Patents

Literature

41results about How to "Slow motion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

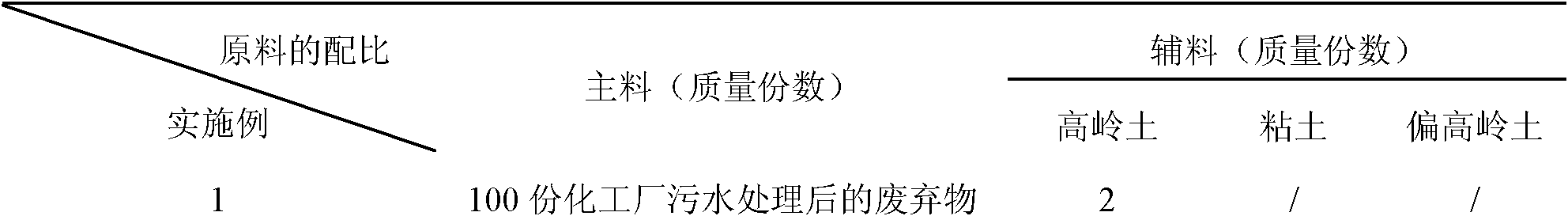

Anti-radiation concrete produced from slag aggregate, and production method thereof

InactiveCN103224369ATotal momentum downReduce the degree of stratificationSolid waste managementSlagTackifier

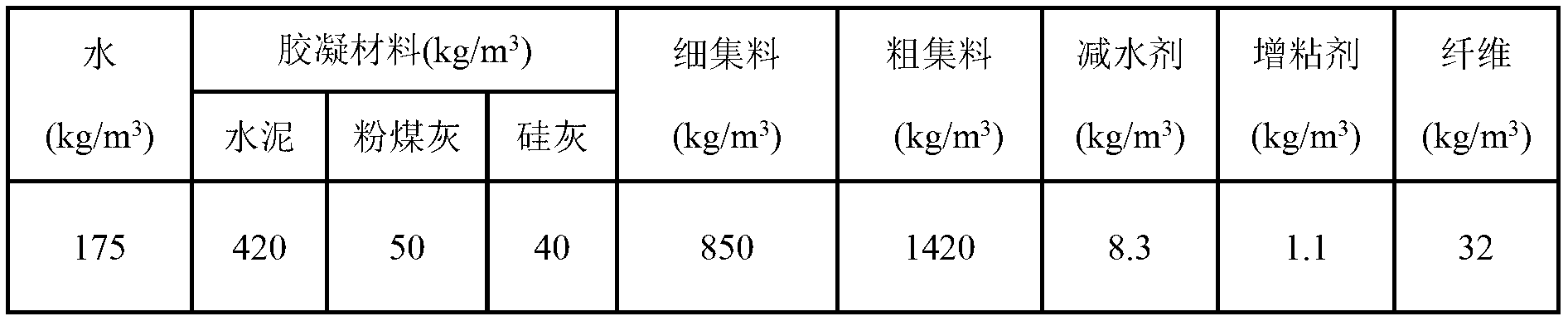

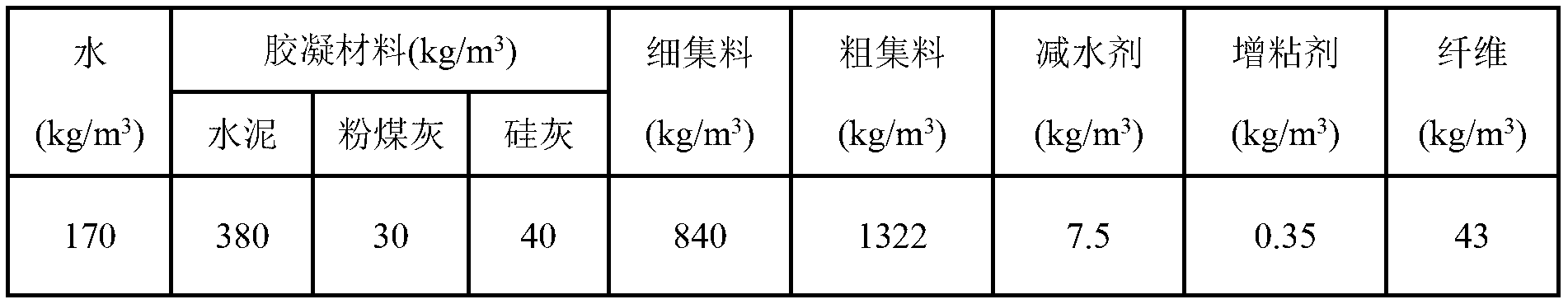

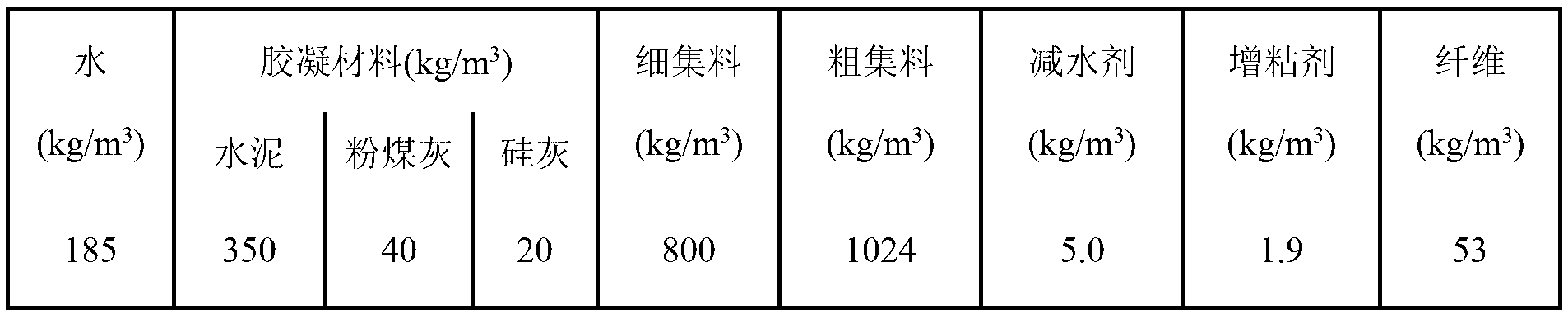

The invention relates to anti-radiation concrete produced from slag aggregate, and a production method thereof so as to effectively consume and utilize mineral waste, and improve an anti-radiation performance and durability of concrete. The anti-radiation concrete produced from slag aggregate comprises the following raw materials, by weight, 140-190 parts of water, 350-630 parts of a cementing material, 750-850 parts of a fine aggregate, 1000-1500 parts of a coarse aggregate, 0.35-1.9 parts of a tackifier, 2.1-7.5 parts of a water reducing agent, and 30-70 parts of fibers, wherein the cementing material comprises cement and a mineral admixture, the mineral admixture comprises silicon ash and fly ash, the cementing material comprises 300-500 parts by weight of the cement, 20-60 parts by weight of the silicon ash and 30-70 parts by weight of the fly ash, the coarse aggregate is a high titanium heavy slag coarse aggregate, the fine aggregate comprises high titanium heavy slag sand and lead powder according to a mass ratio of 1:0.2-3.0, the tackifier is methyl cellulose ether, and the fibers are one or a plurality of material selected from polypropylene fibers, steel fibers and lead fibers.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

