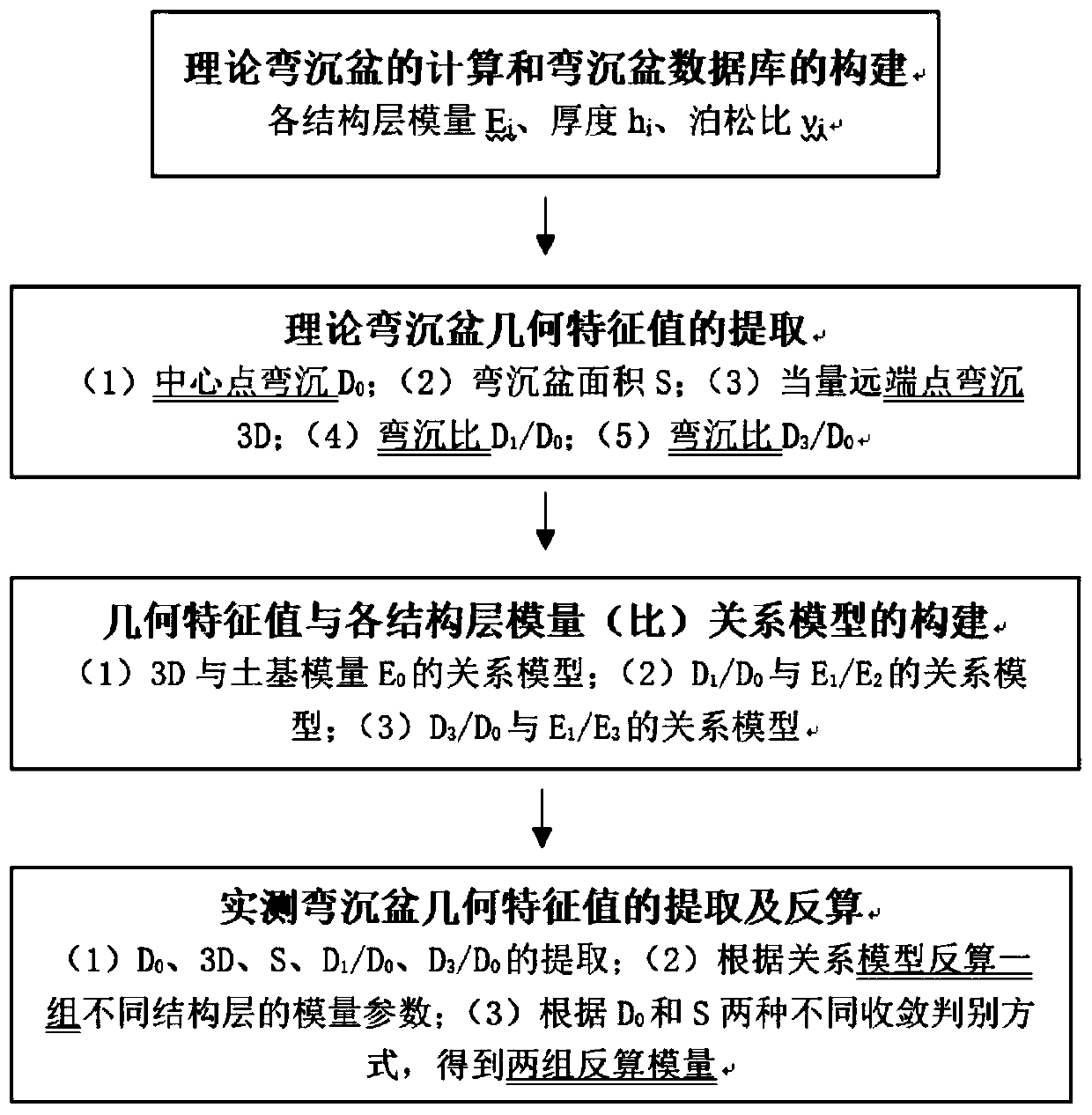

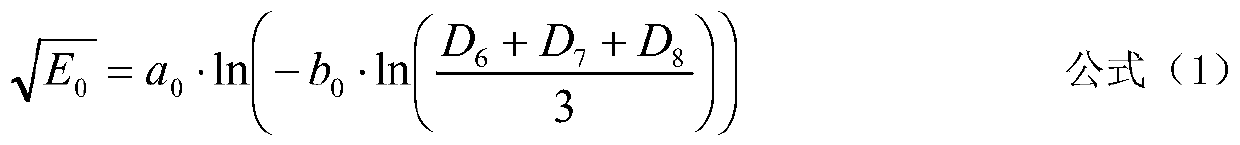

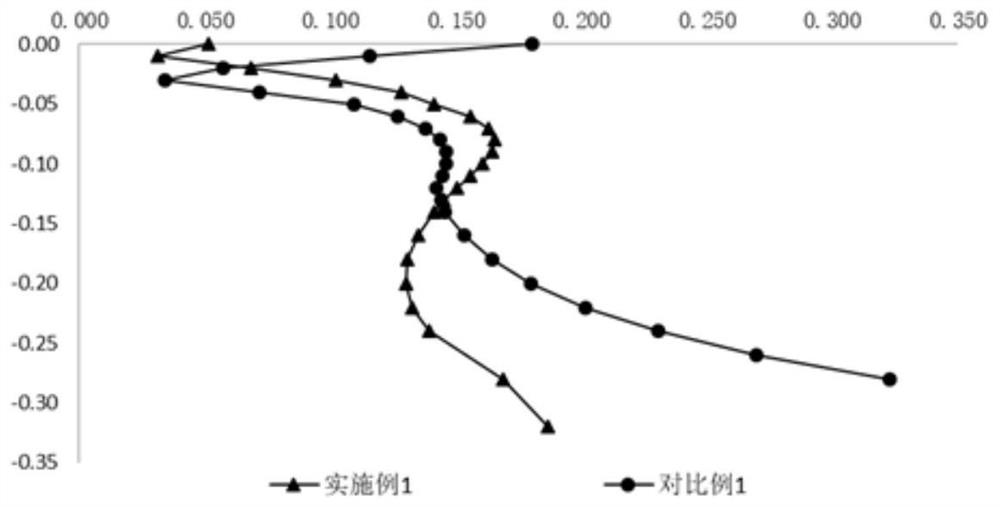

Four-layer pavement modulus back calculation method based on FWD deflection basin geometrical characteristics

PendingCN110765691AReduce mistakesNumerically stableDesign optimisation/simulationMechanical modelsStructural engineering

The invention discloses a four-layer pavement modulus back calculation method based on FWD deflection basin geometrical characteristics. The four-layer pavement modulus back calculation method comprises the following steps: 1, calculating a theoretical deflection basin and corresponding characteristic values of a pavement to be subjected to back calculation by adopting an elastic layered system mechanical model; 2, establishing a relation model of an equivalent far-end deflection point and a soil foundation modulus by adopting a nonlinear function; 3, establishing a relation model of the deflection ratio of the central point and the modulus ratios of the surface layer and the base layer by adopting a nonlinear function; 4, establishing a relation model between the deflection ratio of the fourth point and the central point and the modulus ratio of the surface layer and the subbase layer by adopting a nonlinear function; and 5, extracting a geometrical characteristic value of the actually measured deflection basin according to the constructed relation model, and respectively and reversely calculating modulus parameters of each structural layer corresponding to the actually measured FWD deflection basin according to two different convergence discrimination modes of central point deflection and deflection basin area. The four-layer modulus back calculation result is stable, the difference between the four-layer modulus back calculation result and a theoretical calculation value is small, and a reliable basis can be provided for evaluating the actual modulus state of each structural layer of an in-service pavement.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

