Patents

Literature

132 results about "Aggregate base" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aggregate base is a construction aggregate typically composed of crushed rock capable of passing through a 20 millimetres (³⁄₄ in) rock screen. The component particles will vary in size from 20 mm down to dust. The material can be made of virgin (newly mined) rock, or of recycled asphalt and concrete.

Estimating the Spend Capacity of Consumer Households

ActiveUS20070100719A1Efficient managementIncrease profitabilityMarket predictionsFinanceComputer scienceAggregate base

The spend capacity of a consumer typically increases as the number of consumers in the household increases, since the consumer can draw on the spending power of other consumers in the household. The size of wallet of the household is thus a better indicator of the consumer's spend capacity than an individual size of wallet. All consumers in a given household can be aggregated based on, for example, their address of record. Duplicate tradelines within each household are removed from consideration in a size of wallet estimate. A spend capacity is then estimated for each tradeline using calculations derived from a consumer behavior model. The spend capacities for all tradelines in the household are combined to determine a household size of wallet. Each consumer in the household is then tagged with the household size of wallet, rather than their individual size of wallet.

Owner:AMERICAN EXPRESS TRAVEL RELATED SERVICES CO INC

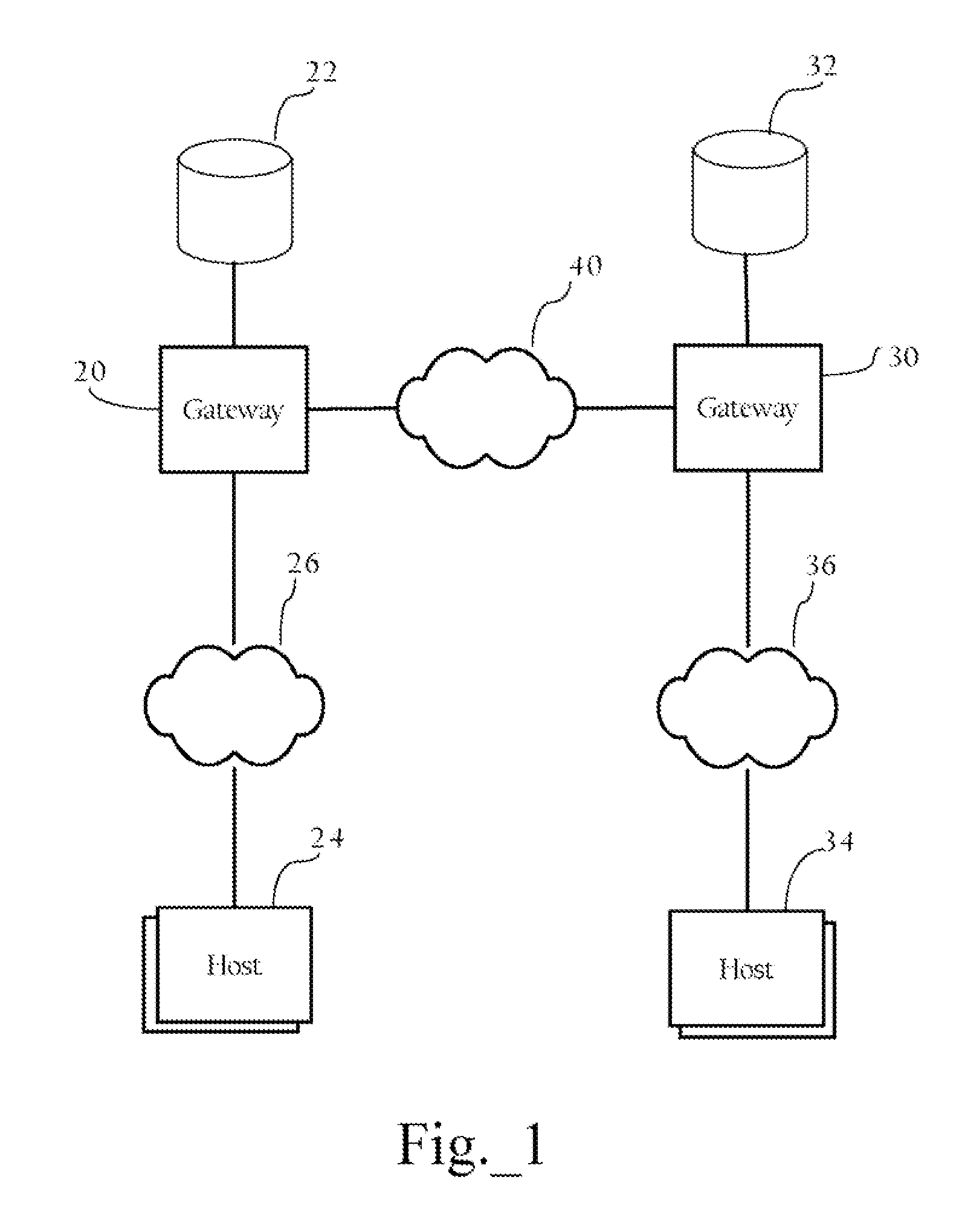

Redundancy elimination by aggregation of multiple chunks

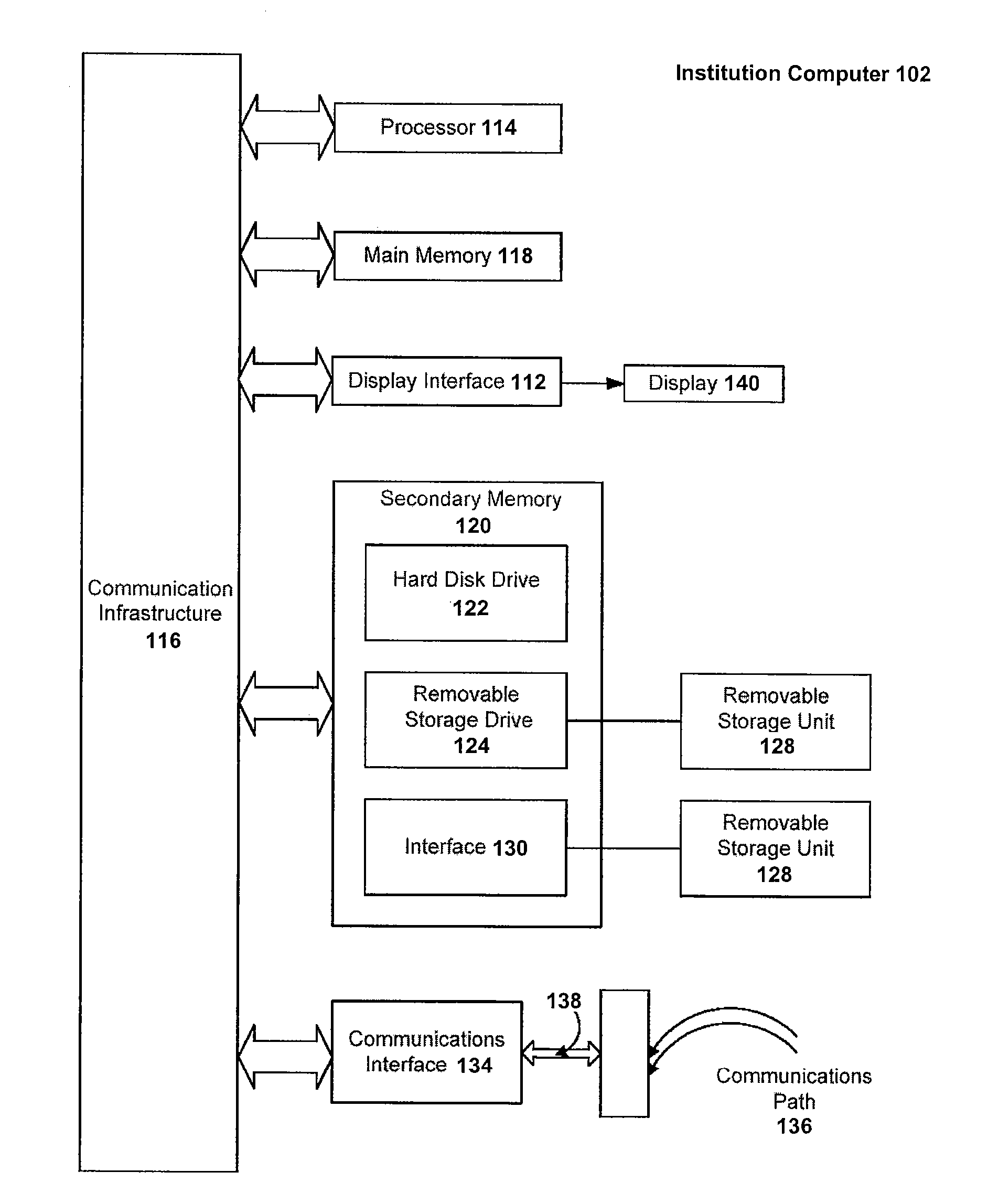

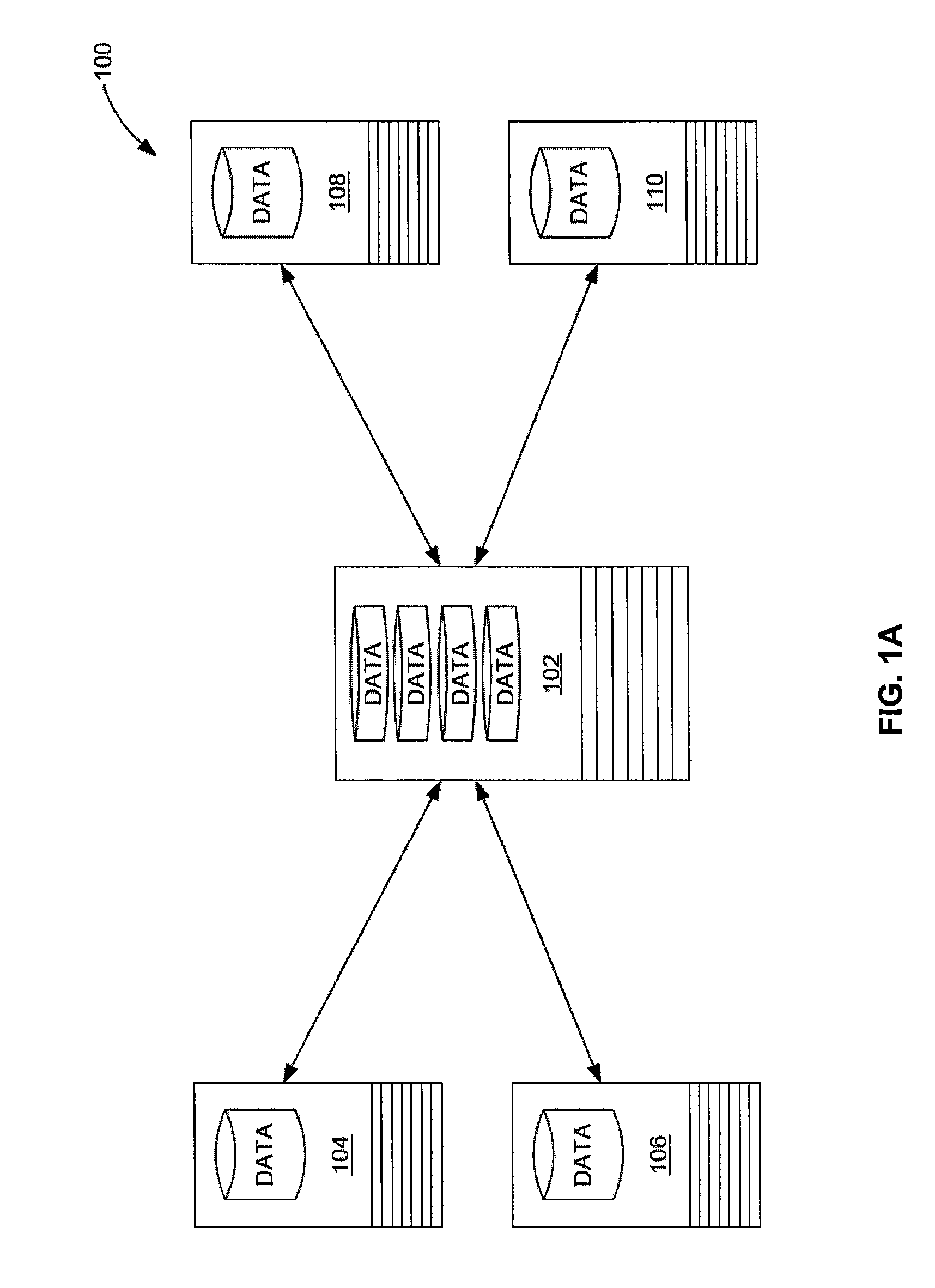

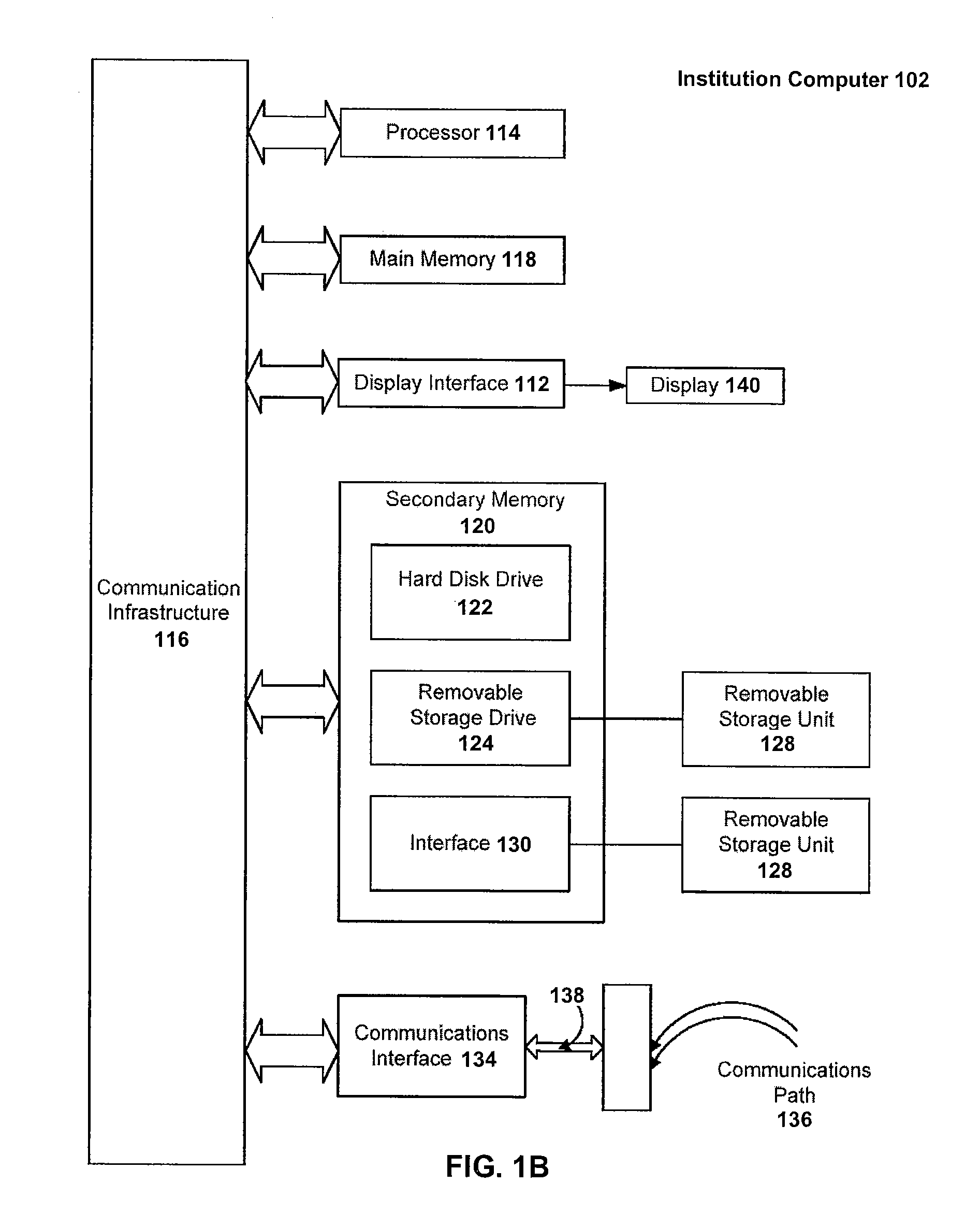

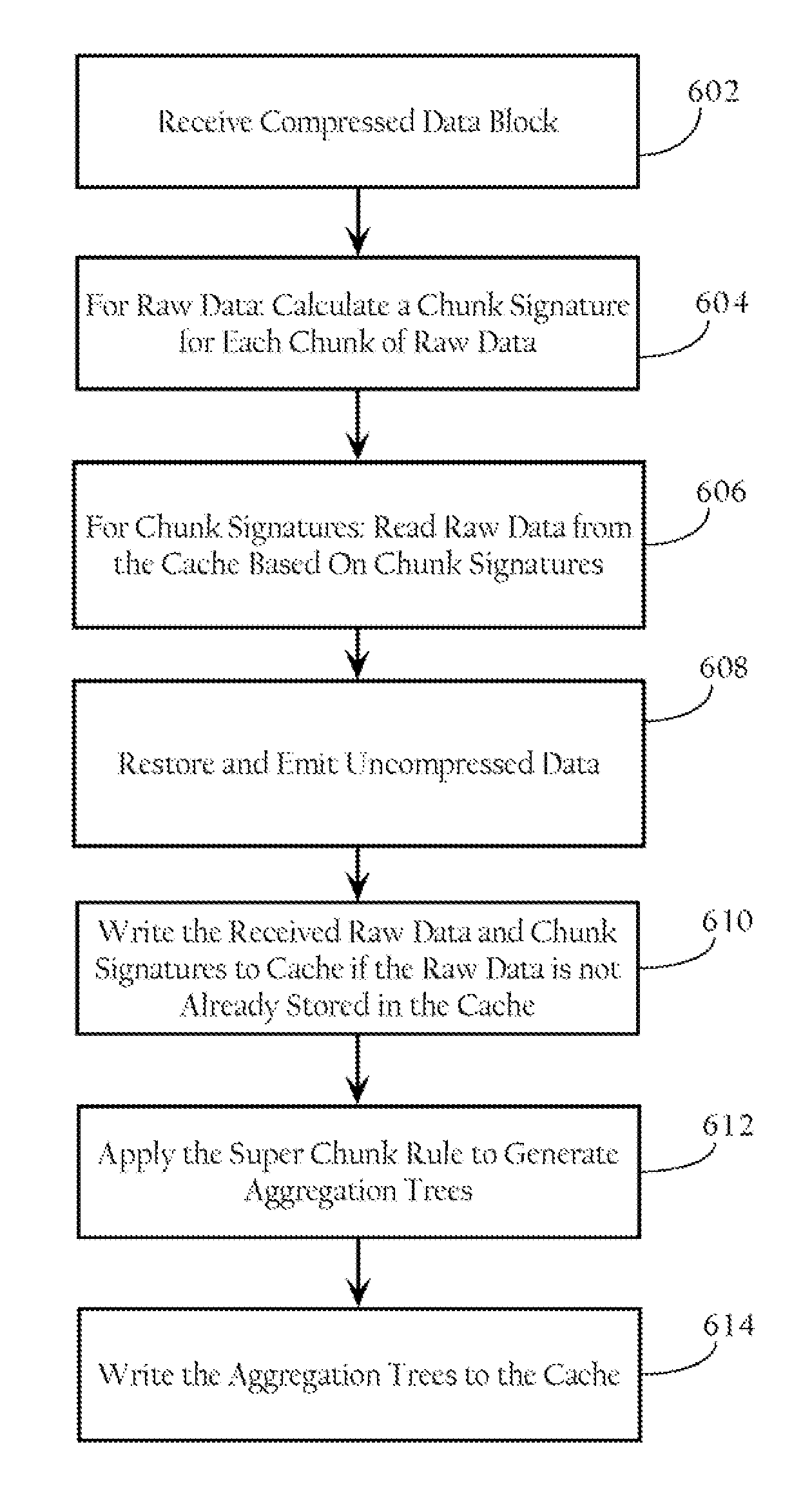

A data redundancy elimination system. In particular implementations, a method includes storing in a memory one or more aggregation trees, each aggregation tree comprising one or more base chunk nodes and one or more super chunk nodes, wherein each base chunk node comprises a chunk signature and corresponding raw data, and wherein super chunk nodes correspond to child base chunk nodes and include a chunk signature; receiving a data block; dividing the data block into a plurality of base chunks, each base chunk having a degree value characterizing the occurrence probability of the base chunk; computing chunk signatures for the plurality of base chunks; applying a super chunk rule to contiguous sequences of base chunks of the plurality of base chunks to create one or more aggregation trees, wherein the super chunk rule aggregates base chunks based on the respective occurrence probabilities of the base chunks; identifying one or more nodes in the one or more created aggregation trees that match corresponding nodes of the aggregation trees in the memory; compressing the received data block based on the identified nodes; and conditionally adding the one or more created aggregation trees to the memory.