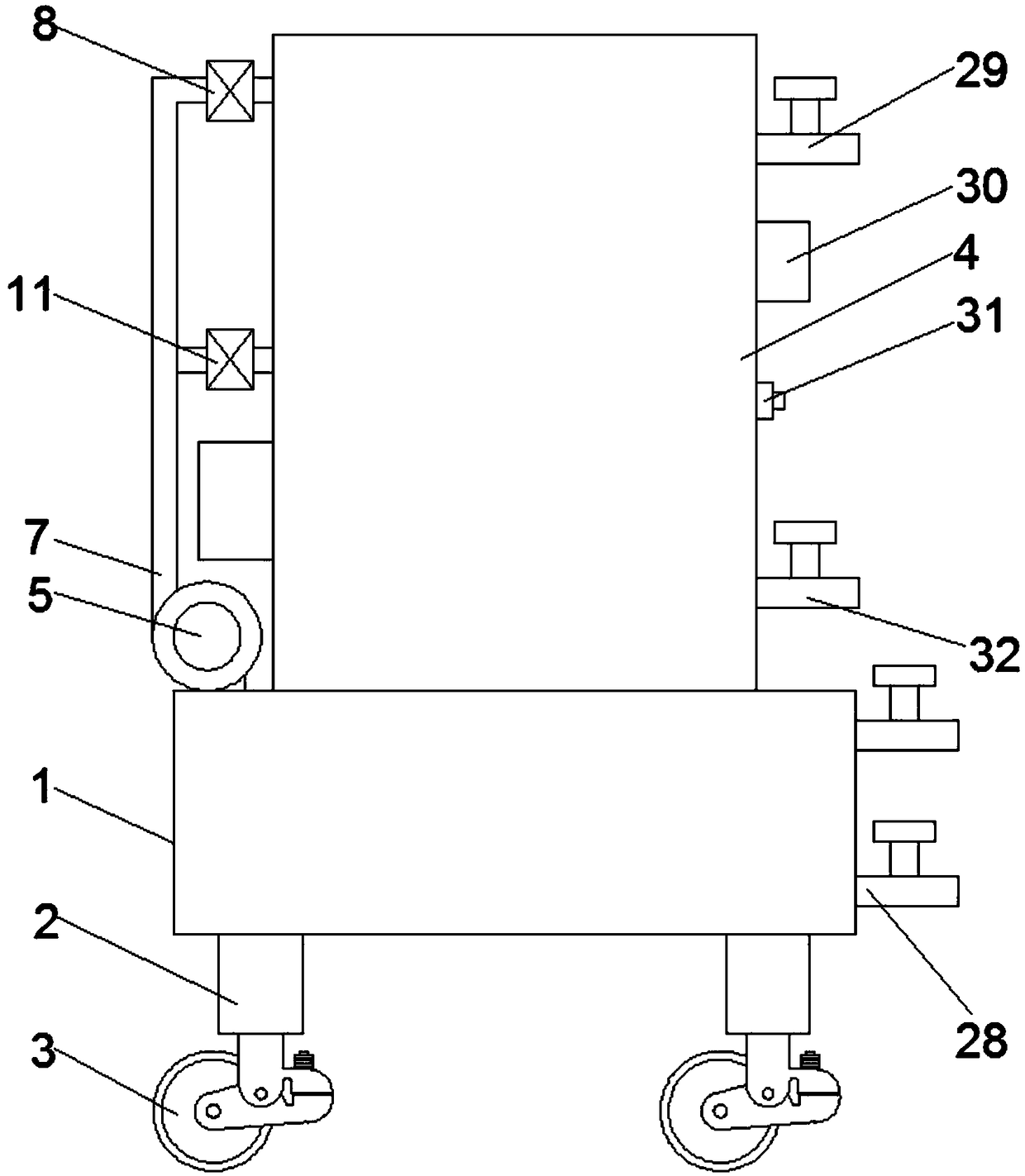

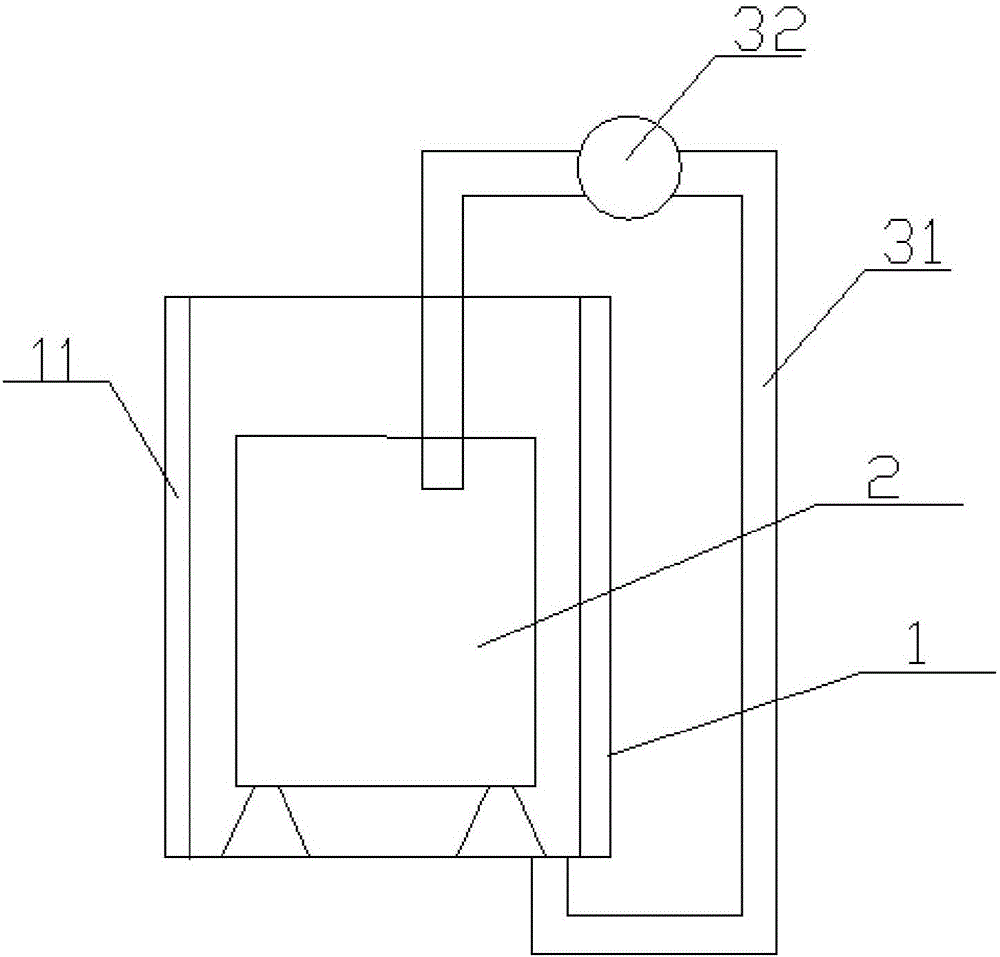

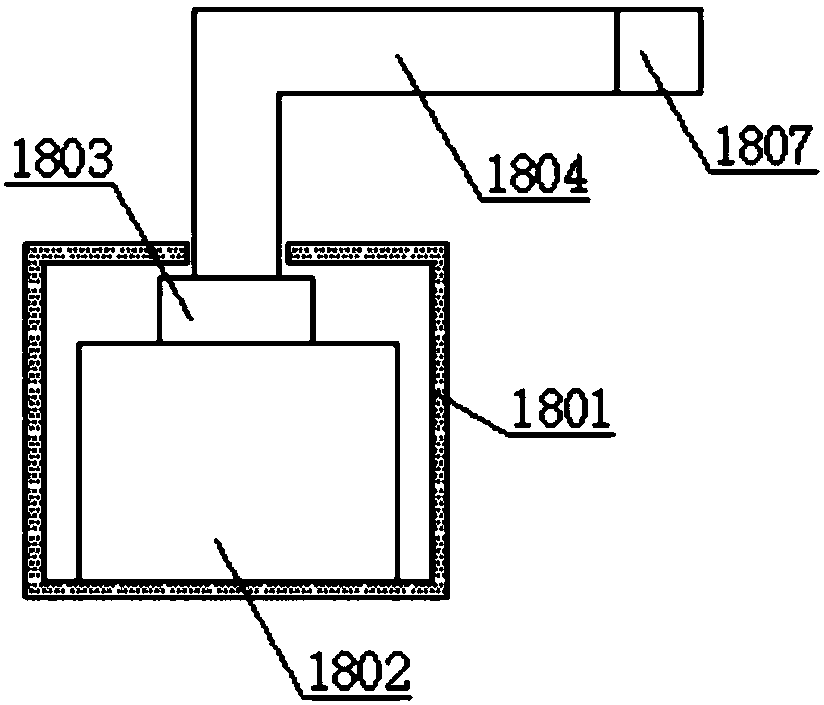

Wet type electrostatic precipitator and working method thereof

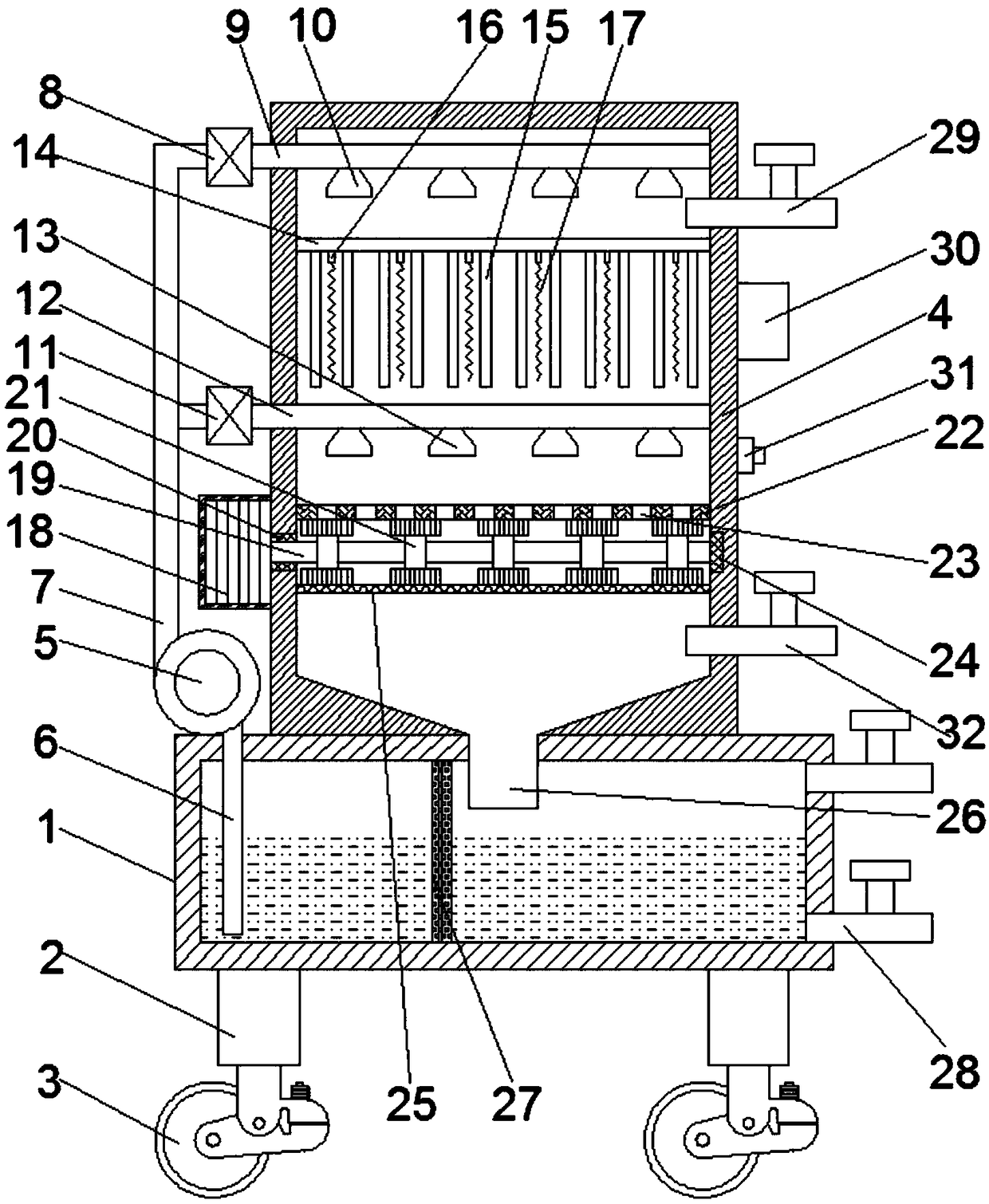

The invention discloses a wet type electrostatic precipitator and a working method thereof. The wet type electrostatic precipitator comprises a water tank, supporting columns, a dust removing box anda water pump. The left and right sides of the lower end of the water tank are symmetrically provided with the supporting columns. The lower end of the supporting column is provided with a damping wheel. The middle of the upper end of the water tank is provided with the dust removing box. The left side of the upper end of the water tank is provided with a water pump. A water inlet of the water pumpis communicated with the water tank through a water drawing pipe. A water outlet of the water pump is connected to a conduit. The wet type electrostatic precipitator has a reasonable structural design. A flow dividing plate reduces the gas movement rate so that the time of contact with an anode dust removing plate is reduced and the effect of dust removal is increased. A nozzle 2 humidifies gas and under the combined action of the nozzle 2 and a filter screen, pretreatment is carried out so that impurities fall off under the gravity and the dust removal efficiency is increased. A motor drivesa rotation shaft to rotate so that a dust removing brush rotates and scrubs the flow dividing plate and the filter screen and thus clogging is prevented and a service life is prolonged. The wet typeelectrostatic precipitator prevents frequent replacement.

Owner:马鞍山科宇环保设备股份有限公司

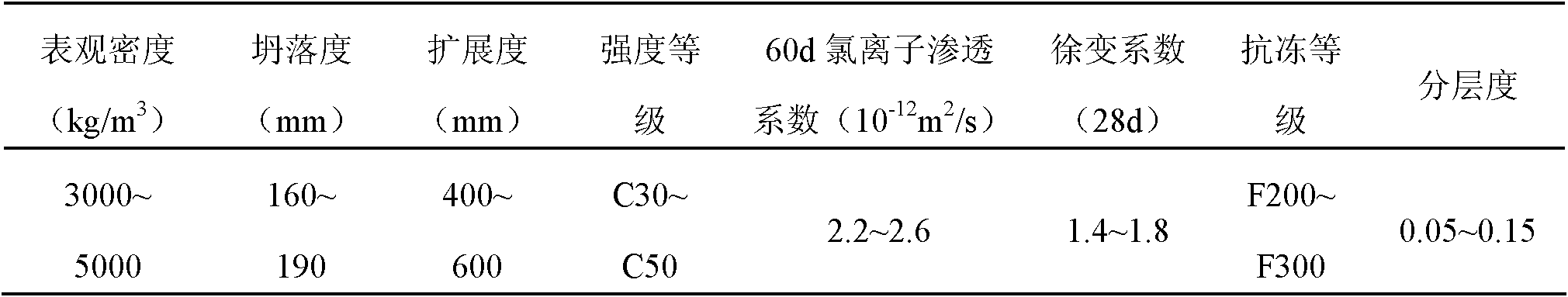

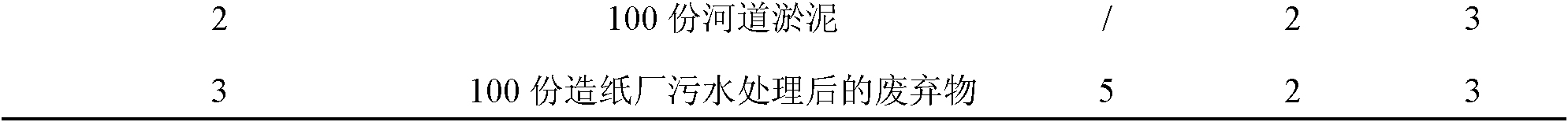

Environmental-friendly functional aggregate-based high-homogeneity radiation-resistant concrete

ActiveCN101921093ATotal momentum downSlow motion rateSolid waste managementResource utilizationSludge

The invention relates to environmental-friendly functional aggregate-based high-homogeneity radiation-resistant concrete. The concrete consists of water, a cementing material, a fine aggregate, a coarse aggregate, a tackifier, a water reducing agent and fibers, wherein the cementing material consists of cement and a mineral admixture; the mineral admixture consists of silica fume and coal ash; the fibers are polypropylene fibers, wherein 1m<3> of concrete comprises the following components: 140 to 160 kg of the water, 300 to 500 kg of the cement, 20 to 60 kg of the silica fume, 30 to 70 kg of the coal ash, 700 too 800 kg of the fine aggregate, 1,000 to 1,300 kg of the coarse aggregate, 0.35 to 1.9 kg of the tackifier, 2.1 to 7.5 kg of the water reducing agent, and 0.6 to 1.0 kg of the polypropylene fibers. The demixing degree of the concrete can be reduced to 0.05; and the concrete has the characteristics of high rheological property, high strength property and durability, and can realize resource utilization of heavy metal-containing urban sludge, mud or industrial waste.

