Artificial lightweight aggregate based on ferrite wave-absorbing composite material and preparation method thereof

A composite material and ferrite technology, applied in the field of building materials, can solve the problems of increased construction cost, difficulty in obtaining wave absorbing properties, and difficulty in realizing wave absorbing materials, and achieves the effect of high absorption rate and harm reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

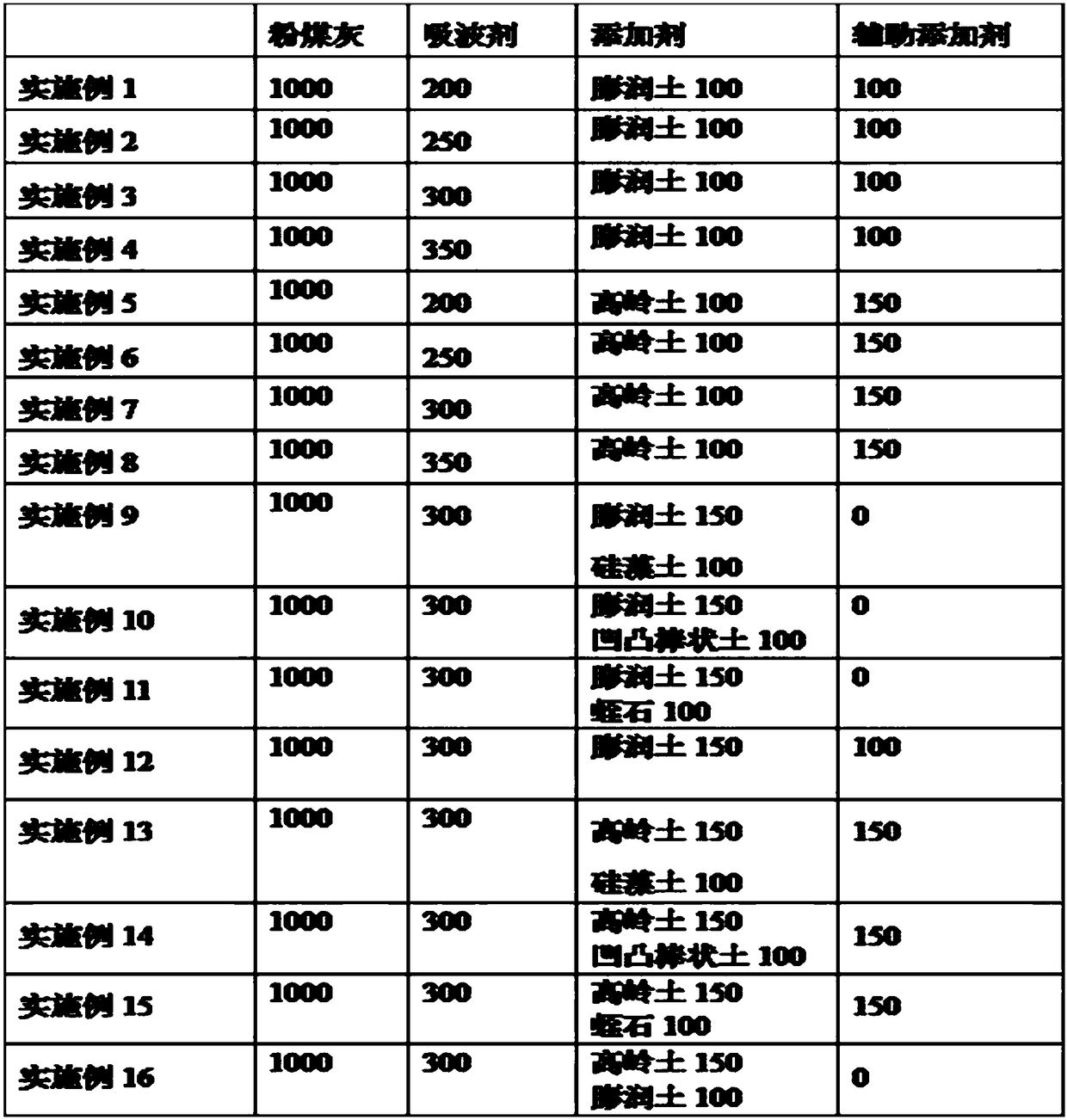

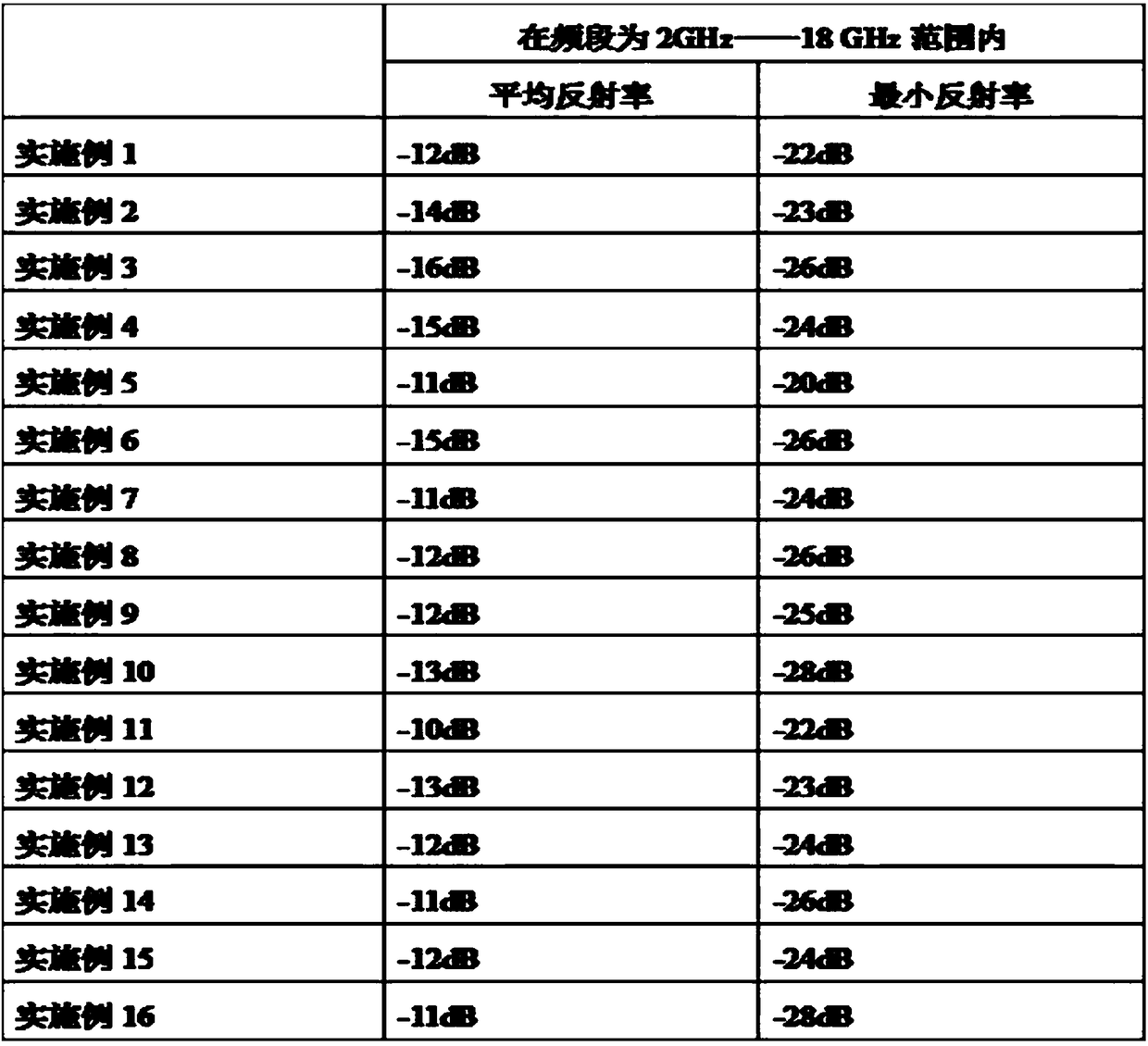

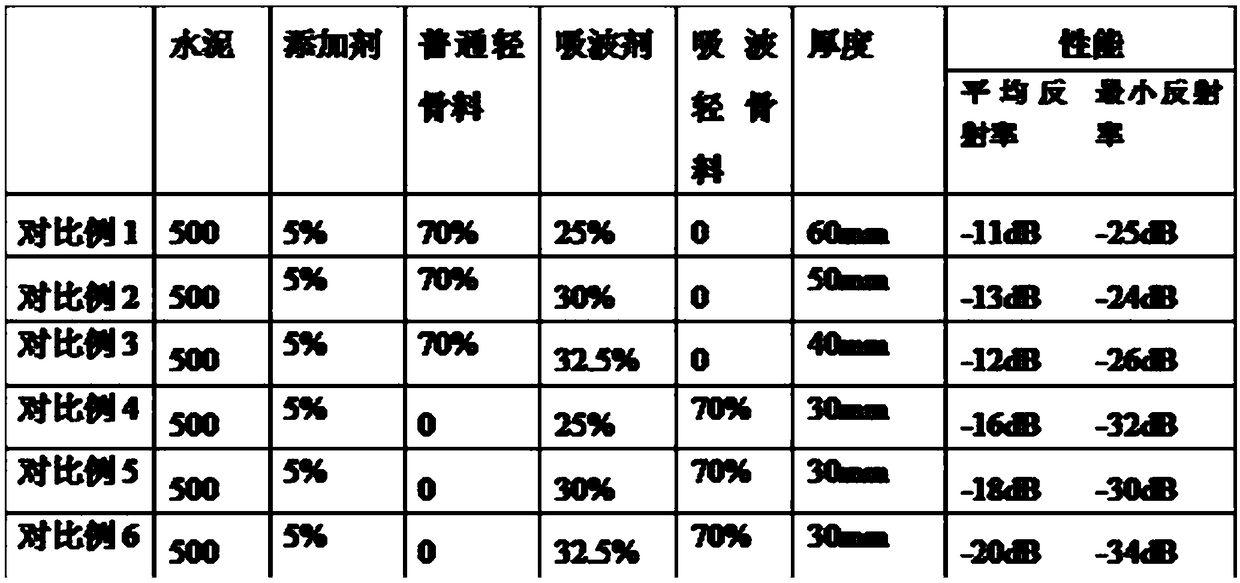

Examples

Embodiment 1

[0024] Solid raw materials: fly ash 1000g, wave absorbing agent 200g, bentonite 100g;

[0025] Liquid auxiliary additives: sodium hydroxide 20g, water glass 80g, water 250g, add sodium hydroxide to water glass, dissolve, stir evenly, wait until the temperature drops to room temperature, it is an alkali activator;

[0026] First, weigh the solid raw material according to the above ratio, stir it in a high-speed mixer for 15-30 minutes, then put the uniformly mixed powder raw material into the disc granulator, and granulate it through the rotating disc at a speed of 30-40r / min. Add liquid auxiliary