Owner:CISCO TECH INC

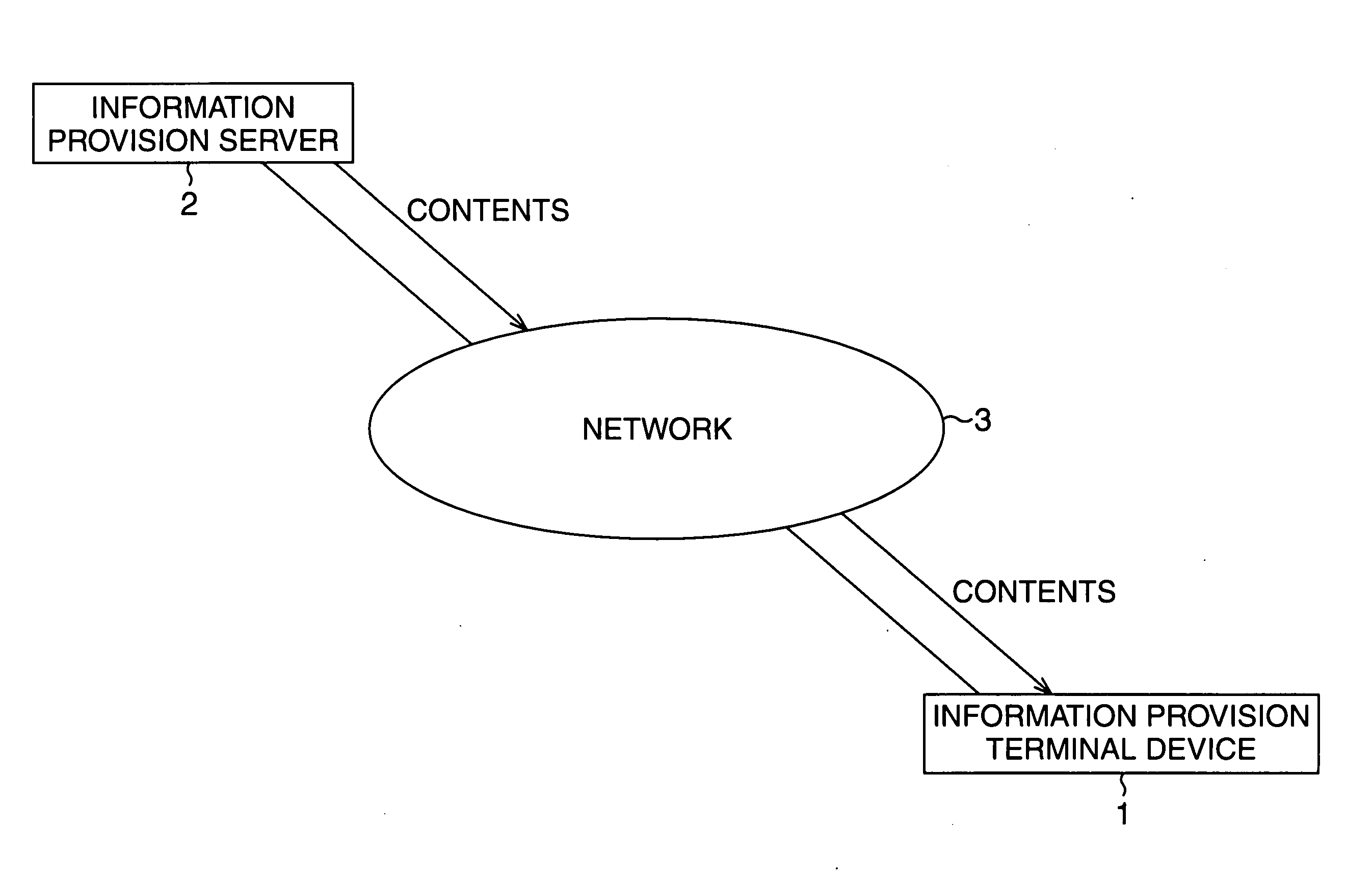

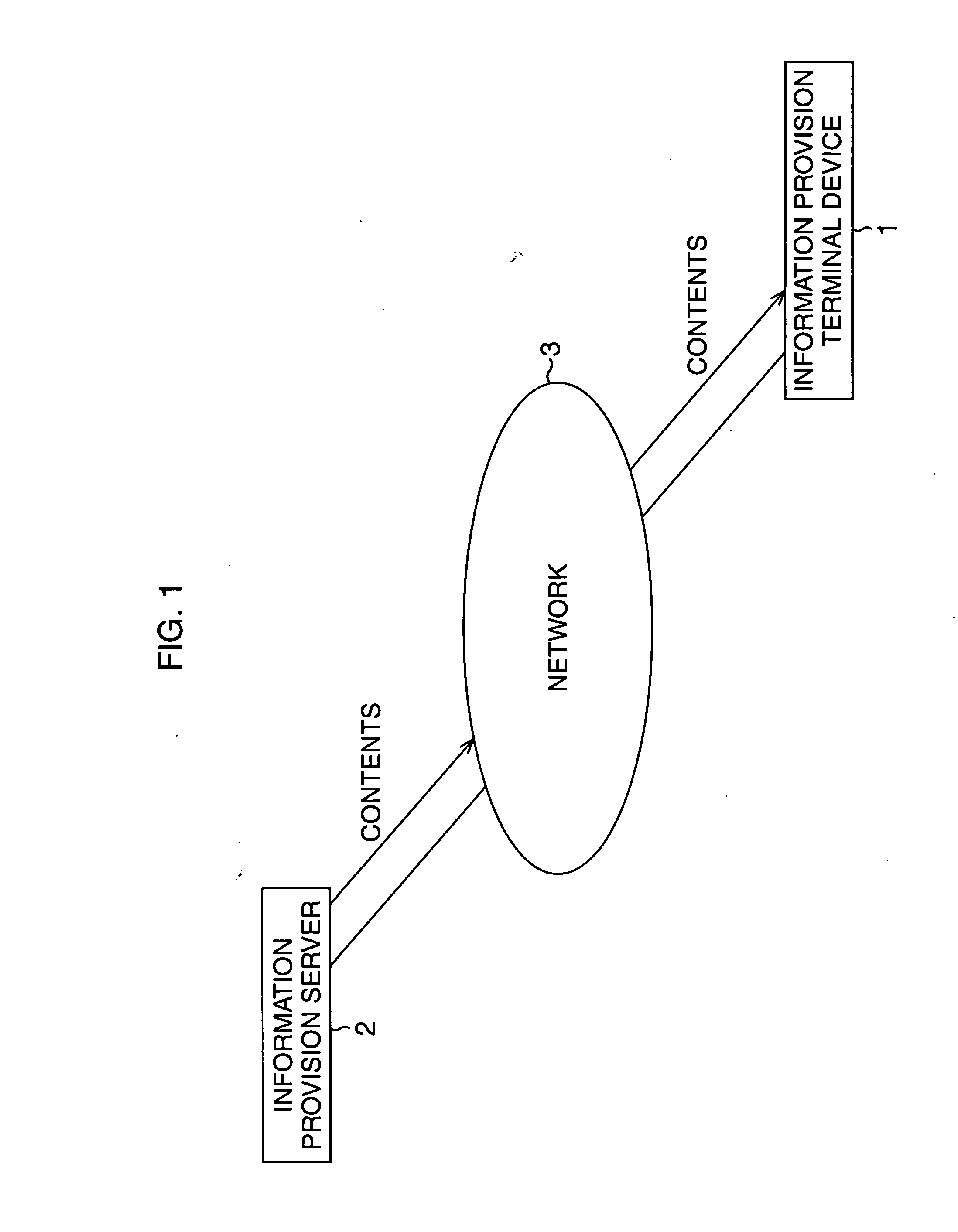

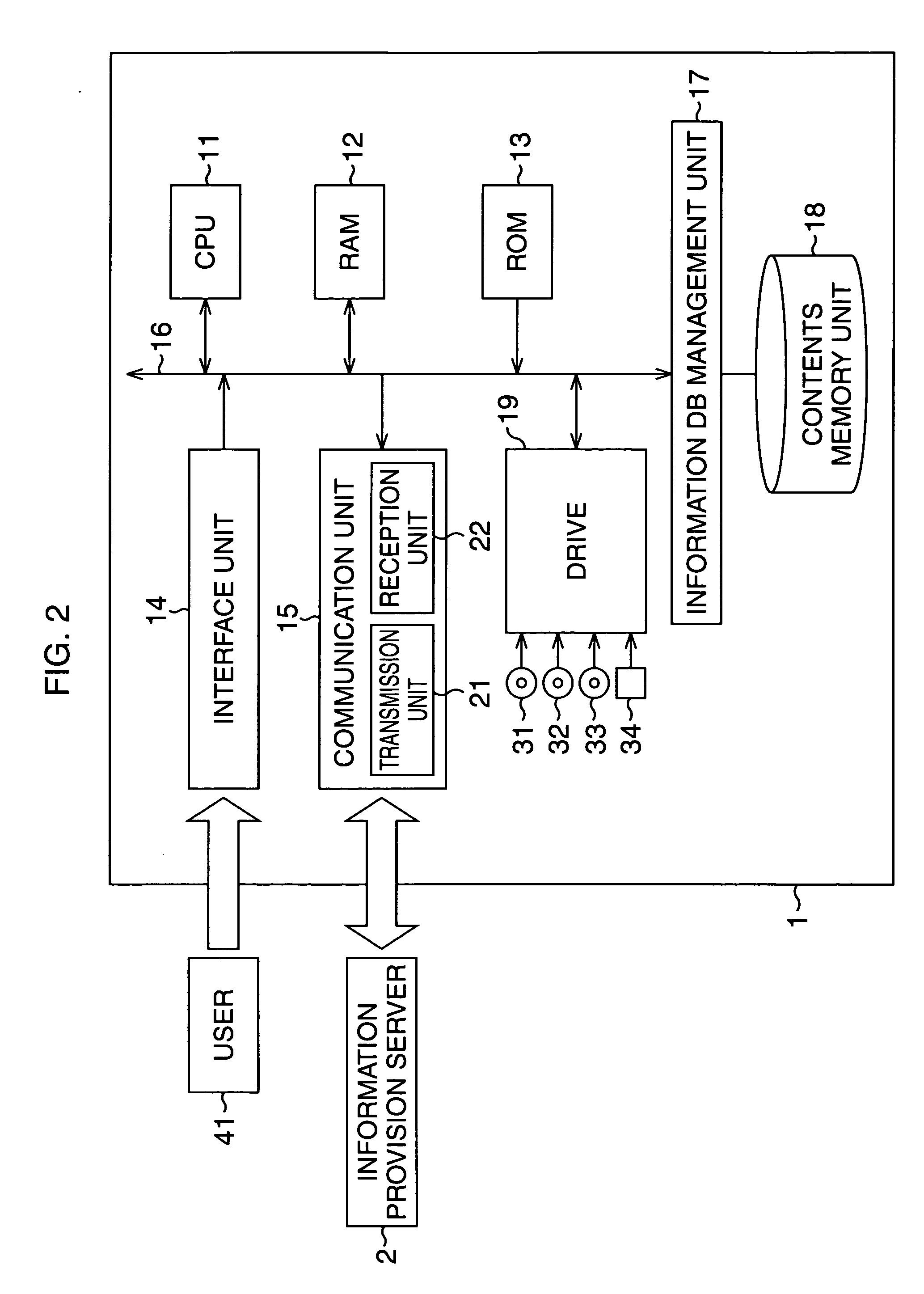

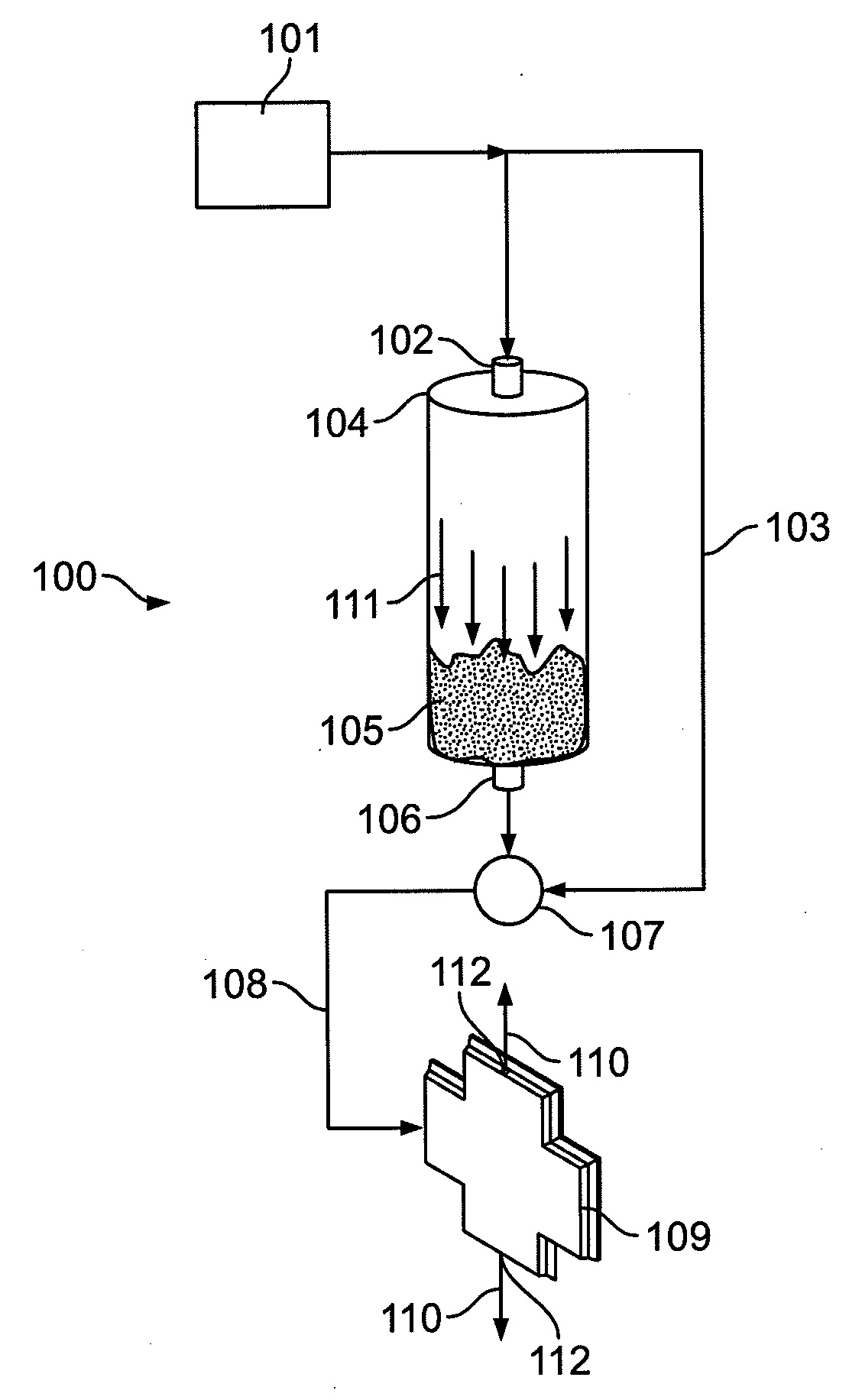

Terminal device, business designation method, contents provision device, contents provision method, recording medium, program, business management system and business management method

InactiveUS20060265228A1Minimum operationDigital computer detailsResourcesData controlCommunication unit

The present invention enables the continuous designation of appropriate business at an appropriate timing and in appropriate order with minimal operation, and enables the management side to comprehend the business condition. A master control unit 101 controls the output of an aggregate based on an event response control program associated with the aggregate containing information being output, and in correspondence with an event. A play list reader 102 controls the output of information contained in an aggregate based on ordinal data associated with the aggregate for which the output thereof has been designated by the master control unit 101. A communication unit 106 controls the transmission of business condition information indicating the condition of business to a business support server 502 for providing the contents based on the event response control program, and in correspondence with an event. The present invention may be employed in a business support system for supporting the implementation of business.

Owner:ORMON CORP

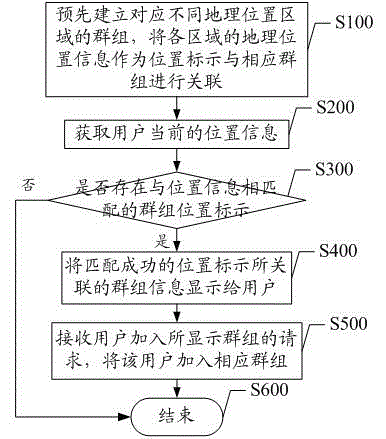

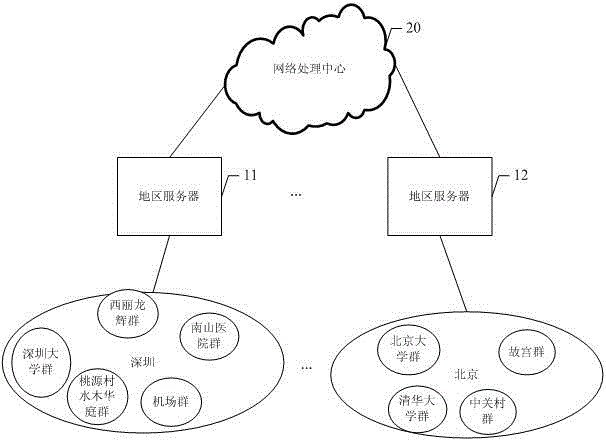

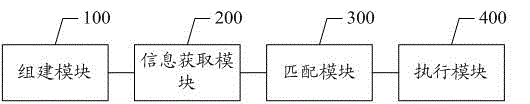

Method and system for using geographical position information for setting up groups

InactiveCN104093125AConvenient lifeConvenient and effective social platformTransmissionLocation information based serviceGeographic siteGeolocation

The invention discloses a method and system for using geographical position information for setting up groups. The method includes the following steps that A, the groups corresponding to different geographical positions are set up in advance, and the geographical position information of all areas serves as position identification and is correlated with the corresponding groups; B, the current position information of a user is obtained and matched with the position identification correlated to all the groups, and if the match succeeds, the information of the group correlated with the position identification matched successfully is displayed to the user; C, the request for joining the displayed group of the user is received, and the user joins the corresponding group. Users in the same geographical area are aggregated based on the groups set up by the LBS service, a social contact platform which is effective and convenient and fast to use is provided for the users in the same geographical area, abundant information exchanging paths can be further provided for group members based on the social contact platform, and great convenience is brought to the life of the users based on mobile terminals.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

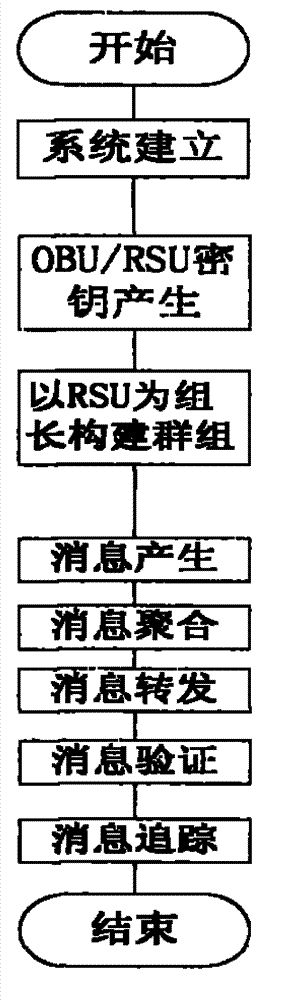

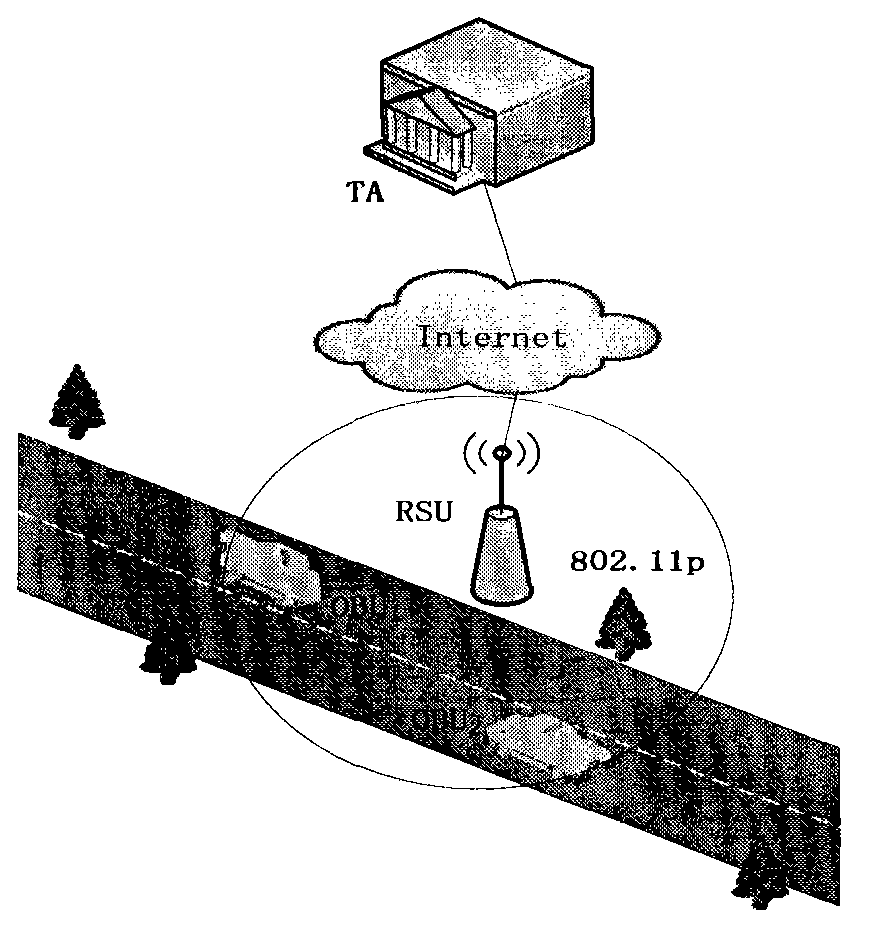

System and method for transmitting VANET (vehicle ad hoc network) safety information aggregate based on RSU (Remote Subscriber Unit)

InactiveCN103051726AProtect real identityAvoid monitoringTransmissionInformation transmissionAggregate signature

The invention discloses a method for transmitting a VANET (vehicle ad hoc network) safety information aggregate based on RSU (Remote Subscriber Unit). The RSU serves as a communication group leader, messages of legal vehicles in a governed region are subjected to information aggregating processing by an aggregate signature algorithm and are further transmitted to a monitoring center, the monitoring center verifies the correctness of signature information at one time through an inverse aggregate signature algorithm, and meanwhile when a false message is found, the real sender of the message can be accurately positioned by starting a tracing process under the assistance of an authentication center. The method has the advantages that double requirements on safety and efficiency of vehicle ad hoc network information transmission are effectively met, and limited transmission wideband is effectively saved on the premise of not affecting the safety by performing aggregating processing on vehicle safety information in the road side unit governed region in a vehicle ad hoc network.

Owner:杨涛

Aggregate-based mandrels for composite part production and composite part production methods

InactiveUS20090014919A1Rapid productionReadily be dried/curedAdditive manufacturing apparatusSolid waste managementParticulatesMicrowave

A method for forming a composite structure, using a mandrel that is later removed from the composite structure, involves production of a mandrel by depositing a particulate mixture, including an aggregate and a binder, into a mold and removing the mandrel from the mold. The mandrel may be treated while still in the mold by heating, curing with an agent, microwave energy, or by some combination thereof. Once finished, the mandrel can be used in manufacturing polymer and / or composite components. The mandrel can also be include materials that can be easily removed from the finished composite structure by water, shakeout, chemically dissolving, or by some combination thereof.

Owner:ADVANCED CERAMICS MFG

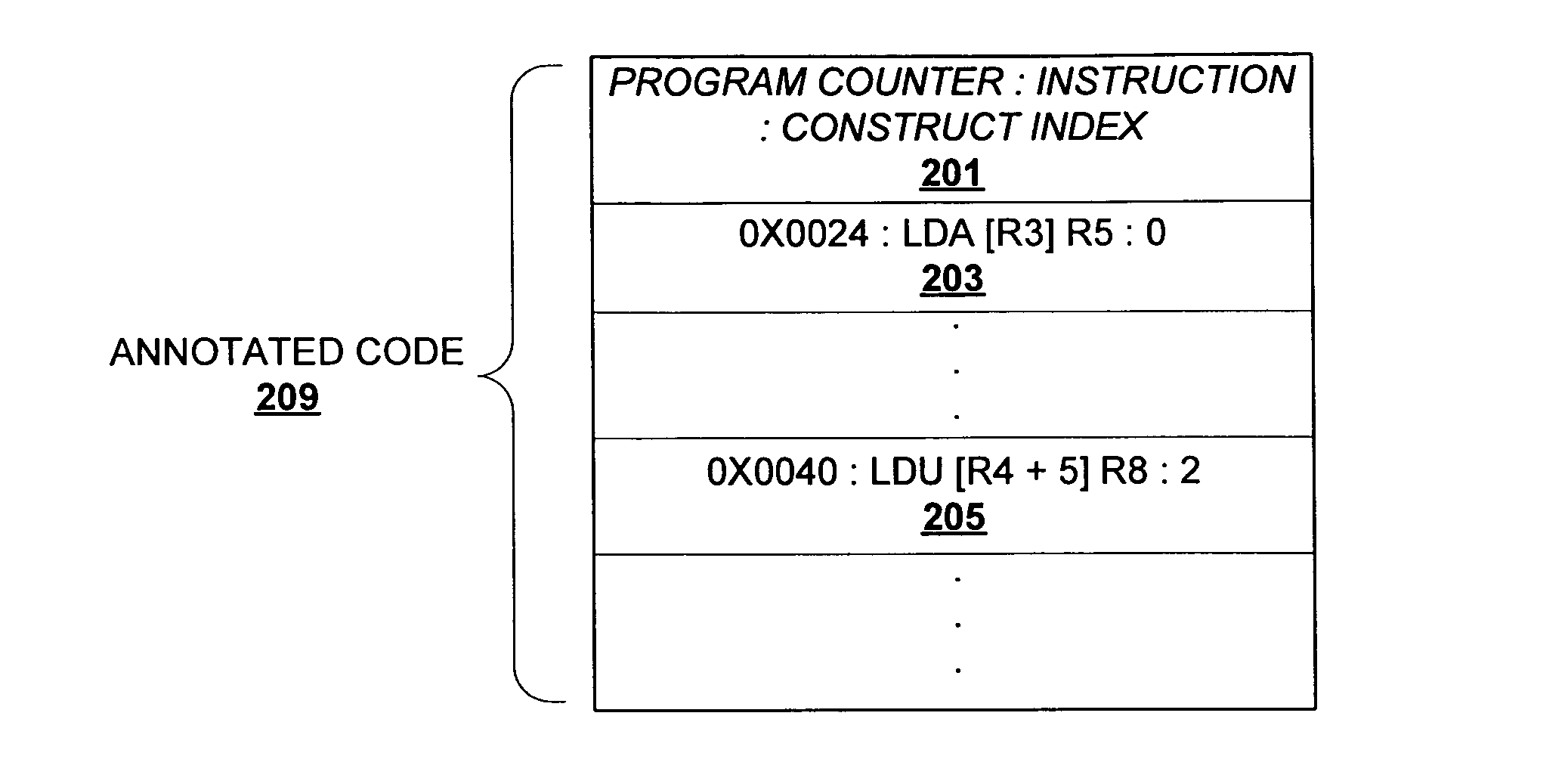

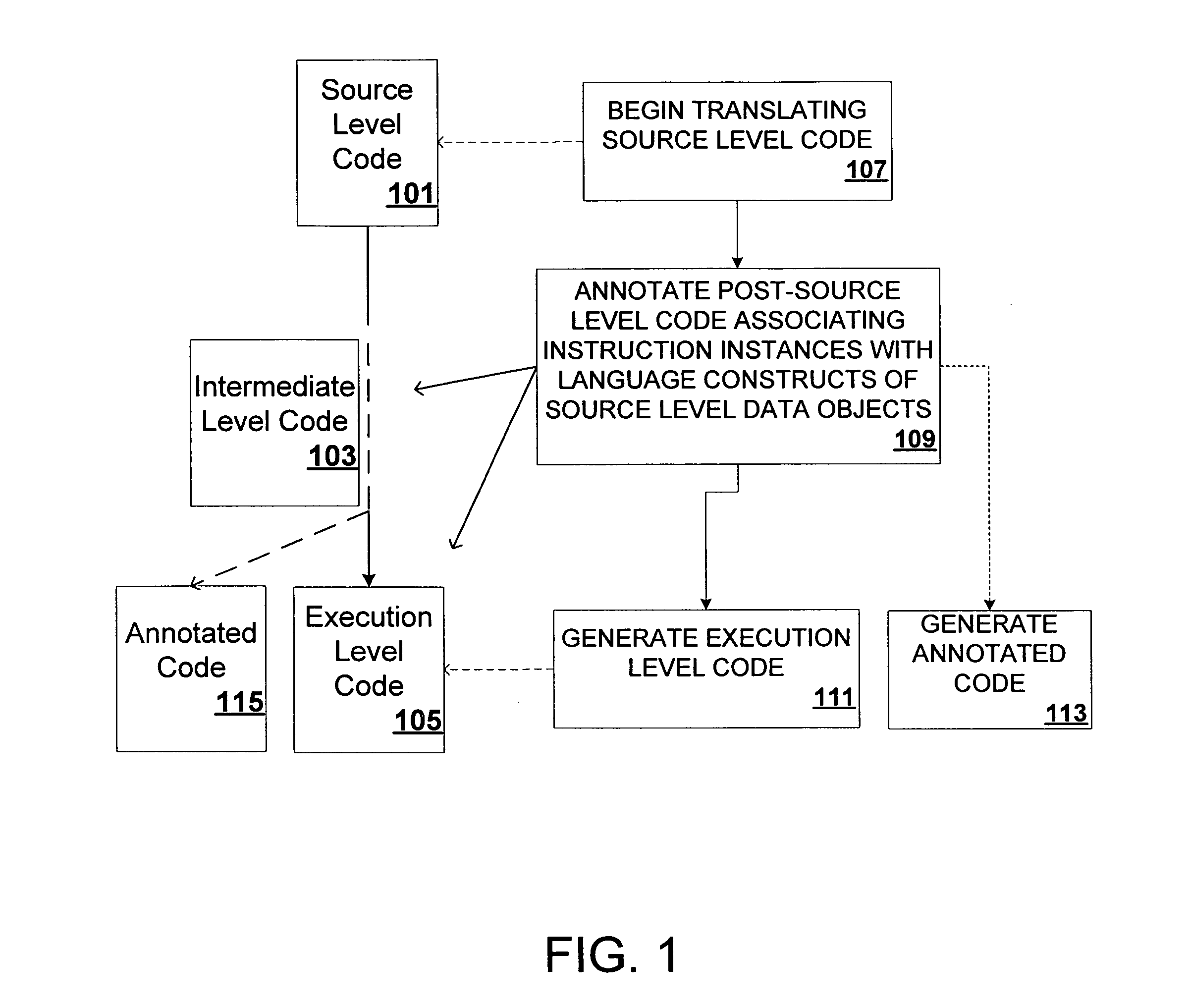

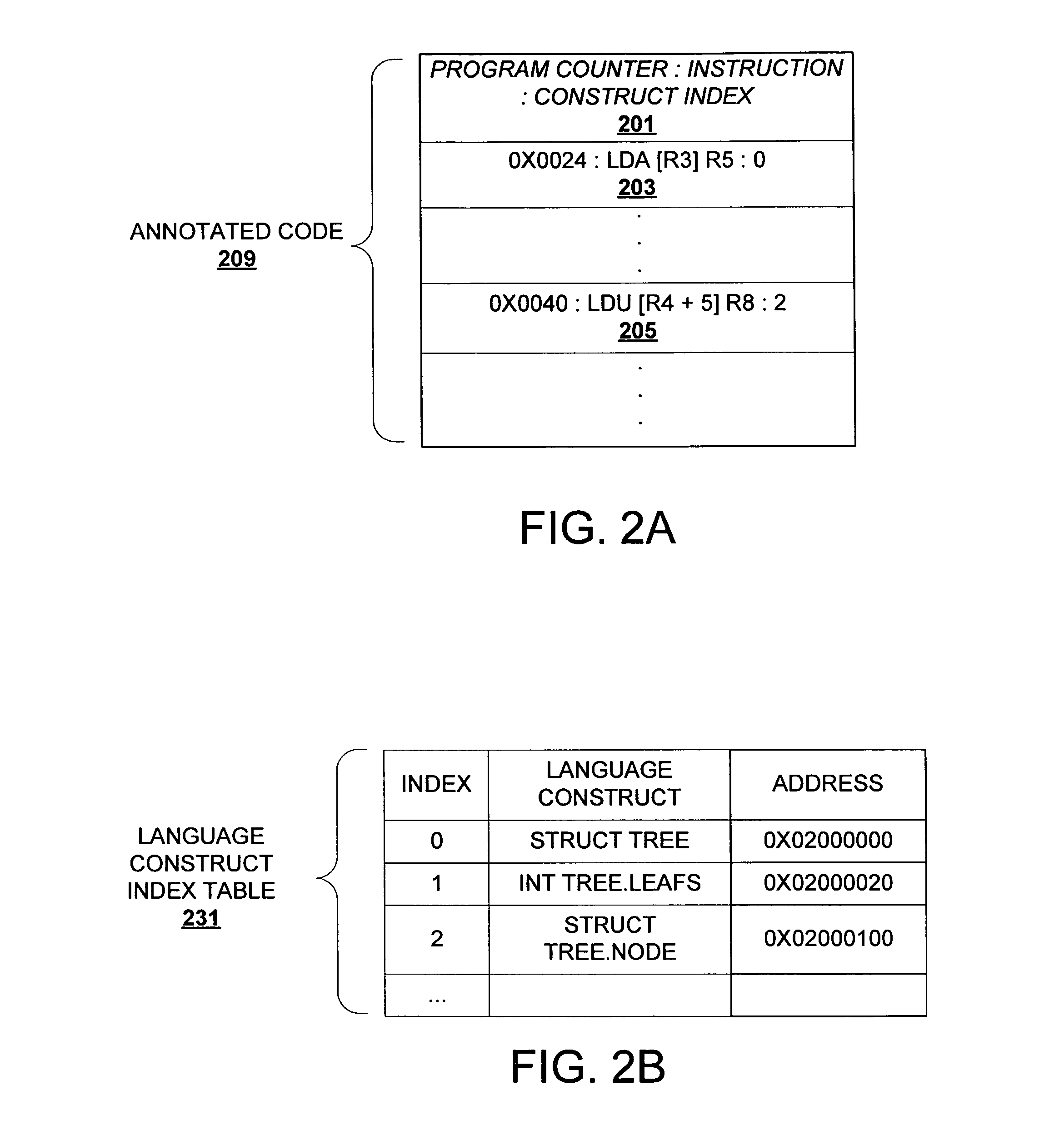

Method and apparatus for correlating profile data

ActiveUS8065665B1Easy to optimizeSophisticated code optimizationError detection/correctionSoftware engineeringTime rangeGranularity

Correlating profile data facilitates sophisticated code optimization. Going beyond one to one relationships between code execution hindrances and single code behavior attributes provides insight into code behavior at a finer level of granularity. The capability to aggregate profile data based on multiple code behavior attributes and filter based on instances thereof, allows code optimization decisions to be made based on presentation of profile data from various perspectives. Profile data, which includes code behavior attributes correlated with code execution hindrances, is aggregated based at least in part on a first code behavior attribute. Code behavior attributes include one or more of memory references, memory reference objects, functions, time ranges, processors, processes, threads, and source-level data objects. The aggregated profile data is filtered based on an instance of the first code behavior attribute. The filtered profile data is then aggregated based on one or more additional code behavior attributes.