Owner:WUHAN UNIV OF TECH

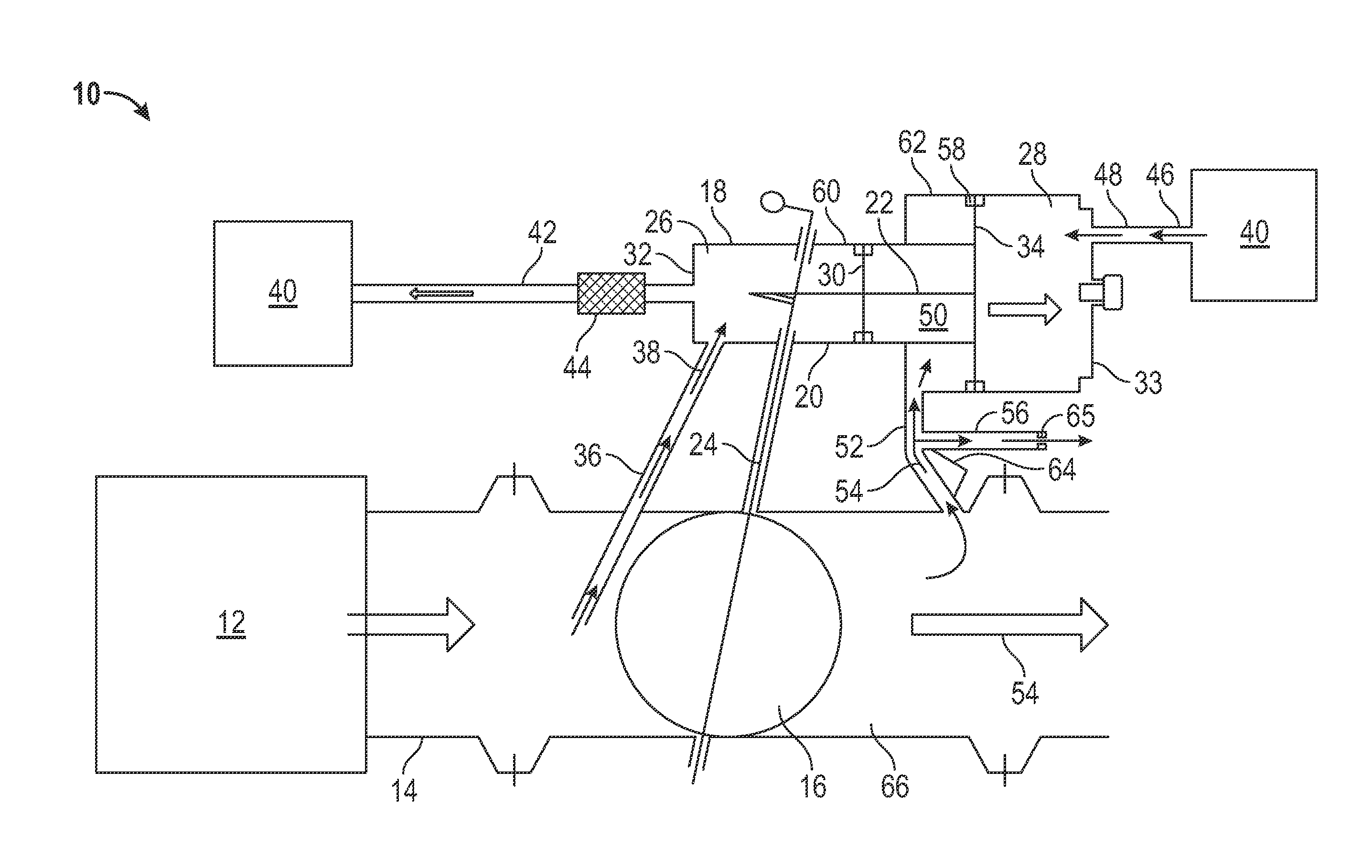

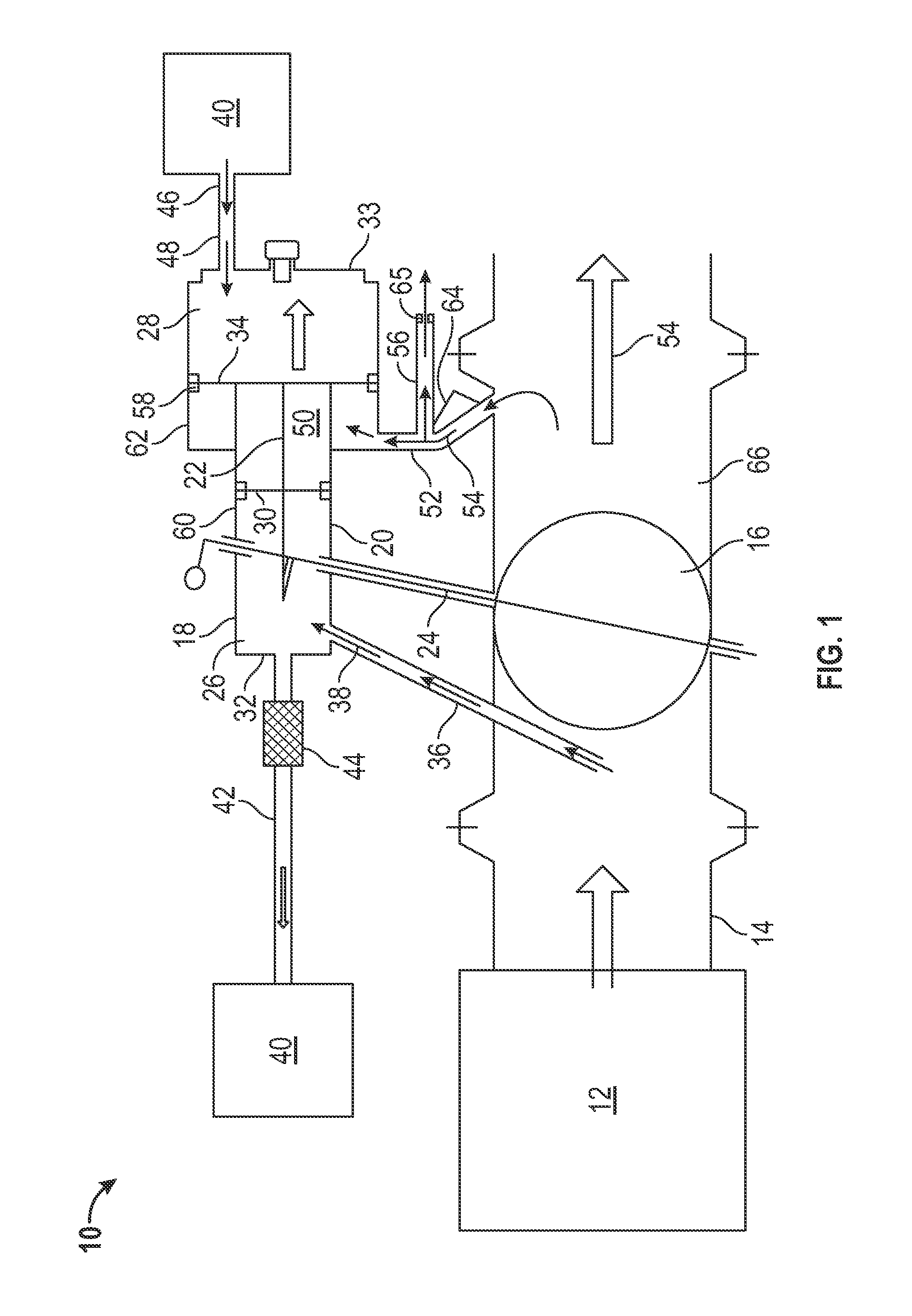

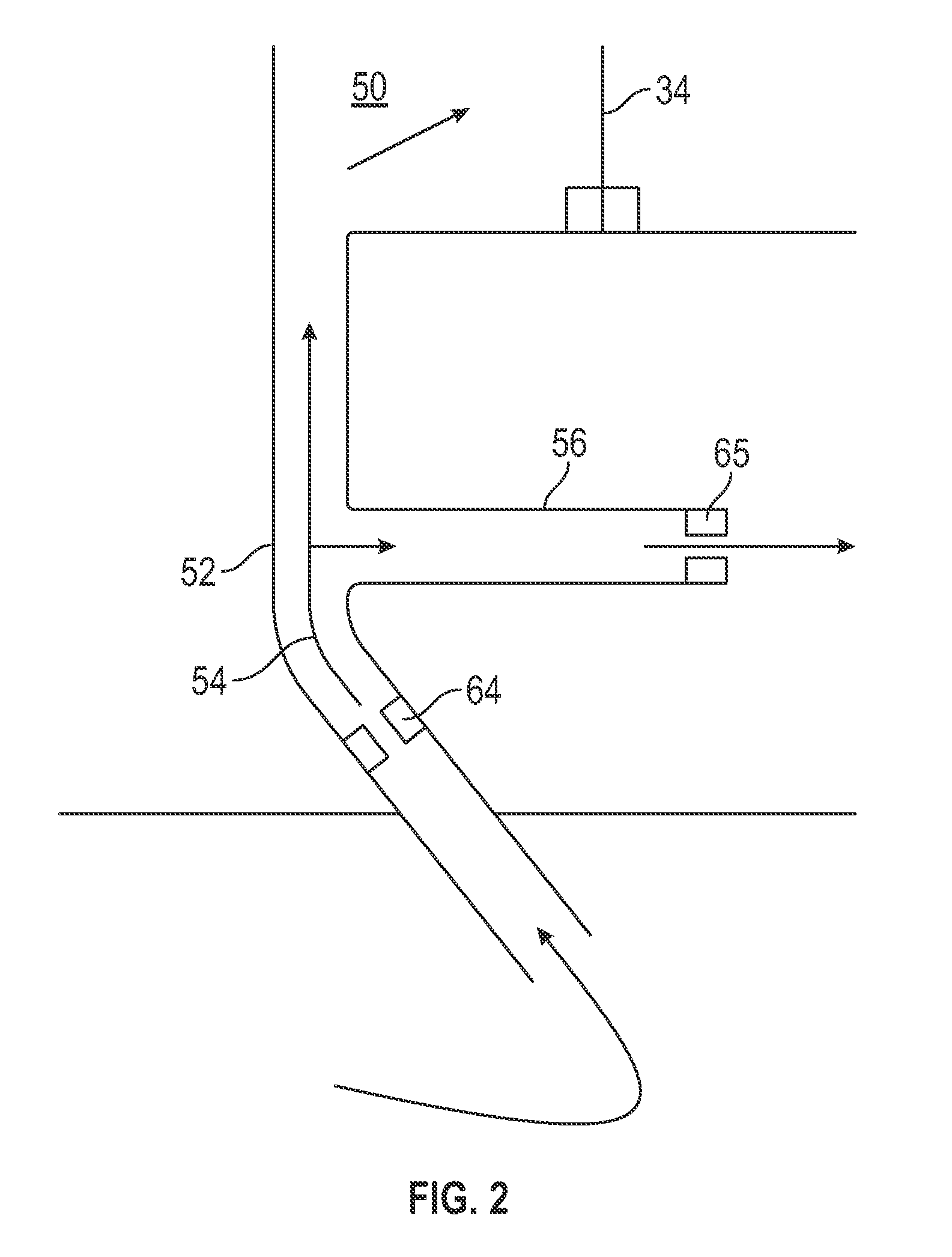

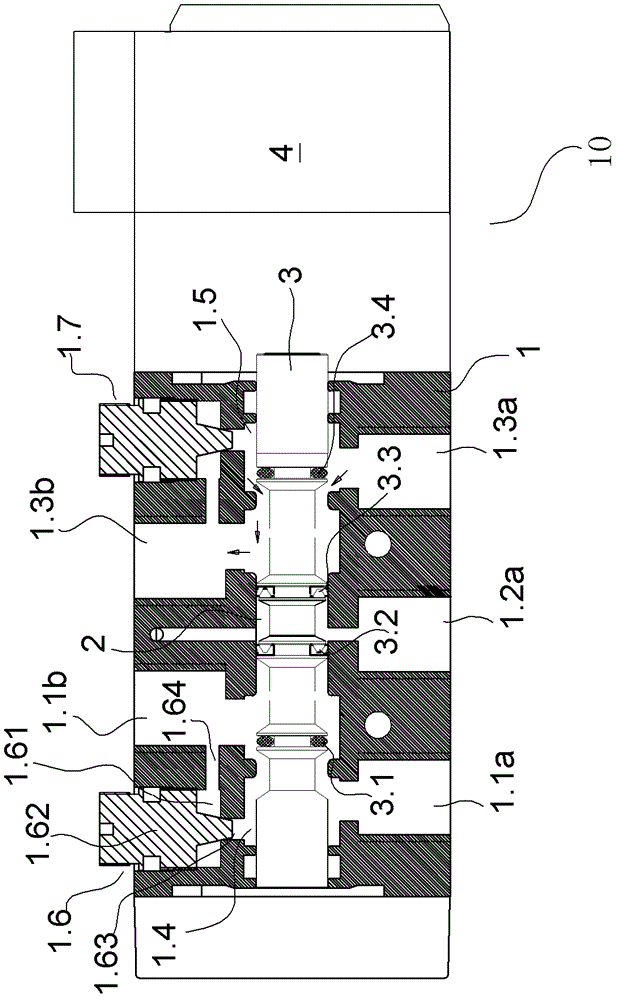

Pneumatic butterfly valve

InactiveUS20130276892A1Slow motion rateSlow downOperating means/releasing devices for valvesEngine manufactureButterfly valvePiston

A butterfly valve includes a duct defining a flow pathway and a valve disc rotably disposed in the flow pathway. A pneumatic actuator includes an intermediate chamber housing an actuator piston and is operably connected to the valve disc to drive rotation of the valve disc. A downstream bleed conduit extends from the flow pathway downstream of the valve disc to the intermediate chamber to pressurize the intermediate chamber thereby reducing a rate of movement of the valve disc in the flow pathway.

