Polypropylene fiber lime-fly ash aggregate base material and preparation method thereof

A technology of polypropylene fiber and fly ash gravel, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem that the drying shrinkage slowing effect is not obvious, and achieve excellent road performance, water The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] 1. Preparation of materials:

[0034] Weigh 100kg of lime and fly ash (28.6kg of lime and 71.4kg of fly ash), 471.4kg of aggregate, 45.8kg of water, and 0.1-0.15kg of polypropylene fiber.

[0035] And divide the polypropylene fiber into 5 equal parts.

[0036] 2. Preparation method steps:

[0037] First, the polypropylene fibers are pre-dispersed in lime and fly ash in 5 batches, and mechanically stirred every time they are added.

[0038] Then the mixture of fly ash (lime and fly ash) and fiber is mixed with aggregate and water by ordinary machinery to prepare the fly ash crushed stone base material mixed with polypropylene fiber.

[0039] 3. Application:

[0040] The prepared fly ash crushed stone base material mixed with polypropylene fiber is supplemented on the base and maintained under standard conditions.

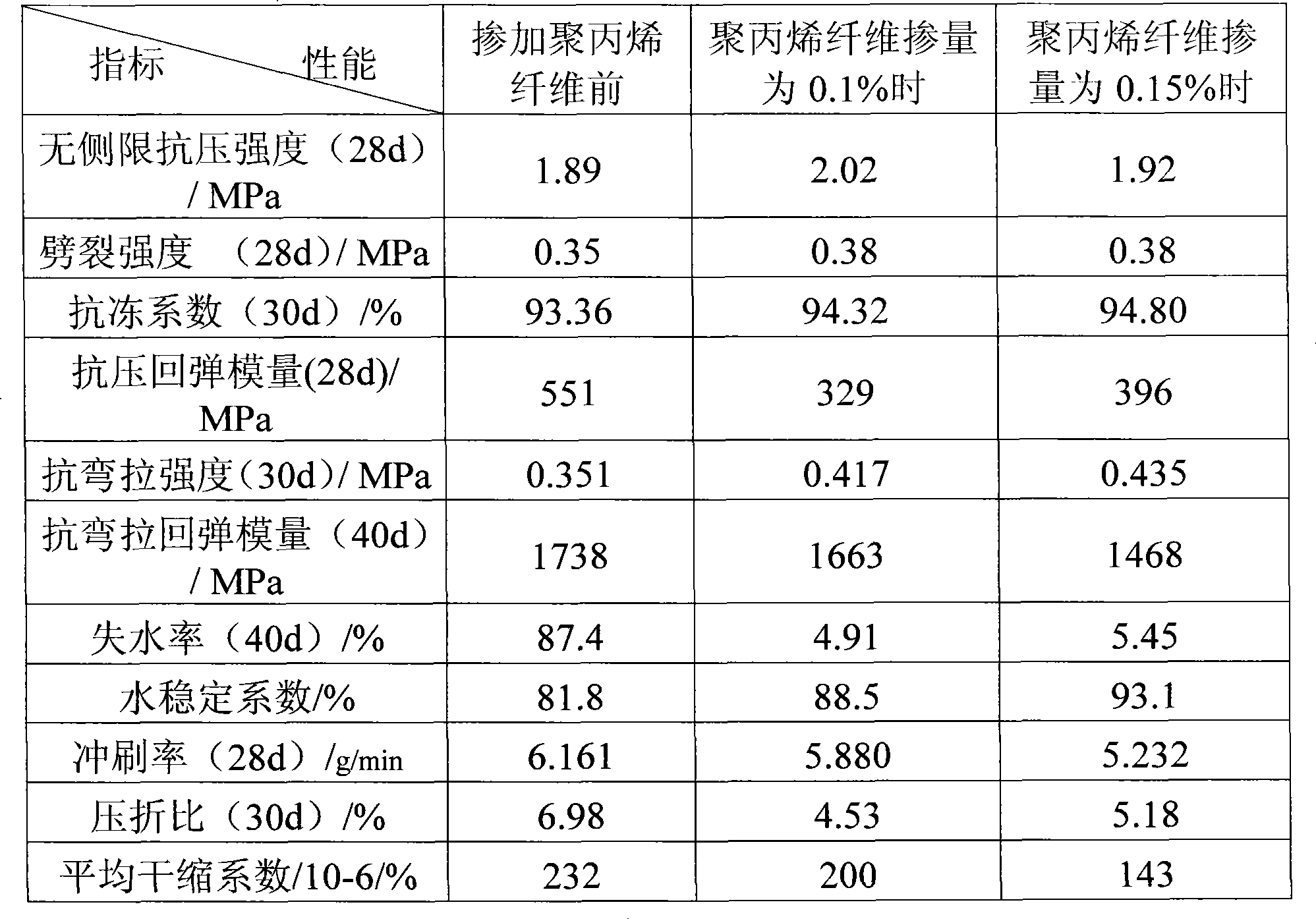

[0041] 4. Detection index and effect:

[0042]

[0043] Through analysis and arrangement, the effect after adding polypropylene fiber is summarized as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com