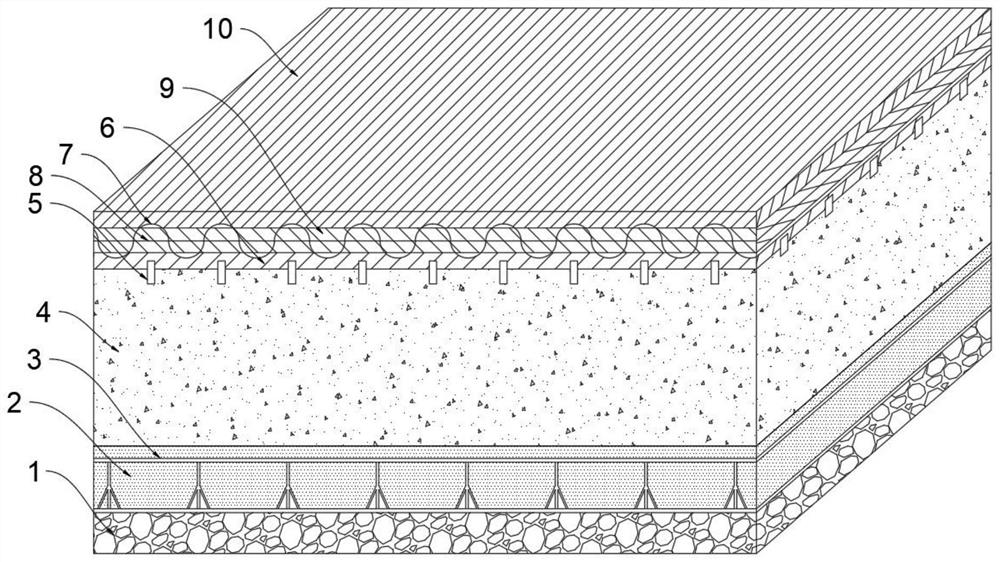

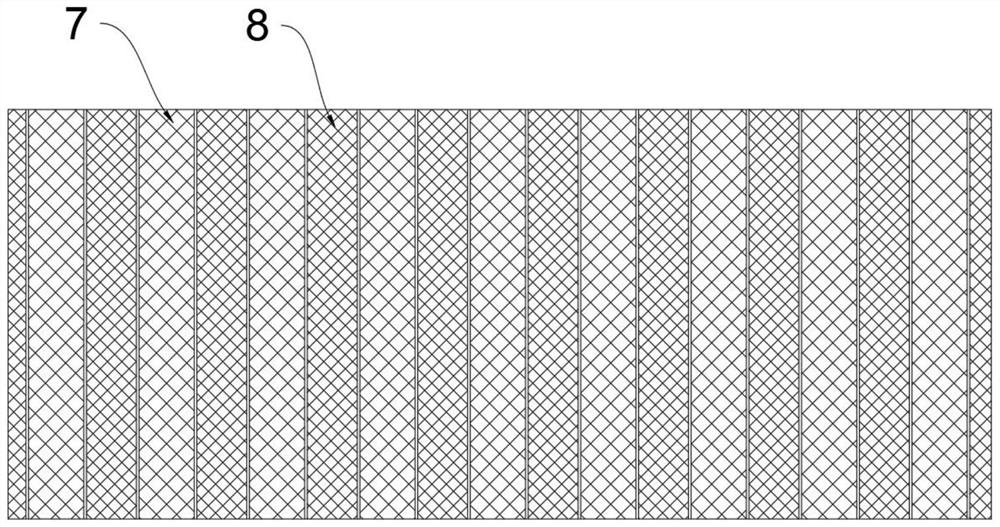

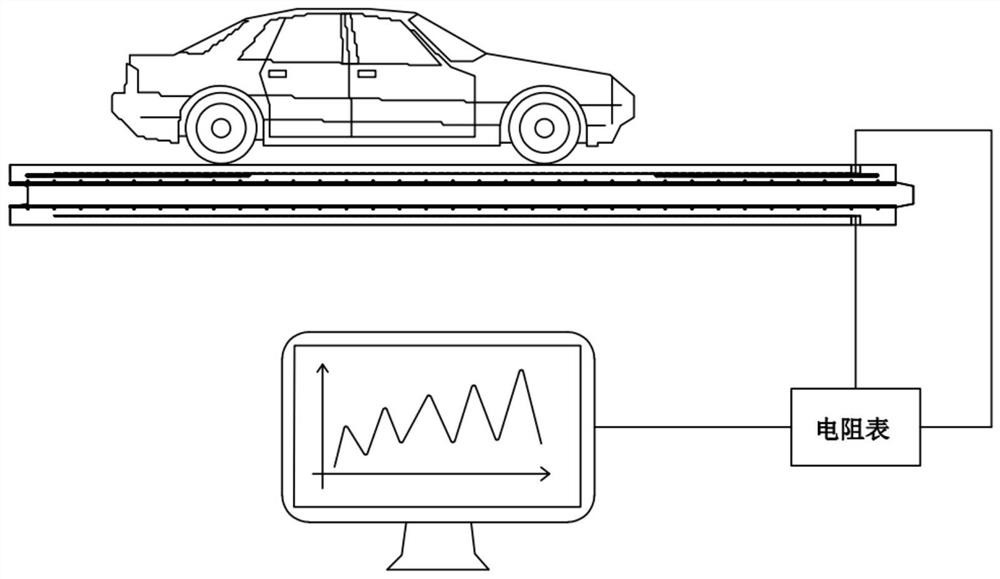

Piezoresistance self-sensing cement concrete material, pavement structure and paving method

PendingCN112500067AWith self-awarenessImprove conductivitySingle unit pavingsEmbedding padsCarbon nanotubeStructural engineering

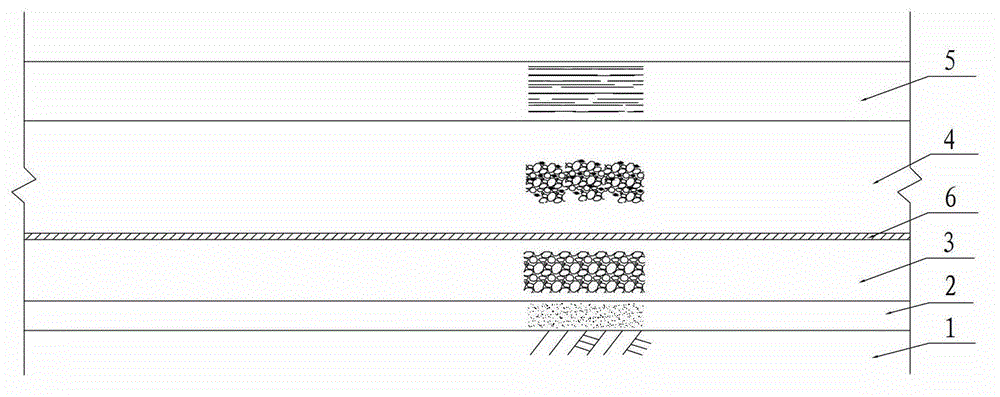

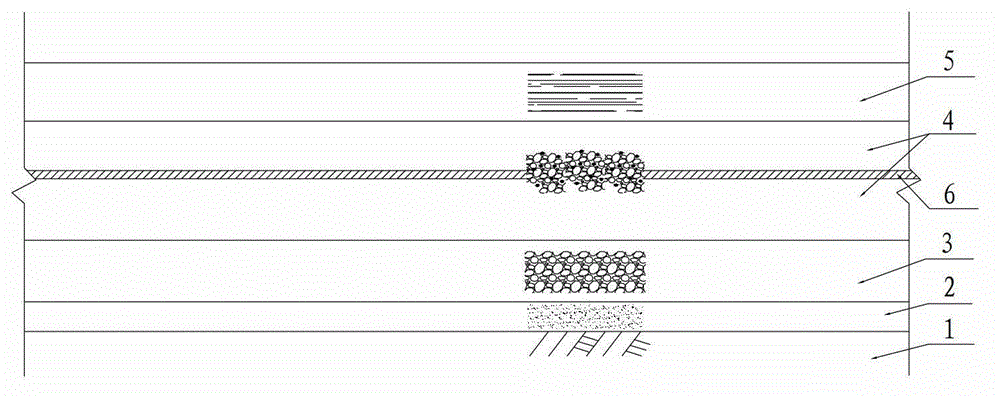

The invention discloses a piezoresistance self-sensing cement concrete material, which is prepared from the following raw material components: cement, water, sand, gravels, graphite powder, steel slag, graphene nanosheets, multi-walled carbon nanotubes and a dispersing agent. The invention further discloses an assembly type cement concrete pavement structure with the piezoresistance self-sensing function. The assembly type cement concrete pavement structure comprises a roadbed layer, a subbase layer, a base layer, waterproof geotextile and a plurality of piezoresistance self-sensing cement concrete pavement slabs which are sequentially arranged from bottom to top. The invention further discloses a paving method of the concrete pavement structure, the self-sensing cement concrete pavement slabs are hoisted on the supporting layer through the lifting hooks and connected through the rabbet mortises and tenons, after laying is completed, the positions of the lifting hooks are leveled, andthe assembly type cement concrete pavement structure with the self-sensing function is obtained. The fabricated cement concrete pavement structure with the self-sensing function provided by the invention can be locally replaced, so that the cost is reduced.