Owner:HAMILTON SUNDSTRAND CORP

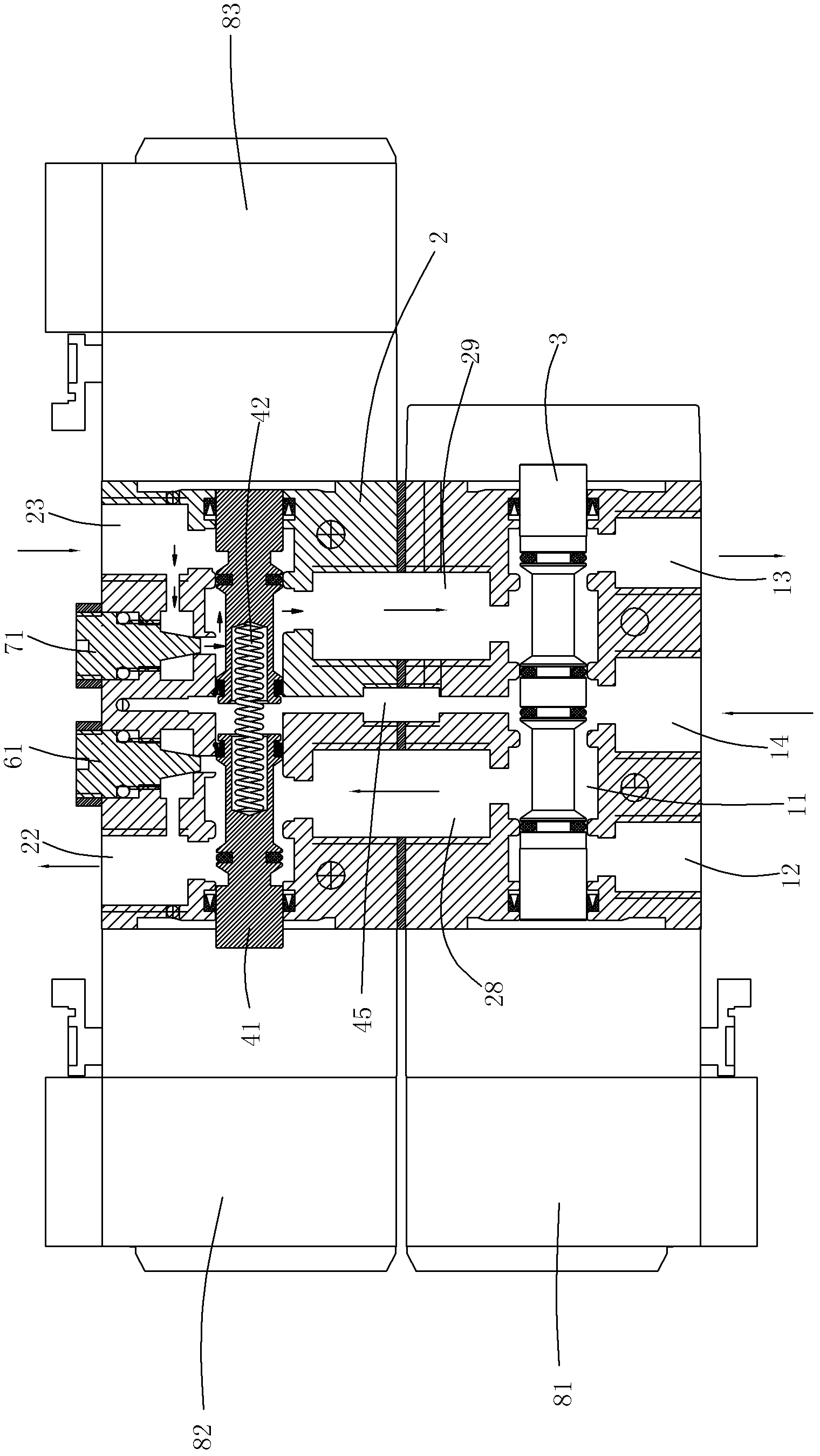

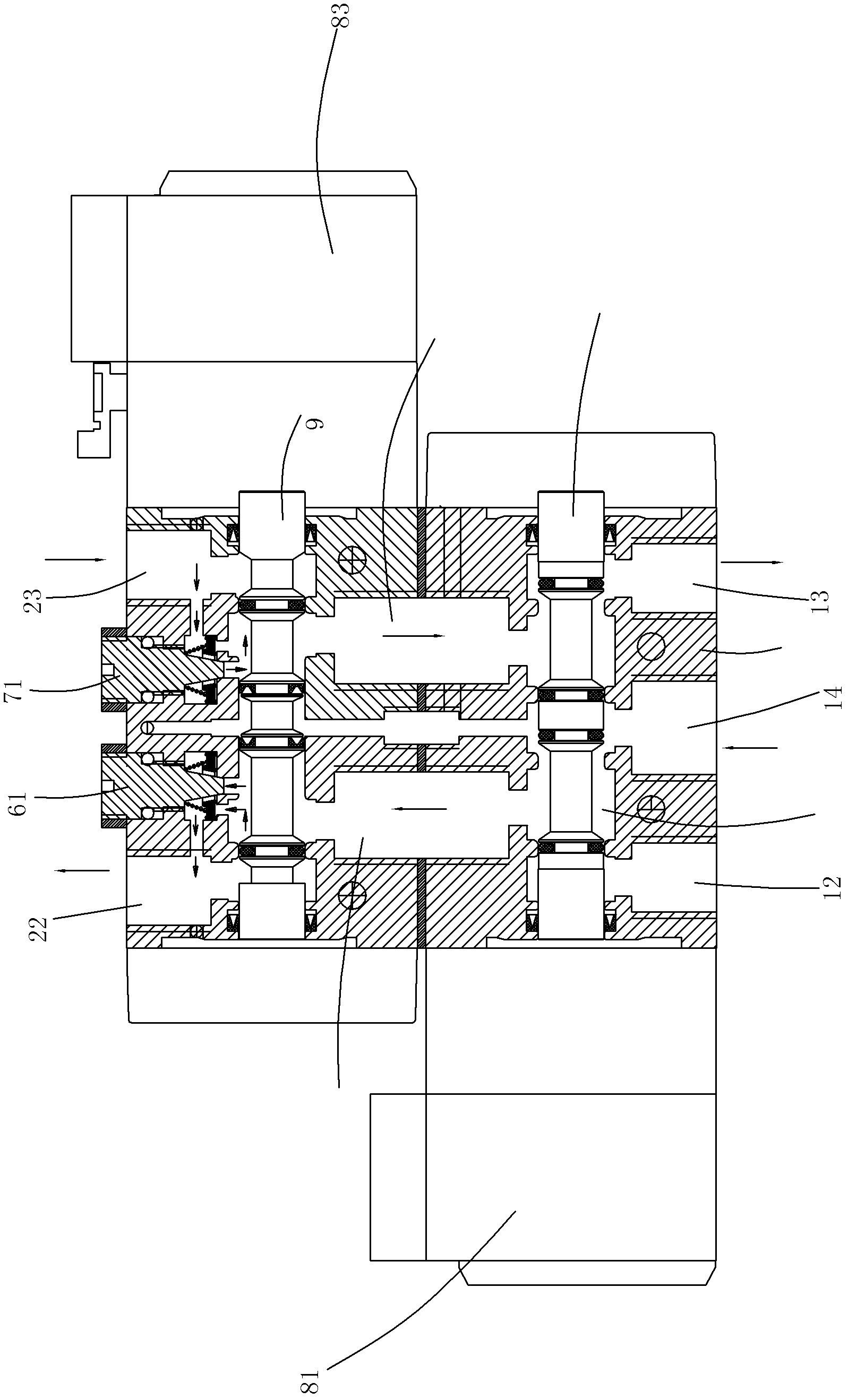

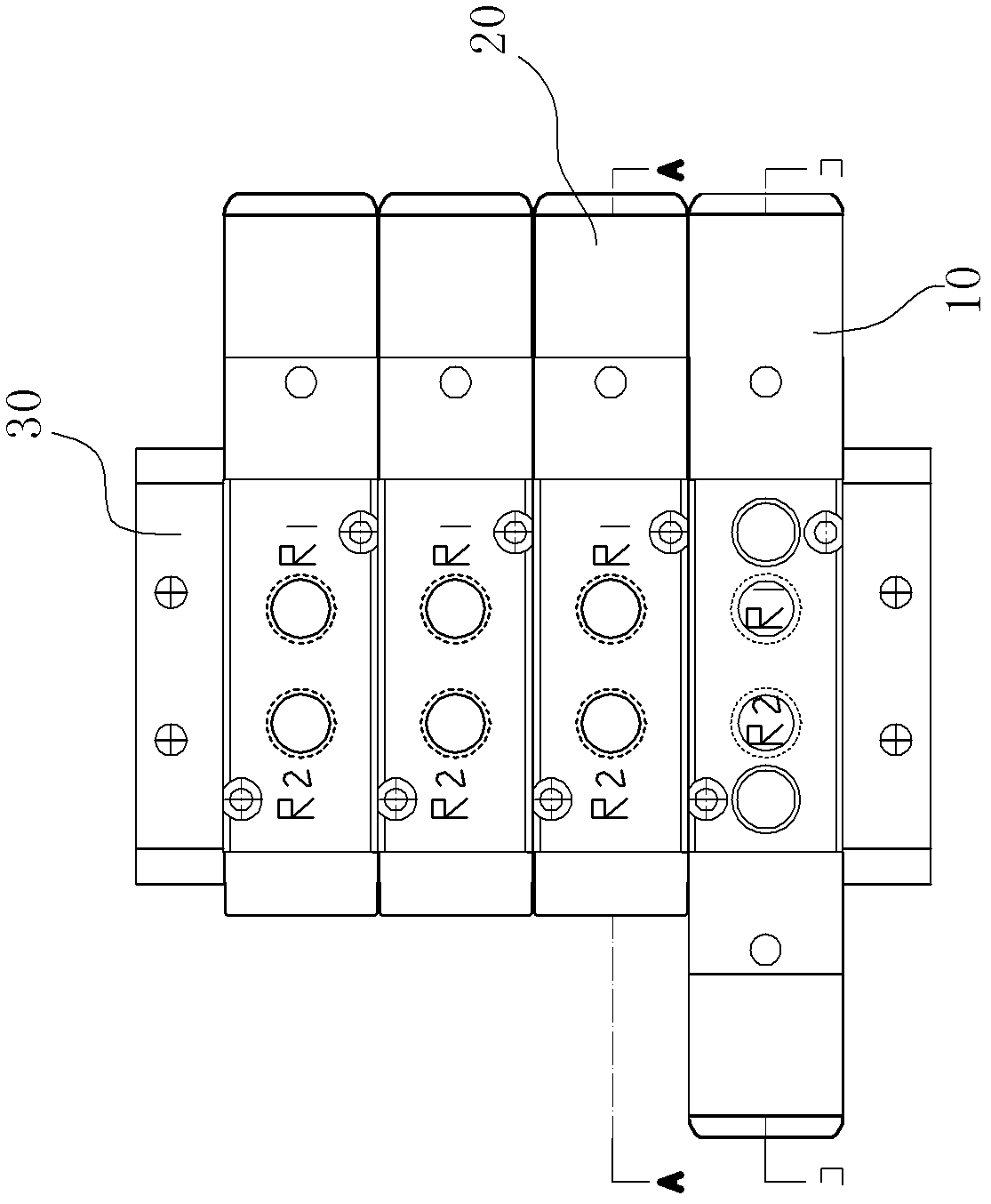

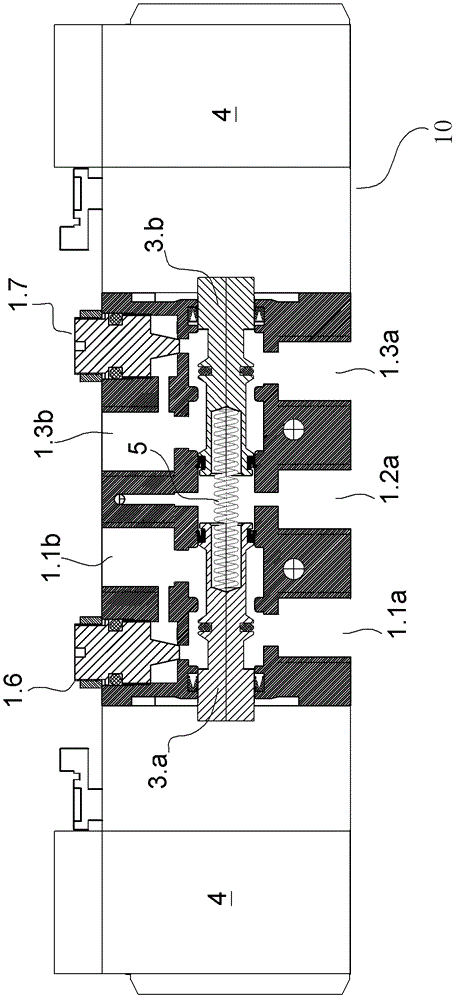

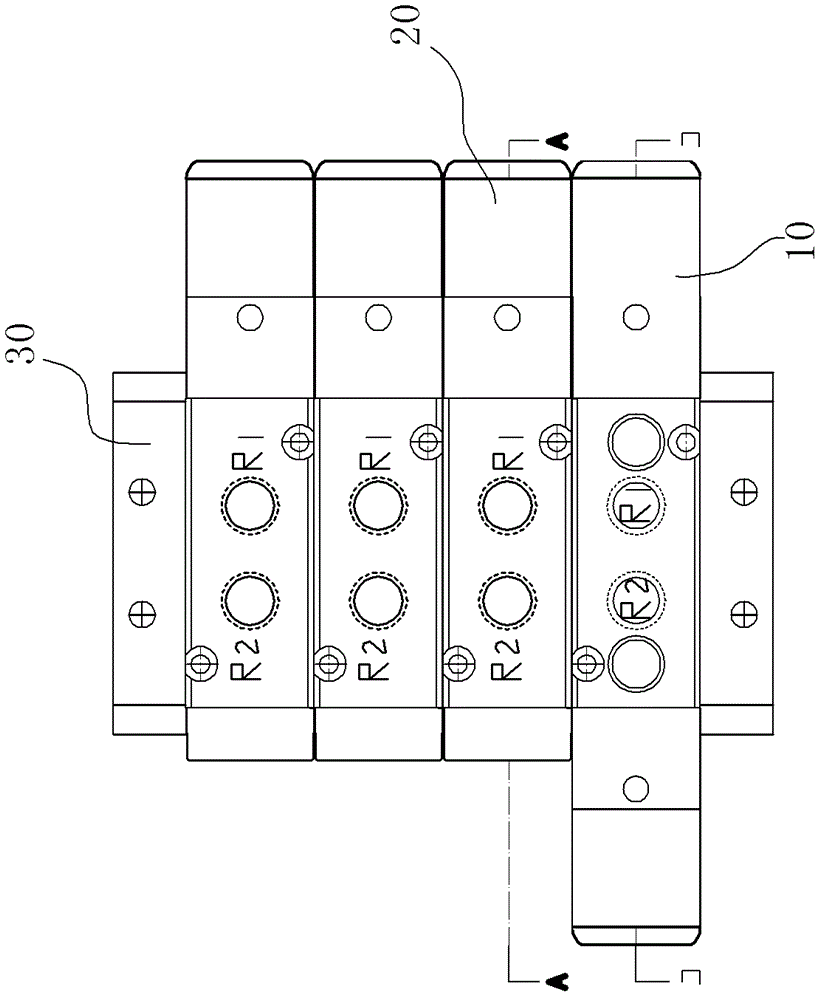

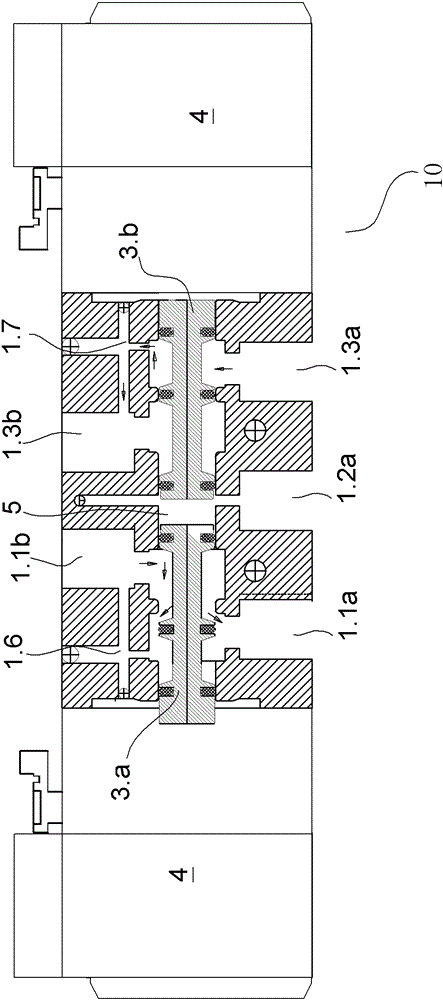

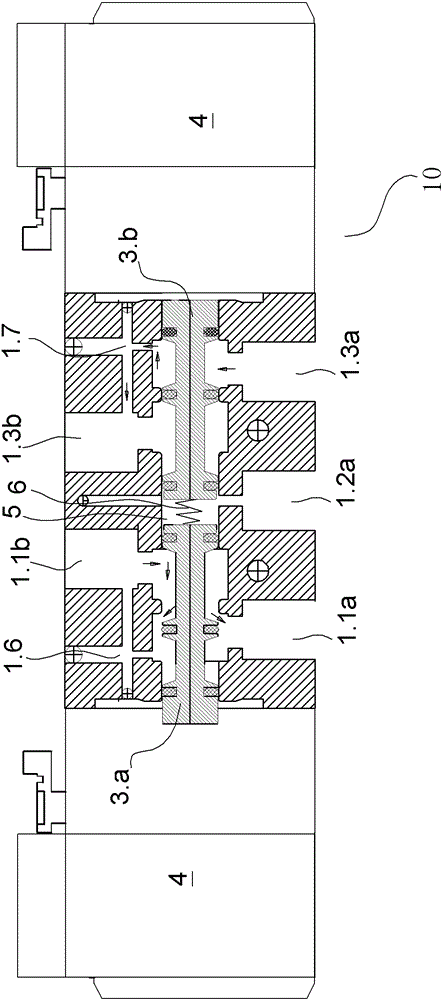

Combined valve

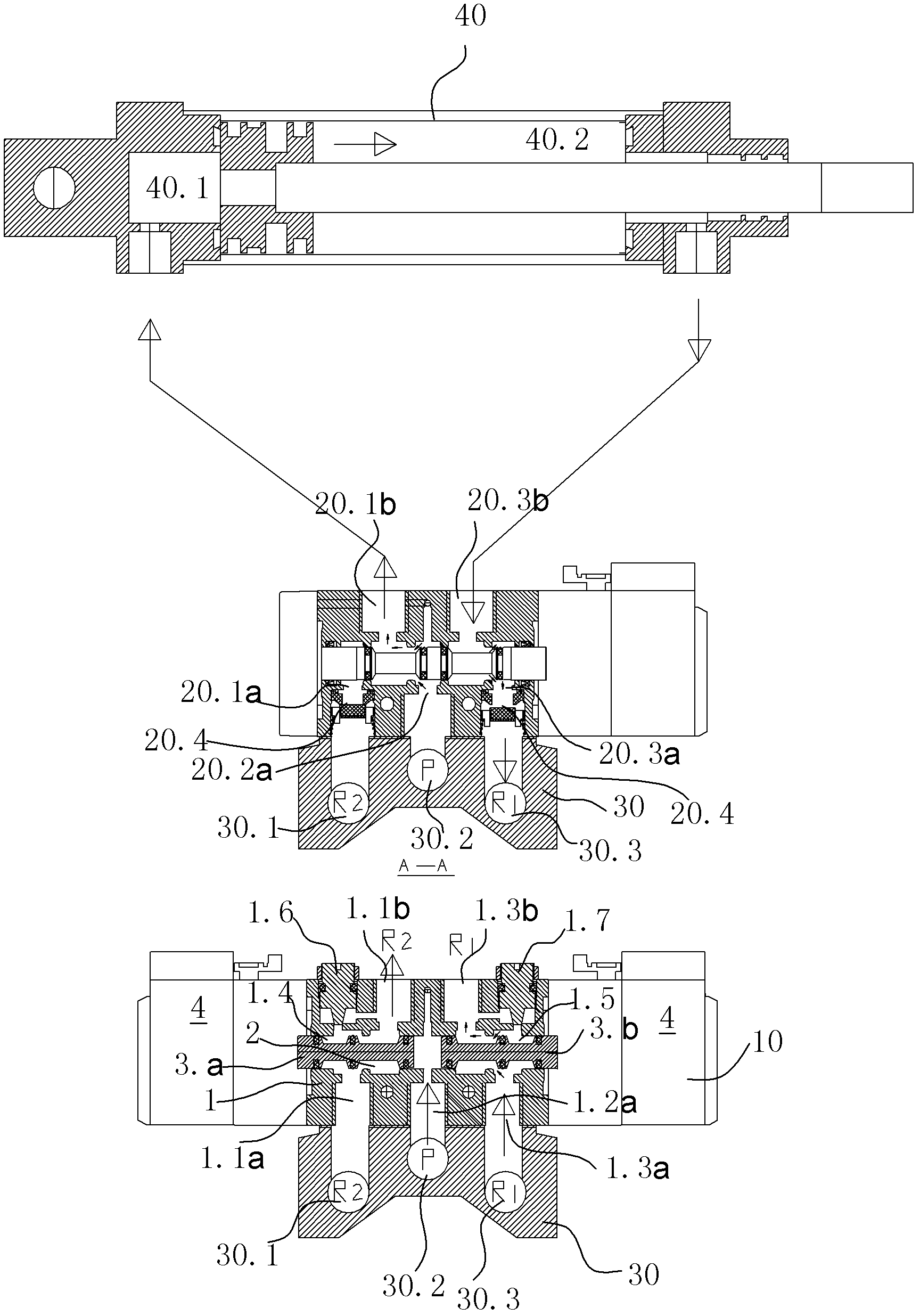

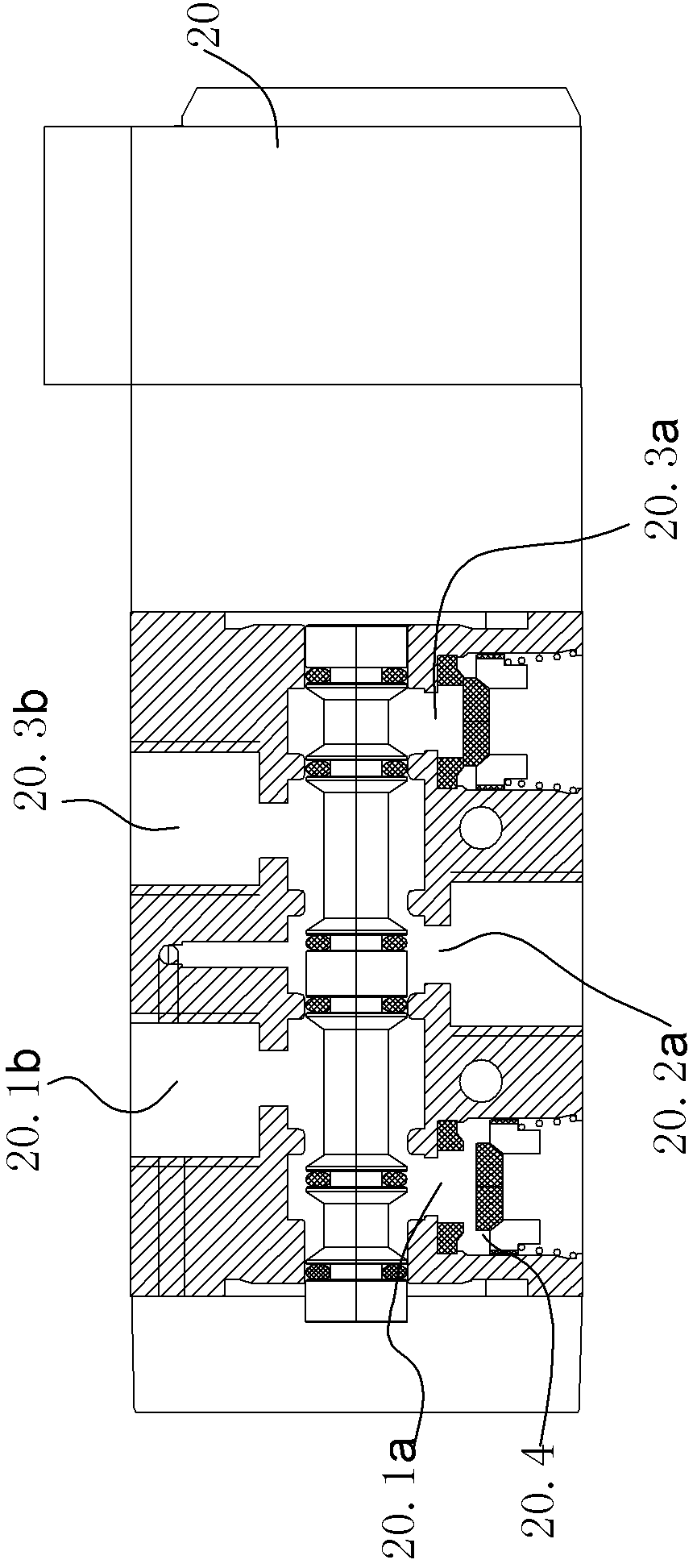

InactiveCN103256404AAvoid mutual influenceAvoid collision wearMultiple way valvesRefluxCylinder block

The invention relates to a combined valve. The combined valve comprises a multifunctional valve, a confluence plate and at least one operation reversing valve, wherein a left opening and a right opening at one side surface of one operation reversing valve are respectively connected to a left cavity and a right cavity of a piston cylinder; a left reflux opening, a middle inlet and a right reflux opening at the other side surface of the operation reversing valve are respectively connected to a left flow channel, a middle flow channel and a right flow channel of the confluence plate; the channels of the left reflux opening and the right reflux opening of the operation reversing valve are respectively provided with a one-way valve; the left reflux opening and the right reflux opening are corresponding connected to a left flow channel and a right flow channel of the confluence plate through respective throttle valves; and the left inlet and right inlet of the multifunctional valve are respectively and correspondingly communicated with a left outlet and a right outlet through respective throttle valves. The combined valve avoids mutual influence among cylinders and collision abrasion to a piston and a cylinder end cover when the piston moves rapidly, prolongs the service life of the piston cylinder efficiently, and guarantees operation safety and stability of the piston cylinder.

