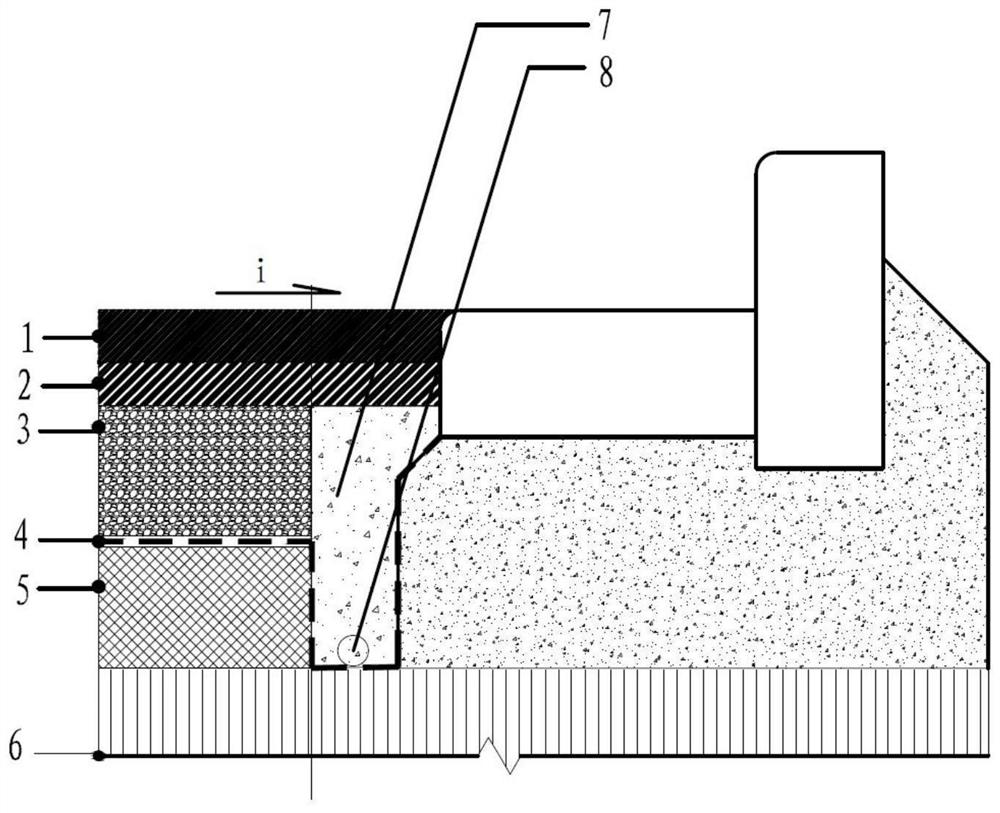

Permeable asphalt pavement structure

A technology of pavement structure and permeable asphalt, which is applied in basic structure engineering, roads, roads, etc., can solve the problems of low bearing strength and poor durability, and achieve the effect of improving bearing capacity, good water permeability and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

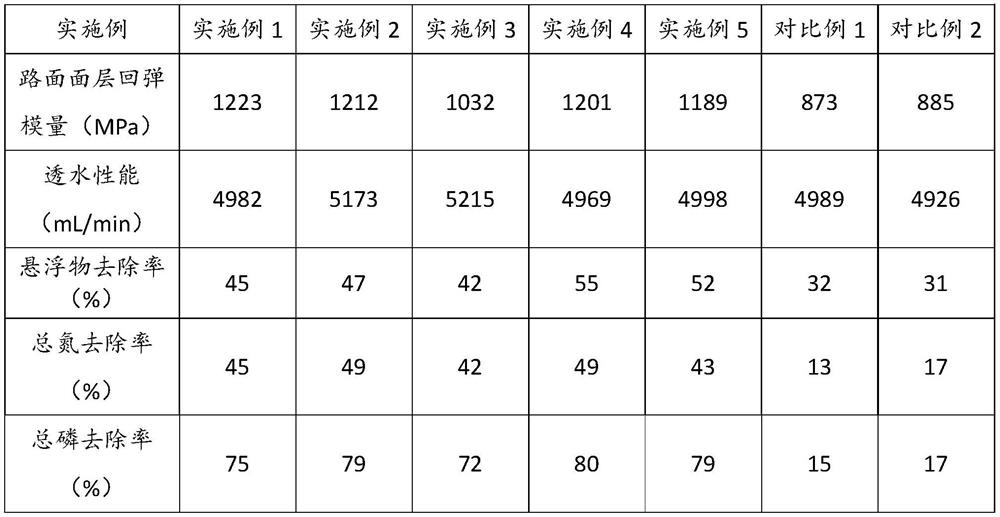

Embodiment 1

[0067] The permeable asphalt pavement structure of this embodiment includes the upper layer of the asphalt mixture, the lower layer of the asphalt mixture, the permeable base layer, the sealing layer, the impermeable subbase layer and the roadbed from top to bottom. The water collecting ditch is filled with steel slag gravel.

[0068] Among them, the upper layer of the asphalt mixture adopts steel slag permeable asphalt mixture PAC-13 with a nominal maximum particle size of 13.2mm. The binder is high-viscosity modified asphalt. The upper layer of the asphalt mixture has a porosity of 19.1% and a thickness of 4 cm.

[0069] The lower layer of asphalt mixture adopts steel slag permeable asphalt mixture PAC-20 with a nominal maximum particle size of 19mm. The amount of steel slag aggregate in the lower layer of asphalt mixture is 80%, and the rest is stone. The lower layer of asphalt mixture has a porosity of 22.6% and a thickness of 7 cm.

[0070] The amount of steel slag agg...

Embodiment 2

[0074] The permeable asphalt pavement structure of this embodiment includes the upper layer of the asphalt mixture, the lower layer of the asphalt mixture, the permeable base layer, the sealing layer, the impermeable subbase layer and the roadbed from top to bottom. The water collecting ditch is filled with steel slag gravel.

[0075] Among them, the upper layer of the asphalt mixture adopts steel slag permeable asphalt mixture PAC-13 with a nominal maximum particle size of 13.2mm. The binder is high-viscosity modified asphalt. The upper layer of the asphalt mixture has a porosity of 19.4% and a thickness of 5 cm.

[0076] The lower layer of asphalt mixture adopts steel slag permeable asphalt mixture PAC-20 with a nominal maximum particle size of 19mm. The amount of steel slag aggregate in the lower layer of asphalt mixture is 80%, and the rest is stone. The lower layer of the asphalt mixture has a porosity of 21.2% and a thickness of 8 cm.

[0077] The amount of steel slag...

Embodiment 3

[0081] The permeable asphalt pavement structure of this embodiment includes the upper layer of the asphalt mixture, the lower layer of the asphalt mixture, the permeable base layer, the sealing layer, the impermeable subbase layer and the roadbed from top to bottom. The water collecting ditch is filled with steel slag gravel.

[0082] Among them, steel slag permeable asphalt mixture PAC-13 with a nominal maximum particle size of 13.2mm is used for the upper layer of asphalt mixture. The content of steel slag aggregate in the upper layer of asphalt mixture is 40%, and the rest is stone and organic binder. The binder is high-viscosity modified asphalt. The upper course of the asphalt mixture has a porosity of 18.4% and a thickness of 5 cm.

[0083] The lower layer of asphalt mixture adopts steel slag permeable asphalt mixture PAC-20 with a nominal maximum particle size of 19mm. The amount of steel slag aggregate in the lower layer of asphalt mixture is 40%, and the rest is ston...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com