Owner:CHANGAN UNIV

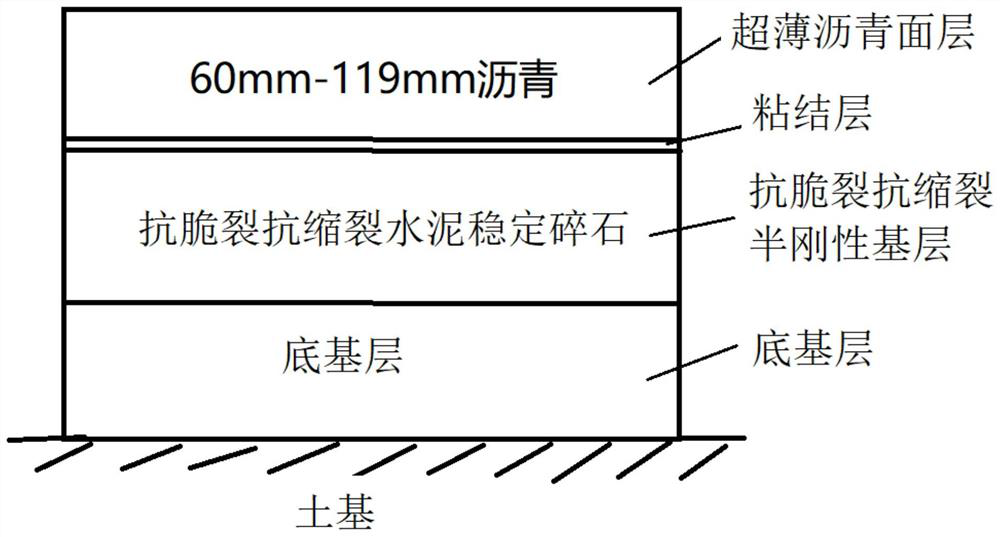

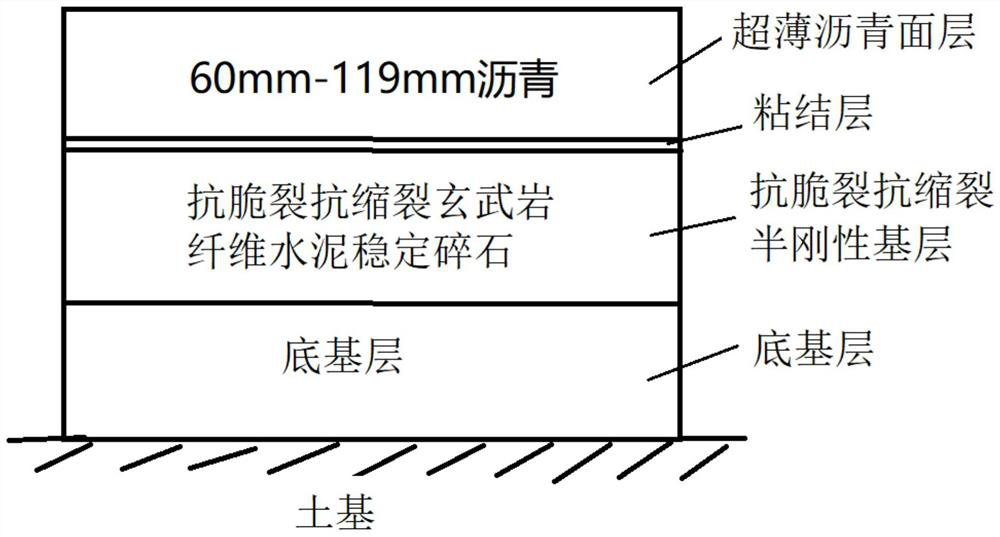

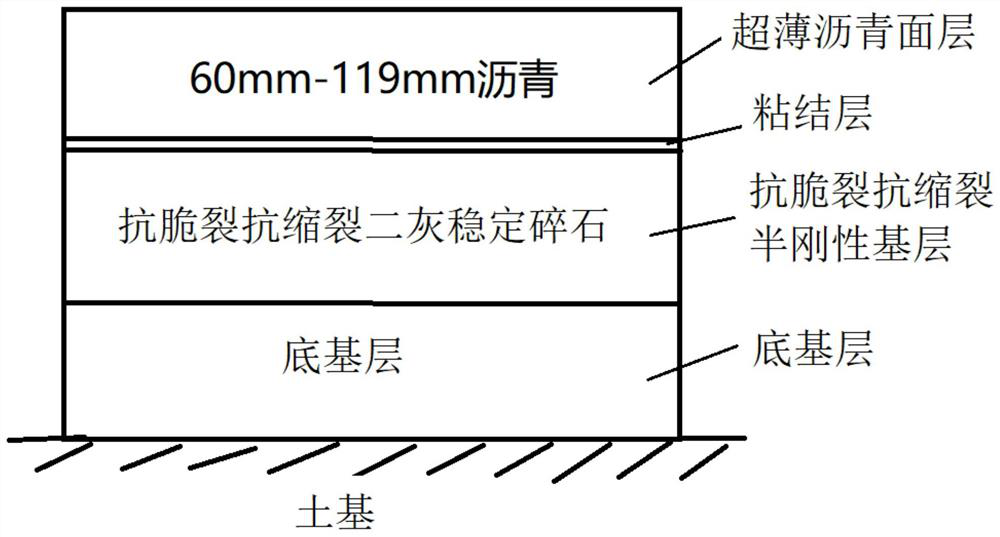

Ultra-thin asphalt pavement for high-grade highway

PendingCN113957761AReduce diseaseSave maintenance moneyIn situ pavingsRoads maintainencePavement maintenanceStructural engineering

The invention provides an ultra-thin asphalt pavement for high-grade highway. The high-grade highway ultra-thin asphalt pavement is specially used for expressways and first-grade highways and comprises an ultra-thin asphalt surface layer, a bonding layer, an anti-brittle-fracture anti-shrinkage-crack semi-rigid base layer, a subbase layer and a soil base, the ultra-thin asphalt surface layer, the bonding layer, the anti-brittle-fracture anti-shrinkage-crack semi-rigid base layer, the subbase layer and the soil base are arranged from top to bottom, the ultra-thin asphalt surface layer is paved on the anti-brittle-fracture anti-shrinkage-crack semi-rigid base layer, and the ultra-thin asphalt surface layer and the anti-brittle-fracture anti-shrinkage-crack semi-rigid base layer are combined through the bonding layer. The pavement rut damage is reduced, and a lot of pavement maintenance funds are saved; and the early damage phenomenon of the asphalt pavement is eliminated, road construction funds are saved, the service life of the pavement is prolonged, the long-life asphalt pavement can be constructed, and a large amount of road construction funds are saved.

Owner:张靖

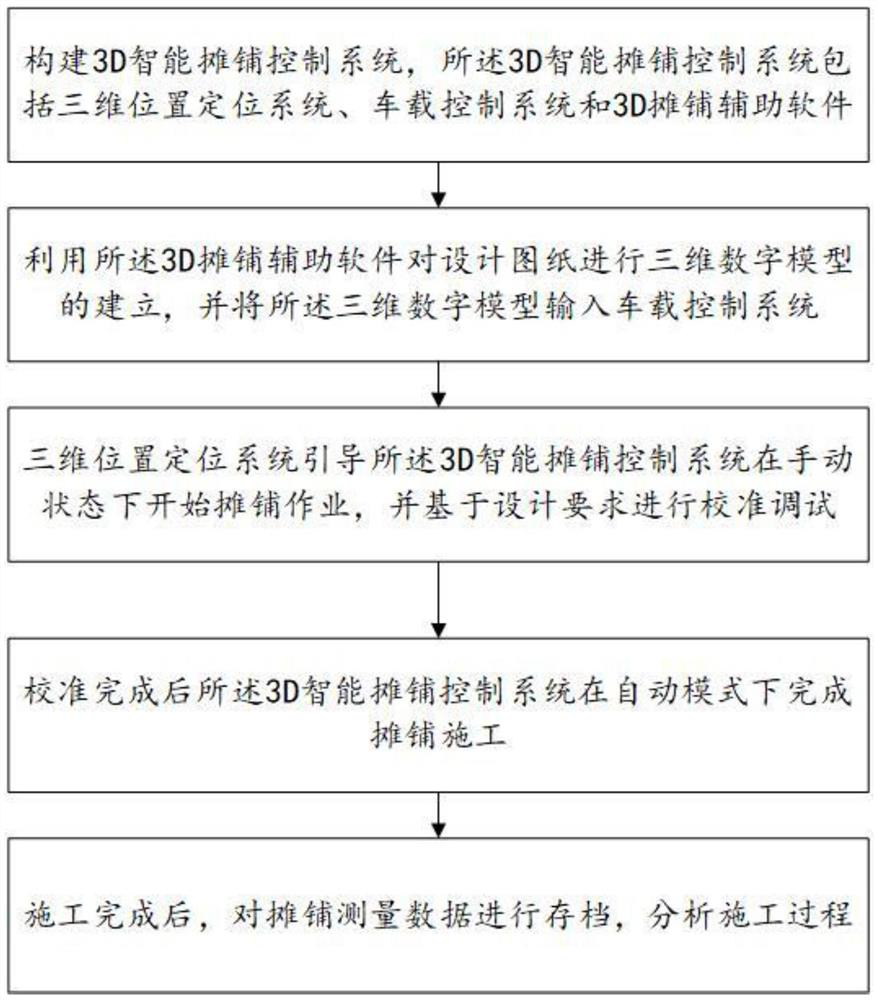

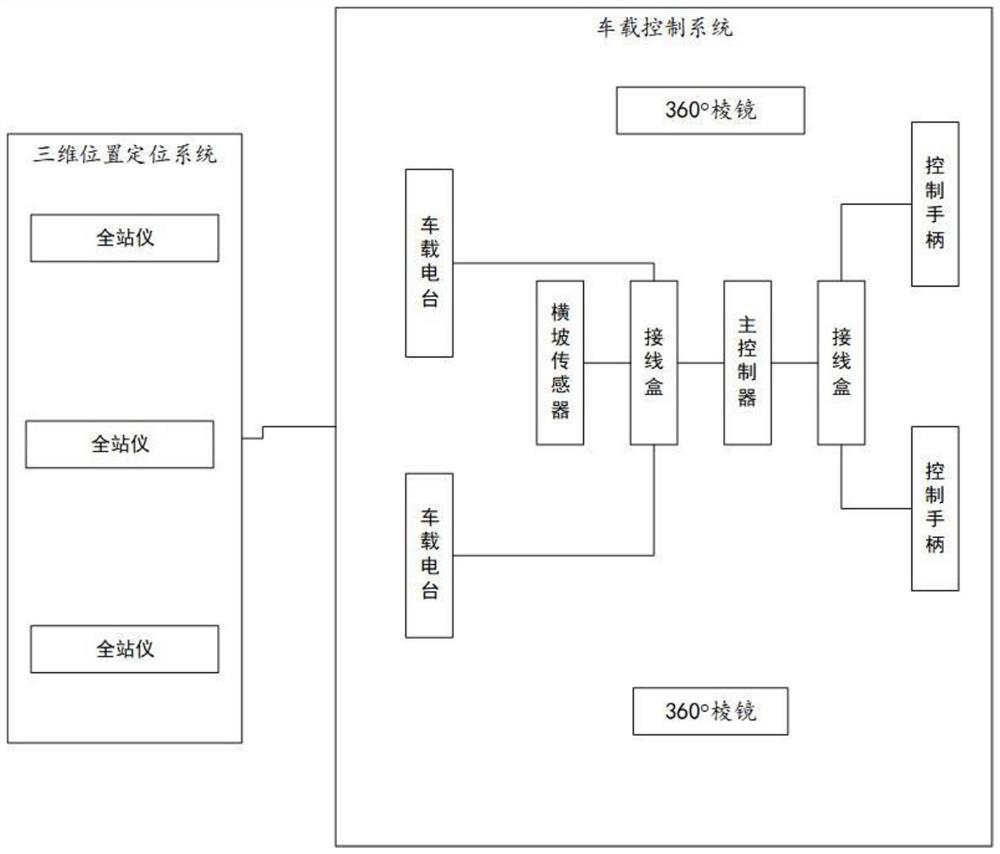

Intelligent paving method and system for asphalt water-stable subbase layer and asphalt undersurface layer

PendingCN114839970AReduce in quantitySolve quality problemsIn situ pavingsClimate change adaptationControl systemIn vehicle

The invention discloses an intelligent paving method and system for an asphalt water-stable subbase layer and an asphalt lower surface layer, and relates to the technical field of pavement paving, and the intelligent paving method comprises the steps that a 3D intelligent paving control system is constructed, and the 3D intelligent paving control system comprises a three-dimensional position positioning system, a vehicle-mounted control system and 3D paving auxiliary software; establishing a three-dimensional digital model for the design drawing by utilizing 3D paving auxiliary software, and inputting the three-dimensional digital model into a vehicle-mounted control system; the three-dimensional position positioning system guides the 3D intelligent paving control system to start paving operation in a manual state, calibration debugging is carried out based on design requirements, and the 3D intelligent paving control system completes paving construction in an automatic mode after calibration is completed; after construction is completed, paving measurement data are archived, and the construction process is analyzed. The problems that in traditional pavement paving construction, quality control is difficult, the work efficiency index is low, and cost input is large can be solved, and the construction efficiency is improved.

