Method Of Removing Solids From Bitumen Froth

a bitumen froth and solid removal technology, applied in the petroleum industry, liquid hydrocarbon mixture production, etc., can solve the problems of inability to achieve real-time monitoring and control of the settling process in paraffinic froth treatment, time and labor-intensive procedures, and inability to lend themselves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

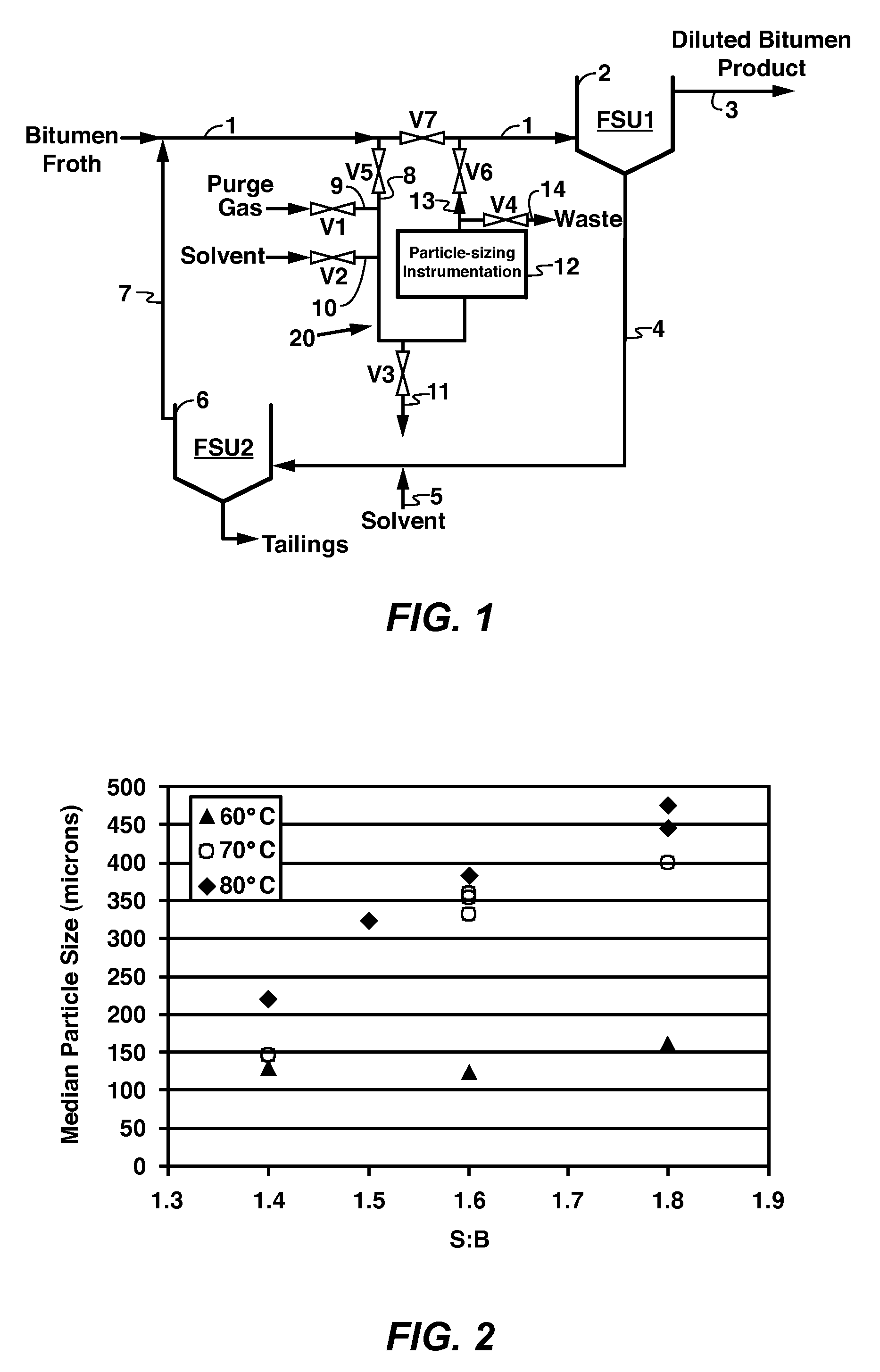

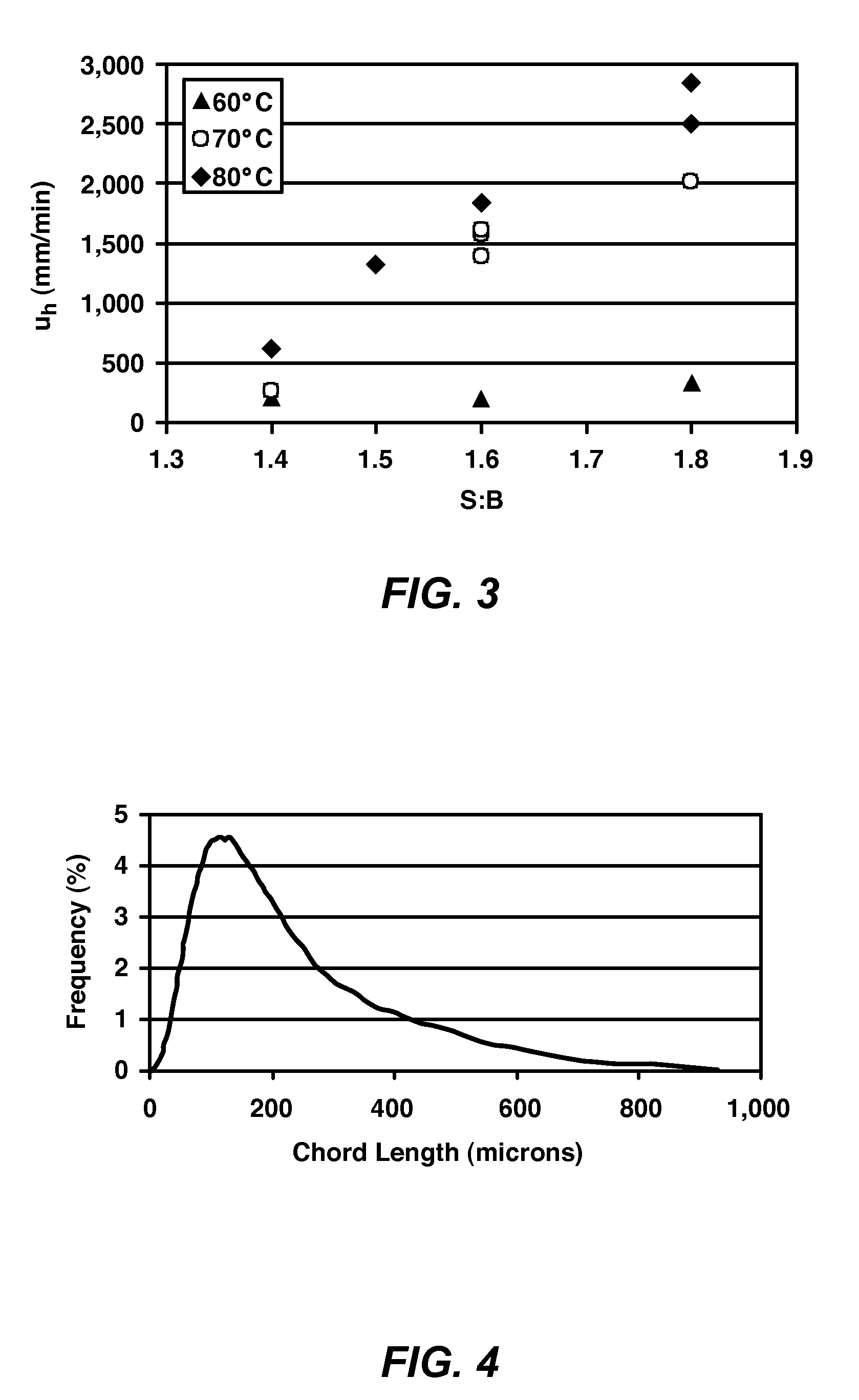

[0051]This example 1 demonstrates variation in median particle size and hindered settling rate with changes in the solvent-to-bitumen ratio (hereinafter “S:B”) or temperature.

[0052]A parametric study was conducted in a 15 barrel per day (bitumen froth feed) pilot plant. Commercial bitumen froth obtained from Syncrude Canada Ltd. (nominally 60 wt % bitumen, 30 wt % water, 10 wt % mineral solids) was fed to a paraffinic froth treatment (“PFT”) process using a 60 / 40 vol % blend of iso / normal pentane as the paraffinic solvent.