Owner:皇甫美蓉

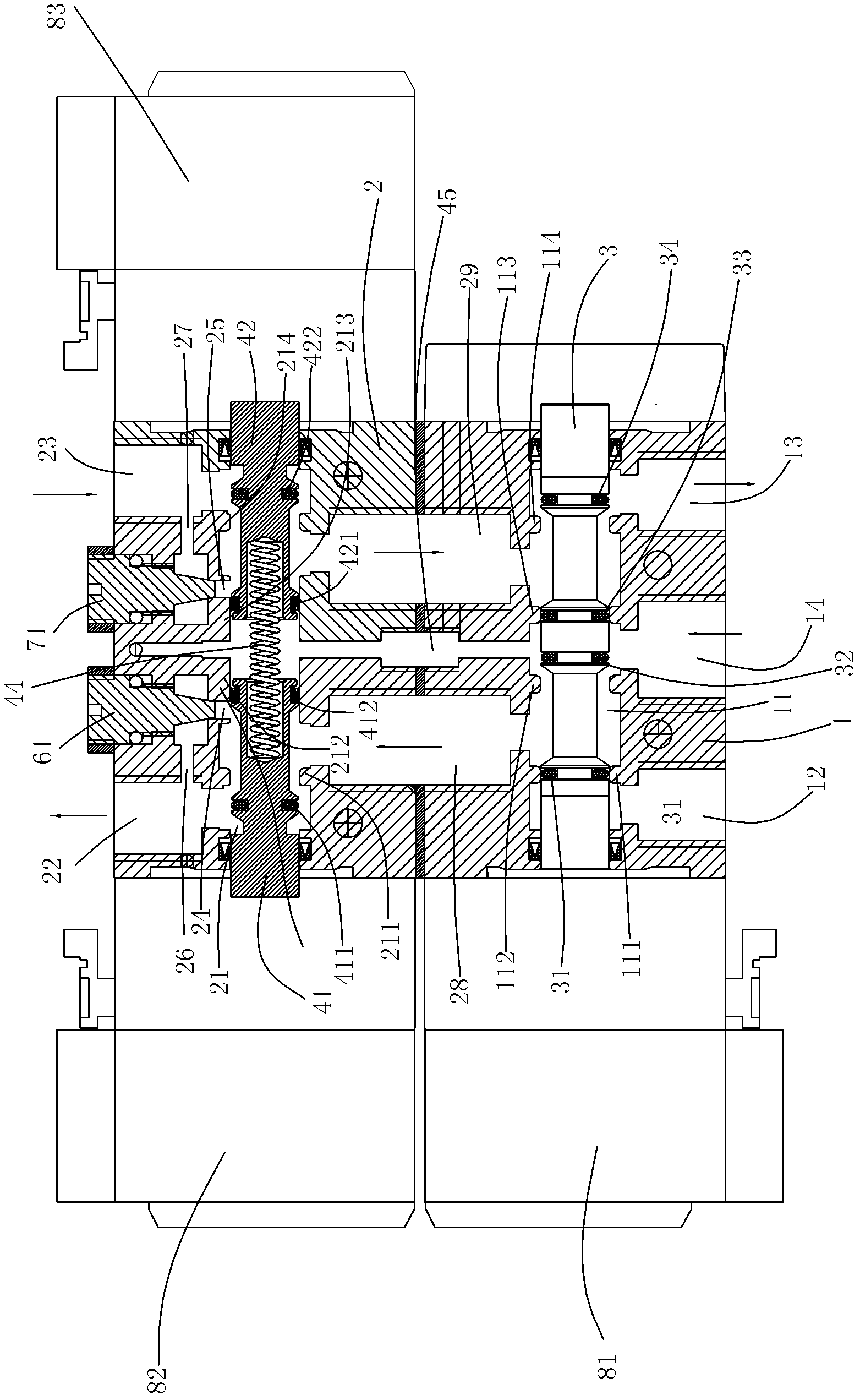

Structure of reversing valve

InactiveCN102359620AGuaranteed running stabilityEasy to operate and controlMultiple way valvesEngineeringMotion resistance

The invention relates to a structure of a reversing valve. The reversing valve comprises a control reversing valve and an action reversing valve, and two groups are matched to realize flow velocity variable control over a pressure medium. Compared with the prior art, the structure of the reversing valve has the advantages that: through a design of a second valve rod and two overflow valves, when a piston moves to be about to contact the end of a piston cylinder, the reflux quantity of the pressure medium is reduced, and the motion resistance of the piston is increased, so that the motion velocity of the piston is reduced, the piston slowly touches the end of the piston cylinder, the piston and the end of the piston cylinder are prevented from being collided and worn when the piston moves at a high speed, the service life of the piston cylinder is effectively prolonged, and the operation safety and stability of the piston cylinder are ensured simultaneously.

Owner:皇甫岳伟

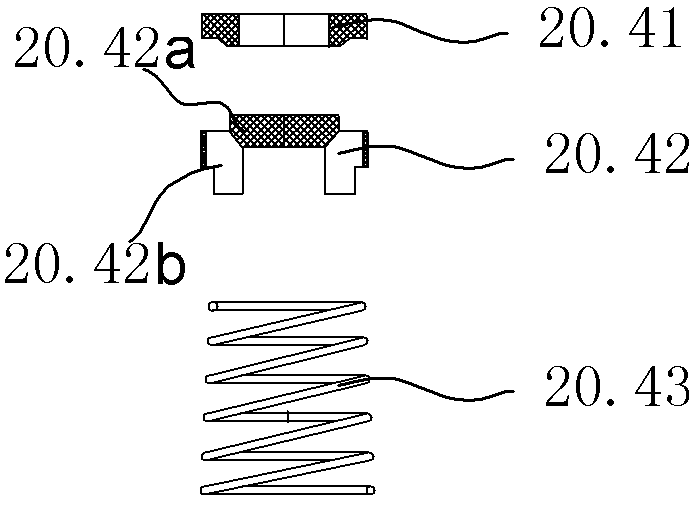

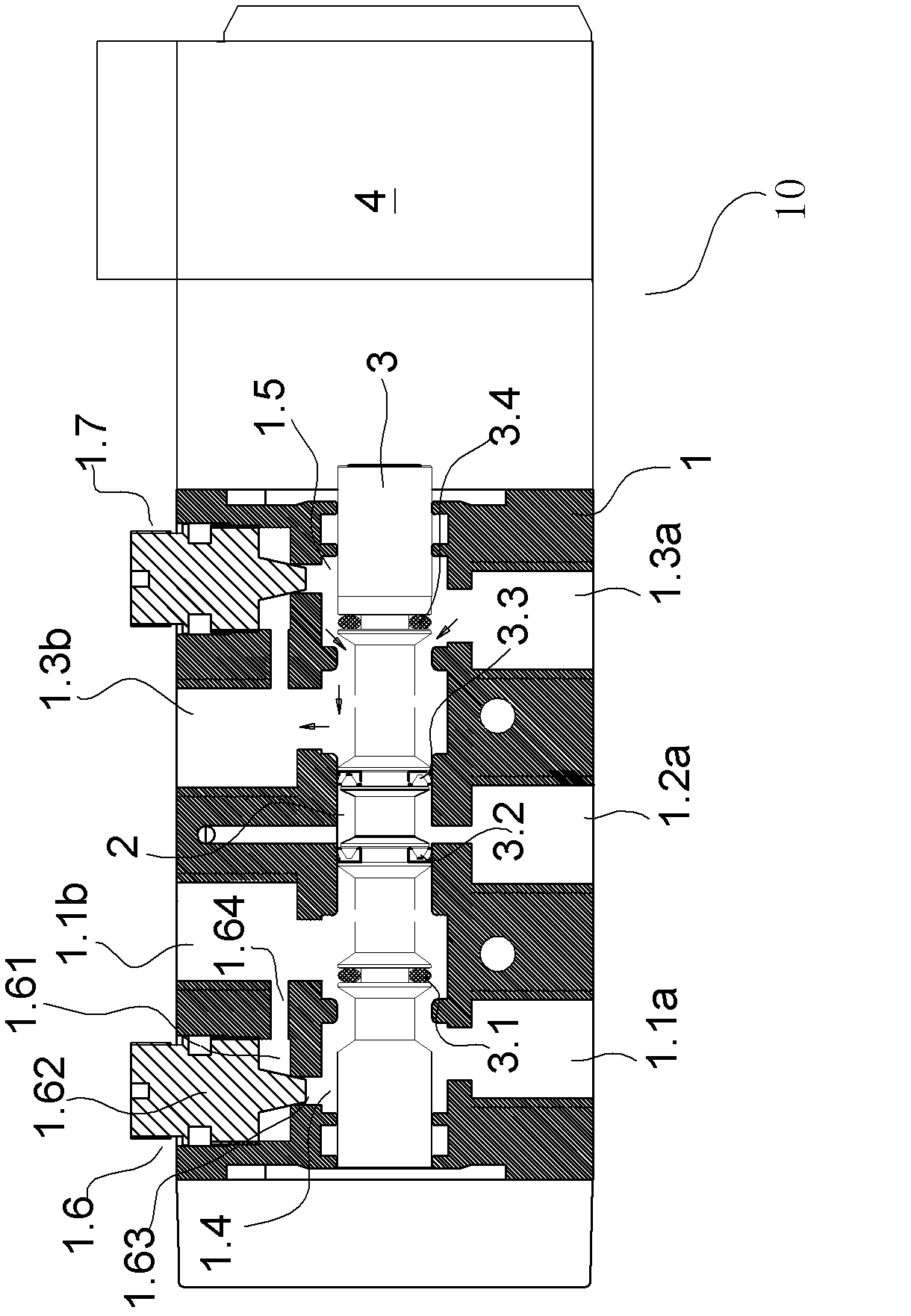

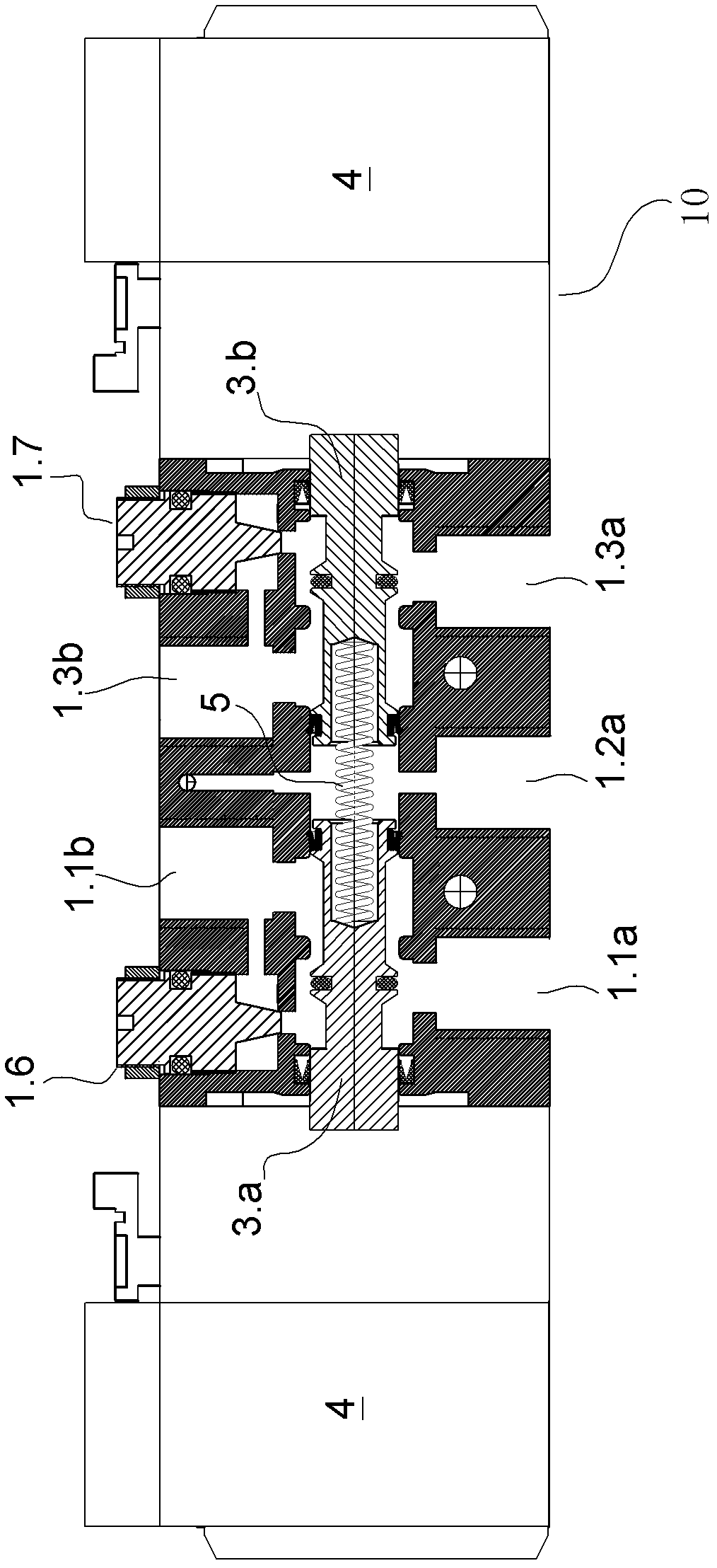

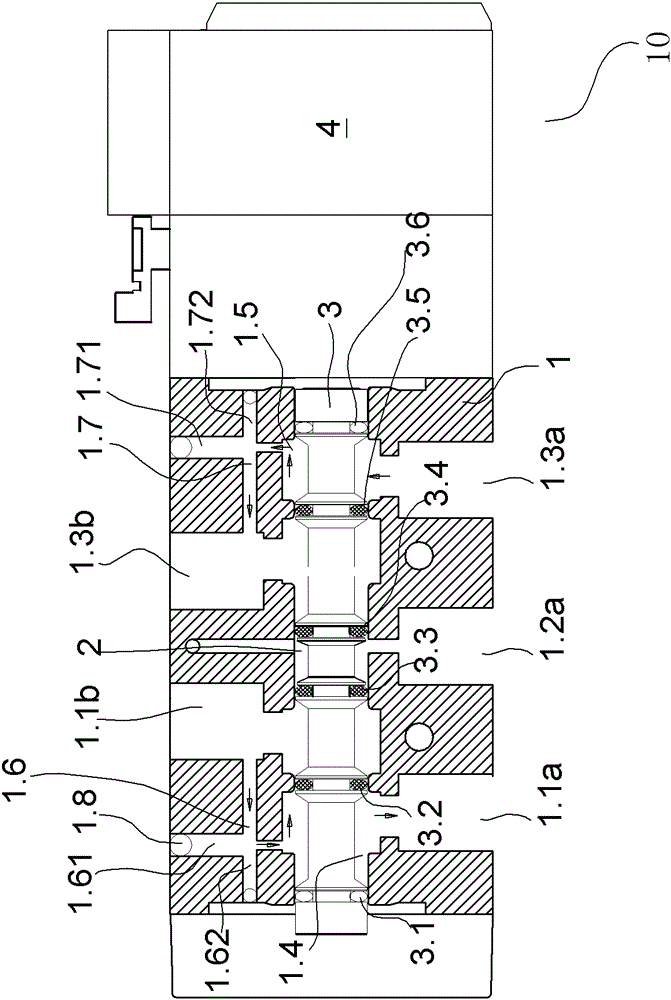

Multifunctional valve and multifunctional valve combination valve

InactiveCN103133720AReduce back flowIncrease resistanceMultiple way valvesFluid-pressure actuatorsPiston cylinderThrottle