Owner:THE 5TH ENG OF THE THIRD ENG GROUP OF CHINA RAILWAY +1

Highway pavement structure utilizing waste residues

PendingCN111485470AImprove bending and tensile strengthIncreased shear strengthIn situ pavingsPre stressRoad surface

The invention belongs to the field of pavement structures, and discloses a highway pavement structure utilizing waste residues. The highway pavement structure comprises a subbase layer, a base layer,a lower surface layer and an upper surface layer which are laid from bottom to top, wherein the subbase layer is a cement waste residue stabilized aeolian sand subbase layer; the pavement is simple instructure, the prestressed concrete layer is adopted as the lower surface layer, the advantage of high strength of prestressed concrete is utilized, longitudinal and transverse pressure stress is applied to the pavement by applying oblique prestress, and the flexural-tensile strength of the concrete plate is improved; in the cement stabilized aeolian sand subbase layer, power plant waste residuesare adopted to replace part of aeolian sand so that the compressive strength of the cement stabilized aeolian sand subbase layer is improved, and the 7d unconfined compressive strength of the obtained cement waste residue stabilized aeolian sand subbase layer is 2.0-2.8 MPa; the strength of the cement waste residue stabilized macadam aeolian sand base layer can still meet the requirements of Technical Regulations for Construction of Highway Pavement Base Layers; and power plant waste residues and aeolian sand can be effectively utilized, and the production cost is low.

Owner:XIAN HIGHWAY INST +1

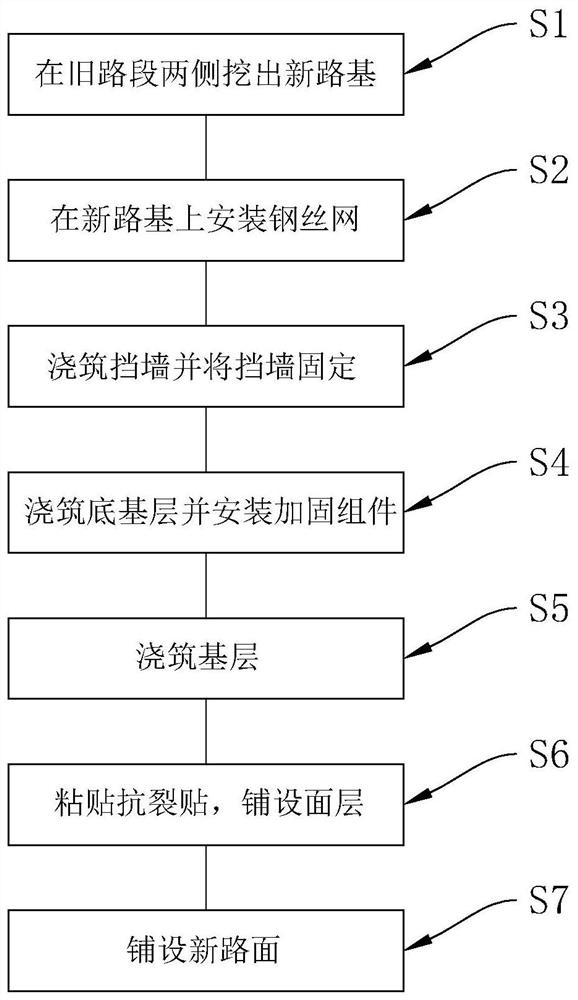

Rural old road reconstruction construction method

PendingCN114855532AImprove bindingImprove stabilityArtificial islandsIn situ pavingsCrushed stoneArchitectural engineering

The invention discloses a rural old road reconstruction construction method, and relates to the technical field of road construction, the rural old road reconstruction construction method comprises an old road section, and the method comprises the following steps: S1, digging a step-shaped first splicing groove and a step-shaped second splicing groove in the two sides of the old road section to form a new roadbed; s2, steel wire meshes are laid at the groove bottoms of the first splicing groove and the second splicing groove, and one sides of the steel wire meshes are inserted into the groove walls of the first splicing groove and the second splicing groove; s3, a retaining wall is poured on the side, away from the old road section, of the new roadbed through concrete; s4, laying 4% cement stabilized graded broken stones on the first splicing groove to form a subbase layer; s5, 5.5% cement stabilized graded broken stones are laid on the subbase layer and the groove bottom of the second splicing groove to form a base layer; s6, an anti-crack patch is attached to the joint of the base layer and the old road section, and asphalt concrete is laid on the old road section and the base layer to form a surface layer; and S7, paving asphalt mastic macadam on the surface layer to form a new pavement. New and old road sections can be more stable.

Owner:重庆昂然建筑工程有限公司

Emulsified asphalt cold-recycled pavement structure and rapid maintenance method of pavement

ActiveCN112301826AShorten the regimen timeEasy to loseIn situ pavingsBitumen emulsionStructural engineering

The invention discloses an emulsified asphalt cold-recycled pavement structure and a and rapid maintenance method of pavement. The method comprises a compacted structure and a newly-laid structure, ajoint is arranged between the compacted structure and the newly-laid structure, and the compacted structure and the newly-laid structure comprise an asphalt upper surface layer, an asphalt middle surface layer, an asphalt lower surface layer, a sealing layer and a roadbed layer from top to bottom; the asphalt upper surface layer includes SMA13 type asphalt, and the thickness of the asphalt upper surface layer is 4cm; the asphalt middle surface layer is made of AC20 type asphalt, and the thickness of the asphalt middle surface layer is 6cm; the asphalt lower surface layer is made of AC25 type asphalt, and the thickness of the asphalt lower surface layer is 8cm; the sealing layer includes SBS modified asphalt; the roadbed layer comprises an emulsified asphalt cold-recycled base layer, a cement stabilized macadam base layer and a cement stabilized macadam subbase layer; and the emulsified asphalt cold-recycled base layer is an emulsified asphalt cold-recycling mixture, and the thickness of the emulsified asphalt cold-recycling mixture is 10cm. According to the invention, the curing time of 5-7 days in the prior art can be shortened to 3 days, the construction time is obviously shortened, and then the construction cost is reduced.

Owner:中国建筑土木建设有限公司

A long-term durable and stable road yard pavement structure layer and its construction method

ActiveCN103233406BReduce distortionIncreased resistance to uneven deformationIn situ pavingsTemporary pavingsSurface layerChipseal

The invention discloses a long-term and durable stably-used road yard pavement structure layer which structurally comprises a sand cushion layer, a broken stone subbase layer, a stabilization layer and a surface layer, which are arranged on a soil base from bottom to top sequentially, wherein the stabilization layer consists of a cement stabilization layer and a flexible structure layer that is made of a geosynthetic material having a reinforcement function. According to the pavement structure layer, the sand cushion layer with certain thickness is paved between the soil base and the graded broken stone cushion layer, so that a load transferred by the subbase layer can be diffused conveniently for reducing the deformation of the soil base and improving the differential deformation resistance of the pavement structure layer; adverse effects of post-construction settlement or differential settlement on the pavement structure layer are reduced to a great extent; the long-term and durable stability of a road yard is improved; the maintenance cost during operation is lowered greatly; and the pavement structure layer is simple and easy to construct, and is suitable for popularization and application.

Owner:CCCC FOURTH HARBOR ENG INST +2

Roadbed pavement structure located on embankment pipeline and construction method

The invention discloses a roadbed and pavement structure located on an embankment pipeline. The structure comprises a surface layer, a base layer, a graded broken stone subbase layer, a composite geomembrane and a roadbed filling layer which are positioned above the embankment pipeline from top to bottom, the surface layer is located on the surface of a road, the base layer is laid below the surface layer, the graded broken stone subbase layer is laid below the base layer, the roadbed filling layer is laid below the graded broken stone subbase layer, the roadbed filling layer is located above an undisturbed soil layer, and the undisturbed soil layer is located above the undisturbed soil layer. A composite geomembrane is laid between the base layer and the graded broken stone subbase layer. According to the method, non-excavation reinforcement measures are adopted for an existing pipeline, the embankment-adjacent area is reinforced through the cement-soil mixing piles, excavation of the embankment foot is avoided, and the foundation strength of the embankment-adjacent pipeline area and the embankment anti-seepage capacity are improved.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