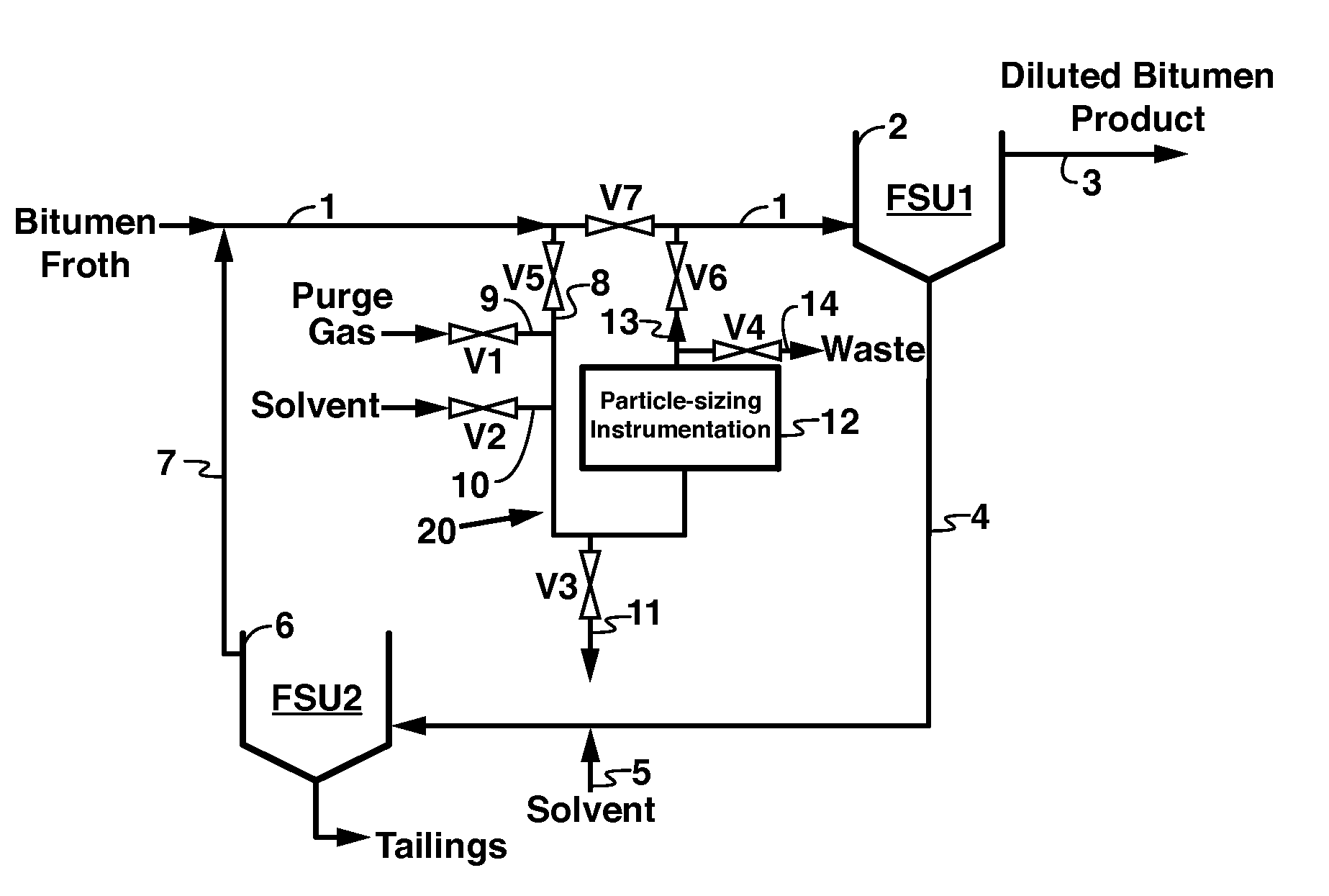

[0053]PSI 12 (Lasentec FBRM by Mettler-Toledo) was placed in the feed piping to the first froth settling unit (FSU1) 2 as indicated in FIG. 1. This location is downstream of the point where solvent in stream 7 is introduced into the bitumen froth feed 1 but upstream of the FSU12. A dichlorodimethylsilane coating had been applied to the probe's window (using the process described in paragraph [0030] prior to insertion into the process piping to reduce the propensity...

example 2

[0058]This Example demonstrates the characteristic PSD associated with a fouled or obscured optical window.

[0059]A parametric study was conducted as in Example 1 including PSI placement, probe window coating and start-up procedure.

[0060]When the process fluid was first introduced past a clean PSI, PSDs similar to that shown in FIG. 4 were observed. In this case 3,736 chords / second were recorded by the probe. However, after 140 min of operation, a PSD like that shown in FIG. 5 was observed. The high particle count, 15,831 chords / s, and noisy distribution are indicative of a fouled probe. The probe was removed from the instrumentation loop and examined. A thick, sticky, black film was observed, confirming that the probe surface was obscured.

example 3

[0061]This Example demonstrates the effectiveness of the described cleaning process.

[0062]In this test, the PSI (Lasentec FBRM by Mettler-Toledo) was placed in the feed piping 1 to the first-stage settling vessel (FSU1) 2 as indicated in FIG. 1. As before, this location is downstream of the point where solvent in stream 7 is introduced into the bitumen froth feed but upstream of the FSU12. A dichlorodimethylsilane coating had been applied to the probe's window as for Example 1 prior to insertion into the process piping to reduce the propensity for fouling. Initial baseline readings of the PSI indicated less than 100 counts. Process fluid was introduced into the PSI piping using the preferred start-up procedure described above for Example 1.

[0063]CLD's similar to that shown in FIG. 6 were observed for the first approximately 90 minutes of operation (curve 20). After 90 minutes, however, a CLD characteristic of a fouled probe was observed (curve 21). At 99 minutes, the following clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| vol. % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com