The invention relates to a multifunctional valve and a multifunctional valve combination valve. The multifunctional valve and the multifunctional valve combination valve comprise a valve body, a valve cavity which is arranged in the valve body and a valve rod which is arranged in the valve cavity, wherein a middle inlet, a left inlet and a right inlet are arranged on one side of the valve body, the middle inlet is used for the entering of pressure mediums, the left inlet and the right inlet are used for the selective entering of the pressure mediums, a left outlet and a right outlet are arranged on the other side of the valve body, the left outlet and the right outlet are used for the discharging of the pressure mediums, and the left inlet and the left outlet and the right inlet and the right outlet are selectively communicated in a corresponding mode through the matching of the valve cavity and the valve rod. The multifunctional valve and the multifunctional valve combination valve are characterized in that the left inlet is communicated with a left cavity correspondingly, the right inlet is communicated with a right cavity correspondingly, and correspondingly, the left cavity and the right cavity are communicated with the left outlet and the right outlet through a left throttle valve and a right throttle valve. According to the multifunctional valve and the multifunctional valve combination valve, a piston can be slowly contacted with the end portion of a piston cylinder, the collision and the abrasion to a piston rod when the piston is moved rapidly are avoided, the service life of the piston cylinder is prolonged effectively, and meanwhile the operation safety of the piston cylinder and the stability of the piston cylinder are ensured.