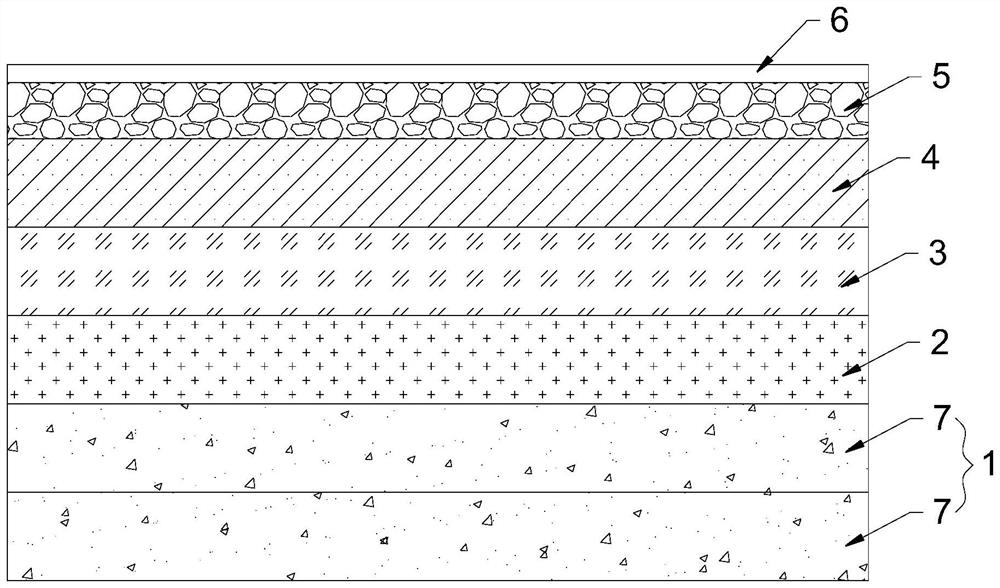

Permeable asphalt pavement structure

ActiveCN110846968BReduce diseaseIncreased durabilityIn situ pavingsPaving gutters/kerbsSoil scienceSlag

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS +1

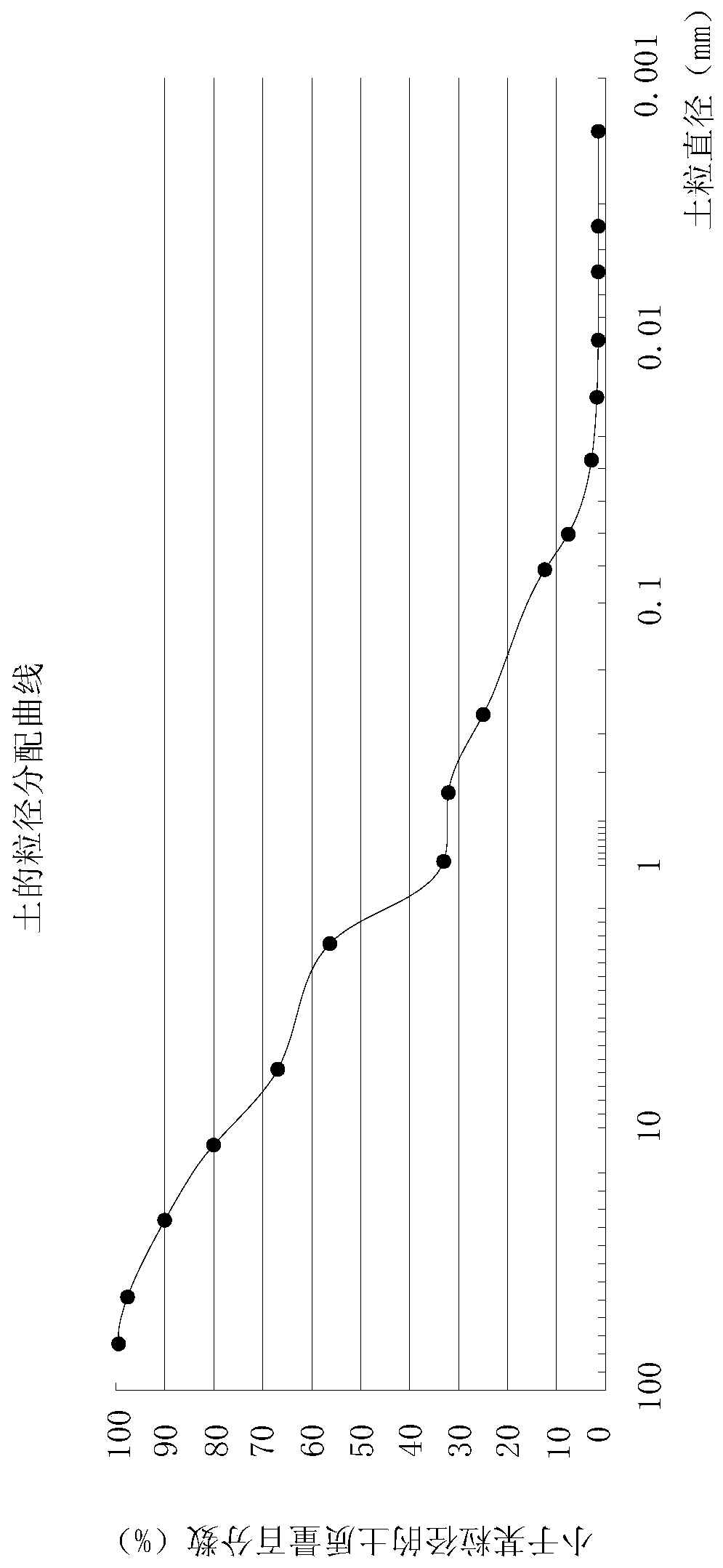

Novel road and construction method thereof

PendingCN114059412AEasing the time to traverse the road surfaceIncreased durabilityIn situ pavingsRoads maintainenceRoller-compacted concreteSoil science

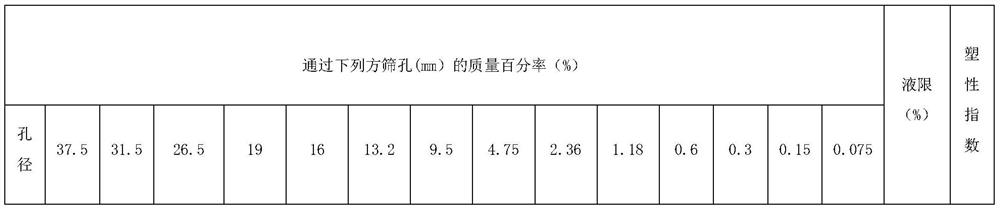

The invention relates to a novel road which comprises a cement-stabilized soil layer, a graded broken stone hardcore, a cement-stabilized graded broken stone subbase layer, a roller compacted concrete base layer, an asphalt mastic broken stone structural layer and an asphalt thin overlay which are sequentially paved, according to the the cement-stabilized soil layer, gravel soil or sandy soil is selected as filler, the maximum nominal particle size of the filler is smaller than or equal to 53 mm, the soil particle non-uniformity coefficient is larger than 10, the liquid limit is smaller than or equal to 40, the plasticity index is smaller than or equal to 12, and the organic matter content is smaller than 2%. The asphalt mastic macadam structure layer can effectively relieve the time that reflection cracks penetrate through the pavement, so that the durability of the pavement is improved, the service life of the pavement is prolonged, meanwhile, the total thickness of the pavement structure layer can be reduced, geological materials are saved, and the construction period of a project is shortened. The invention further relates to a construction method of the novel road.

Owner:GUANGDONG GUANYUE HIGHWAY & BRIDGE

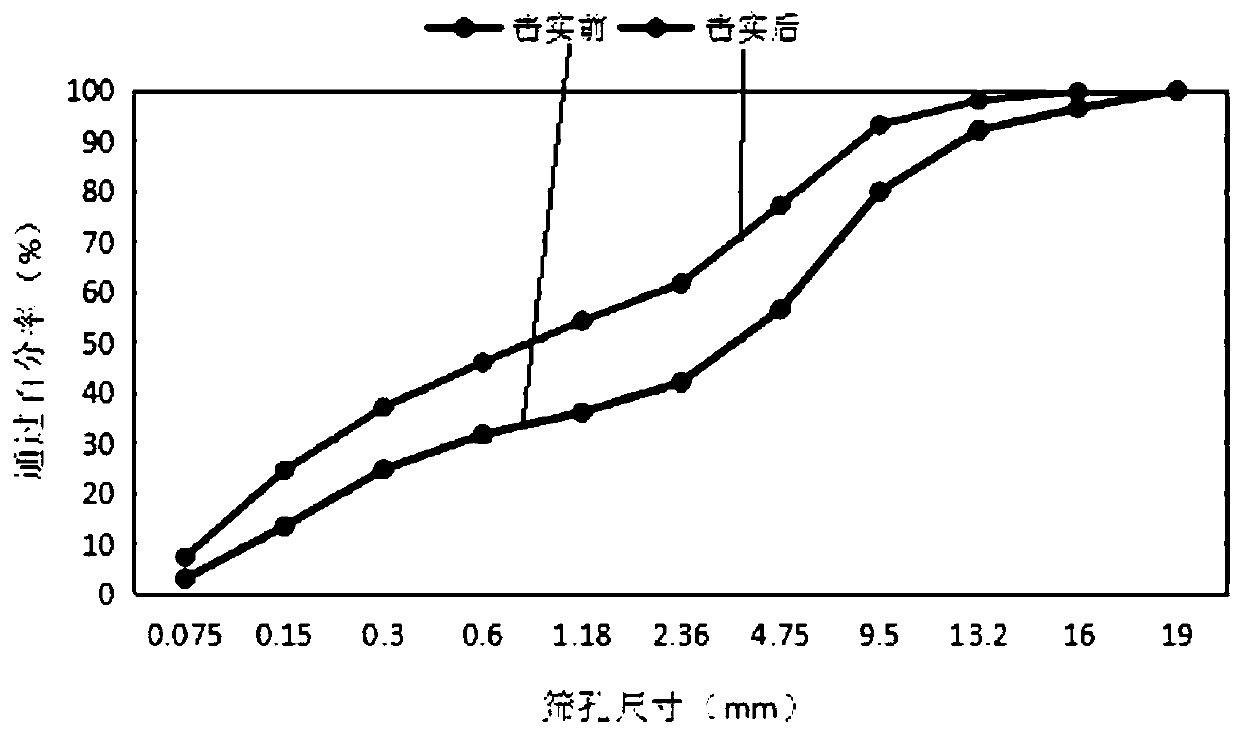

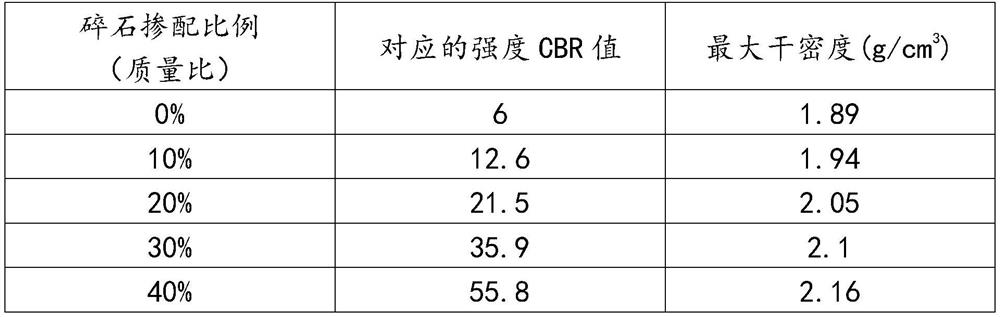

Highway pavement subbase construction method

InactiveCN112323584AImprove deformation resistanceImprove bearing capacityRoads maintainenceSoil scienceRoad surface