Owner:ORACLE INT CORP

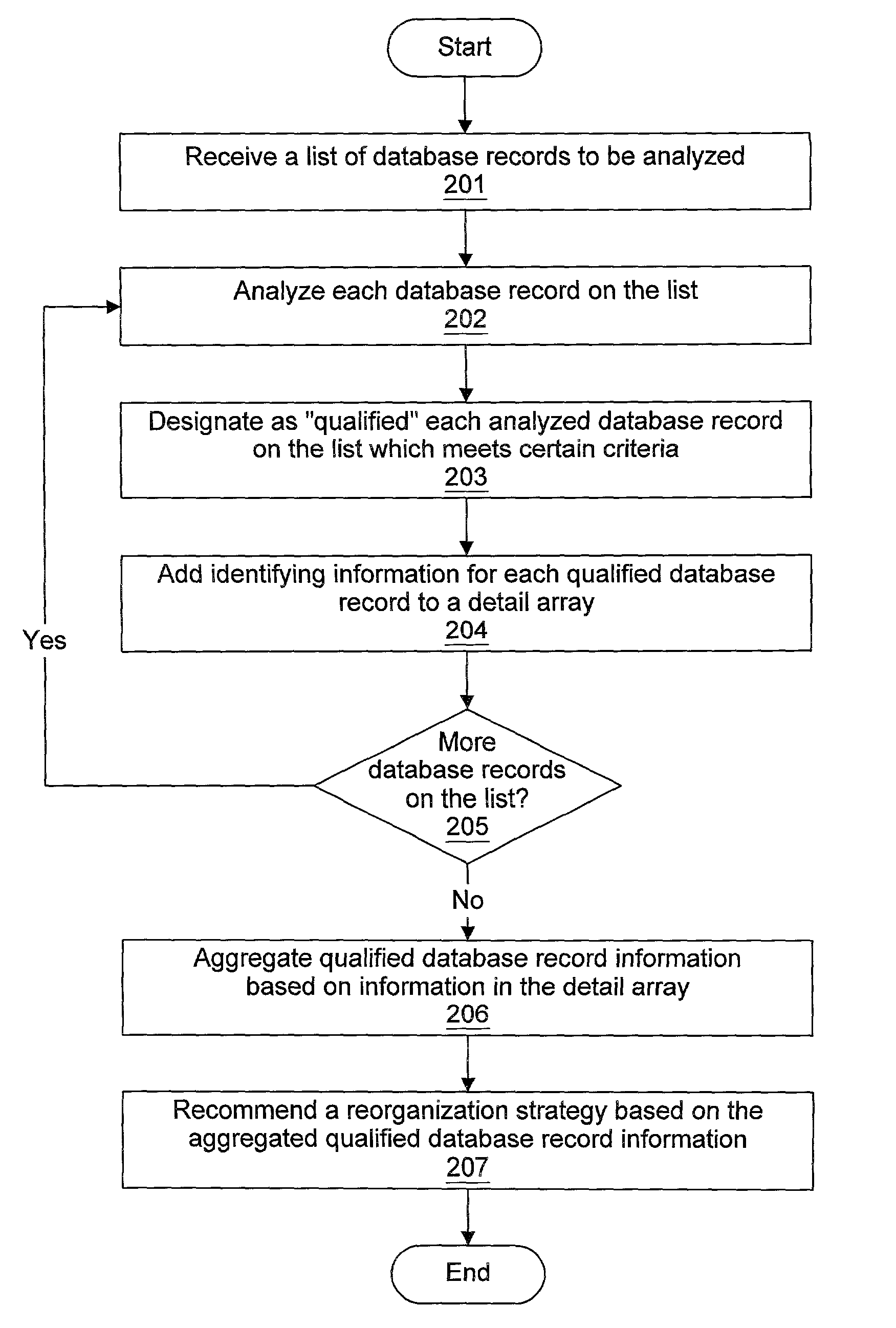

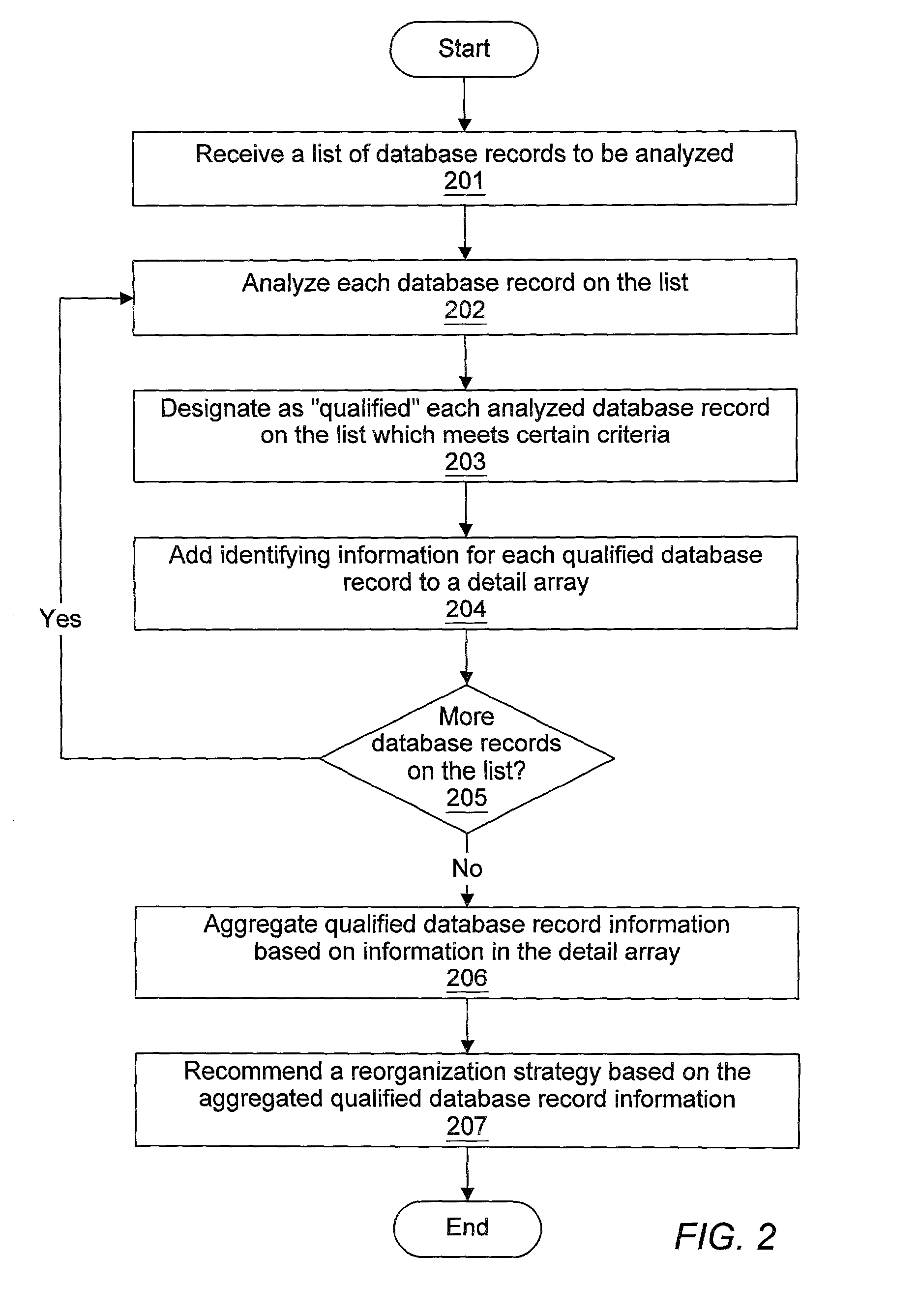

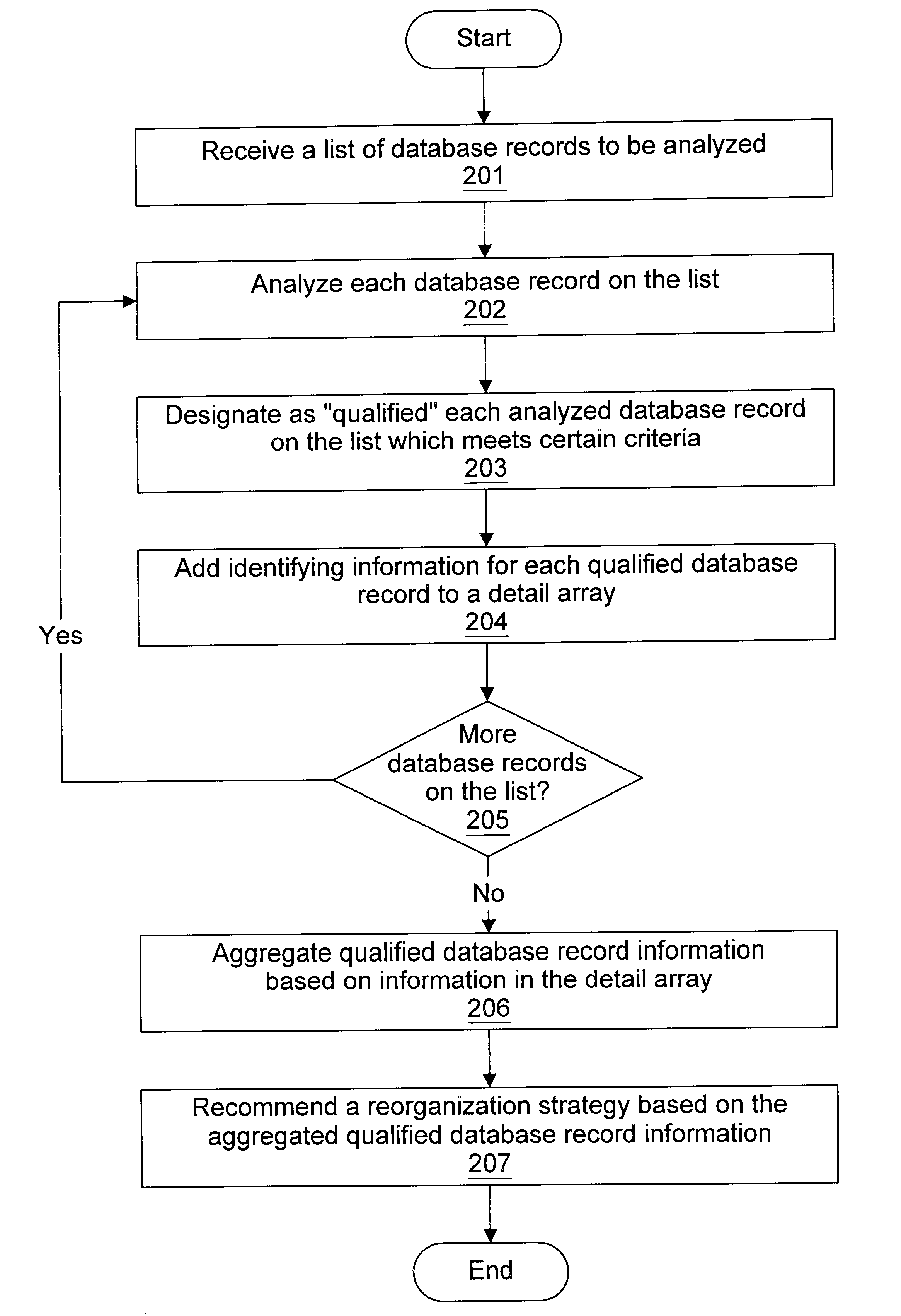

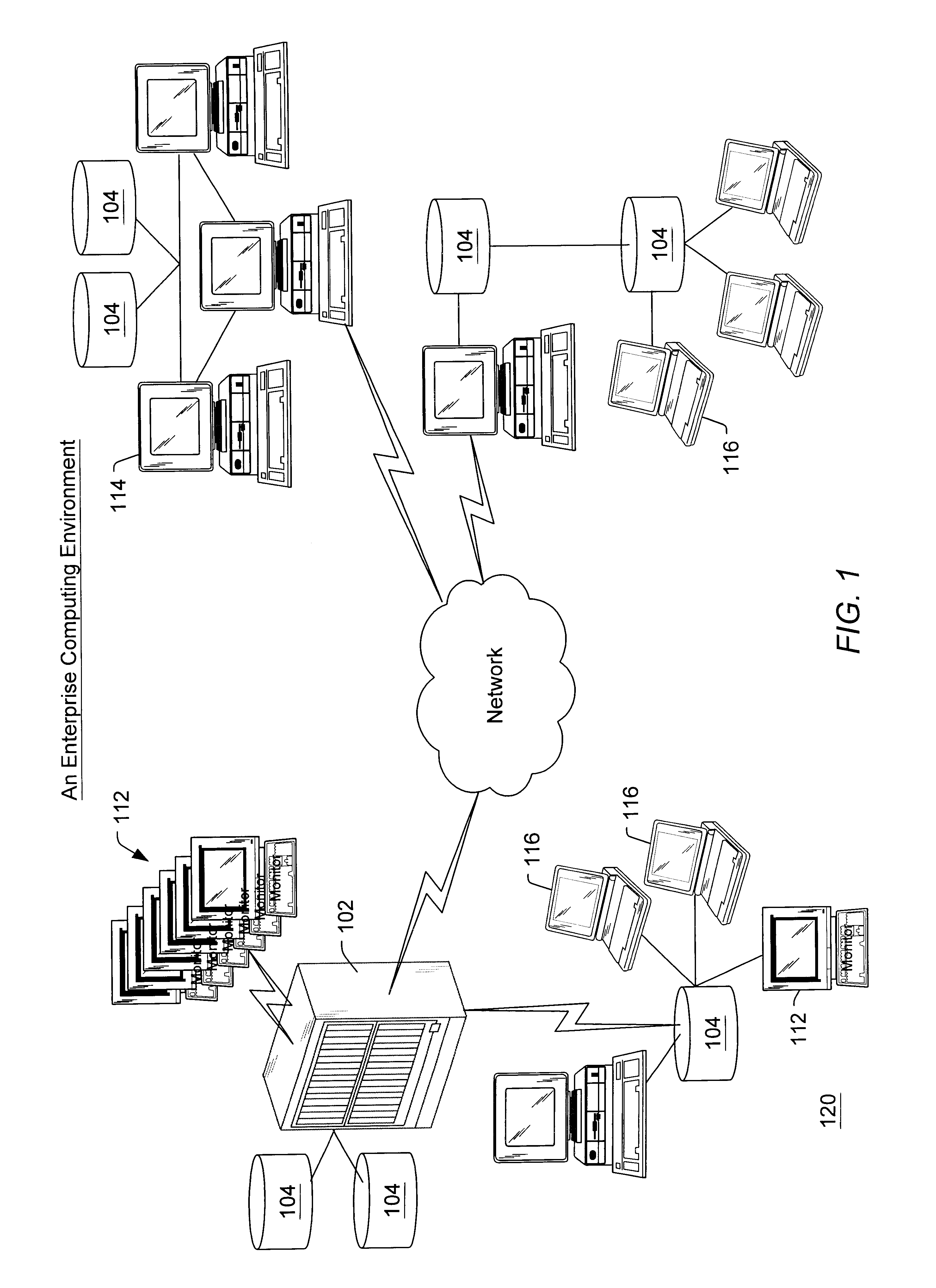

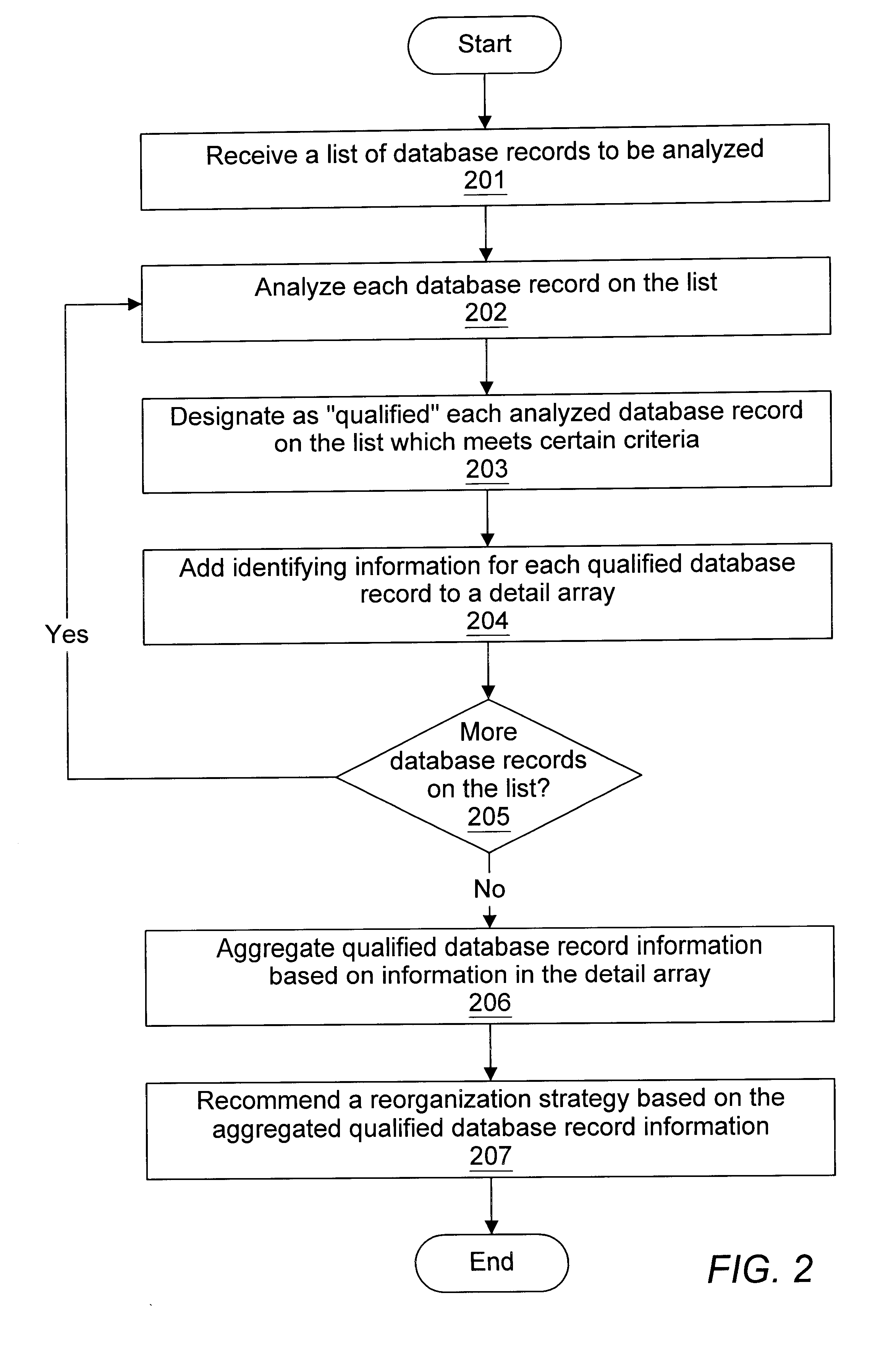

System and method for analyzing a database for on-line reorganization

InactiveUS20020143763A1Digital data information retrievalData processing applicationsArray data structureAnalysis data

An improved method and system for analyzing a database for determining a recommended reorganization of a database. In one embodiment, the method involves receiving a list of database records to be analyzed. Each analyzed database record which meets certain criteria may be designated as "qualified". Identifying information for each qualified database record may be added to a detail array. The qualified database record information may be aggregated based on information in the detail array. The process of aggregating the qualified database record information may include constructing additional arrays (e.g., a roll-up array and a results tracking array). A reorganization strategy may be recommended based on the aggregated qualified database record information. The recommended reorganization strategy may be for an amount (e.g., none, full, partial) of reorganization of the database and a method (e.g., off-line, concurrent, on-line) of reorganization of the database. The recommended reorganization strategy may be implemented.

Owner:BMC SOFTWARE

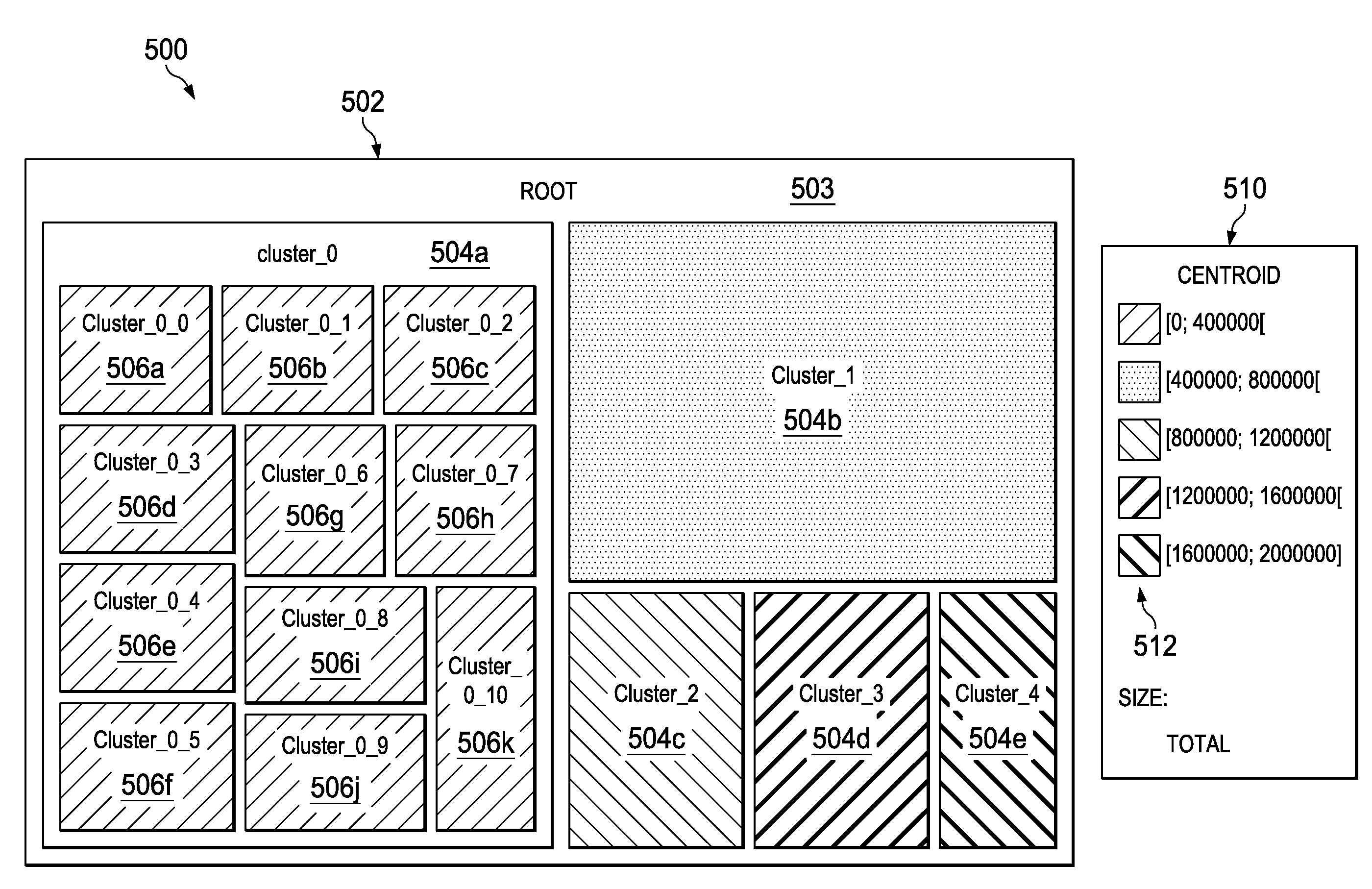

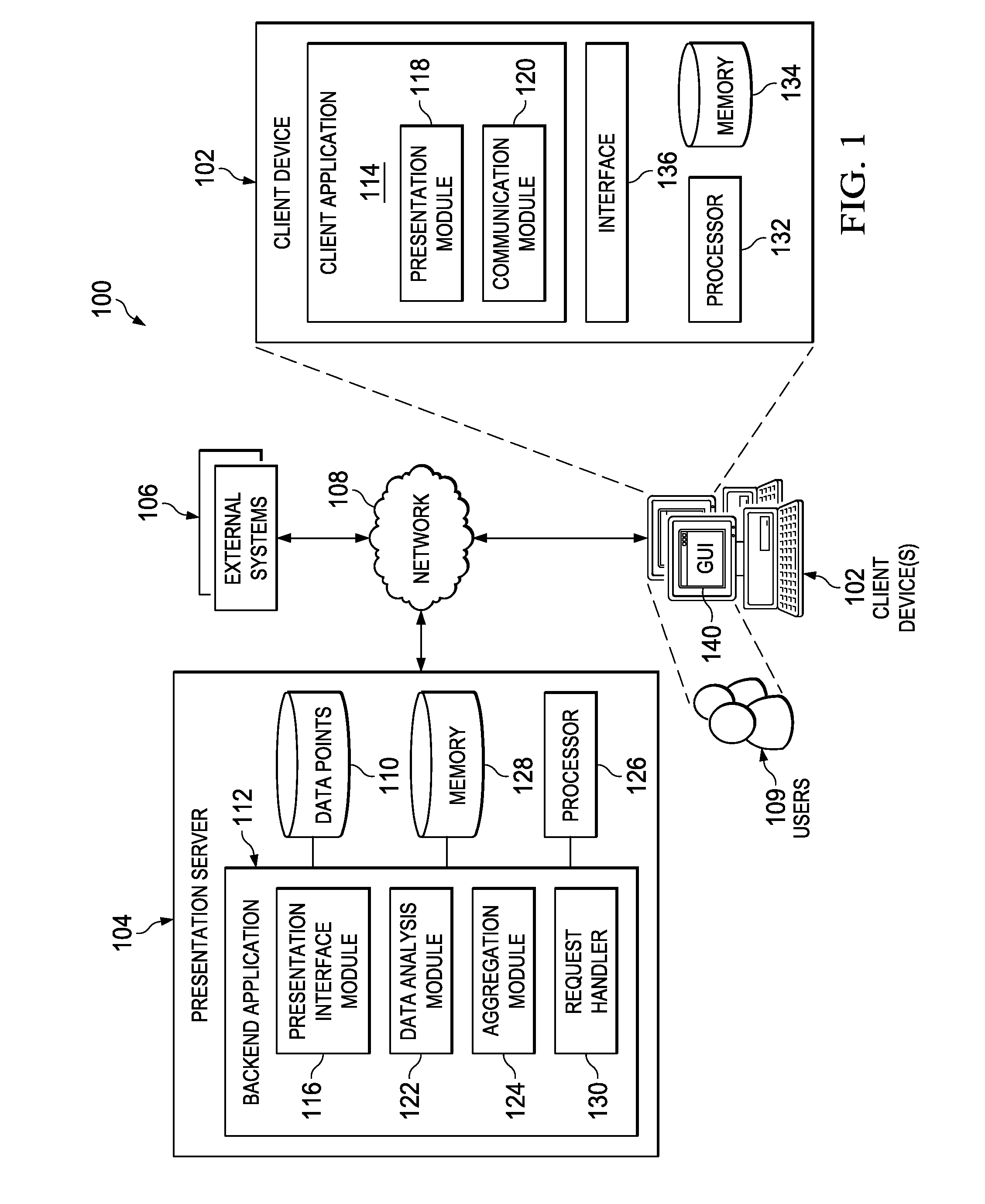

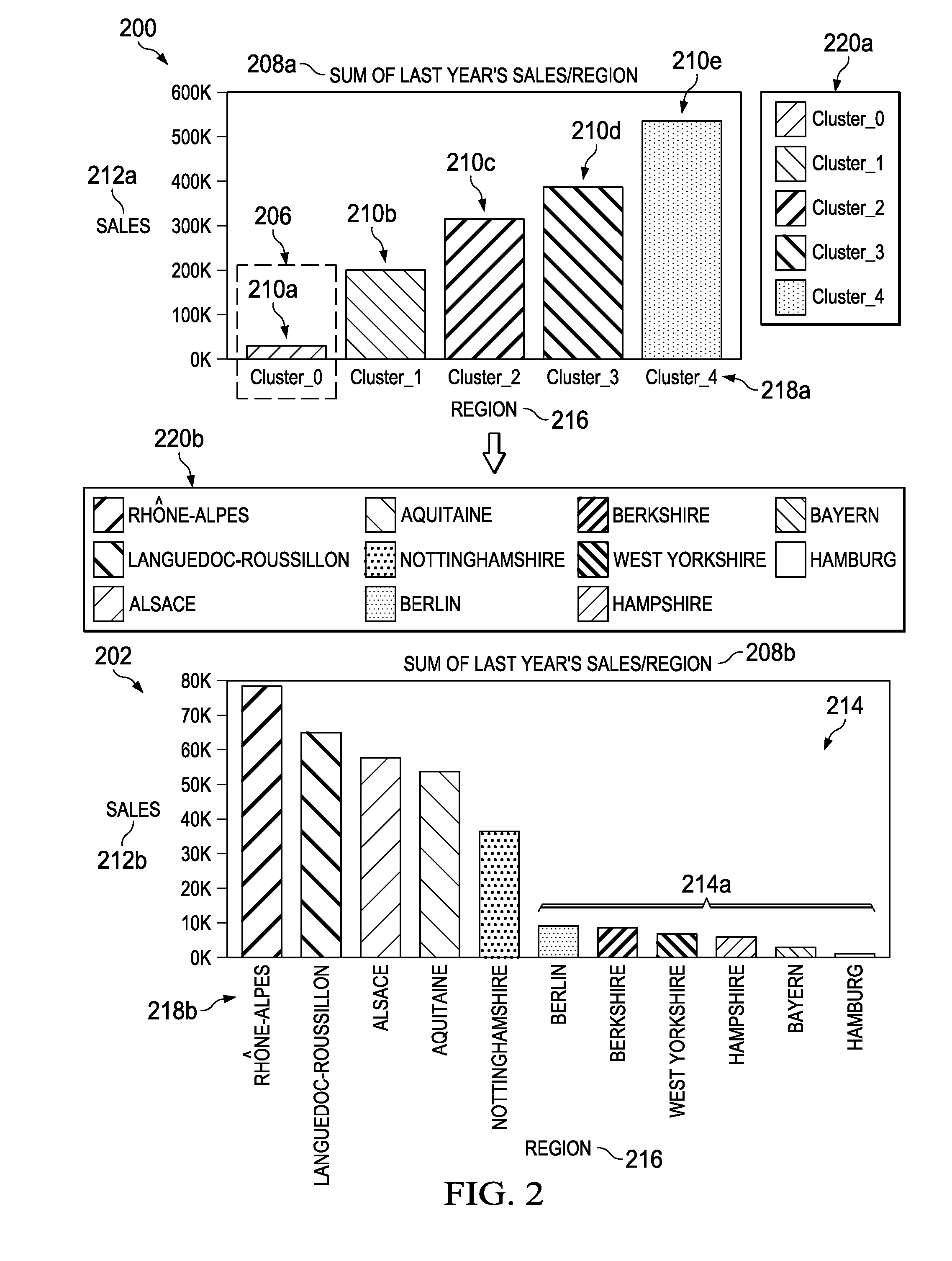

Visualization of data clusters

ActiveUS20160180556A1Easily comprehendedEasy to operateImage enhancementDrawing from basic elementsGraphicsUser input

The disclosure generally describes computer-implemented methods, software, and systems, including a method for presenting information. A first graph is presented that represents plural groups, each representing an aggregated set of data points grouped based on a first set of common attributes. User input selecting a particular group is received. The aggregated set of data points is analyzed to determine whether the number of aggregated set of data points exceeds a threshold. In response to determining that the number exceeds the threshold, the aggregated set of data points is re-grouped. A second set of common attributes associated with the re-grouped set of data points is identified. The data points are aggregated based on the second set of common attributes. A second graph is provided for presentation, the updated graph representing plural groups, each group representing an aggregated subset of data points from the aggregated set of data points.