Owner:皇甫美蓉

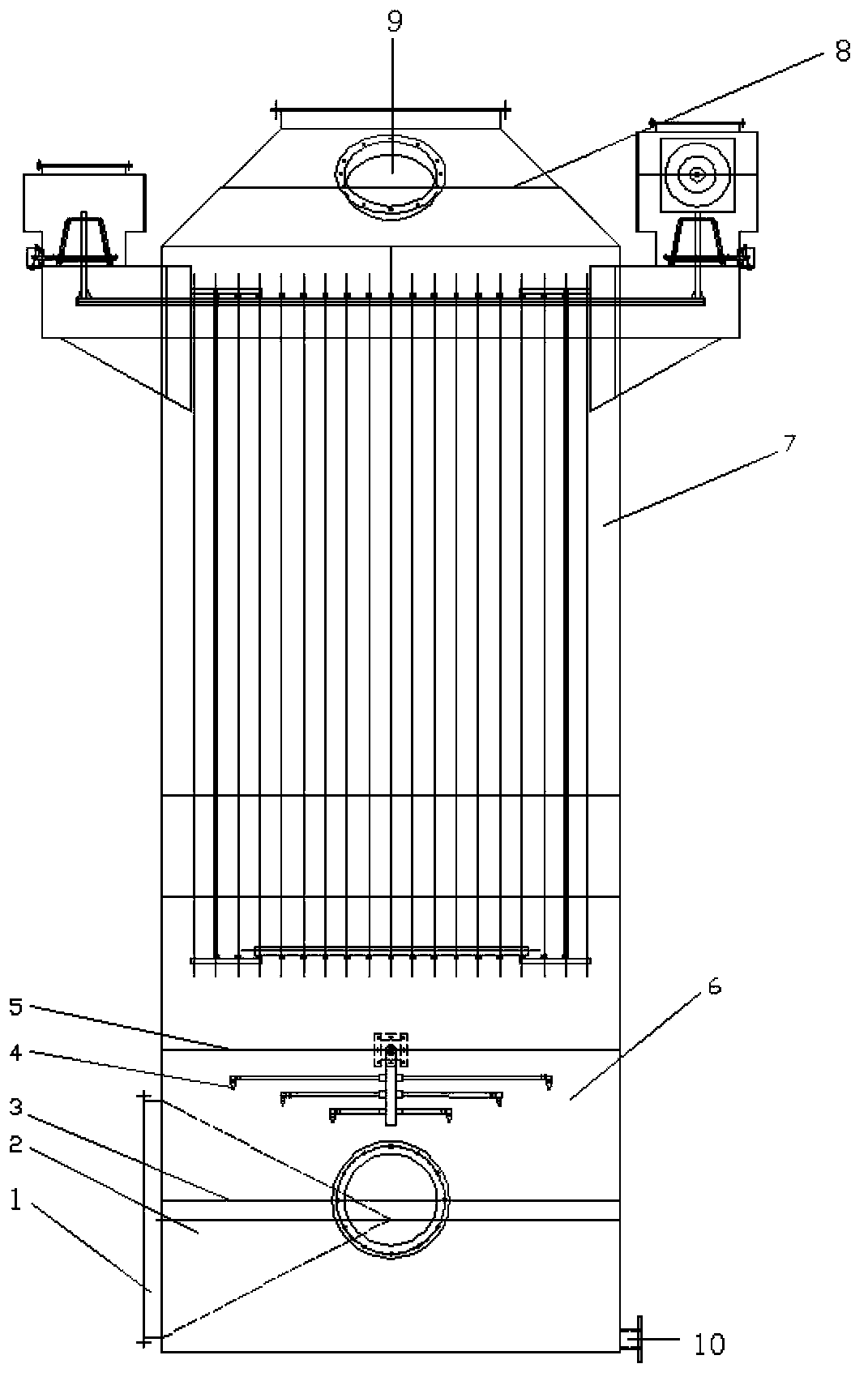

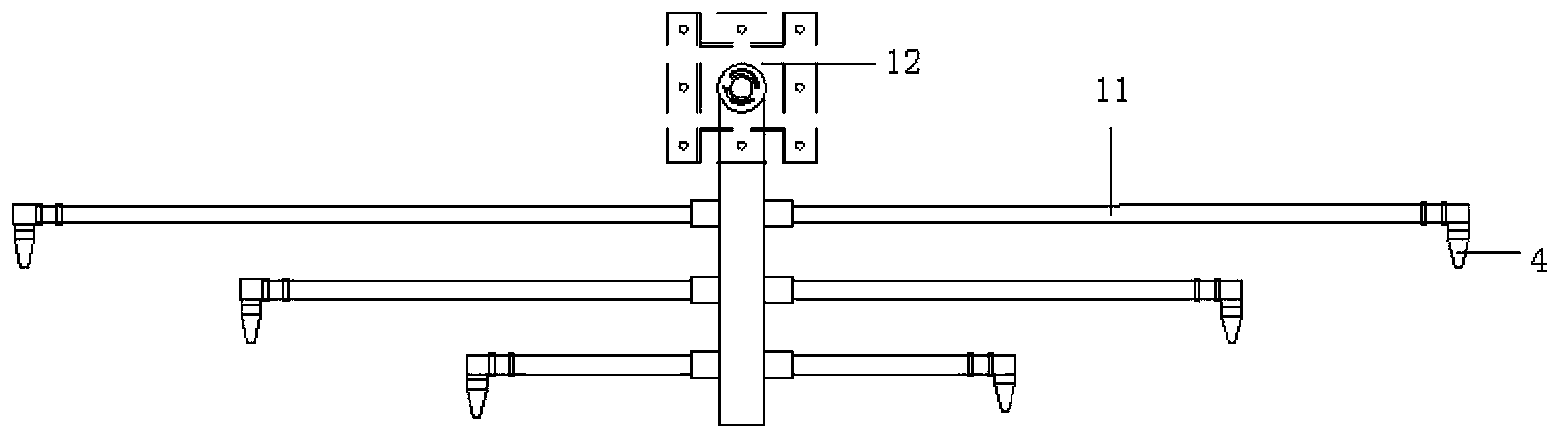

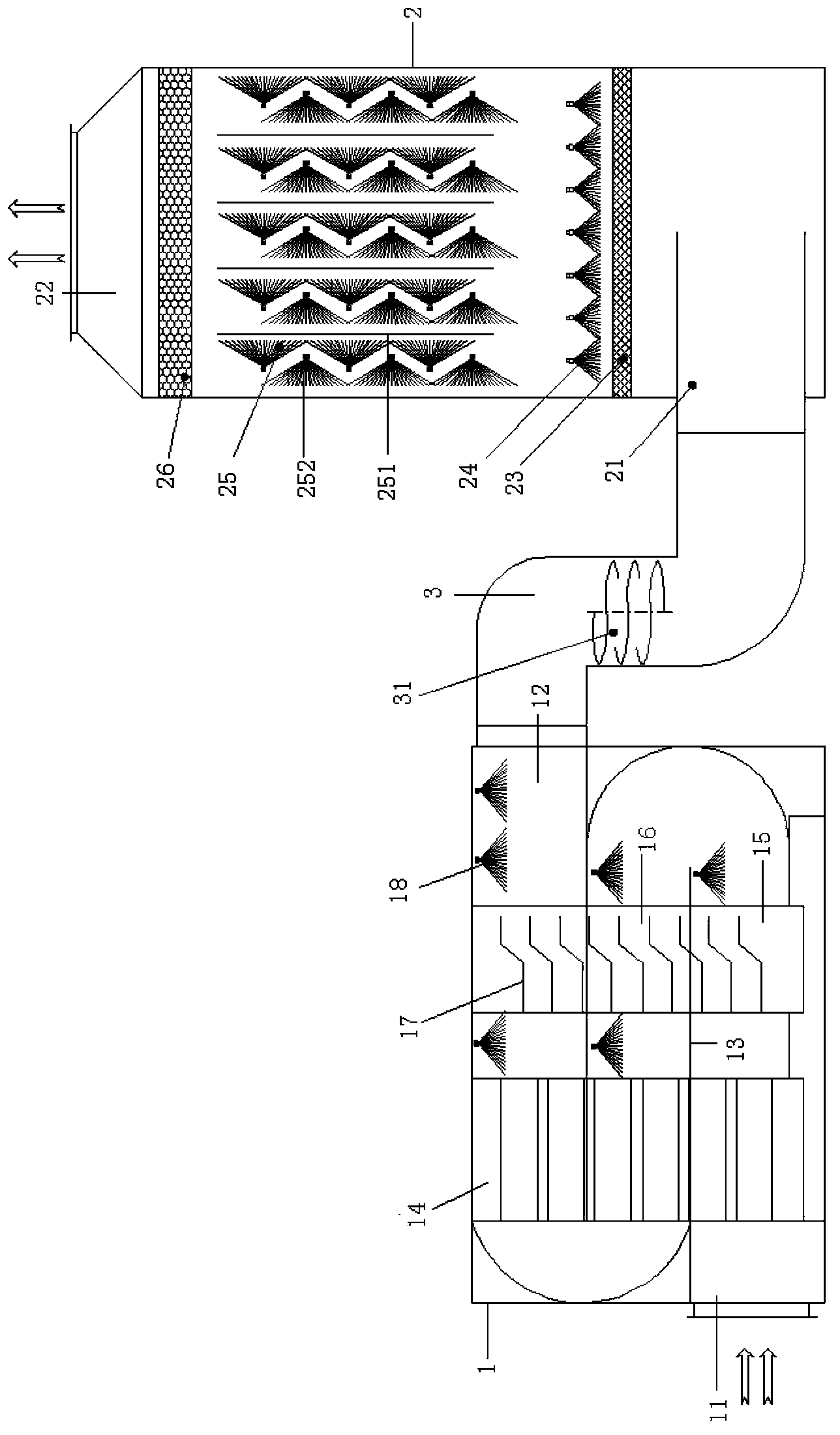

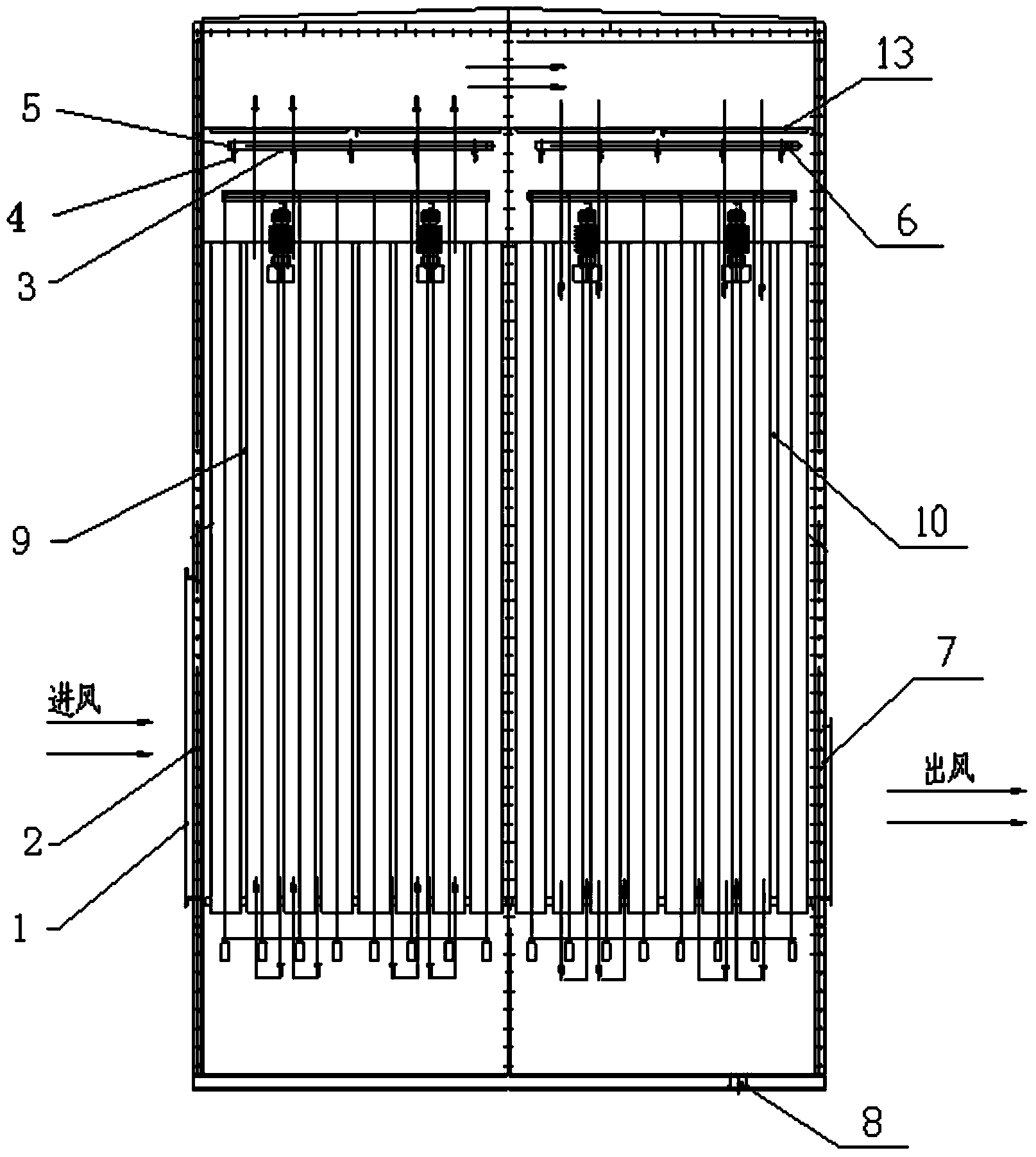

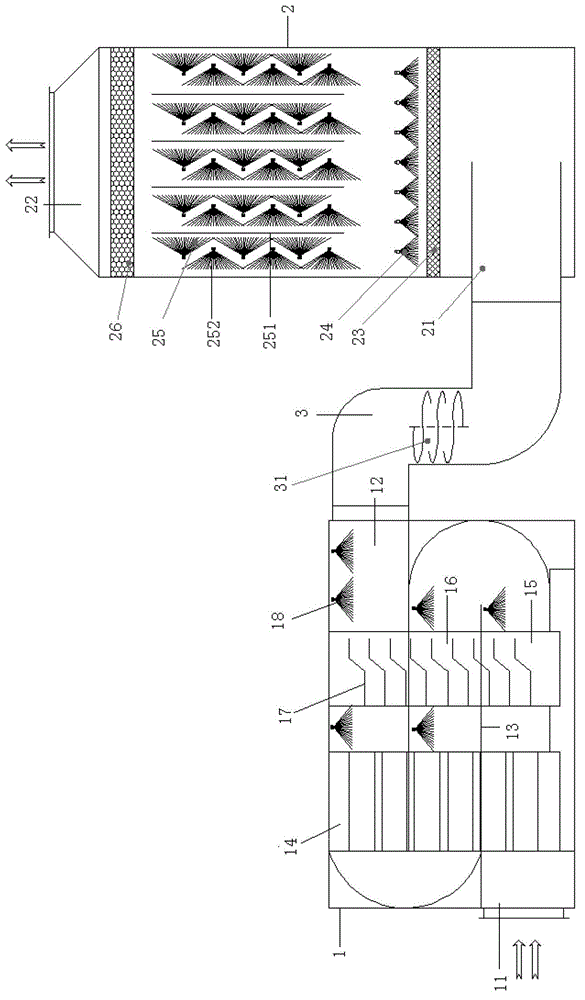

Electrostatic precipitator for exhaust gas through wet process

InactiveCN103406202ASlow motion rateImprove dust collection efficiencyExternal electric electrostatic seperatorElectrostatic separation detailsLiquid wasteEngineering

The invention discloses an electrostatic precipitator for exhaust gas through a wet process. The electrostatic precipitator comprises a precipitator body and further comprises an atomizing spray mechanism, a uniform direct-current high-voltage electric field mechanism and an electric control device, wherein the precipitator body comprises a precipitator housing; the atomizing spray mechanism and the uniform direct-current high-voltage electric field mechanism are arranged inside the precipitator housing; the electric control device is used for controlling the movement of the atomizing spray mechanism and the uniform direct-current high-voltage electric field mechanism; a whirlwind inlet is formed in one side of the bottom of the housing; a waste liquor outlet is formed in the other side of the bottom of the housing; an air outlet is formed in the top of the housing; a gas condenser used for cooling and condensing high-temperature gas is arranged at the position of the whirlwind inlet and used for liquefying oil in the gas; the atomizing spray mechanism is arranged above the whirlwind inlet; the uniform direct-current high-voltage electric field mechanism is arranged above the atomizing spray mechanism; the atomizing spray mechanism is composed of a water curtain wall composed of a plurality of atomizing nozzles. According to the electrostatic precipitator, because the atomizing spray mechanism and the high-voltage electric field mechanism are adopted, dust collection efficiency is improved, the production cost is reduced, and the electrostatic precipitator can be widely applied to waste gas treatment of printing, dyeing and shaping machines.

Owner:ZHEJIANG HAILIANG ENERGY MANAGEMENT +2

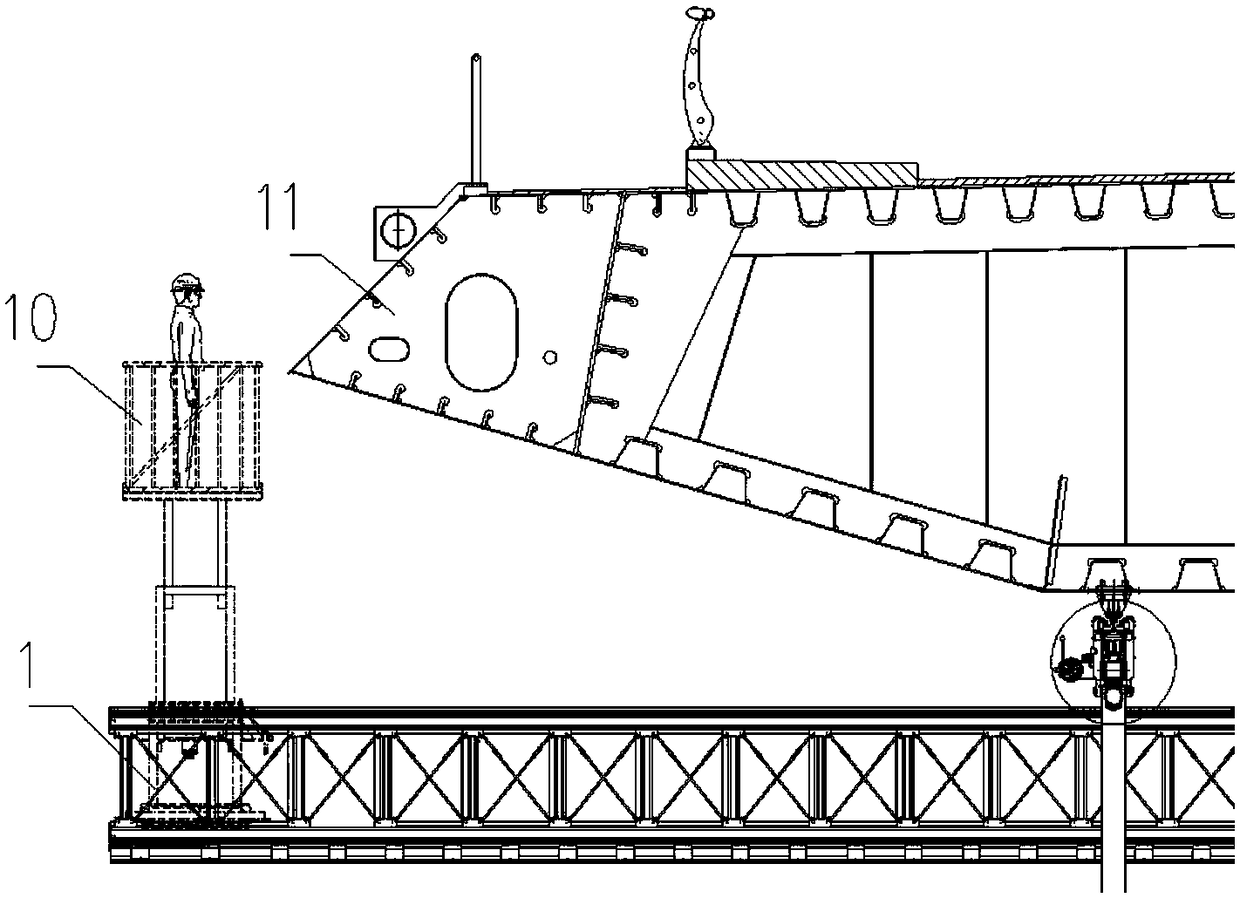

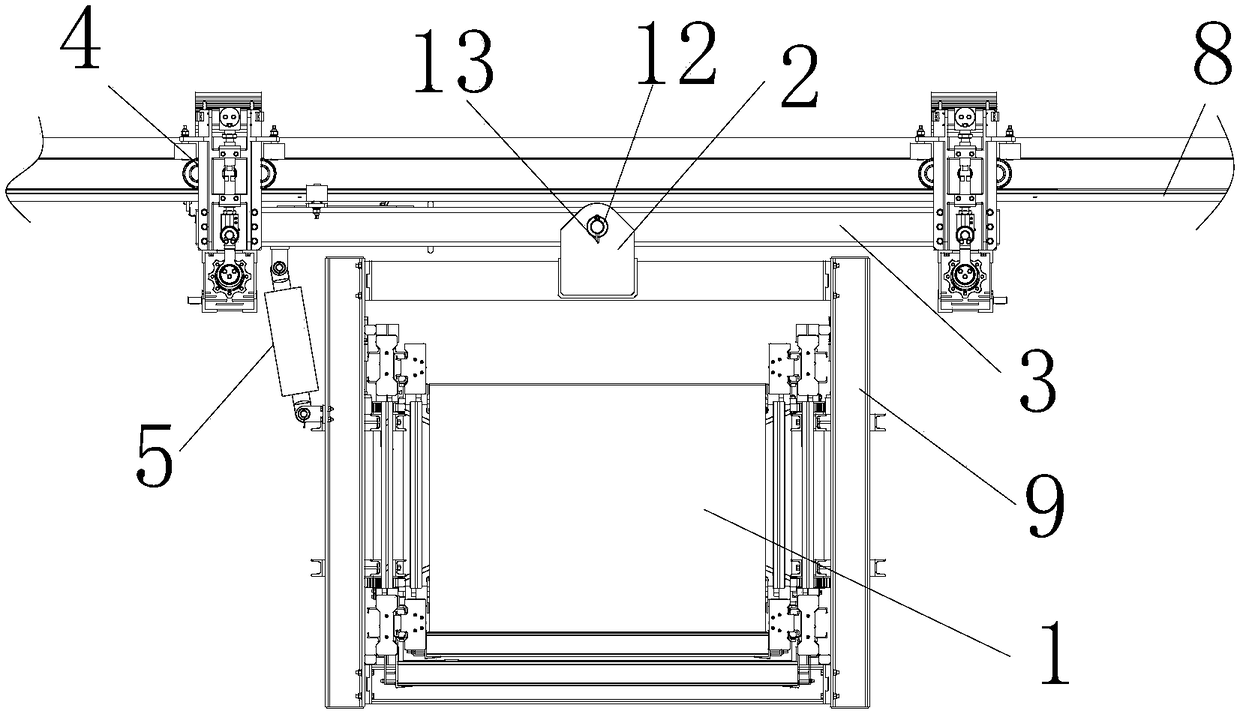

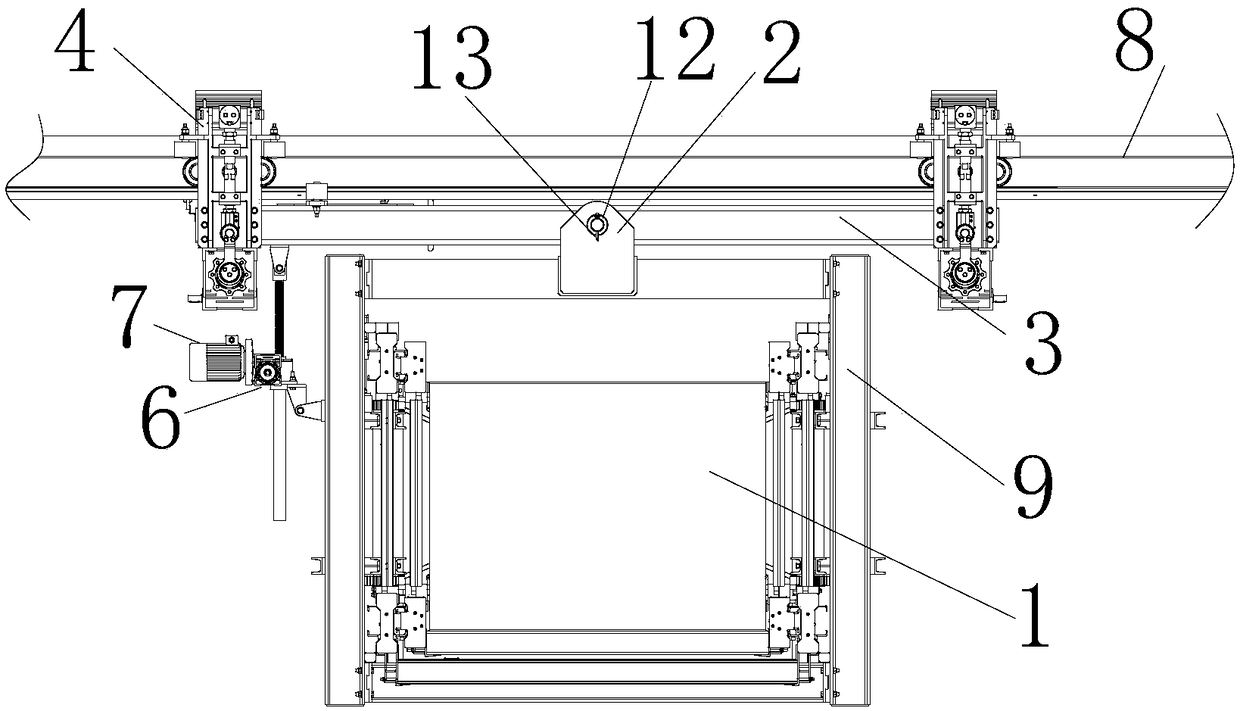

Bridge inspection vehicle leveling device and bridge inspection equipment

InactiveCN108086149AAvoid security issuesAvoid influenceBridge structural detailsMarine engineeringSteep slope

The invention provides a bridge inspection vehicle leveling device and bridge inspection equipment. As a buffering device is arranged in the bridge inspection vehicle leveling device, the buffering device can apply an acting force to a portal frame when a truss overhauling platform is inclined, the portal frame drives the truss overhauling platform so that the truss overhauling platform can slowlyrecover to the horizontal state; therefore, when a running mechanism moves to a steep slope position, the truss overhauling platform is prevented from shaking to cause injuries of operation workers within the truss overhauling platform and on a lifting overhauling platform and affect equipment within the truss overhauling platform and on the lifting overhauling platform.