The invention relates to a highway pavement subbase construction method, and belongs to the technical field of building construction. The method is used for improving the strength of gravelly soil andimproving and utilizing an existing soil source to enable an originally substandard material to reach the technical standard of a subbase material of a pavement. According to the construction method,30% of gravels are doped into 70% of gravelly soil according to a mass ratio, the gravelly soil is improved, a land leveler and a road roller are matched to stir and compact the mixed gravelly soil and a gravel mixture, the mixed gravelly soil and original gravel particles in a soil body jointly form a framework structure, a bearing capacity of the soil body is improved, and deformation resistance of the subbase is enhanced. The actually measured deflection value of the gravelly soil subbase after the gravelly soil subbase is improved by mixing the gravelly soil is obviously improved, and thegravelly soil subbase improved by the gravelly soil is more compact in structure.

Owner:SHANGHAI CONSTRUCTION GROUP

Construction method of subbase of highway pavement

InactiveCN114790671AImprove stress resistanceReduce washoutIn situ pavingsPaving detailsInsulation layerReinforced concrete

The invention discloses a construction method of a subbase layer of a highway pavement, and particularly relates to the technical field of building construction, and the construction method comprises the following steps: step 1, cleaning and trimming the surface of the subbase layer, step 2, recovering a center line, step 3, paving cobblestones and reinforced concrete on the surface of the subbase layer, step 4, adding a thermal insulation layer and an anti-crack layer, and step 5, stacking a conventional mixture. According to the construction method, on the basis of original conventional mixture laying construction, the cobblestones and the reinforced concrete are fully mixed and coagulated by laying the cobblestones and the reinforced concrete, so that a powerful supporting surface is formed on the surface of the bottom of the subbase layer, and the overall pressure resistance of a highway pavement is improved; meanwhile, the thermal insulation mixture and the anti-cracking mixture are additionally arranged on the basis of the subbase layer, so that the influence on the highway pavement caused by frost cracking of the bottom of the subbase layer due to cold weather is avoided, and the high strength, the high thermal insulation property and the high anti-cracking property of the highway pavement are improved on the basis of not influencing conventional construction.

Owner:安徽中诚建业建设工程有限公司

Asphalt highway capable of preventing water accumulation and construction method

PendingCN110656551ASolve the problem of stagnant waterWater will notSewerage structuresProtective constructionStructural engineeringRoad surface

The invention discloses an asphalt highway capable of preventing water accumulation and a construction method. The asphalt highway capable of preventing water accumulation comprises a road; the road comprises a surface course, a base course, a subbase course and a cushion course; the surface course is arranged on the top layer of a road; the base course is below the surface course; the subbase course is below the base course; the cushion course is arranged in the bottom layer of the road; water drainage ditches are formed in the two sides of the road; cover plates cover openings of the water drainage ditches; and protecting structures are arranged on one sides, far away from the road, of the water drainage ditches. The asphalt highway capable of preventing water accumulation has the advantages that the design is reasonable, the water accumulation problem of a pavement can be effectively solved, accumulated water can be prevented from splashing in rainy days, and accidents caused by water accumulation can be reduced.

Owner:CITIC GUOAN CONSTR GRP CO LTD

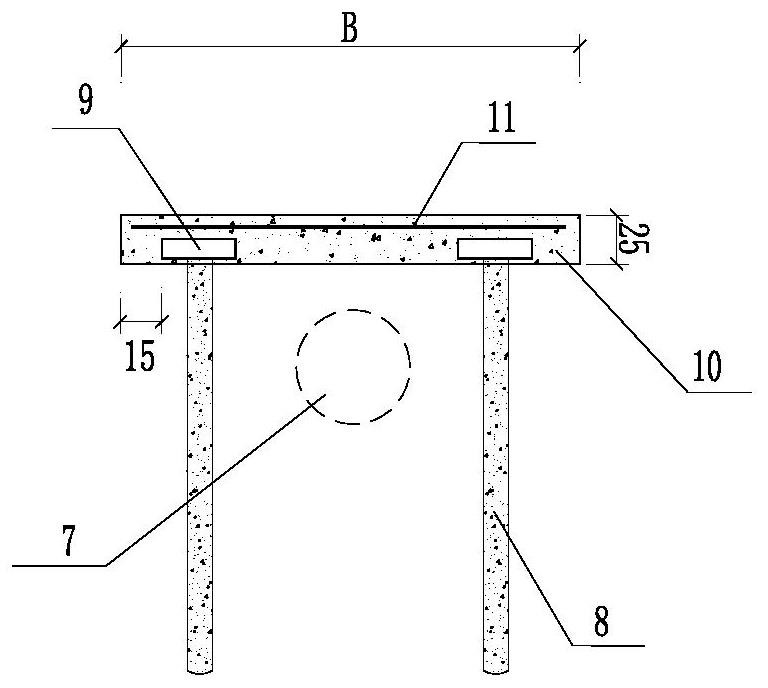

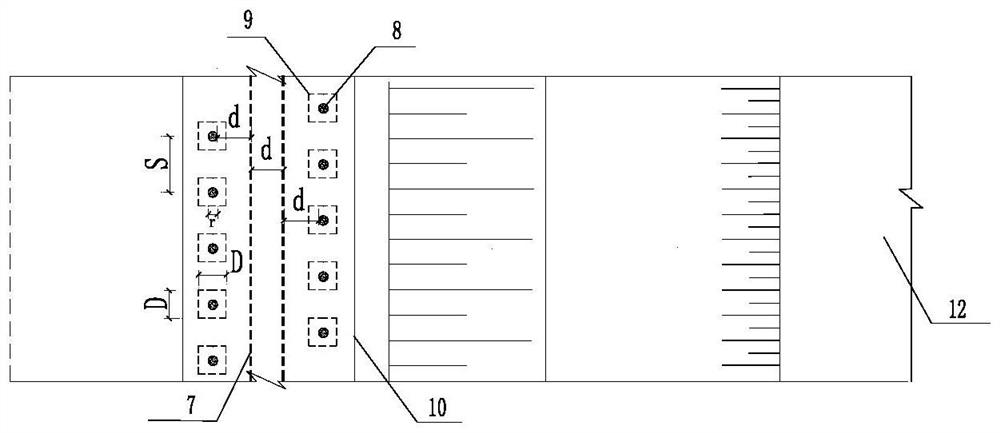

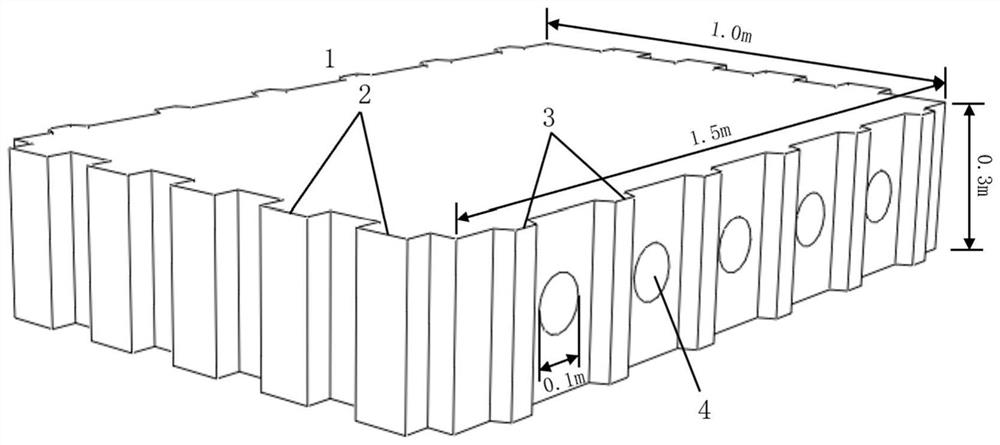

A combined assembled cement concrete pavement structure and construction method

ActiveCN108999053BImprove integrityImprove temperature stabilityTemporary pavingsArchitectural engineeringStructural engineering

The invention provides a combined assembled cement concrete pavement structure and a construction method, wherein a water barrier layer, a drainage strip and a drainage base layer are laid on the subbase layer, and the drainage strip is connected with the vertical drainage pipe in the prefabricated panel section; A joint end plate, a joint end plate 2 and a squeeze filler body are arranged at thevertical joint of the prefabricated plate section and the cast-in-place joint section, and a limit joint and a flexible joint layer are arranged at the joint of the lower surface, and the upper surface is provided. The deformation coordination plate is disposed, and the tension connecting rib is disposed in the middle; the tension connecting rib of the prefabricated plate segment and the cast-in-place connecting segment is provided with a limiting clip through the two ends of the hole, and the tension connecting rib is connected by the locking bolt; The upper surface of the lower connecting platform of the cast-in-place connecting section is provided with a connecting limit groove, and the bottom is integrally formed with the vertical reinforcing pier. The pavement structure and the construction method provided by the invention can not only improve on-site construction efficiency and construction quality, but also enhance the integrity of the pavement structure and improve the temperature stability and durability of the pavement structure.