Owner:BUSINESS OBJECTS SOFTWARE

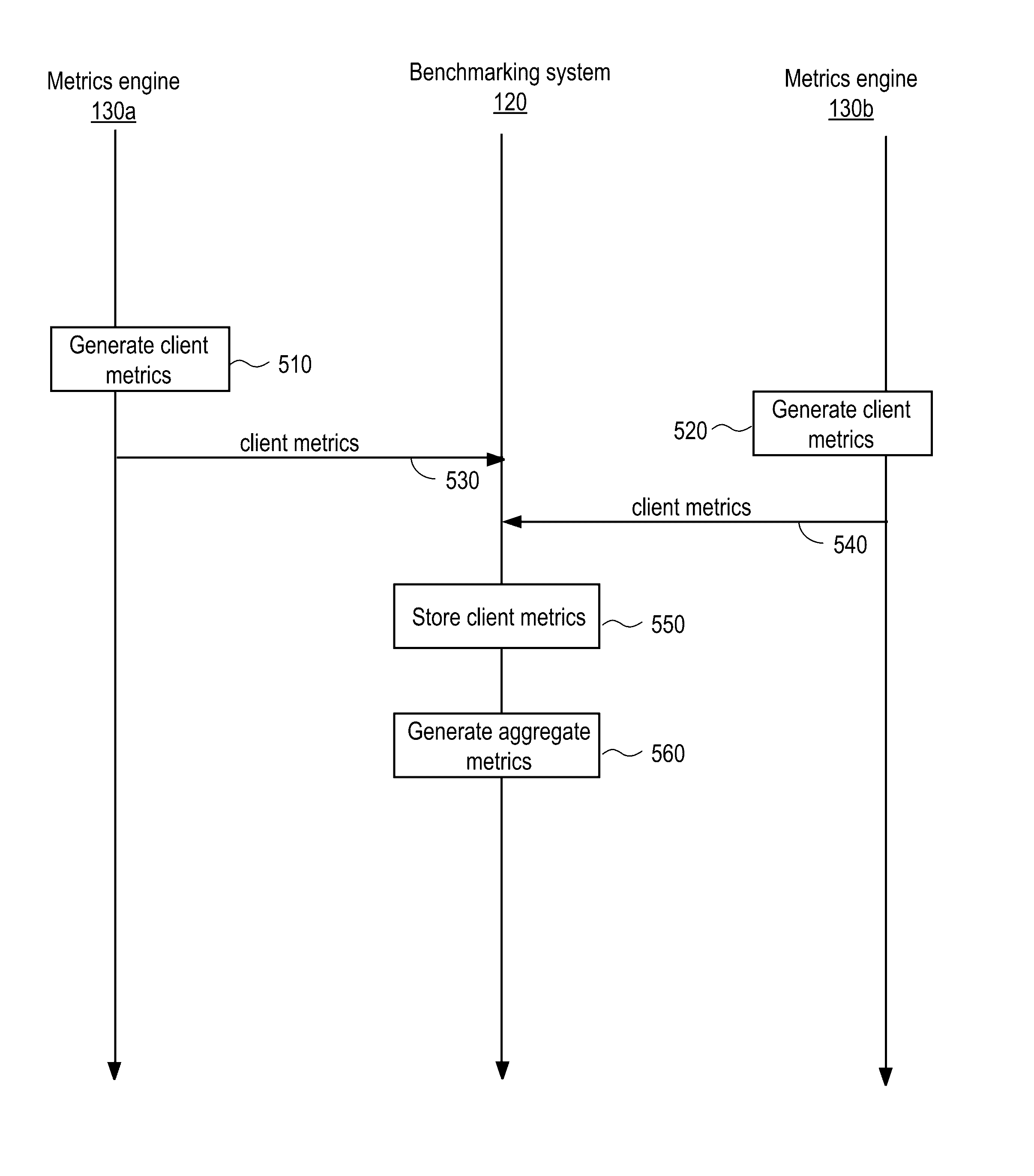

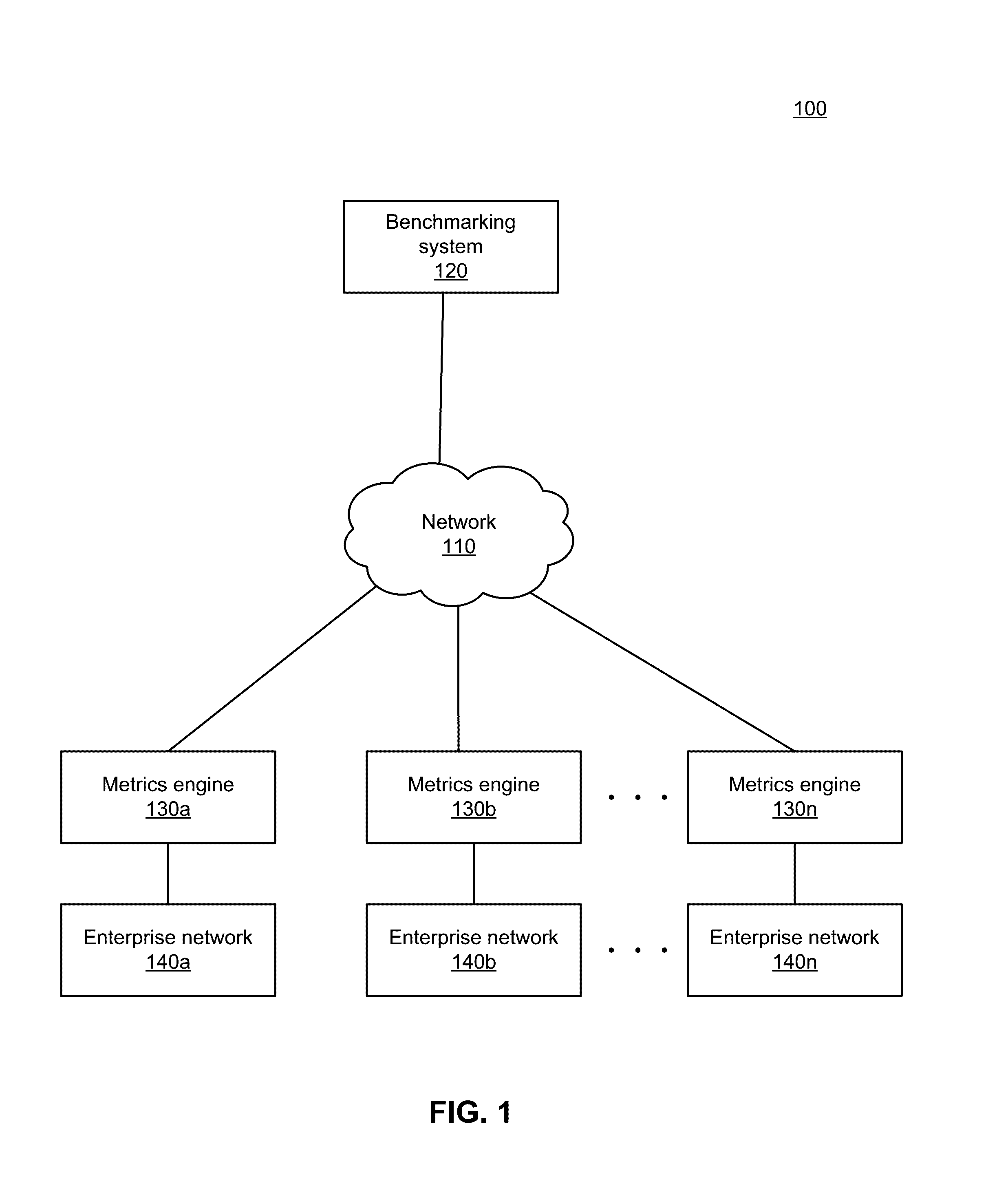

Comparing an organization's security data to aggregate security data

An organization's security data is compared to an aggregation of multiple organizations' security data. Security data is received from multiple organizations having organizational characteristics. The received security data is aggregated based on the organizational characteristics to generate sets of aggregate data associated with the organizational characteristics. A query is received from an organization of the multiple organizations. The query specifies a particular organizational characteristic. A set of aggregate data associated with the specified organizational characteristic is identified. A representation of the organization's security data in relation to the identified set of aggregate data is generated. The representation is transmitted to the organization in response to the query.

Owner:TRIPWIRE

Method for modifying recycled aggregate based on aerobic basophilic mixed bacterium mineralization deposition

ActiveCN107226630ANo negative impact on physical and mechanical propertiesImprove surface compactnessSolid waste managementMicroorganismsScreening methodOxygen

The invention discloses a method for modifying recycled aggregate based on aerobic basophilic mixed bacterium mineralization deposition. The method comprises I, screening aerobic basophilic mixed bacteria and II, modifying recycled aggregate. Through a bacterial screening method, aerobic basophilic mixed bacteria having good practicability to the survival environment are screened. In the environment with enough calcium sources, oxygen and water, the mixed bacteria realize mineralization deposition of a large amount of calcium carbonate precipitates through metabolism. Through the excellent mineralization deposition capacity of the mixed bacteria, cracks and holes on the surface of recycled aggregate are repaired. In modification of the recycled aggregate, the desired mixed bacteria are screened and then are cultured, then the bacterium solution is adsorbed by the surface of recycled aggregate through a vacuum absorption method, and a calcium lactate solution is sprayed to the recycled aggregate to cure the recycled aggregate so that the surface defects of the recycled coarse aggregate are repaired. The method can effectively improve the physical and mechanical properties of the recycled coarse aggregate.

Owner:山西耀辉实业发展股份有限公司

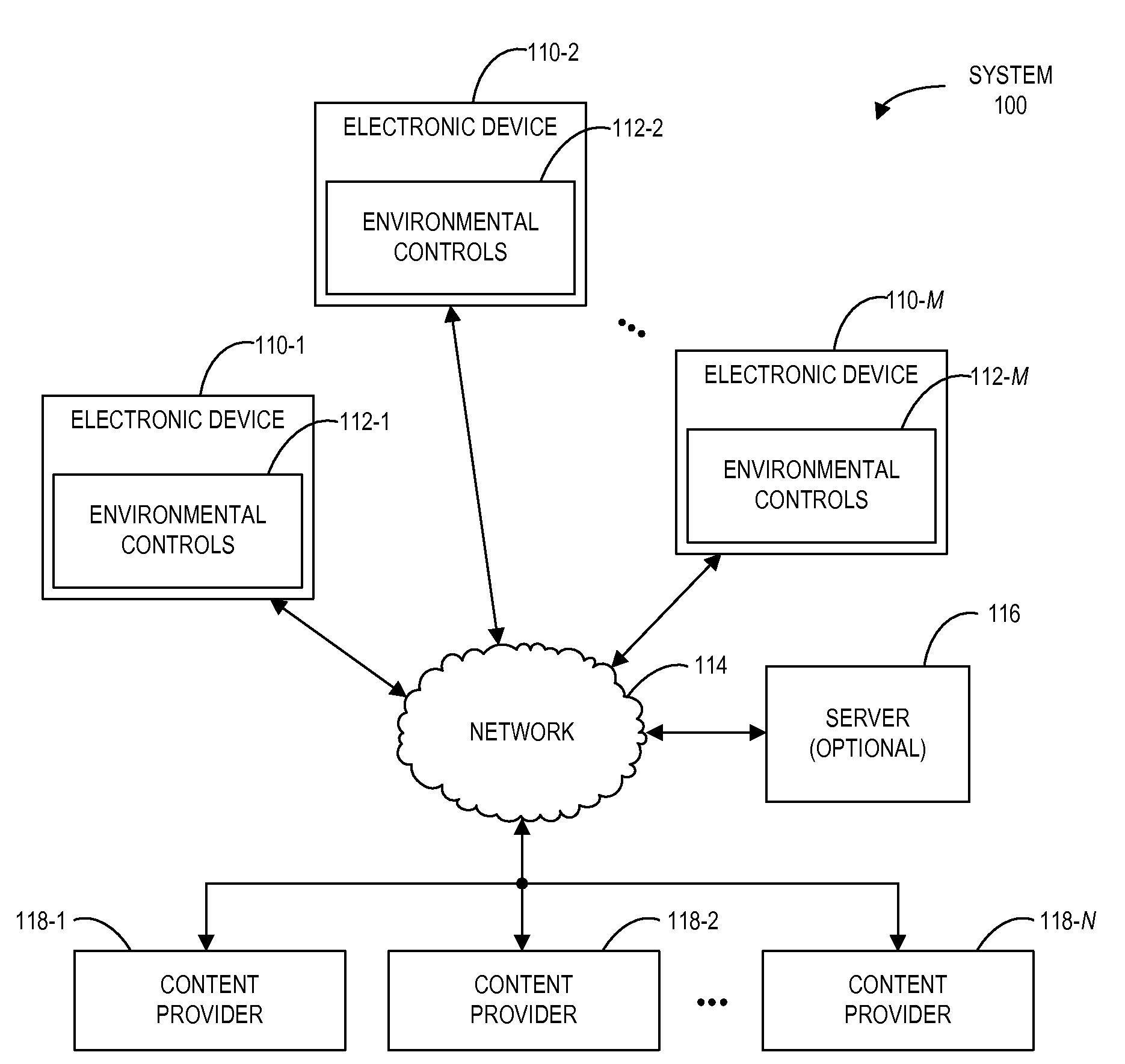

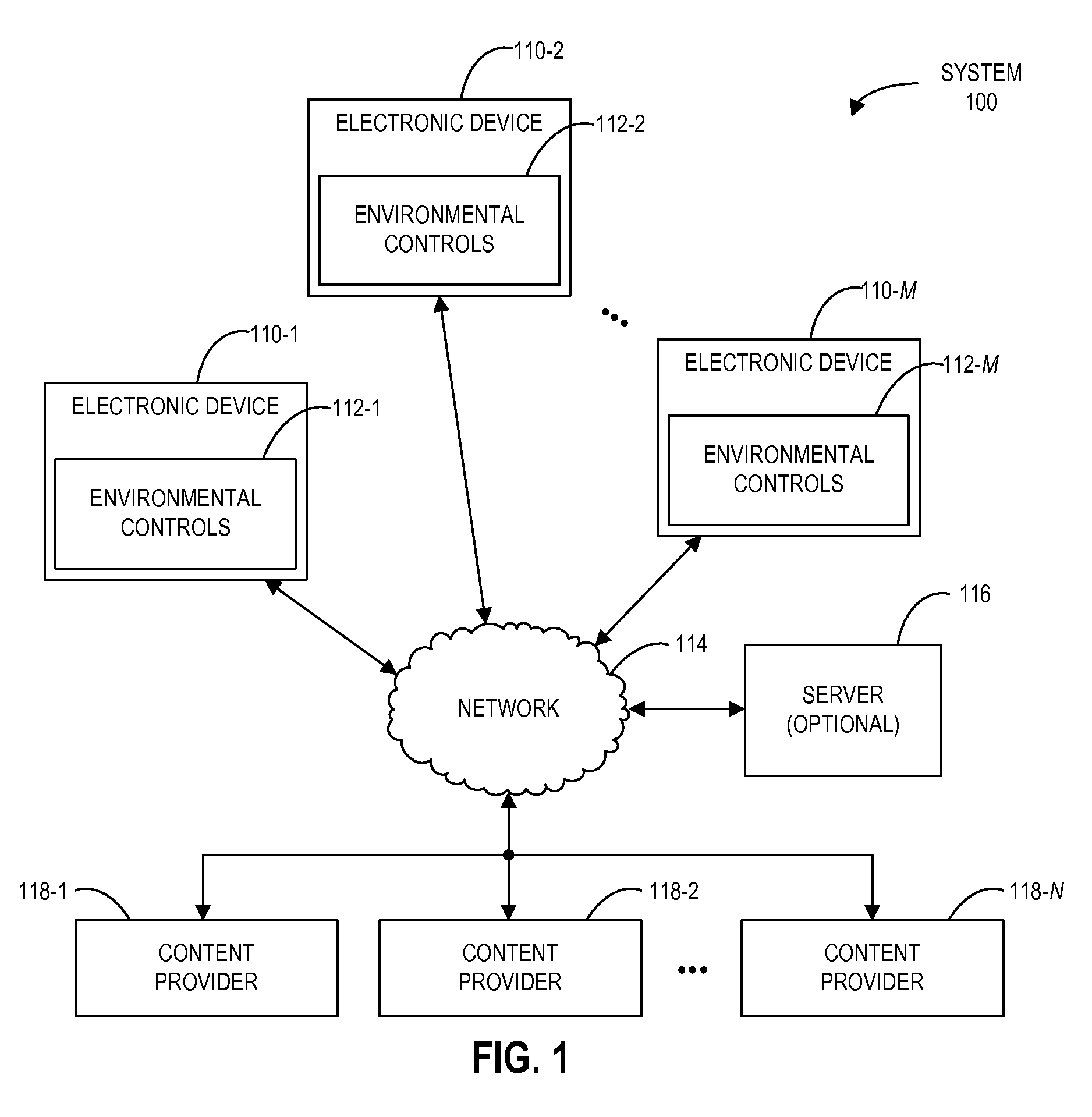

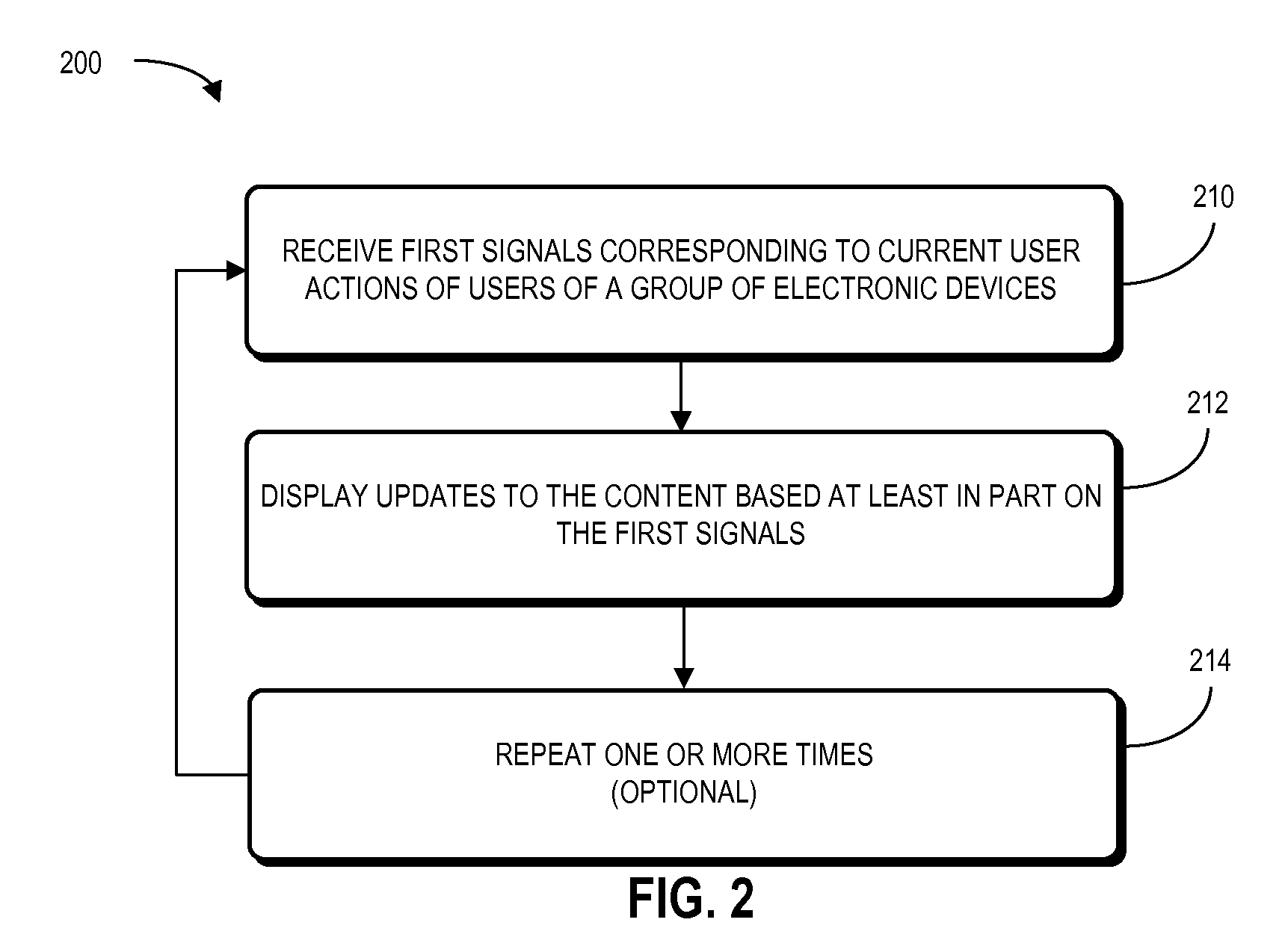

System for collaboratively interacting with content

ActiveUS20100269054A1Facilitates collaborative interactionCommerceInput/output processes for data processingSocial networkAggregate base

Embodiments of a system, a method, and a computer-program product (e.g., software) that facilitates collaborative interaction with content by multiple users are described. In this system, users of a distributed group of dedicated electronic devices provide signals that indicate their current actions as they view the content. Using these signals, the system provides additional signals for display on the group of electronic devices. These additional signals provide an environment that includes the content and the current user actions, which allows the users to collaboratively interact with the content and with each other. Moreover, the multiple users may be dynamically aggregated based on their actions, which allows a social network to be established and dynamically maintained based on user activities and interests.