additives during the granulation process, spray granulate into spherical particles with a particle size of 5-15mm, then maintain at a temperature of 70°C and a humidity of ≥90% for 24 hours, and dry at 120°C for 2 hours to obtain green pellets ;

[0027] Then put the green balls into a high-temperature furnace or a rotary kiln to sinter at a heating rate of 2°C / min to 1100°C for 2 ho...

Embodiment 2

[0029] Solid raw materials: fly ash 1000g, wave absorbing agent 250g, bentonite 100g;

[0030] Liquid auxiliary additive: take by weighing 10g of sodium carbonate, 40g of water glass, and 250g of water, add sodium carbonate in the water glass, dissolve, stir evenly, and wait for the temperature to drop to room temperature to be an alkali activator;

[0031] First, weigh the solid raw material according to the above ratio, stir it in a high-speed mixer for 15-30 minutes, then put the uniformly mixed powder raw material into the disc granulator, and granulate it through the rotating disc at a speed of 30-40r / min. Add liquid auxiliary additives during the granulation process, spray granulate into spherical particles with a particle size of 5-15mm, then maintain at a temperature of 70°C and a humidity of ≥90% for 24 hours, and dry at 150°C for 2 hours to obtain green pellets ;

[0032] Put the green billet into a high-temperature furnace or a rotary kiln at a heating rate of 2°C / ...

Embodiment 3

[0034] Solid raw materials: fly ash 1000g, wave absorbing agent 300g, bentonite 100g,

[0035] Liquid auxiliary additive: take 20g of potassium hydroxide, 80g of water glass, and 250g of water, add potassium hydroxide to the water glass, dissolve, stir evenly, and wait for the temperature to drop to room temperature to be an alkali activator;

[0036] First, weigh the solid raw material according to the above ratio, stir it in a high-speed mixer for 15-30 minutes, then put the uniformly mixed powder raw material into the disc granulator, and granulate it through the rotating disc at a speed of 30-40r / min. Add liquid auxiliary additives during the granulation process, spray granulate into spherical particles with a particle size of 5-25mm, then maintain at a temperature of 70°C and a humidity of ≥90% for 24 hours, and dry at 100°C for 5 hours to obtain green pellets ;

[0037] Put the green balls into a high-temperature furnace or a rotary kiln and sinter at a heating rate of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com