Owner:JIANGXI BOHUI ENG TECH SERVICE CO LTD

New and old pavement connecting structure and construction process

InactiveCN114837035AAvoid crackingAvoid separationPaving reinforcementsClimate change adaptationGlass fiberArchitectural engineering

The invention discloses a new and old pavement connecting structure and a construction process, and belongs to a road construction technology. The pavement structure comprises an old pavement structure and a new pavement structure, the old pavement structure is sequentially provided with a cement concrete pavement panel, a cement concrete base layer and a cement concrete subbase layer from top to bottom, and the extending lengths of the cement concrete pavement panel, the cement concrete base layer and the cement concrete subbase layer towards the new pavement structure are increased layer by layer; a connecting section is arranged between the old pavement structure and the new pavement structure, and a step surface is arranged on one side, close to the new pavement structure, of the connecting section; a connecting section matched with the step face on the second cast-in-place cement concrete is arranged on the side, close to the old pavement, of the new pavement structure, and glass fiber grids are arranged at the joints of the connecting section and the step face. The problems of pavement cracking, separation, high and low quality, short road service life, poor driving comfort and the like are effectively solved.

Owner:CHINA MCC17 GRP

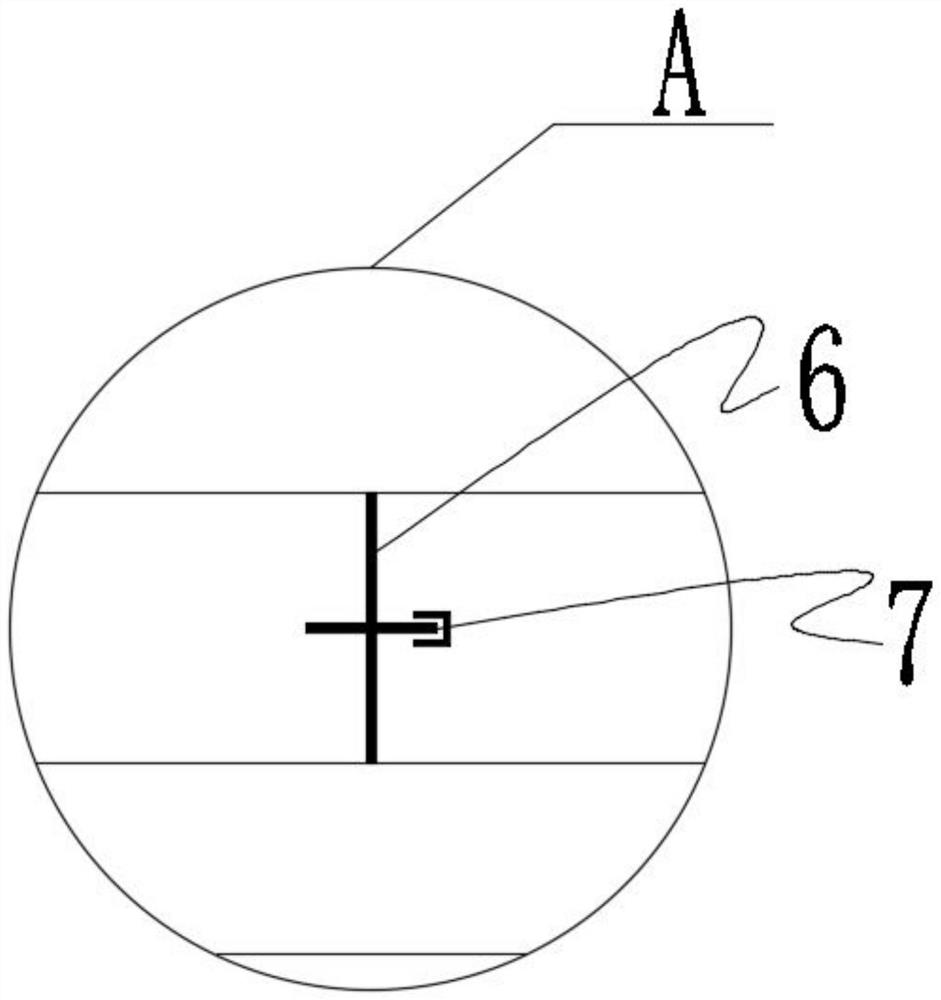

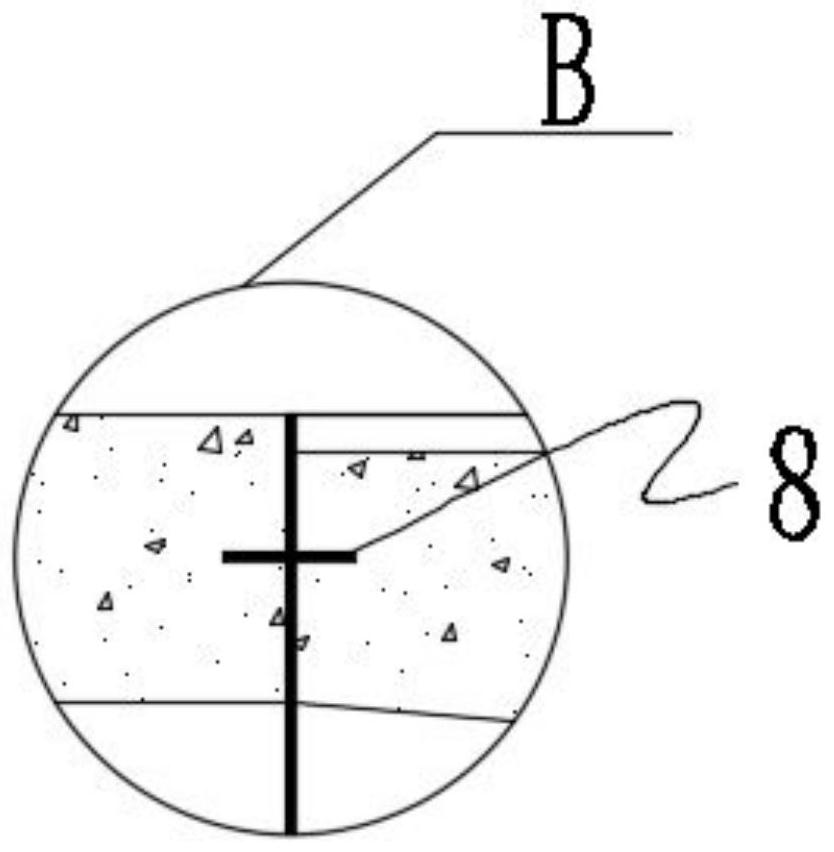

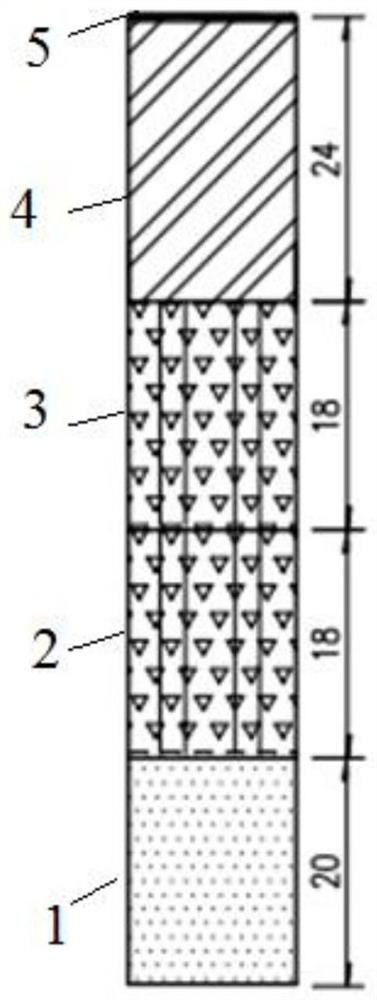

Curve braking performance test pavement and construction method thereof

ActiveCN114032732AEasy to useGuaranteed accuracyPaving reinforcementsIn situ pavingsStructural engineeringRoad surface

The invention relates to a curve braking performance test pavement and a construction method thereof. The curve braking performance test pavement sequentially comprises a subbase layer, a base layer, cement concrete and a carborundum pavement from bottom to top, the subbase layer is lime stabilized soil with the thickness being 20-70 cm, the base layer is a cement stabilized macadam layer with the thickness being 15-70 cm, the cement concrete is a cement concrete layer with the thickness being 24-40 cm, and the carborundum pavement is a carborundum layer with the thickness of 8-10 mm. According to the curve braking test pavement provided by the invention, the service life of the test road can be prolonged while the accuracy of the detection result of the curve braking test pavement is ensured.

Owner:北京愚公道路养护有限公司 +1

Reservation and replacement of cast-in-place curb stones on asphalt concrete pavement and its construction method

ActiveCN108625249BImproving the construction quality of filling and rollingGuaranteed structural sizePaving gutters/kerbsRoads maintainenceStructural engineeringRoad surface

The invention relates to cast-in-place kerbstone for reserved replacement of an asphalt concrete pavement. The cast-in-place kerbstone comprises a reserved groove mold, a gravel dense screen bag, a lightweight rib separating block, a cast-in-place slip form system, the cast-in-place kerbstone and the asphalt concrete pavement. A cement stabilized macadam foundation is arranged on a subbase course,wherein a kerbstone indwelled groove is excavated on the cement stabilized macadam foundation by a separator kerbstone mould; in addition, a indwelled groove mold is arranged in the kerbstone indwelled groove; the lightweight rib separating block and the gravel dense screen bag are arranged in the indwelled groove mold; the cement stabilized macadam foundation is sequentially provided with a coarse-grained asphalt concrete layer and a fine-grained asphalt concrete layer from bottom to top. According to the cast-in-place kerbstone for the reserved replacement of the asphalt concrete pavement,disclosed by the invention, by adopting slip-form construction for the kerbstone, the construction method has the advantages of high construction speed, less required labor and no prefabricated site;the paved kerbstone has high integral structural strength and smooth and beautiful linetype.