Owner:XEROX CORP

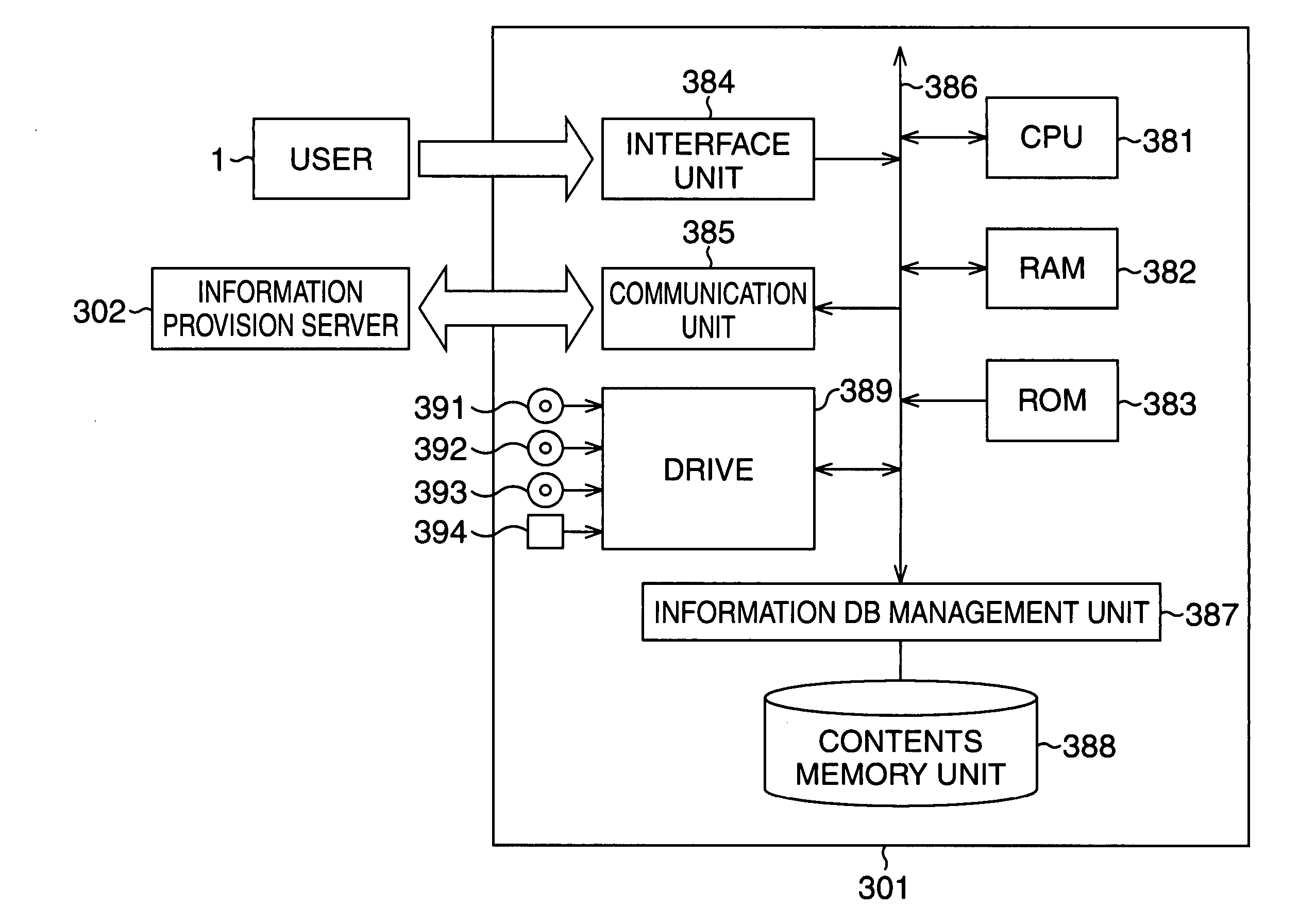

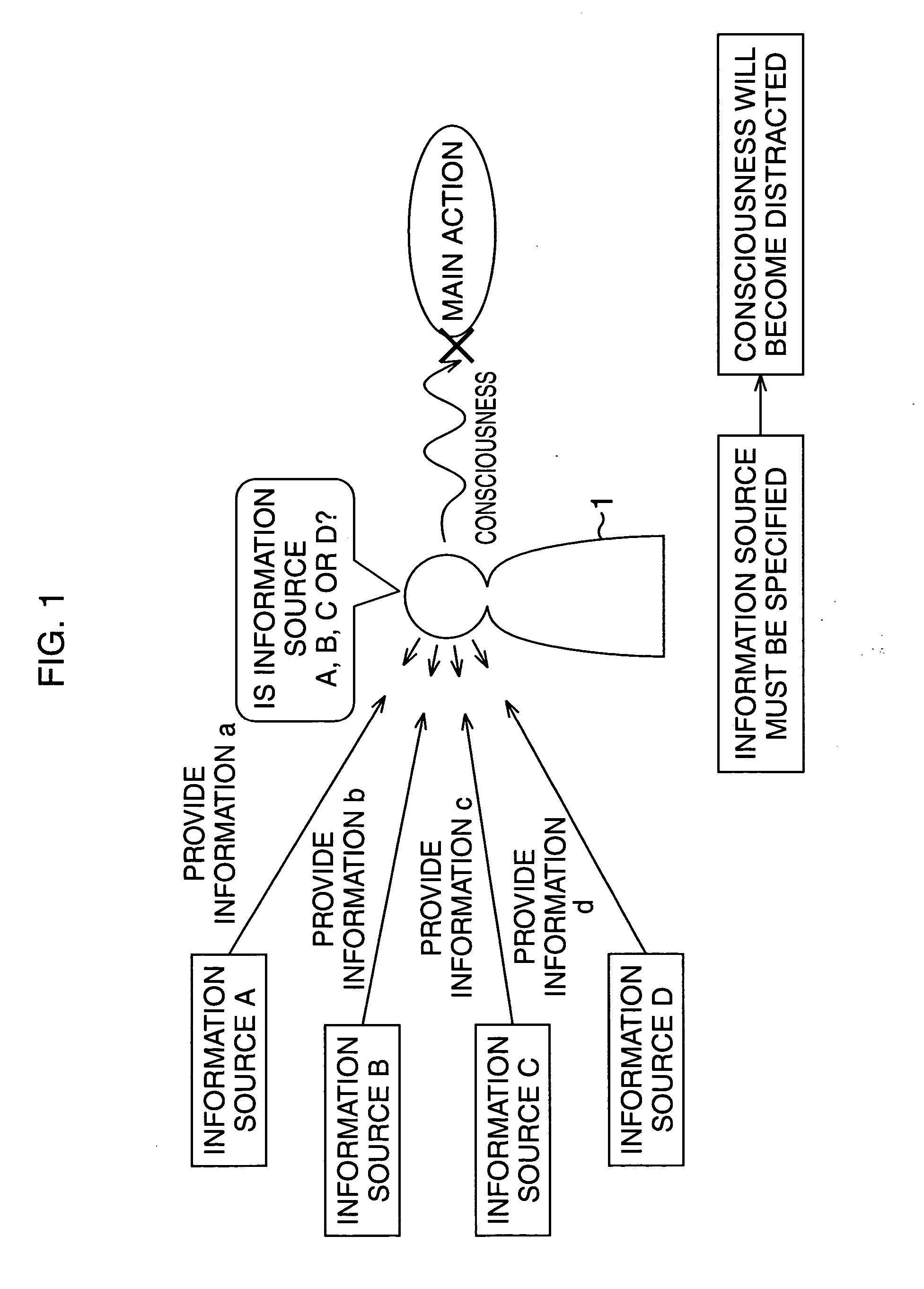

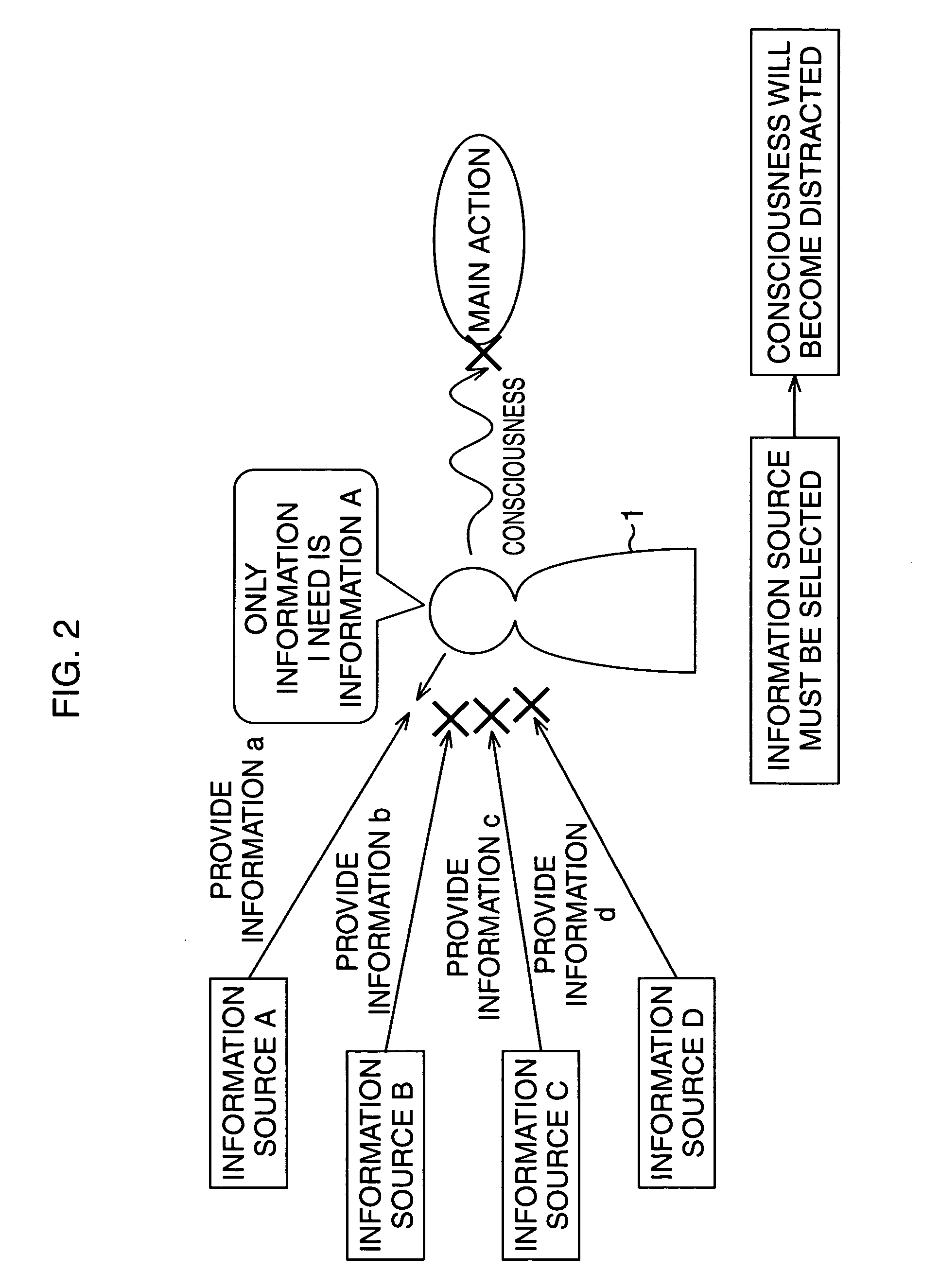

Information output device and method, information reception device and method, information provision device and method, recording medium, information provision system, and program

InactiveUS20050257236A1Minimum operationTelevision system detailsInstruments for road network navigationData controlTerminal equipment

The present invention enables the continuous output of appropriate information at an appropriate timing and in appropriate order with minimal operation. The master control unit 451 controls the output of an aggregate based on an event response control program associated with the aggregate which contains the information being output, of the event response control programs having described therein a command for an event associated with each of the aggregates, and in correspondence with the event. The play list reader 452 controls the output of the information contained in the aggregate based on ordinal data associated with the aggregate, the output of which has been instructed by the master control unit 451, of the ordinal data having described therein the output order of the information associated with each of the aggregates. The present invention may be applied to an in-car information provision terminal device.

Owner:ORMON CORP

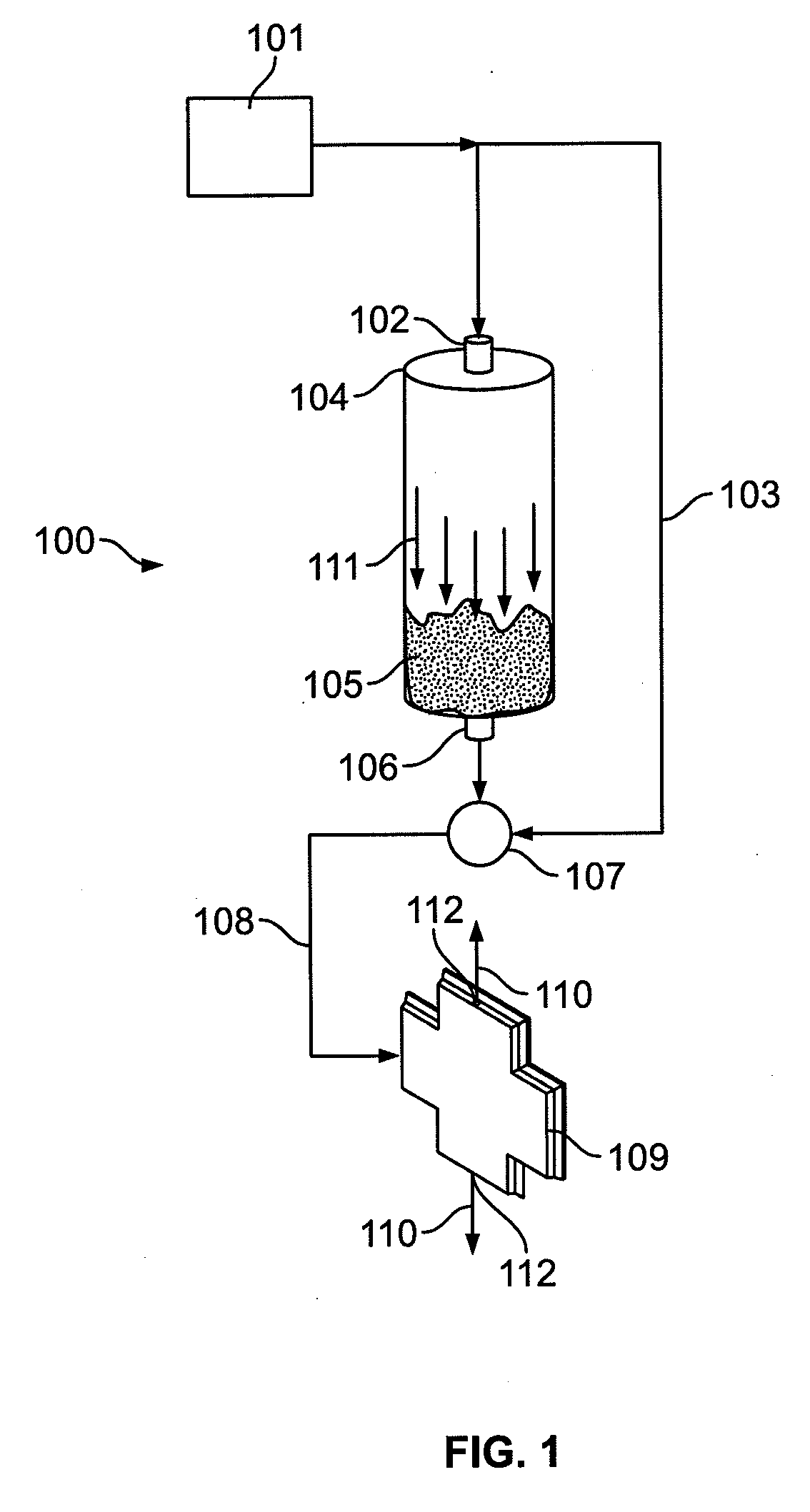

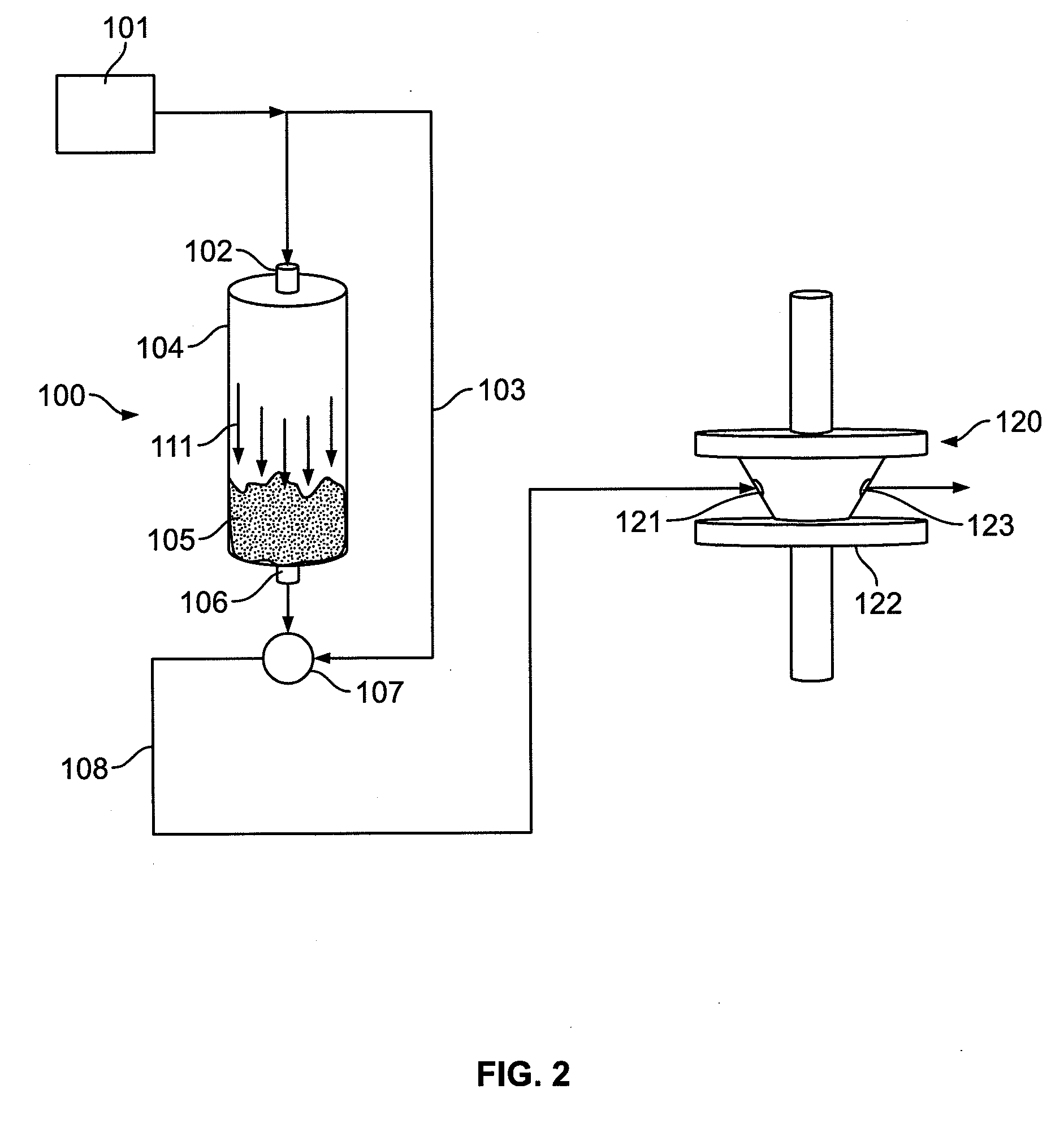

Method Of Removing Solids From Bitumen Froth

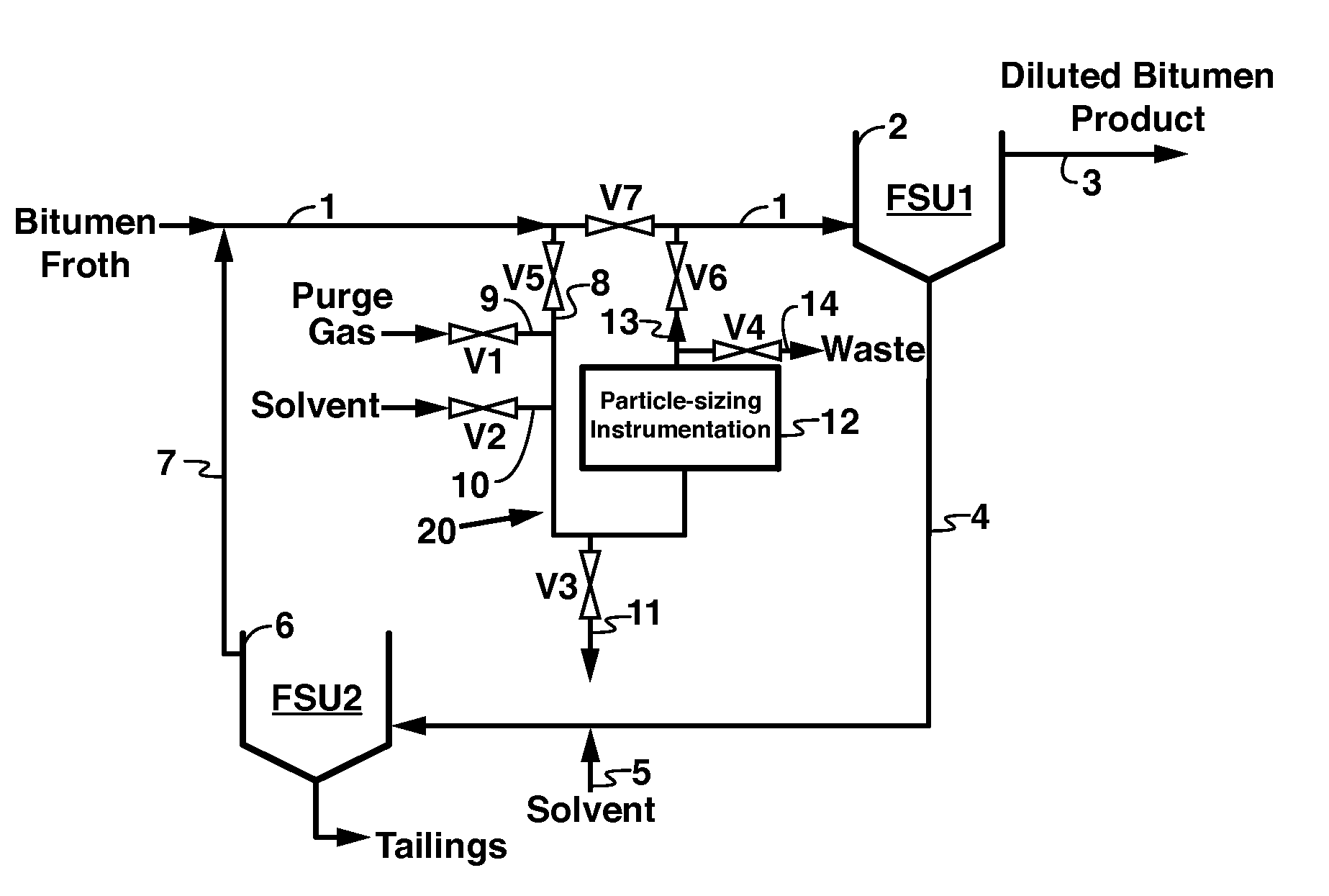

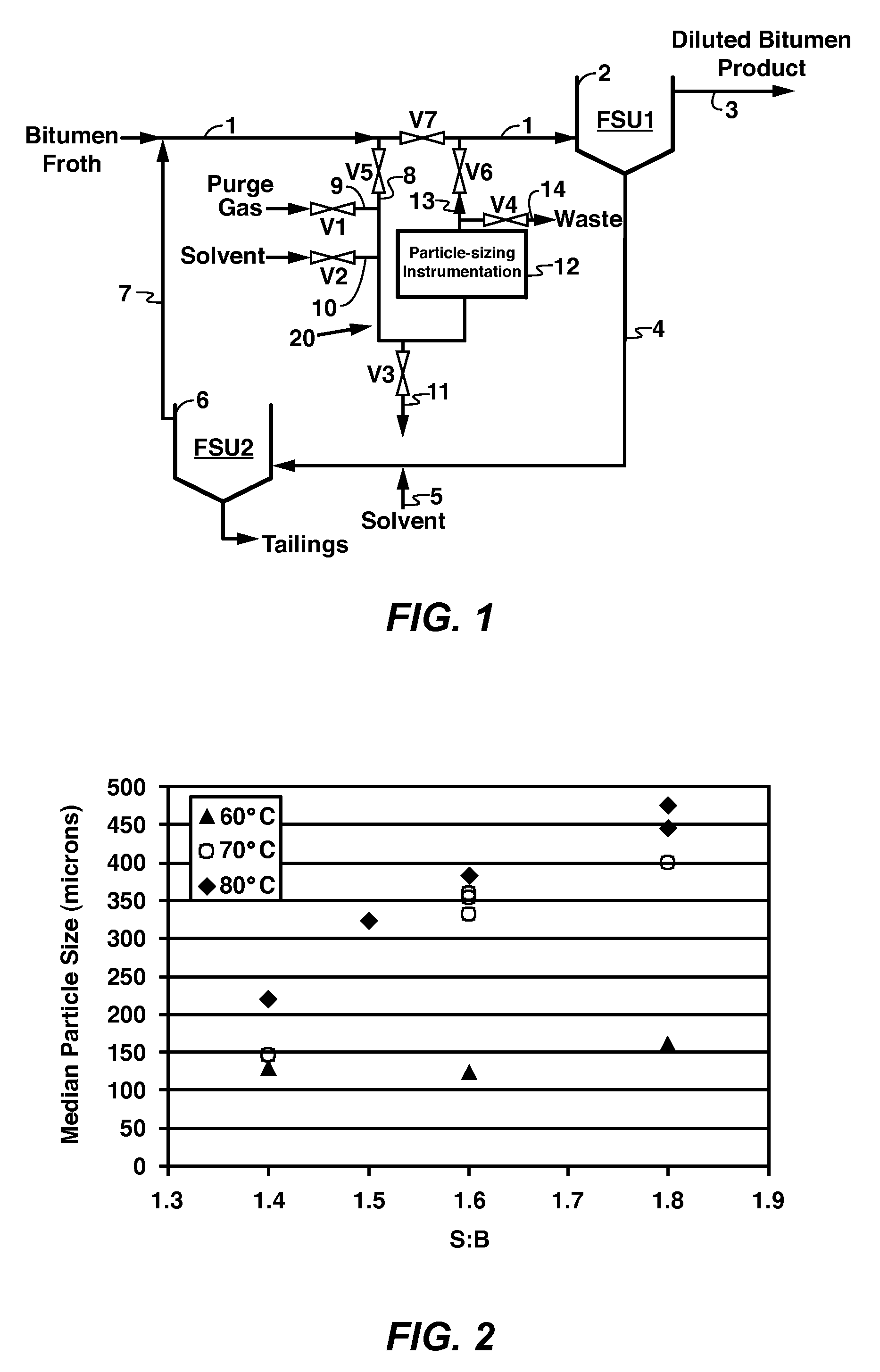

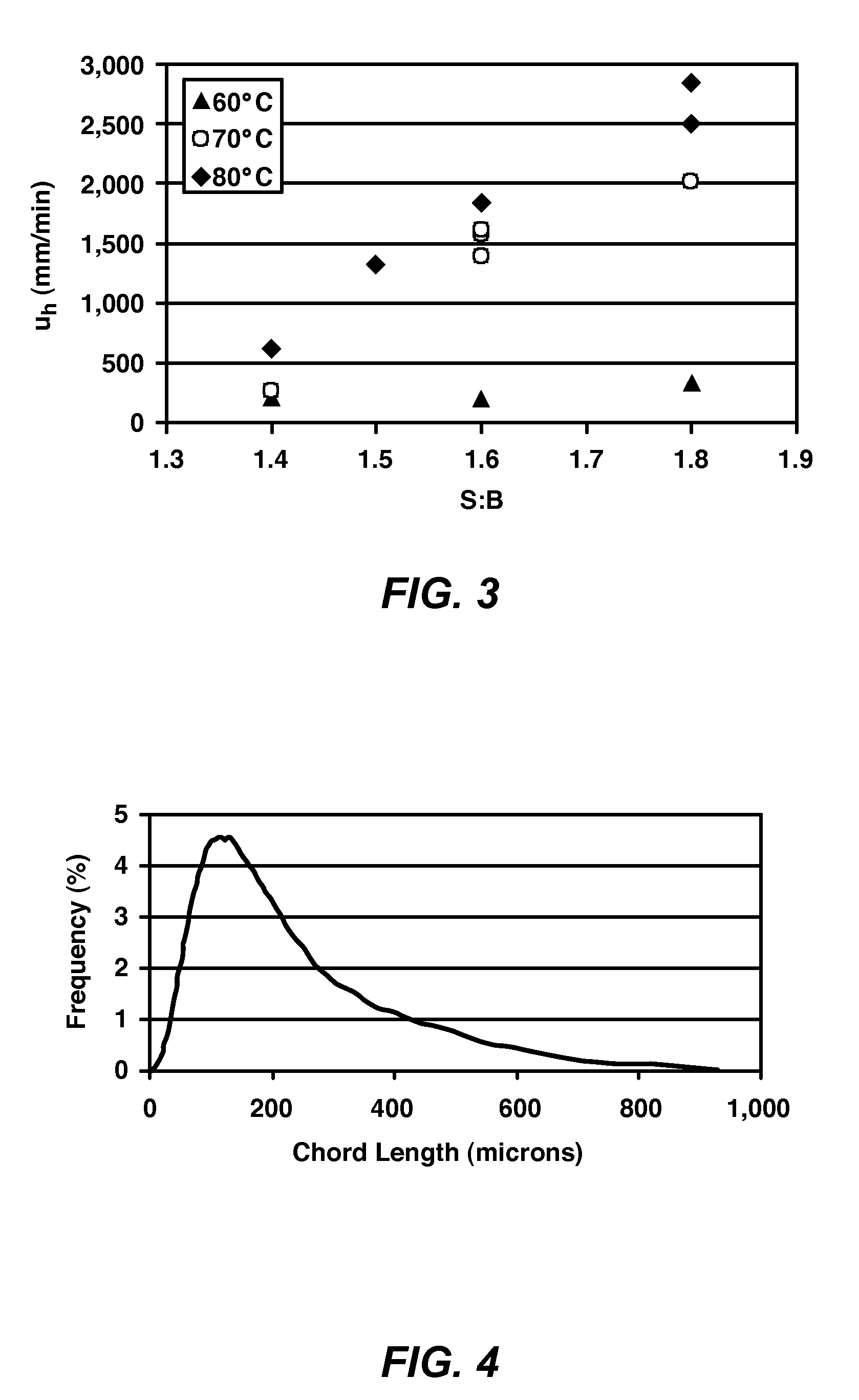

A paraffinic solvent, gravity-based process is disclosed for removing solids content from bitumen froth streams comprising the steps of placing particle-sizing instrumentation in a bitumen froth inlet stream to a gravity settling vessel subsequent to the addition of paraffinic solvent. The addition of solvent forming aggregates. A representative particle size distribution of entrained aggregates is measured with the particle-sizing instrumentation. The settling rate of the aggregates from the particle size distribution is determined mathematically. Operating data is collected while repeating one or more times the foregoing process steps and while changing one or more process conditions of the gravity-based process. A set of operating conditions are then established based upon particle size and settling rate from the generated data. The paraffinic solvent, gravity-based process is operated by adjusting process conditions to optimize the settling rate of the aggregates based upon the established set of operating conditions.

Owner:HOMMEMA SCOTT E

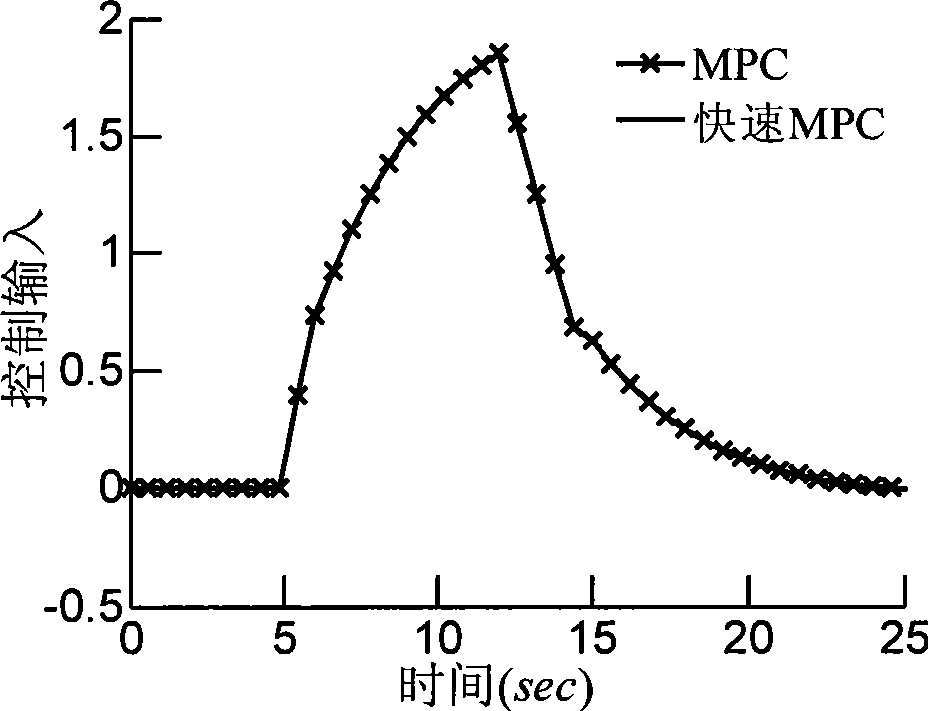

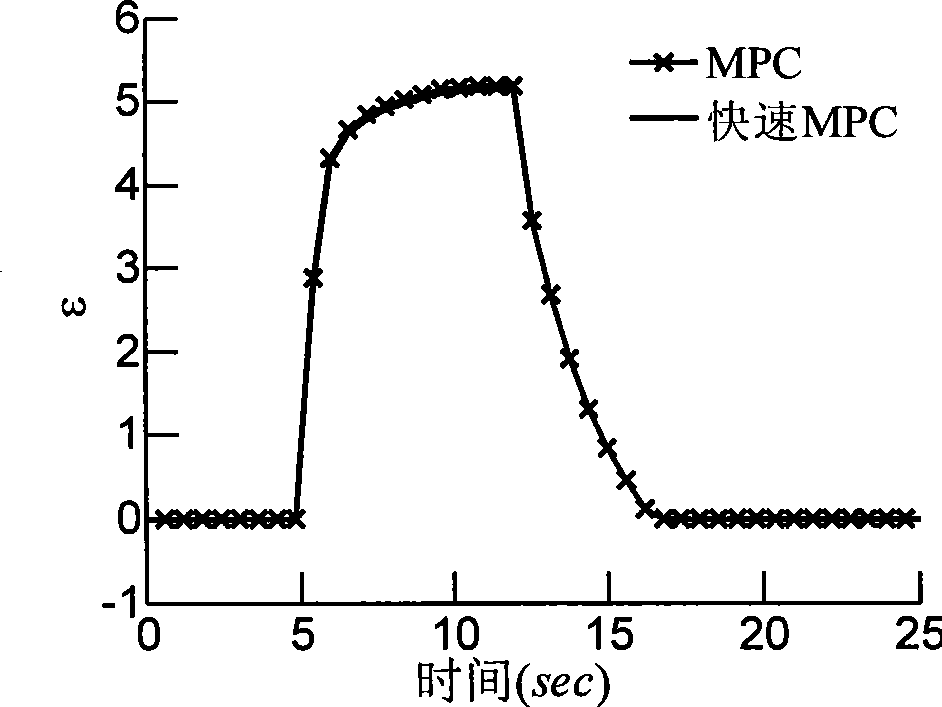

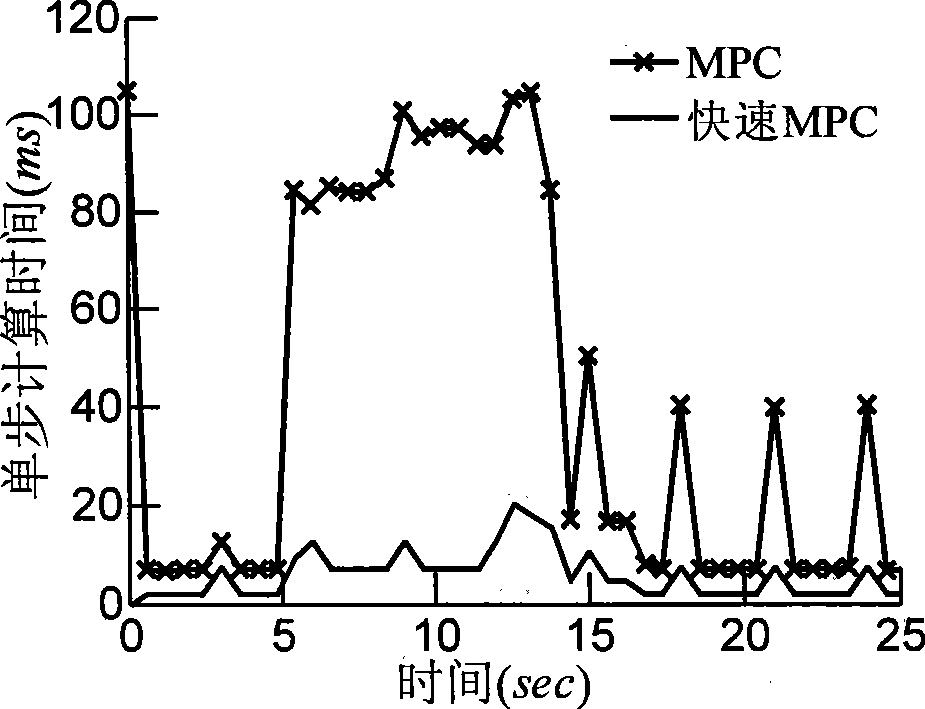

Rapid model prediction control method

InactiveCN101458498AGuaranteed optimal control functionReduce the numberAdaptive controlHorizonOptimal control

The invention relates to a method for rapid predicting controlling a model which includes steps as follows: 1) matrix converting an inequality constraint aggregate; 2) selecting compression matrix parameter of the inequality constraint aggregate; 3) constructing the inequality constraint aggregate compression matrix; 4) mapping changing of the constraint aggregate based on compression matrix; 5) rolling horizon strategies of model predicting optimization problem; 6) applying of rapid control model predicting control rule. The invention only convert to the constraint aggregate and dose not refer to any conversion of waited optimization variable that can reduce scale of MPC optimization control problem efficiently, decrease the on-line calculating amount, increase calculating efficiency, and does not effect calculation inputted by optimization control, can ensure MPC optimization control function. The method has few waited parameter, simple construction method, is easy to on line debugging, and is suitable for industry process, for example petrochemical engineering, and also is suitable for high real-time control field, for example car and robot.

Owner:TSINGHUA UNIV

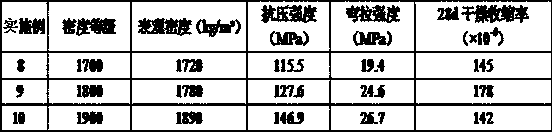

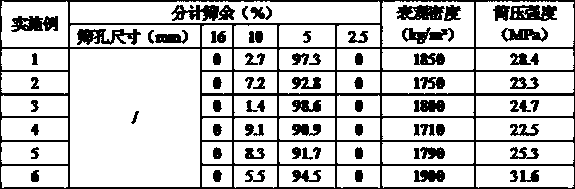

Ceramsite concrete insulating brick and production method thereof

ActiveCN101748841AHigh compressive strengthImprove insulation effectSolid waste managementBuilding componentsBrickExpanded clay aggregate

The invention discloses a ceramsite concrete insulating brick and a production method thereof. A brick block per cubic meter comprises the following components: ceramsite of 150-170kg, waste residue of 830-860kg, cement of 130-160kg, fly ash of 10-20kg and water of 120-130kg. The manufacturing method comprises the following steps: mixing the ceramsite and the waste residue to prepare a first mixture; mixing the cement and the fly ash to prepare a second mixture; mixing the first mixture and the second mixture, adding an appropriate amount of water, and mixing again; and forming through vibrating extrusion, stripping the mold and maintaining in an conventional way to obtain the ceramsite concrete insulating brick in the invention. The ceramsite can form a vitrified shell after firing formation, and the shell has good compressive strength, small shrinkage and good insulation properties. Since the waste residue is used as the main aggregate based on the ceramsite concrete, the weight proportion of the waste residue is 72 percent at least, the stacking density of the waste residue is 1100kg / m3, and the ceramsite concrete insulating brick is 30 percent lighter than other concrete porous bricks generally produced with limestone powder and other materials, the ceramsite concrete insulating brick of the invention has the advantages of low volume weight, small shrinkage, high compressive strength and good insulation properties.

Owner:枣庄高新建设集团有限公司

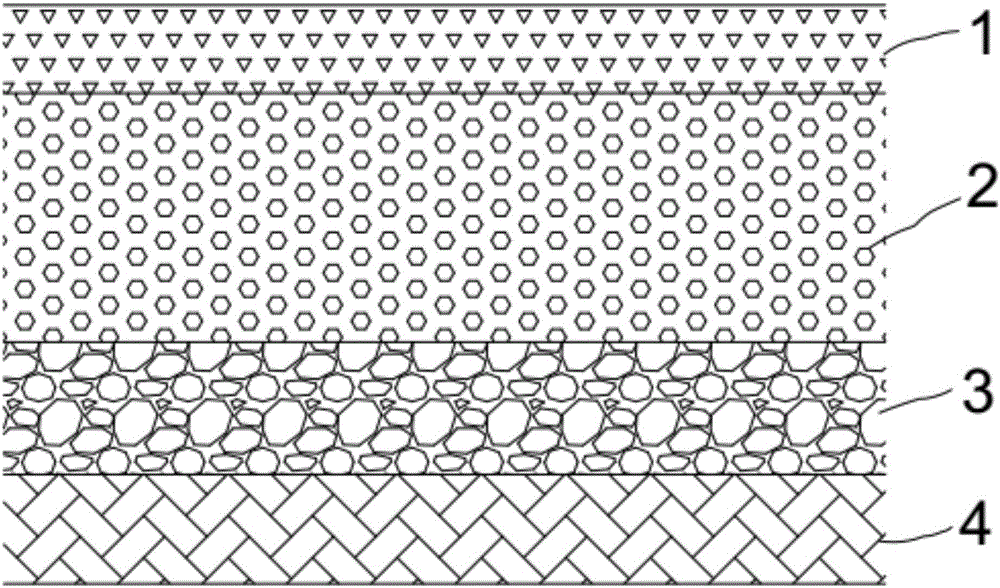

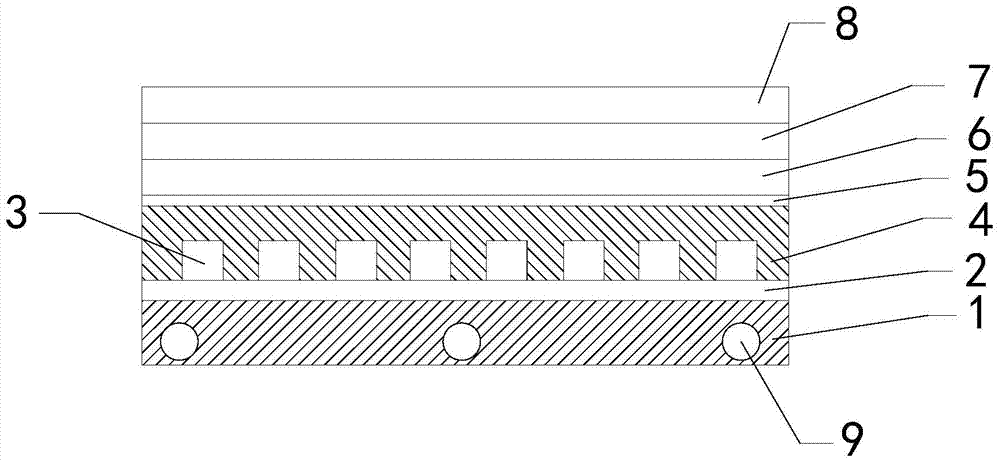

Novel ecological water permeation concrete pavement

InactiveCN106758650AWith compressive strengthGood water permeabilityIn situ pavingsPaving gutters/kerbsWater storageSurface layer

The invention discloses a novel ecological water permeation concrete pavement. The novel ecological water permeation concrete pavement comprises a water permeation surface layer, a water permeation structural layer, a renewable aggregate base layer and a compacted soil substrate layer which are successively arranged; the water permeation structural layer is made of coal ash ceramicite water permeation concrete; and the renewable aggregate base layer is made of concrete-type construction garbage renewable aggregates. By adopting the novel ecological water permeation concrete pavement, the problem of the pollution of the coal ash waste is solved, the concrete-type construction garbage is sufficiently utilized, waste is converted into treasure, and the environmental protection is facilitated; and the water permeability and the water storage property are good, the strength is high, and the comprehensive utilization of the sponge urban construction for solid wastes and construction garbage is realized.

Owner:TIANJIN INDZATION CONSTR CO LTD

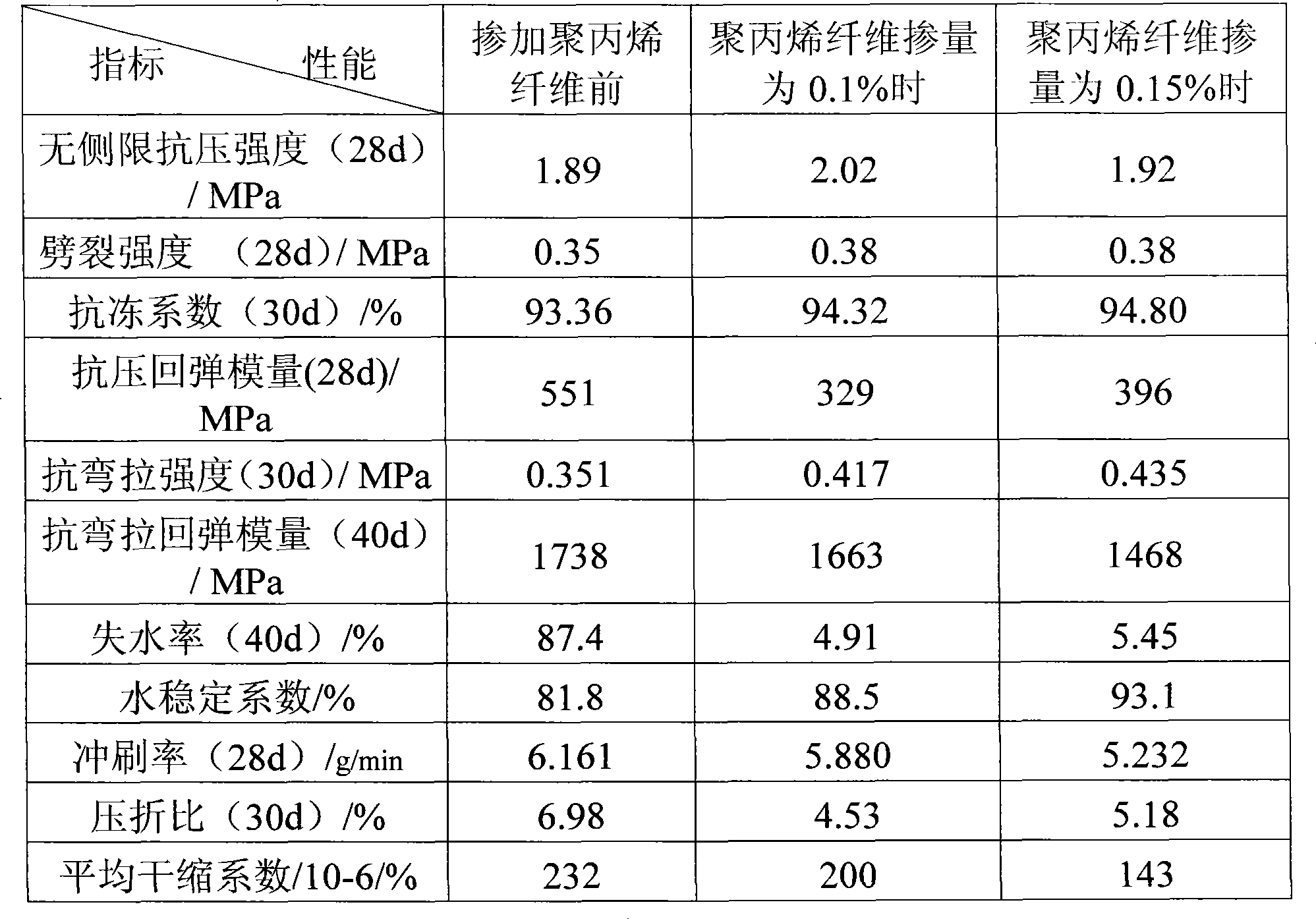

Polypropylene fiber lime-fly ash aggregate base material and preparation method thereof

InactiveCN101386484AImprove performanceImprove road performanceSolid waste managementCrushed stoneFly ash

The invention polypropylene fiber lime fly-ash broken stone base course and a method for preparing the same and relates to the technical field of road semi-rigid base course modification. The preparation method is as follows: polypropylene fiber is per-dispersed in lime and fly-ash, and then is mixed with aggregate and water to form the polypropylene fiber lime fly-ash broken stone base course. Compared with the prior lime fly-ash broken stone base course, the polypropylene fiber lime fly-ash broken stone base course has the advantages of higher cracking resistance, bending strength, indirect pull strength and water stability and smaller temperature shrinkage and dry shrinkage.

Owner:YANGZHOU UNIV

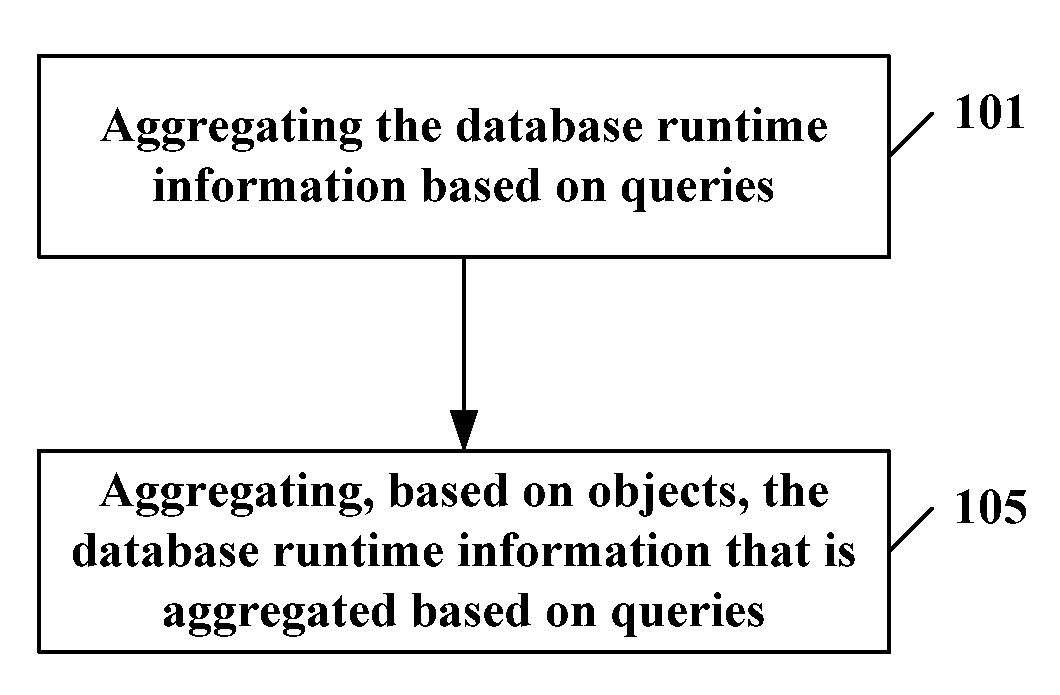

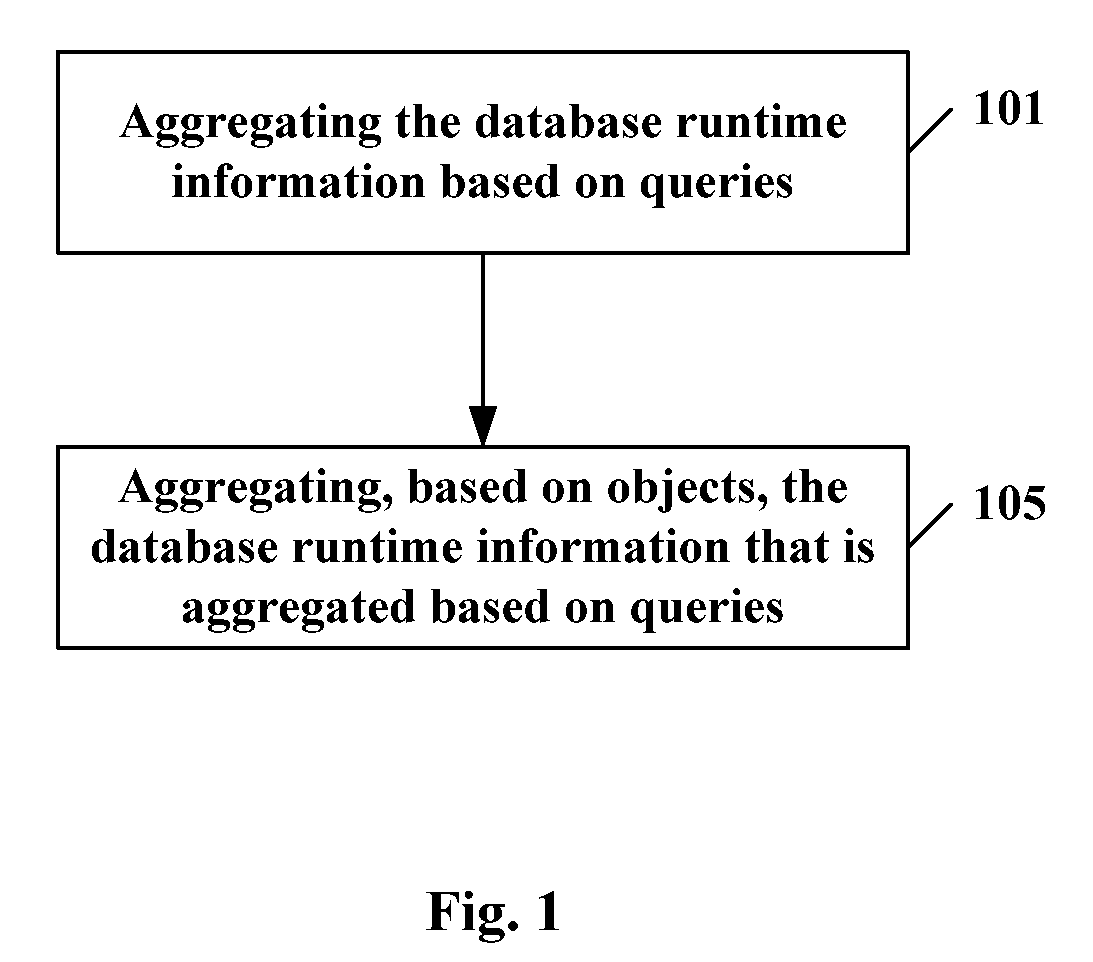

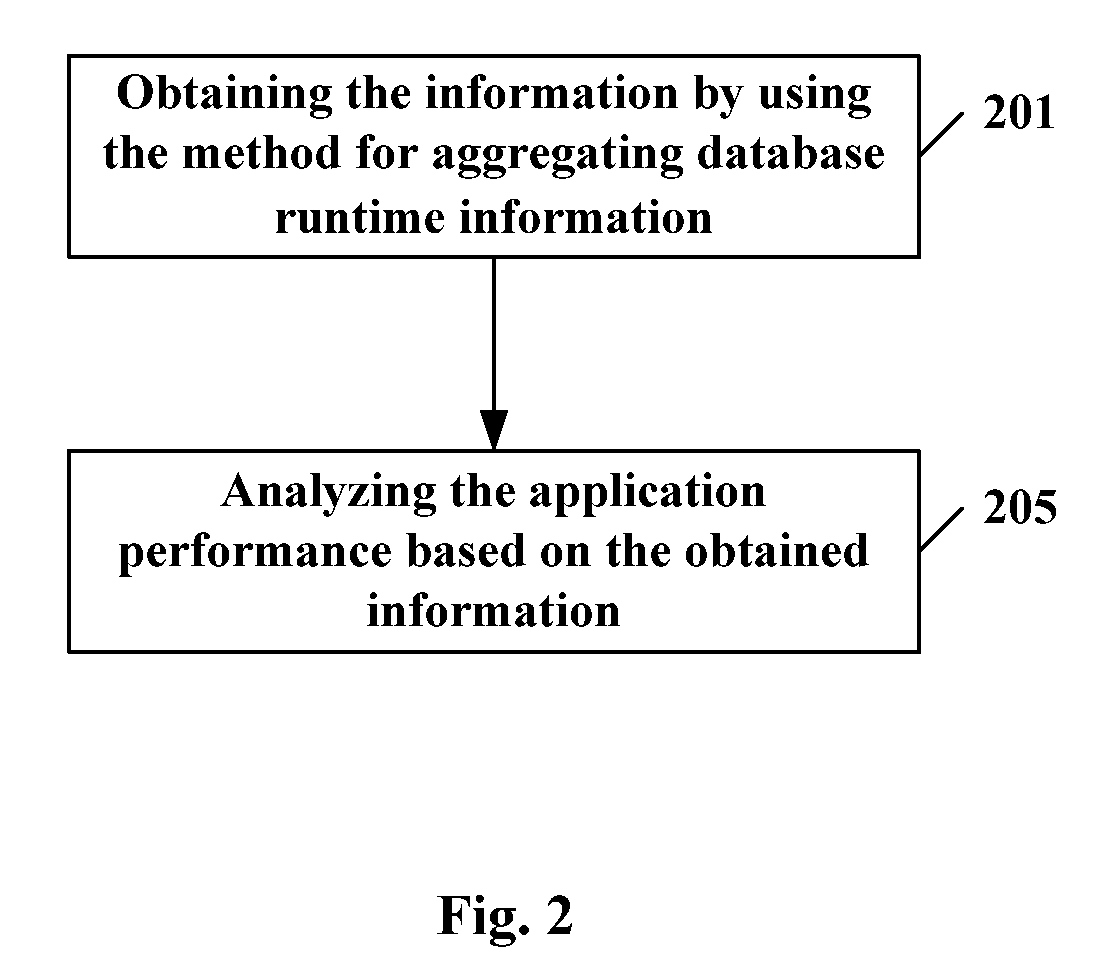

Method and apparatus for aggregating database runtime information and analyzing application performance

InactiveUS20080140627A1Digital data information retrievalSpecial data processing applicationsObject basedDatabase

The present invention provides a method and an apparatus for aggregating database runtime information and analyzing application performance. According to one aspect of the present invention, there is provided a method for aggregating database runtime information, comprising: aggregating said database runtime information based on queries; and aggregating, based on objects, said database runtime information that is aggregated based on queries.

Owner:IBM CORP

Novel asphalt concrete pavement structure

InactiveCN103498399AImprove deformation resistanceIncreased durabilityIn situ pavingsAsphalt masticRoad surface

The invention discloses a road pavement structure, and particularly relates to a novel asphalt concrete pavement structure. The novel asphalt concrete pavement structure has high quick-drying and water drainage performance, is obvious in supporting effect and has certain collapsing preventive performance. A mortar bonding layer covers a base layer, cement concrete prefabricated blocks arranged in parallel and at intervals are arranged on the mortar bonding layer, the long edges of the cement concrete prefabricated blocks are perpendicular to the stretching direction of a road, a rubble layer is padded in clearances between adjacent cement concrete prefabricated blocks and covers the cement concrete prefabricated blocks, a slurry seal layer, a coarse grain type asphalt concrete layer, a medium grain type asphalt concrete layer and an asphalt mastic rubble mixed material layer cover the rubble layer from bottom to top in sequence, the base layer is a cement stabilizing aggregate base layer, and the rubble layer comprises rubbles and aggregate chips padded in the clearances among the rubbles.

Owner:聂晓鸿

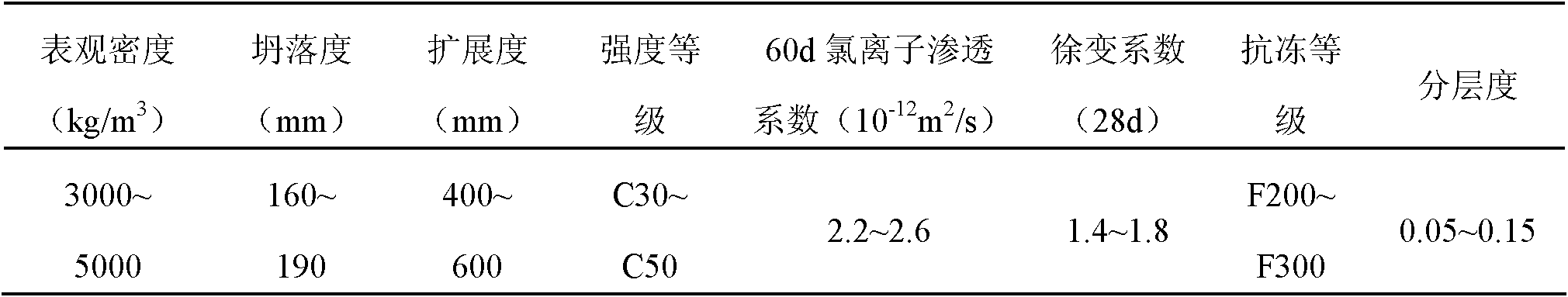

Environmental-friendly functional aggregate-based high-homogeneity radiation-resistant concrete

ActiveCN101921093ATotal momentum downSlow motion rateSolid waste managementResource utilizationSludge

The invention relates to environmental-friendly functional aggregate-based high-homogeneity radiation-resistant concrete. The concrete consists of water, a cementing material, a fine aggregate, a coarse aggregate, a tackifier, a water reducing agent and fibers, wherein the cementing material consists of cement and a mineral admixture; the mineral admixture consists of silica fume and coal ash; the fibers are polypropylene fibers, wherein 1m<3> of concrete comprises the following components: 140 to 160 kg of the water, 300 to 500 kg of the cement, 20 to 60 kg of the silica fume, 30 to 70 kg of the coal ash, 700 too 800 kg of the fine aggregate, 1,000 to 1,300 kg of the coarse aggregate, 0.35 to 1.9 kg of the tackifier, 2.1 to 7.5 kg of the water reducing agent, and 0.6 to 1.0 kg of the polypropylene fibers. The demixing degree of the concrete can be reduced to 0.05; and the concrete has the characteristics of high rheological property, high strength property and durability, and can realize resource utilization of heavy metal-containing urban sludge, mud or industrial waste.