Owner:HANGZHOU JIANGRUN TECH LIMITED

A road paving method

ActiveCN109537394BImprove construction efficiencyImprove toughnessArtificial islandsIn situ pavingsArchitectural engineeringStructural engineering

The invention relates to a road pavement method. A roadbed, an underlayer, a subbase layer, an upper base layer and a face layer are sequentially involved. The method comprises the construction stepsof roadbed finishing, underlayer paving, template adjustment, preliminary grinding, preliminary framework installation, material supplementing, secondary paving, secondary grinding and maintenance. The road pavement method has the advantages that the construction efficiency is high, the toughness, structural strength and the mutual adhesion effect between every two layers are good, the safety of apipe network is guaranteed, and the structural strength of a road itself is also effectively improved.

Owner:浙江坤宇建设有限公司

High-quality cold asphalt pavement and construction method thereof

InactiveCN113215906AImprove structural strengthImprove performanceIn situ pavingsRoads maintainenceStructural engineeringRoad surface

The invention relates to the technical field of road construction and particularly relates to a high-quality cold-state asphalt pavement and a construction method thereof. The high-quality cold-state asphalt pavement comprises an asphalt surface layer, a base layer, a subbase layer and a cushion layer which are sequentially laid on a roadbed from top to bottom. Compared with the prior art, the construction method is advantaged in that the stress condition of the pavement structure is improved, the number of reflection cracks is reduced, and use performance of the highway pavement is improved, so the service life of the pavement is prolonged, the structural strength of the pavement is effectively improved by reasonably limiting the elasticity modulus and laying thickness of the asphalt surface layer, the base layer and the subbase layer, reflection cracks formed by asphalt pavement are reduced, and the road service life is increased. According to the modified rubber asphalt, various modifiers are added into an asphalt matrix with low wax content, so comprehensive performance of the asphalt is greatly improved, high-temperature storage stability, the high and low temperature performance, the aging performance, the viscoelasticity and viscosity and toughness are obviously improved, and the use requirements in alpine regions or high-temperature regions are met.

Owner:河南金欧特实业集团股份有限公司

A long-life flexible base asphalt pavement structure

ActiveCN112376349BGuaranteed service lifeImproves rutting resistanceIn situ pavingsCrushed stoneStructural engineering

Owner:SOUTHEAST UNIV

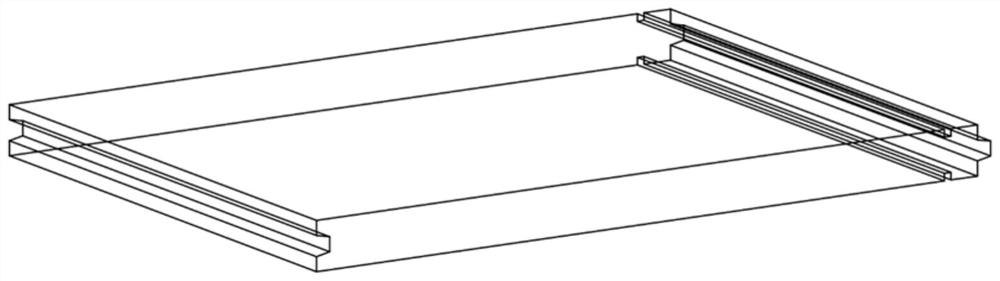

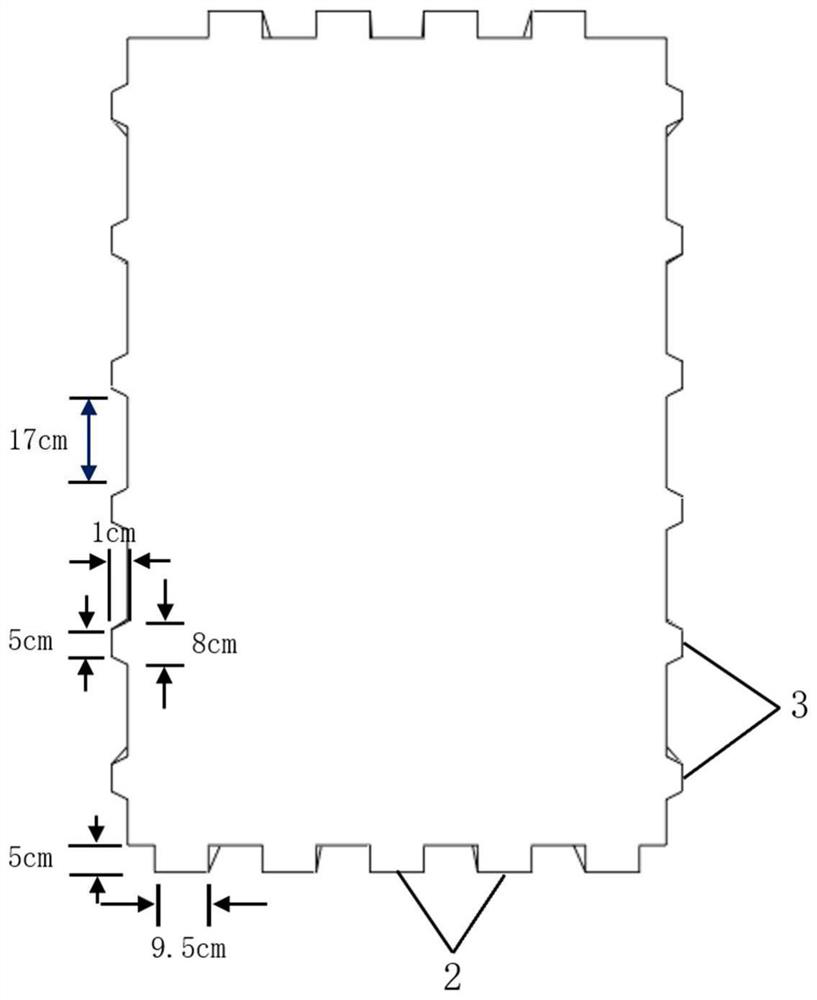

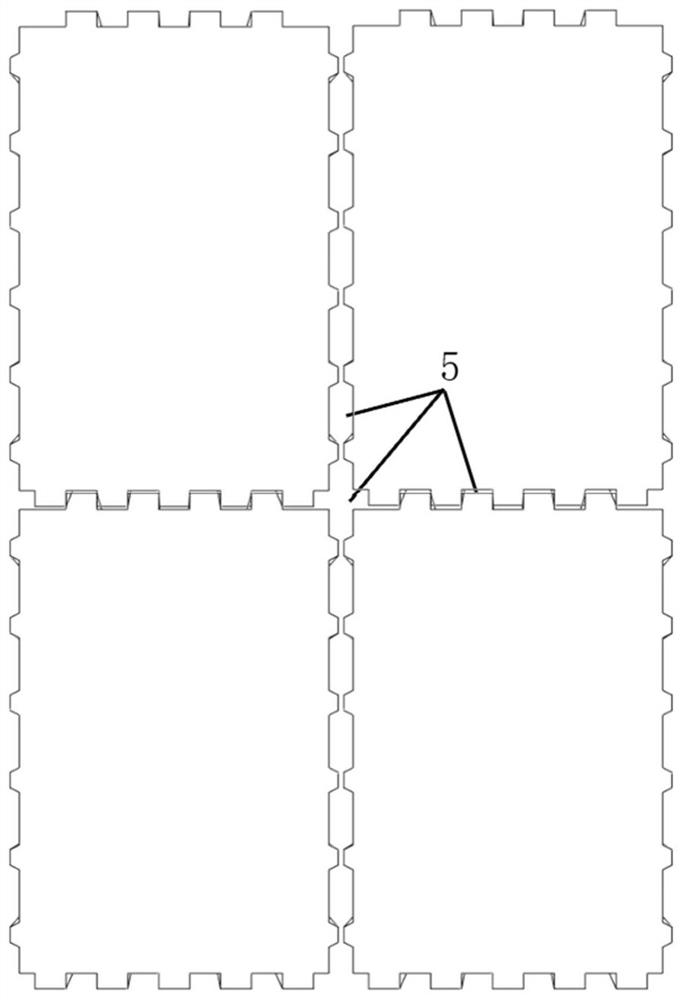

Prefabricated assembly type hollow cement concrete base plate structure and construction method

ActiveCN112342855AImprove mechanical performanceImprove load carrying capacitySingle unit pavingsArchitectural engineeringStructural engineering

The invention discloses a prefabricated assembly type hollow cement concrete base plate structure and a construction method. Rectangular connecting grooves are formed in the front side and the rear side of the assembly type hollow cement concrete base plate, trapezoidal connecting grooves are formed in the left side and the right side of the assembly type hollow cement concrete base plate, evenly-distributed through holes perpendicular to the traveling direction are formed in the middle of a plate body, and PVC isolation plates are placed in the through holes to serve as connectors of two adjacent plates. The connecting grooves between a front plate and a rear plate can be mutually embedded and extruded to form a tenon-and-mortise type structure, and the connecting grooves between the leftside and the right side need to be bonded through joint materials. The construction method comprises the following steps: paving a subbase, paving a leveling layer on the subbase, mounting the base plates from the center line of the road to the two sides, mounting the cross sections one by one, and paving other pavement structure layers. Compared with a traditional cement concrete base construction mode, the method has the advantages of being good in heat insulation effect, rapid to install, easy and convenient to maintain, small in construction pollution and the like, and has wide application prospects.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com