Owner:WUHAN UNIV OF TECH

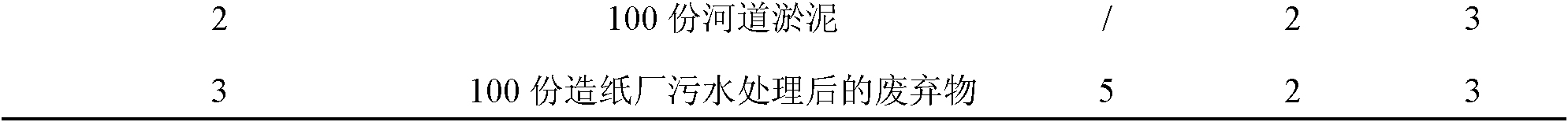

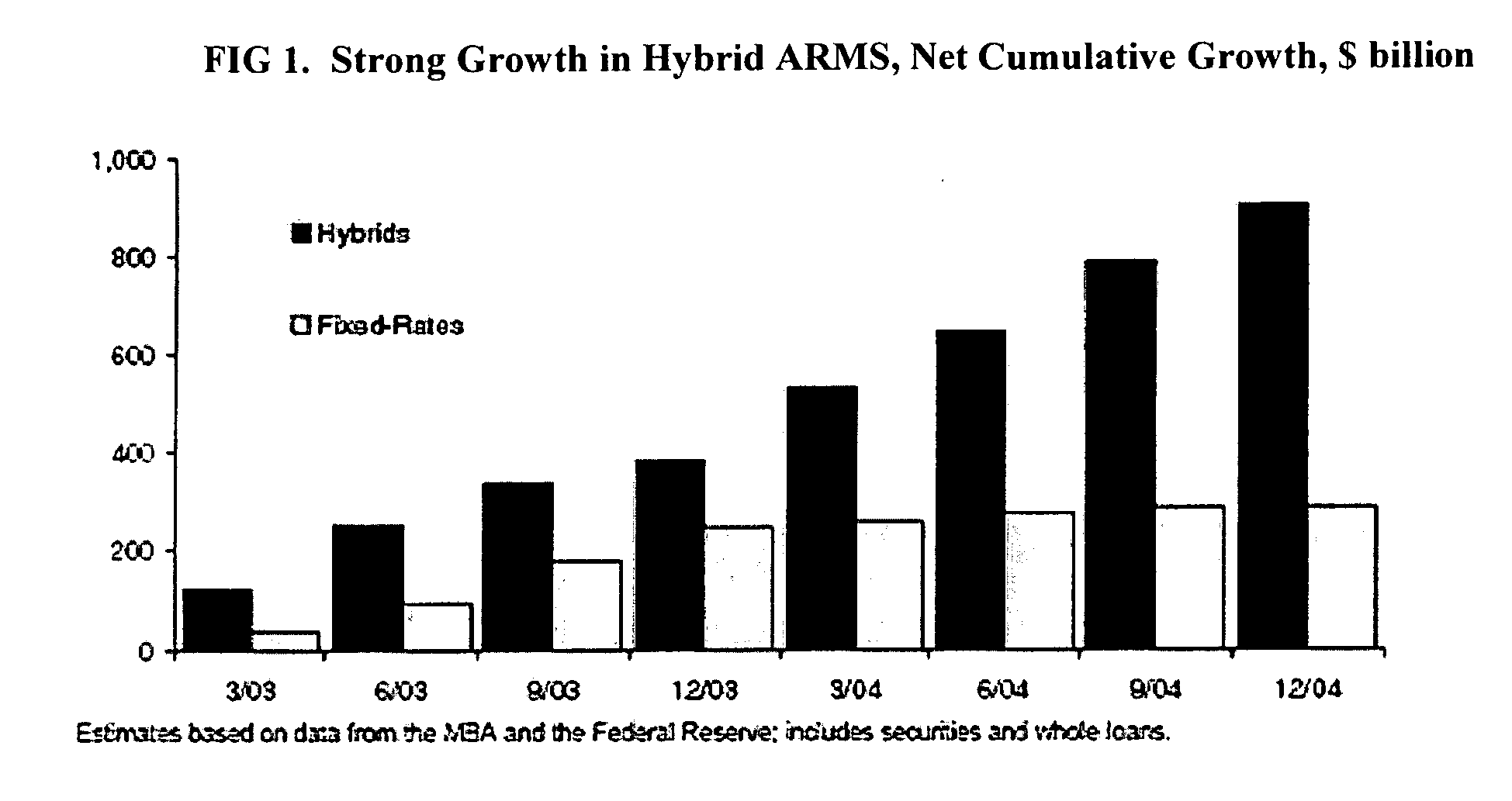

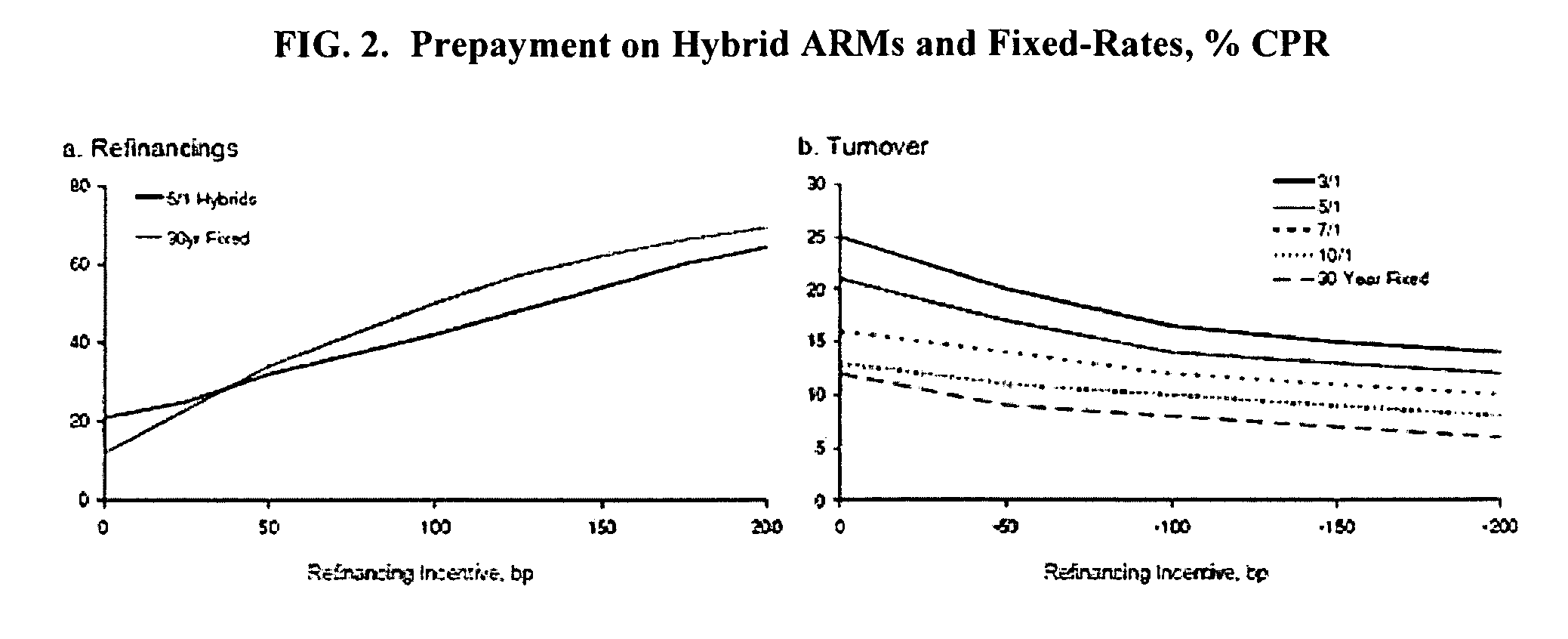

Hybrid arm index

In at least one aspect, the invention comprises constructing one or more hybrid adjustable rate mortgage aggregates based on one or more of: agency, program, coupon, and origination year; for each of one or more of the aggregates, constructing one or more sub-aggregates based on one or more of: rate-index, capitalization structure, and existence of interest-only feature; mapping pools of adjustable rate mortgages to the aggregates and sub-aggregates; constructing an index based on the mapping; and pricing the index.

Owner:BLOOMBER FINANCE LP

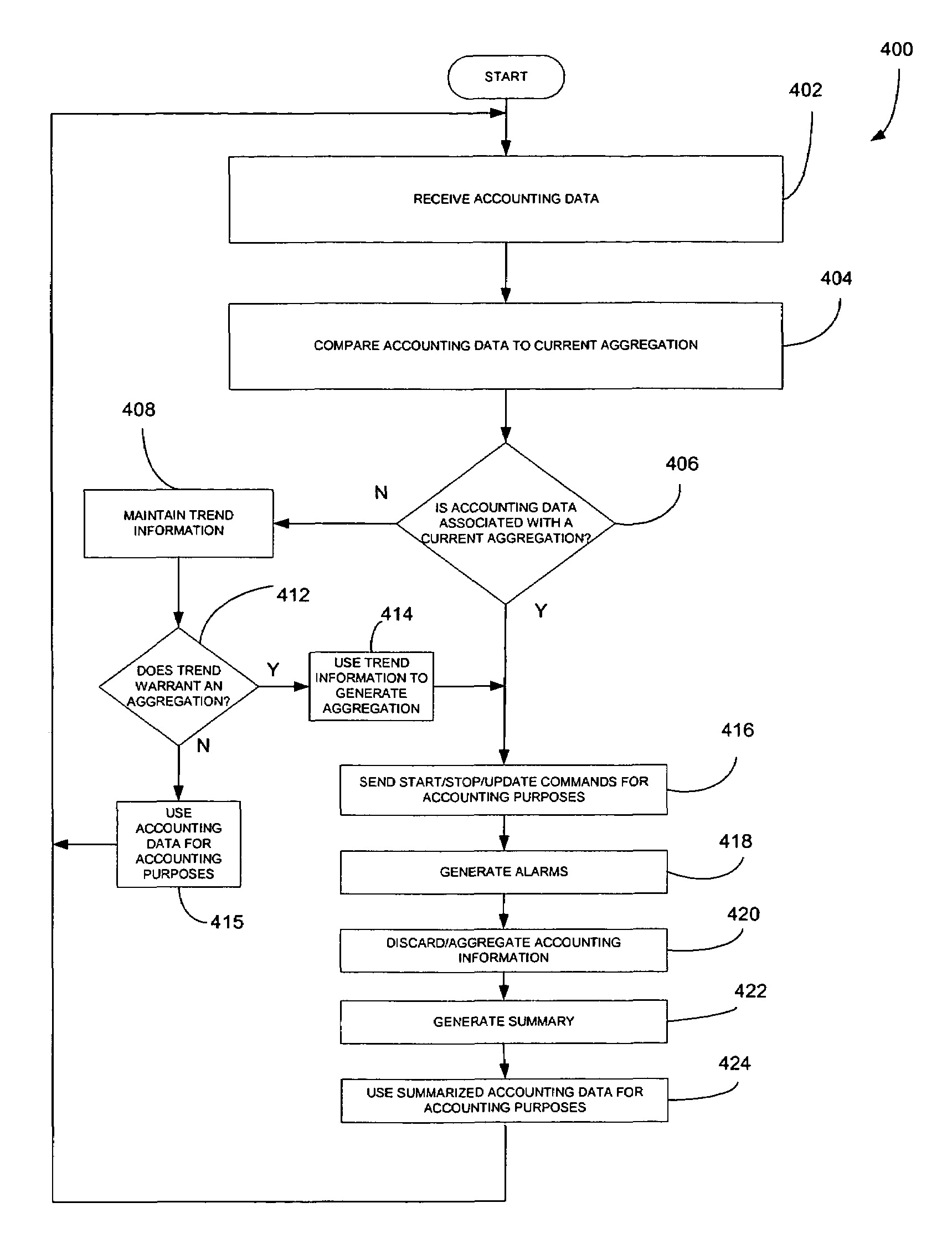

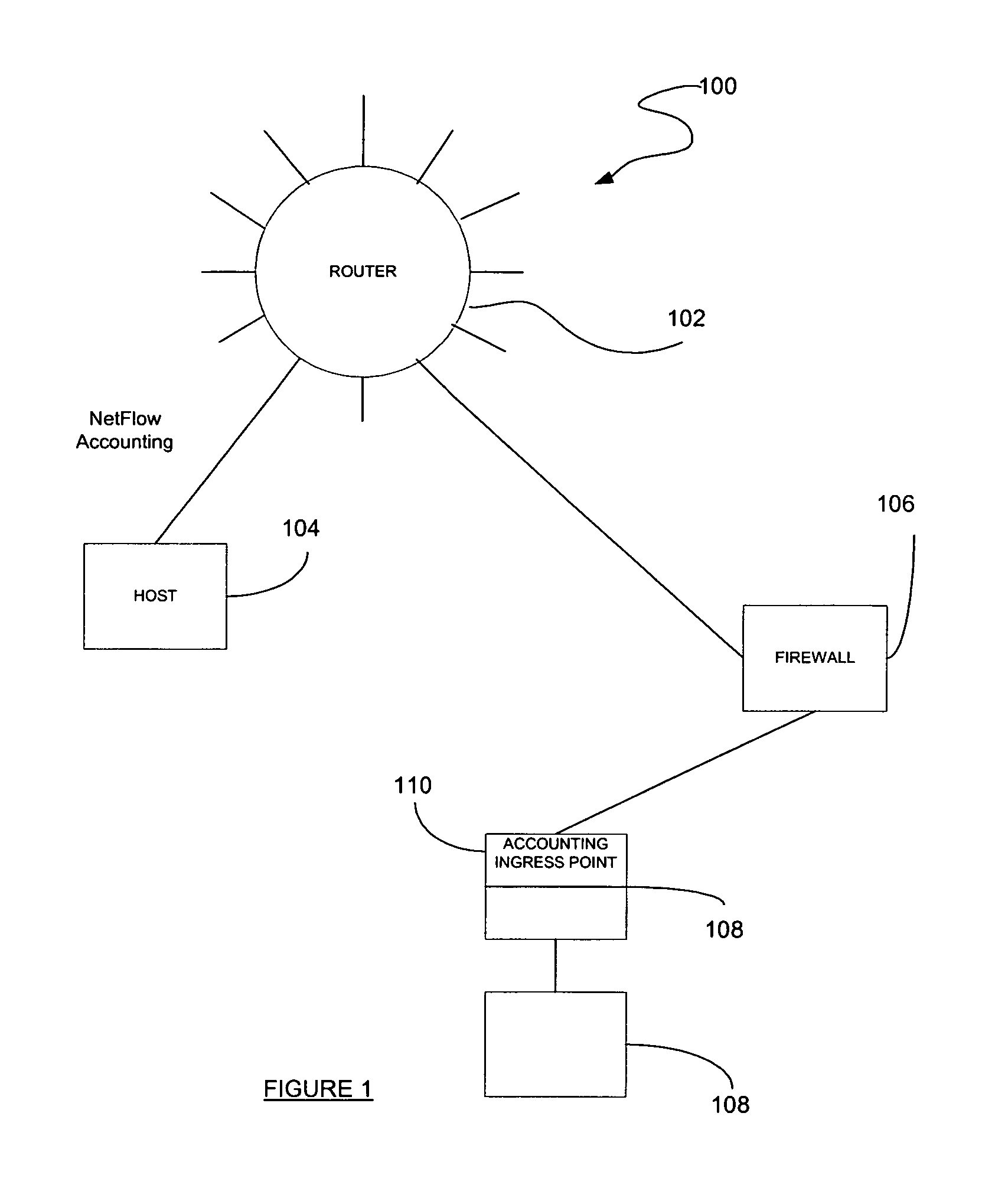

System, method and computer program product for processing network accounting information

InactiveUS7099940B2Guaranteed uptimeEffective and efficient meanMetering/charging/biilling arrangementsError preventionTraffic capacityNetwork attack

A system, method and computer program product are provided for processing network accounting information. First, accounting information is received utilizing a packet-switched network. During use, at least one aspect of the received accounting information is monitored. In order to provide a defense against network attacks, dealing with heavy network traffic, or any other type of surge of network events, at least a portion of the accounting information is discarded and / or aggregated based on the monitored aspect. This prevents a system from being overloaded during the network accounting process.

Owner:AMDOCS DEV LTD +1

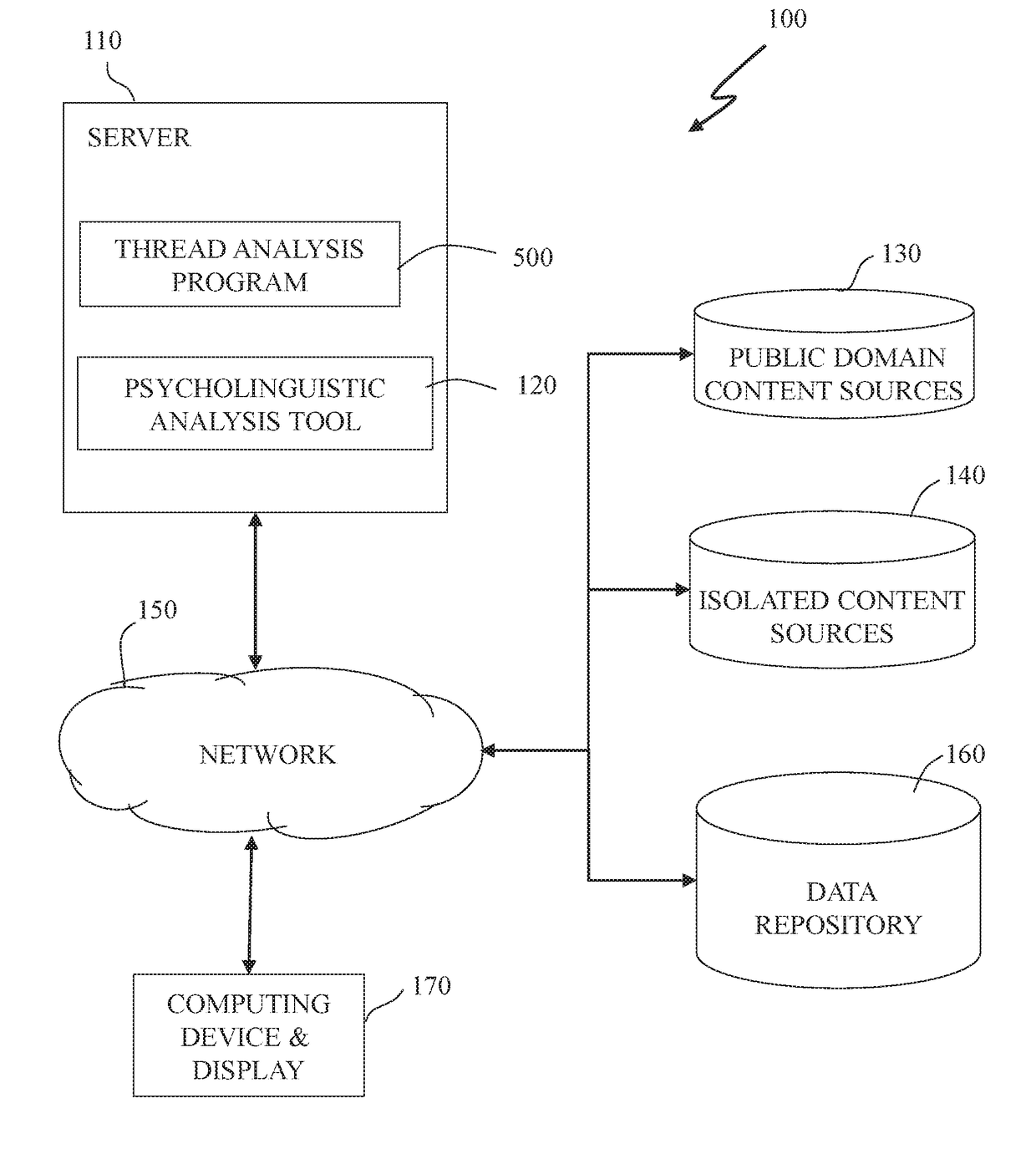

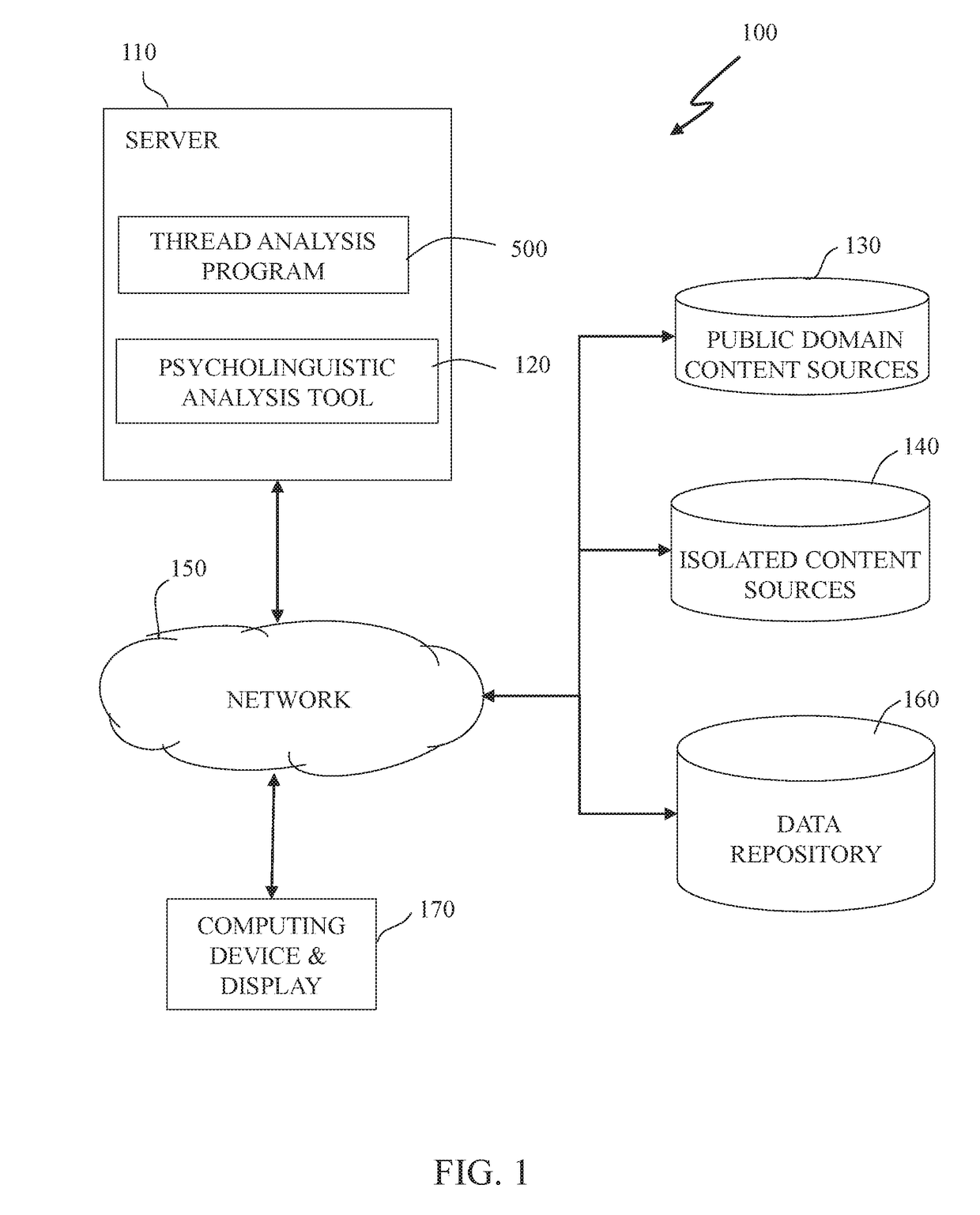

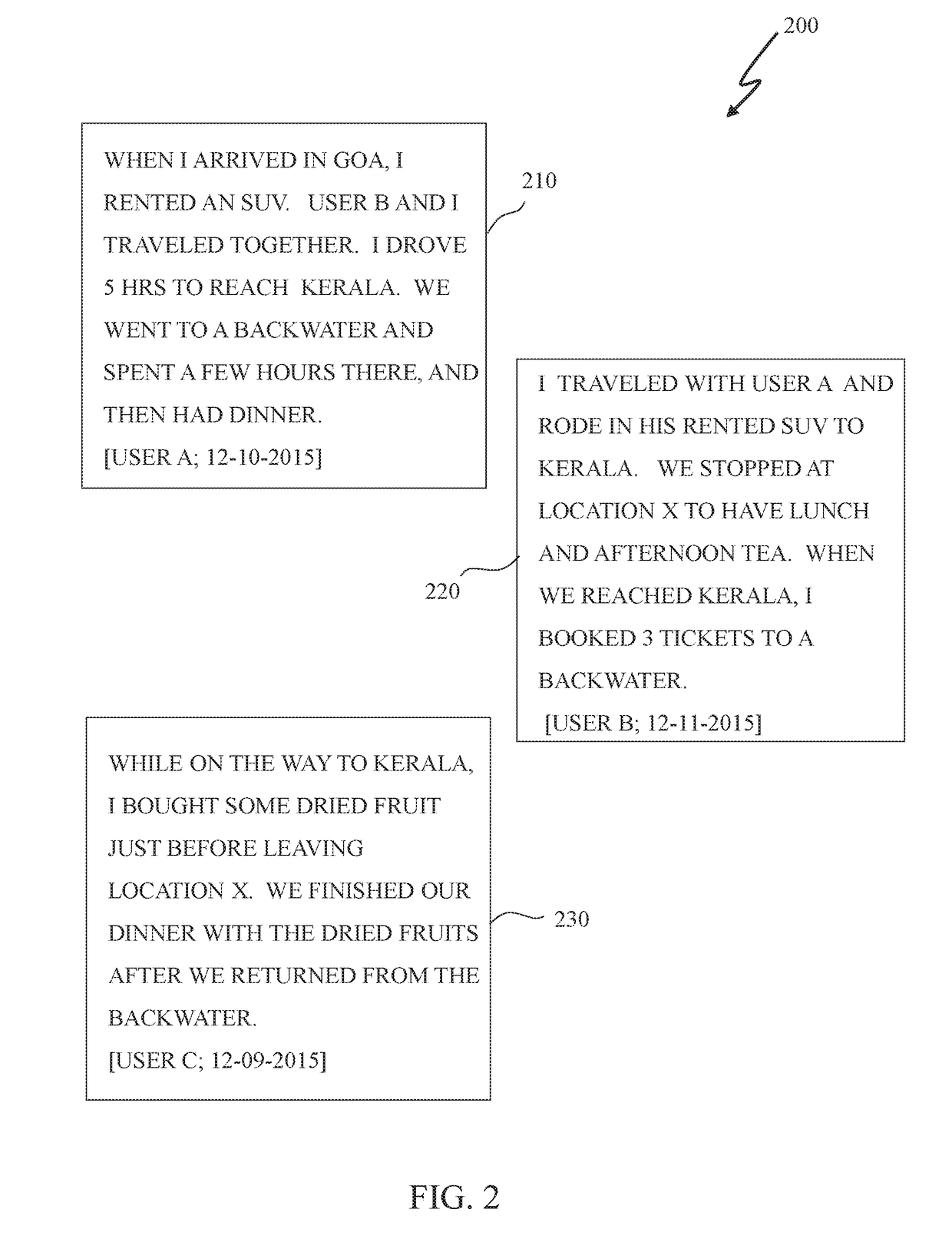

Determining user influence by contextual relationship of isolated and non-isolated content

One or more processor to receives content over distributed network media sources and isolated content, authored by one or more users of the plurality of users, in which the content and isolated content are directed to a plurality of topics. The content and isolated content are parsed into content segments and aggregated based on topics to which the content segments are directed, and users authoring the content segments are identified, the aggregated content segments forming at least part of a discussion thread. One or more processors determine a probability that the discussion thread is complete, based on a set of user behavioral pattern metrics generated by analysis of historical content, and one or more processors, in response to the discussion thread being substantially complete and exceeding a probability threshold, determines the discussion thread, including the content and the isolated content to be ready for a contextual relationship analysis.

Owner:IBM CORP

Self-made low-defect ultra-high-strength lightweight aggregate, preparation method and uses thereof

The invention relates to the technical field of building materials, particularly to a self-made low-defect ultra-high-strength lightweight aggregate, which is prepared from the following raw materialsby weight: 700-770 parts of cement, 90-110 parts of fly ash, 210-230 of silica fume, 90-135 parts of hollow glass micro-beads, 4-8 parts of polyvinyl alcohol fiber, 360-520 parts of quartz sand, 1.8-2.2 parts of an active activator, 28-35 parts of a water reducing agent, 0.06-0.08 part of an antifoaming agent, and 135-155 parts of water. According to the present invention, the self-made low-defect ultra-high-strength lightweight aggregate based on the technical scheme has obvious advantages in the preparation of lightweight high-strength concrete, breaks through the strength problem of lightweight concrete represented by ceramsite concrete and solves the problem of poor coordination between aggregate and matrix in concrete, and further has advantages of good feasibility and broad application prospect.

Owner:CHONGQING CONSTR ENG NEW BUILDING MATERIALS +1

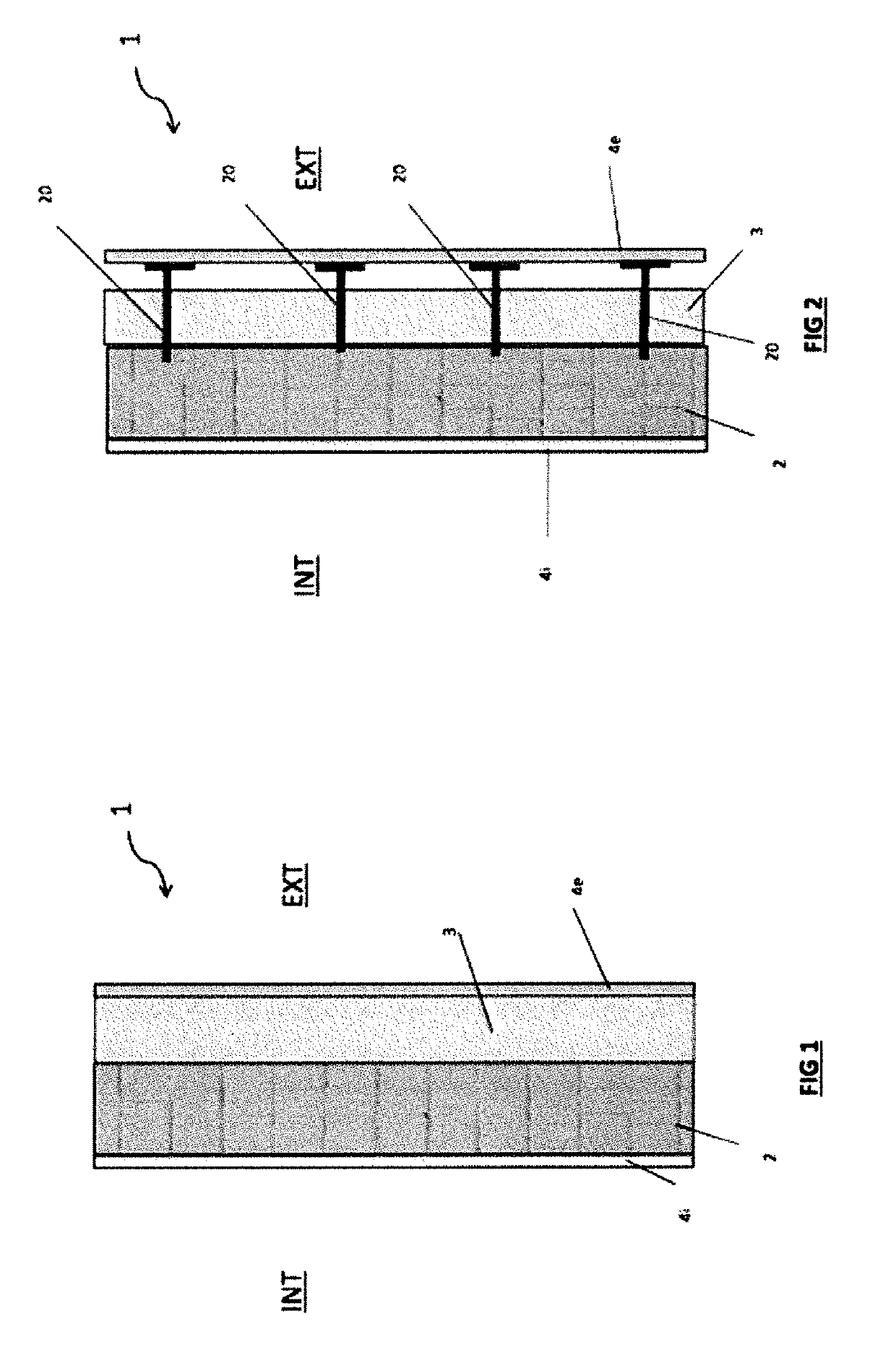

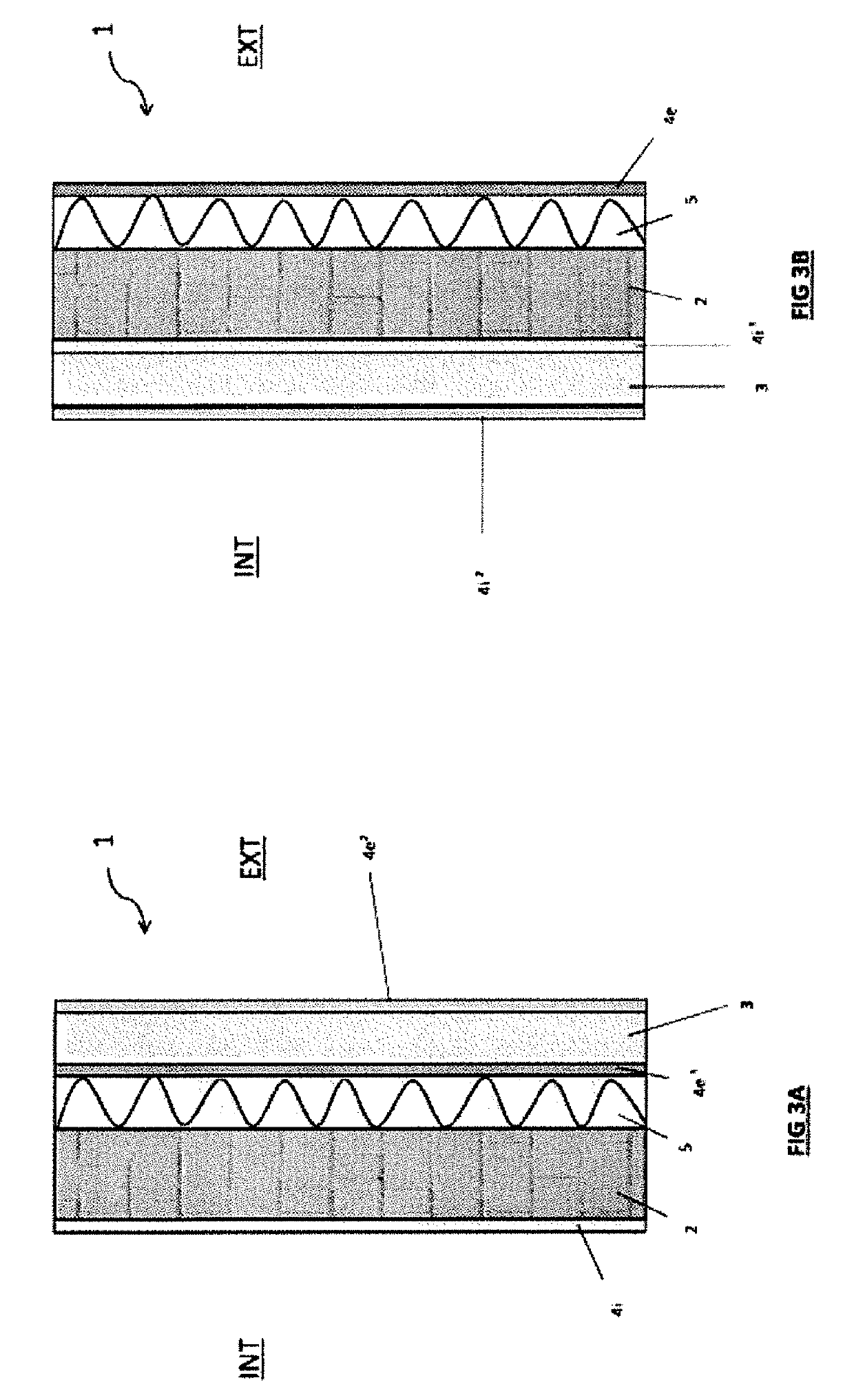

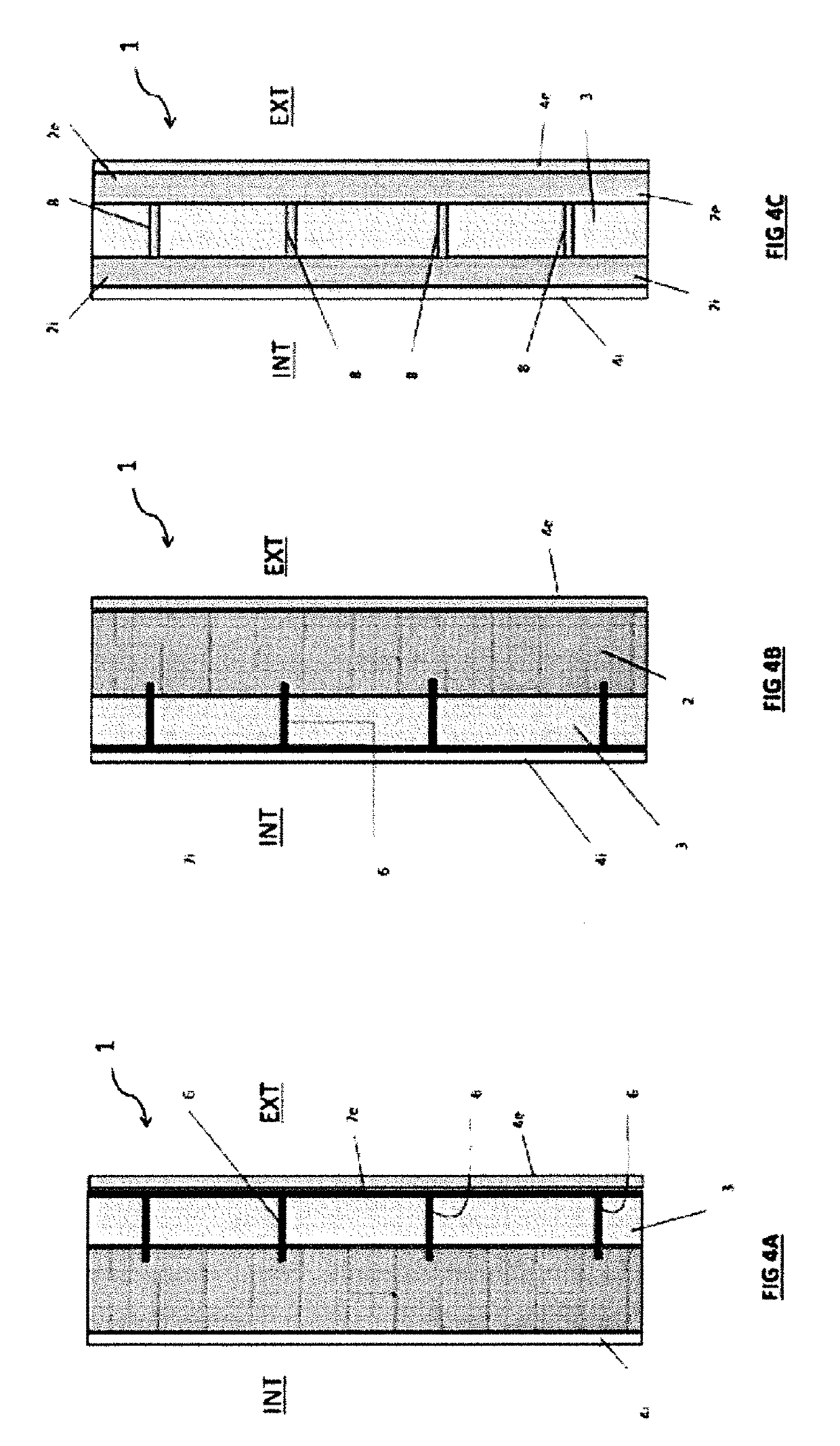

Multilayer insulating construction system for a building - method for its manufacture - dry composition for use in such manufacture

The aim of the invention is to provide a novel construction system for buildings, having the properties of being multilayer, insulating, ductile, and lightweight.To this end, the invention relates to a multilayer insulating construction system for a building, characterized in that(a) this system comprises at least one wall associated with at least one hardened insulation layer,(b) the maximum thickness of the hardened insulation layer is between 1 and 60 cm,(c) the hardened insulation has a bulk density (BD) in kg / m3 that is less than or equal to 450; 300; 250; 200; 150; 100; and more preferably between 50 and 300; 150 and 250;(d) this hardened insulation layer is prepared by mixing, with water, a dry composition (d) comprising:-A at least one binder including:-A1- at least one hydraulic or air binder;-A2- possibly at least one water retention agent-A3- possibly at least one surfactant;-B- at least one bio-sourced aggregate based on sunflower stalk and / or corn stalk and / or rape stalk, having a Bulk Density(BD) in kg / m3 that is less than 110; preferably between 10 and 80;(e) this composition having a ratio of A / B [mass of dry binder -A- in kg] / [mass of dry filler -B- in kg] comprised between 1 and 10.Another object of the invention is the dry composition which, after mixing with water, enables manufacturing the hardened insulation layer of this construction system. The invention also includes the method for manufacturing the construction system.

Owner:PAREXGROUP SA

System and method for analyzing a database for on-line reorganization

InactiveUS6633884B2Data processing applicationsDigital data information retrievalArray data structureAnalysis data

An improved method and system for analyzing a database for determining a recommended reorganization of a database. In one embodiment, the method involves receiving a list of database records to be analyzed. Each analyzed database record which meets certain criteria may be designated as "qualified". Identifying information for each qualified database record may be added to a detail array. The qualified database record information may be aggregated based on information in the detail array. The process of aggregating the qualified database record information may include constructing additional arrays (e.g., a roll-up array and a results tracking array). A reorganization strategy may be recommended based on the aggregated qualified database record information. The recommended reorganization strategy may be for an amount (e.g., none, full, partial) of reorganization of the database and a method (e.g., off-line, concurrent, on-line) of reorganization of the database. The recommended reorganization strategy may be implemented.< / PTEXT>

Owner:BMC SOFTWARE

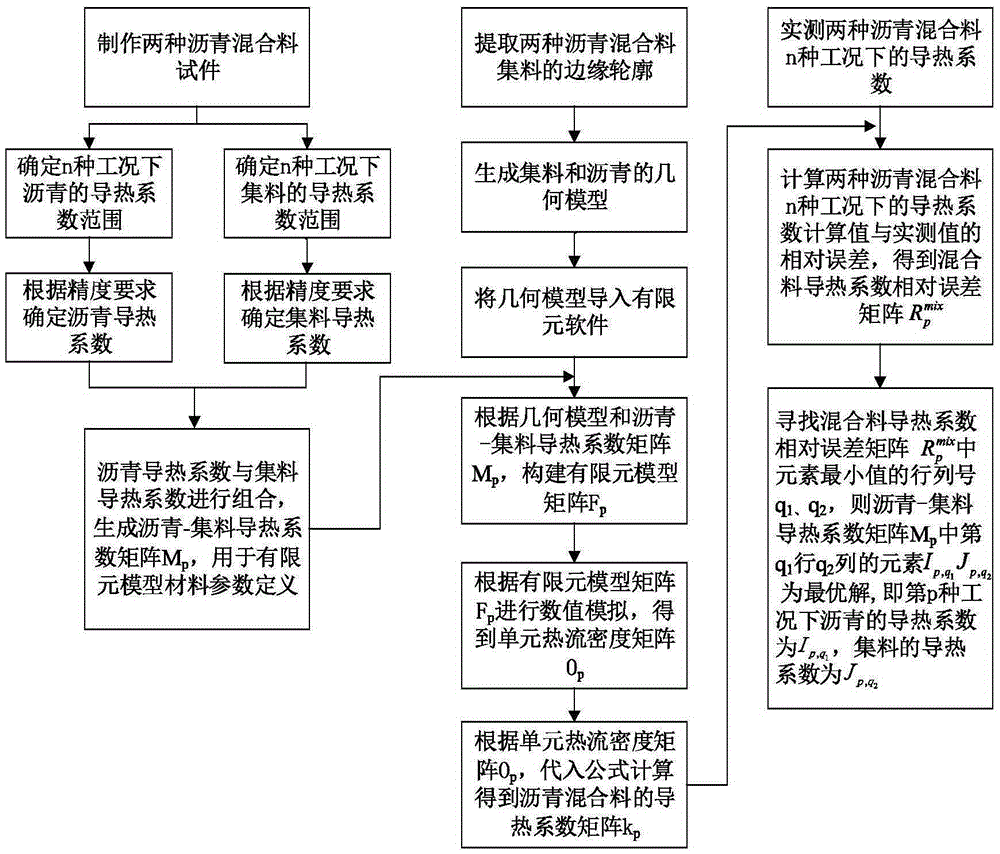

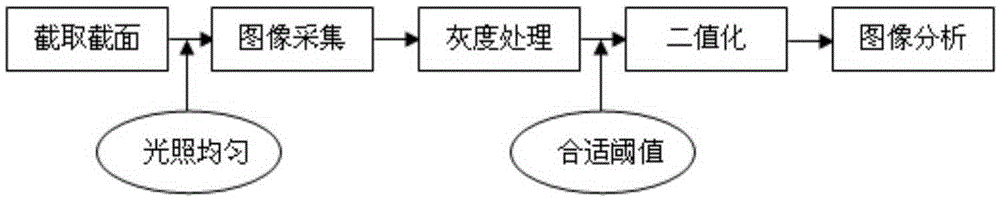

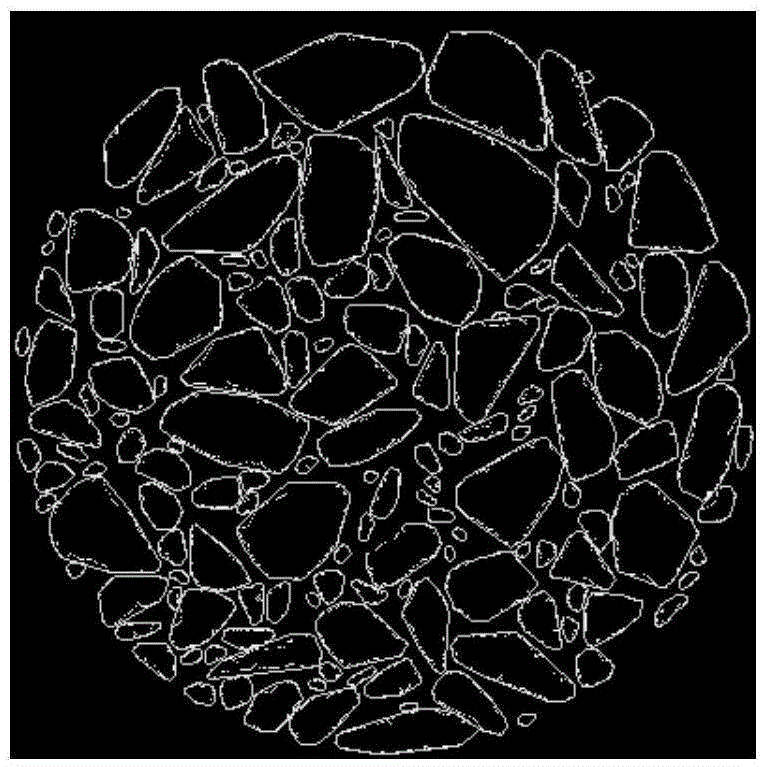

Retrieval method for heat conductivity coefficients of asphalt and aggregates based on mixture microstructure characteristics

ActiveCN105203593AHigh precisionMeet the measurement accuracy requirementsMaterial heat developmentFinite element methodRoad surface

The invention relates to the field related to the asphalt pavement material test and especially relates to a method for measuring the heat conductivity coefficients of asphalt and aggregates. According to the method, under the known working condition and the forming condition of the asphalt mixture, the heat conductivity coefficients of the asphalt and aggregates in the asphalt mixture under the working condition can be acquired. The method comprises the following steps: firstly, preparing two asphalt mixture test pieces which are same in component and different in asphalt dosage and gradation, and meanwhile, setting an asphalt and aggregate heat conductivity coefficient matrix Mp under different working conditions according to the demand on test precision; calculating the heat conductivity coefficient matrixes of the two mixtures under different working conditions by the geometric models of the two mixtures through a finite element method; lastly, inverting the heat conductivity coefficients of asphalt and aggregates under different working conditions by utilizing an error between a calculated value and a practically measured value of the heat conductivity coefficients of the mixtures.

Owner:SOUTHEAST UNIV

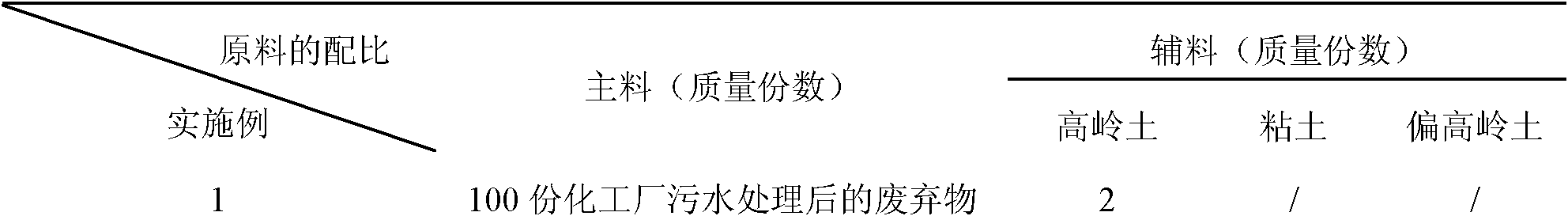

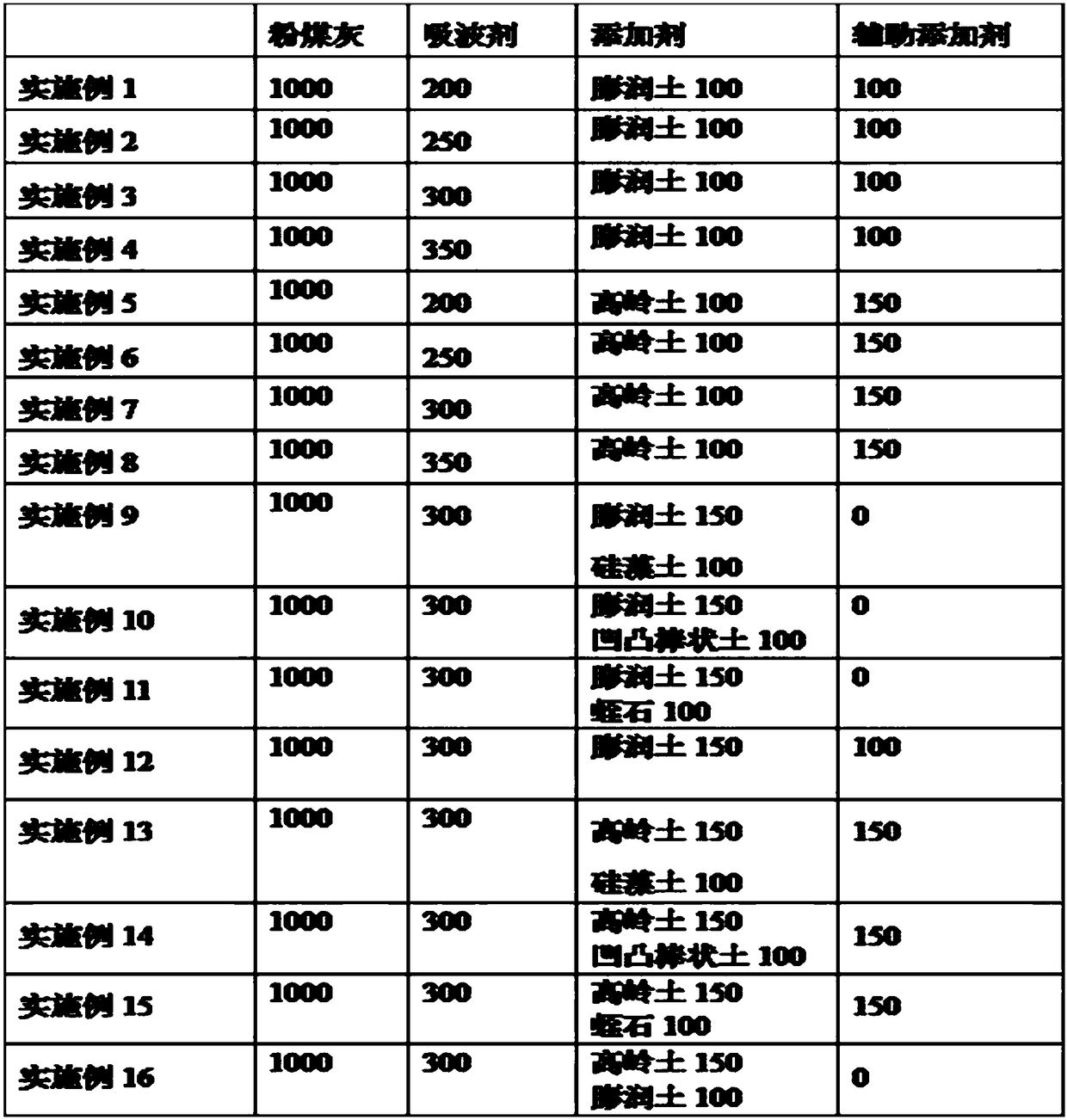

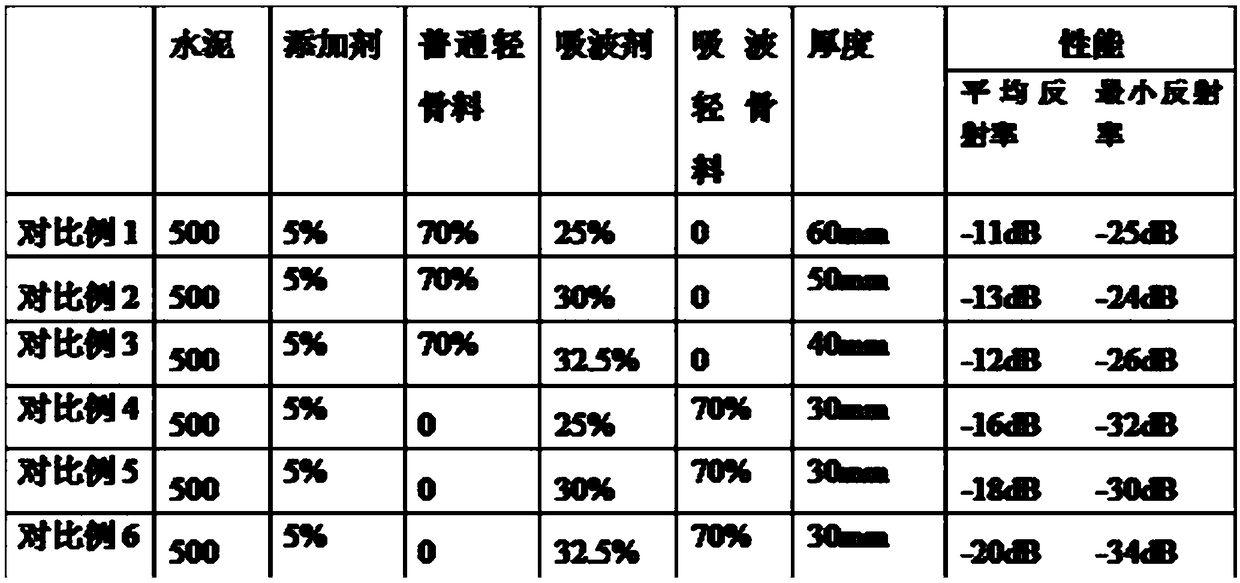

Artificial lightweight aggregate based on ferrite wave-absorbing composite material and preparation method thereof

ActiveCN108793965AImprove performanceImprove absorption rateCeramic materials productionClaywaresSodium BentoniteFerrite powder

The invention provides an artificial lightweight aggregate based on a ferrite wave-absorbing composite material and a preparation method thereof. The artificial lightweight aggregate is prepared fromthe raw materials in parts by weight: 1,000 parts of flyash with particle size of 20-100 microns, 200-350 parts of wave absorbing agent and 100-300 parts of additives, wherein the wave absorbing agentis ferrite powder with average particle size of 0.4-100 microns; the additives are selected from one or more of kieselguhr, attapulgite, kaolin, bentonite and vermiculite. The invention aims to improve the electromagnetic wave radiation absorption performance of aggregate products as important components of building concrete and appears in the wave absorption performance of the aggregates for thefirst time.

Owner:TSINGHUA INNOVATION CENT IN DONGGUAN +1

Freeze-thaw stability testing method for bearing capacity of aggregate base

InactiveCN101576461AAccurate and reliable measurement resultsSimple methodPreparing sample for investigationInvestigating material hardnessFreezing thawingEngineering

The invention discloses a freeze-thaw stability testing method for bearing capacity of an aggregate base layer, which detects the variation value of the modulus of resilience of test pieces with the same specifications under various grades of load respectively under the situations of non freezing and a plurality of times of freezing circulation. The freeze-thaw stability testing method for bearing capacity of aggregate base layer has the beneficial technical effect of disclosing a method capable of effectively detecting the variation value of the modulus of resilience of the aggregate base layer, which provides reliable basis for estimating the subsequent freeze-thaw stability of the aggregate base. The method is simple and easy to operate, has reliable measuring result, and has broad applicable range.

Owner:CHONGQING JIAOTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com