Owner:BEIJING HENGLI TIEKE TECH DEV +1

Multi-stage spray treatment device for waste gas of printing and dyeing setting machine

InactiveCN103405977AImprove dust collection efficiencyReduce manufacturing costUsing liquid separation agentSpray nozzleTower

The invention discloses a multi-stage spray treatment device for waste gas of a printing and dyeing setting machine. The multi-stage spray treatment device comprises purification chambers including a primary purification chamber and a secondary purification chamber, wherein the interior of the primary purification chamber is divided into multiple layers of purification areas through partition boards; the partition boards are horizontally arranged in parallel in a staggered manner; an all-directional fine atomization area is arranged above a second air inlet of the secondary purification chamber; a water curtain wall blockage area is arranged at the upper part of the fine atomization area; a plurality of tower plates are vertically arranged in the water curtain wall blockage area, a plurality of spray nozzles are placed between the inner wall of the water curtain wall blockage area and the tower plates and between every two tower plates in a staggered manner, and the outlet directions of the spray nozzles are opposite; the spray nozzles spray airflow and water to the inner wall of the water curtain wall blockage area or the tower plate walls simultaneously to form a water curtain wall, so that liquid drops flow downwards along the tower plate walls or the inner wall of the water curtain wall blockage area, and the purified gas runs upwards continuously. According to the invention, the spray mechanism has three different effects, so that the dust collecting efficiency is improved, the production cost is reduced, and the multi-stage spray treatment device can be widely applied to treatment of waste gas of the printing and dyeing setting machine.

Owner:ZHEJIANG HAILIANG ENERGY MANAGEMENT +2

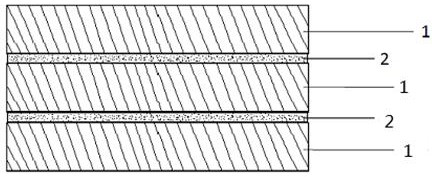

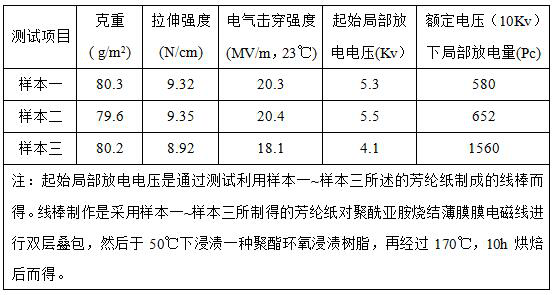

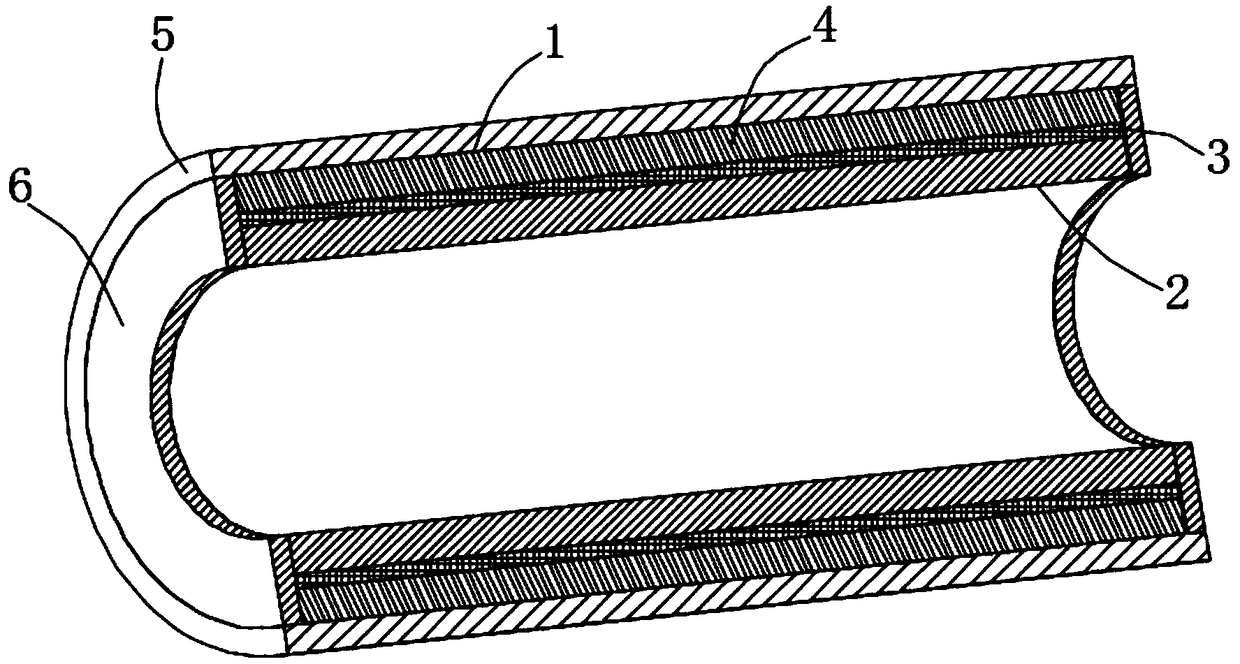

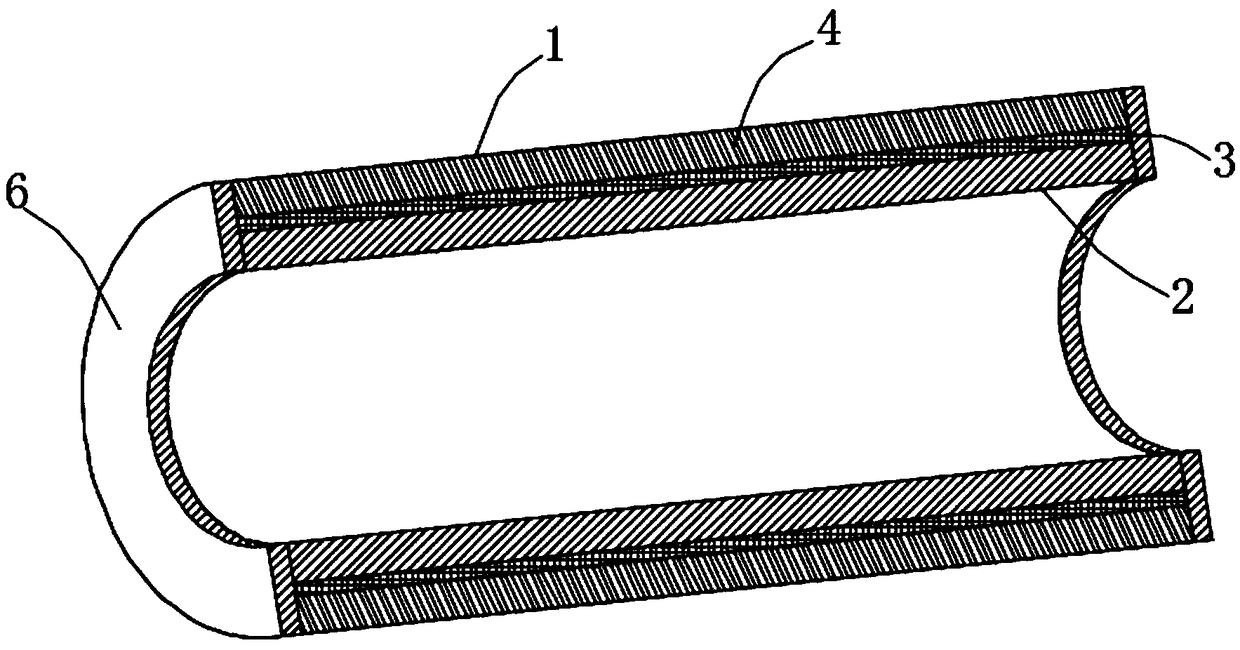

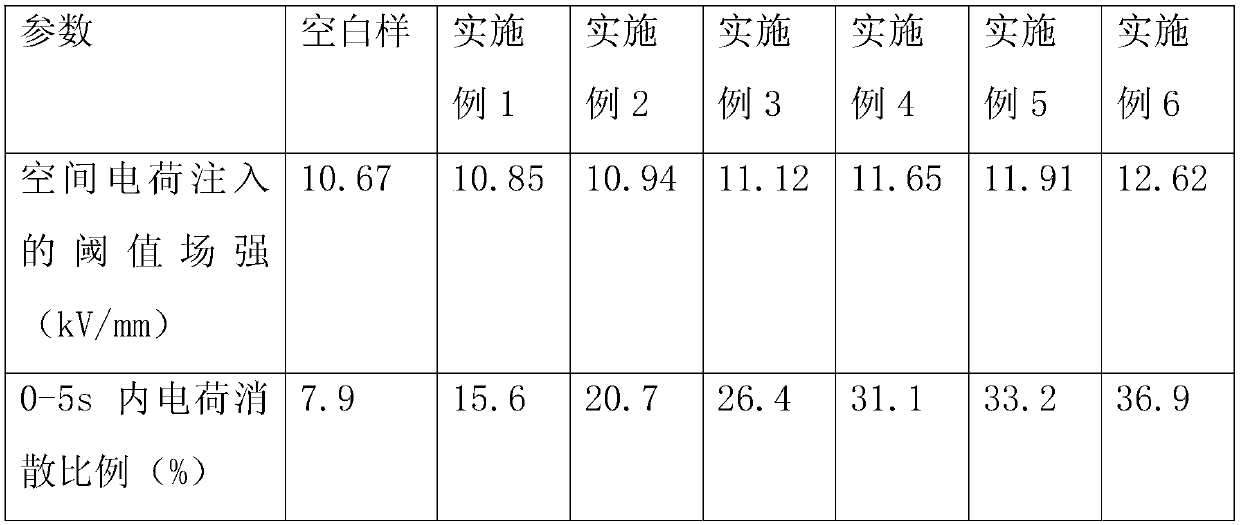

Composite aramid paper with high dielectric property

InactiveCN112746522AImprove high temperature resistanceCorona resistantNon-macromolecular adhesive additivesSpecial paperDielectricAdhesive

The invention provides composite aramid paper with high dielectric property. The composite aramid paper comprises more than two layers of single-layer aramid paper, and the single-layer aramid paper is combined into a whole through a high-temperature-resistant adhesive layer containing inorganic nanofiller to form the composite aramid paper. The preparation method comprises the following steps: blending the high-temperature-resistant adhesive, an inorganic nano filler, a diluent and a dispersing agent, stirring at a high speed, uniformly dispersing, preparing a high-temperature-resistant adhesive solution, uniformly spraying the prepared high-temperature-resistant adhesive solution to a to-be-bonded surface of single-layer aramid paper, baking to volatilize a solvent, bonding the surfaces of more than two layers of single-layer aramid paper, and carrying out hot rolling to form a whole. According to the composite aramid paper, the paper contains the inorganic nano material layer in a bonding manner, and the inorganic nano material has the effects of inhibiting space charge aggregation in insulation paper, reducing the movement rate of current carriers and weakening overload pulse voltage so that the composite aramid paper has corona resistance of pulse voltage resistance and higher breakdown strength, and the insulation protection performance and the service life of a motor insulation system can be greatly improved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

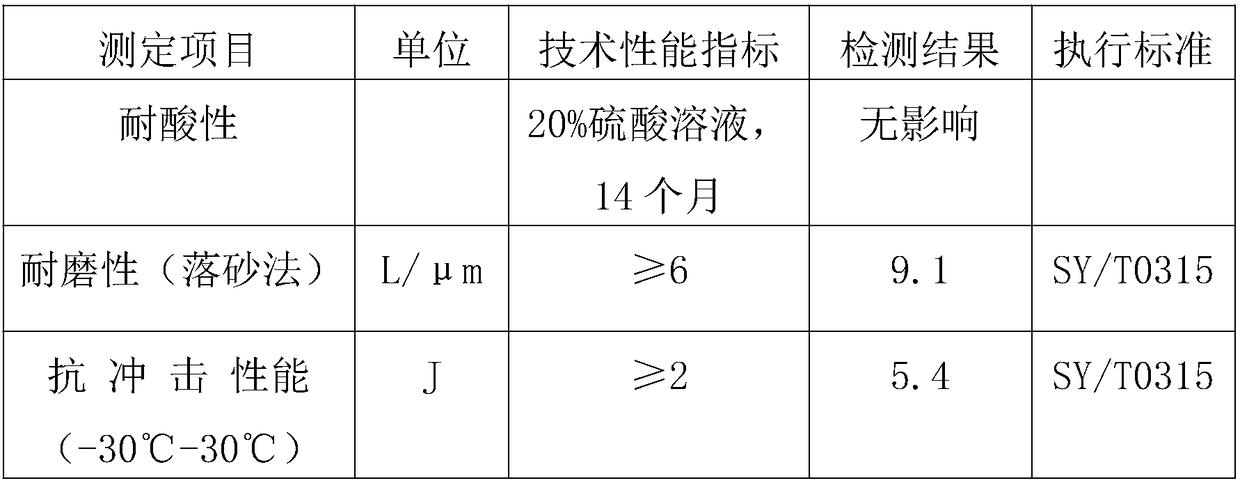

Heat-preservation durable gas pipeline and preparation technology thereof

PendingCN108758106AImprove insulation effectImprove delivery efficiencyThermal insulationAnti-corrosive paintsEngineeringNano zinc oxide

The invention relates to the technical field of pipeline production, in particular to a heat-preservation durable gas pipeline and a preparation technology thereof. The heat-preservation durable gas pipeline comprises a gas pipeline body, an outer layer sleeve and annular connecting pieces. The gas pipeline body sequentially comprises an inner layer pipe blank, a heat-preservation interlayer and an outer layer pipe blank from inside to outside. An anti-corrosion coating is sprayed on the outer wall of the outer layer pipe blank. A water-proof coating is sprayed on the inner wall of the inner layer pipe blank. The heat-preservation interlayer is embedded between the inner layer pipe blank and the outer layer pipe blank. The inner layer pipe blank and the outer layer pipe blank are connectedthrough the annular connecting pieces welded to the left ends and the right ends of the inner layer pipe blank and the outer layer pipe blank. The outer layer sleeve is fixed to the outer layer pipeblank in a sleeving mode. According to the heat-preservation durable gas pipeline and the preparation technology thereof, the heat-preservation property of the gas delivery pipeline can be improved significantly through the heat-preservation interlayer, and the gas delivery efficiency is improved; and the prepared pipeline has the high acidic medium etching resisting capability by using quartz powder and nano-zinc oxide in the outer layer sleeve, and accordingly the service life of the gas pipeline is prolonged.

Owner:新兴中燃城市燃气发展有限公司

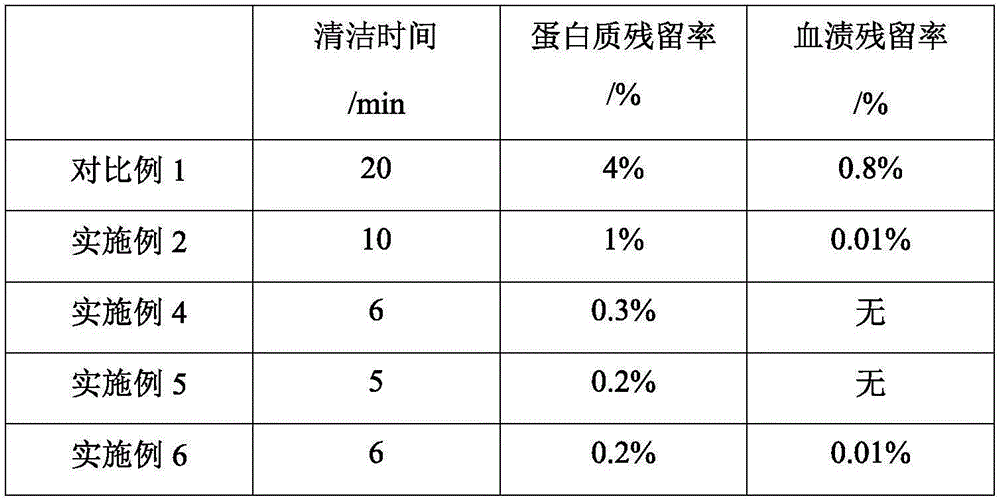

Biological multienzyme cleaning agent and preparation method thereof

InactiveCN105154253AKeep aliveExtension of timeInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAmylaseDecomposition

The invention discloses a biological multienzyme cleaning agent which is characterized by comprising the following raw materials in parts by weight: 15.5-94 parts of deionized water, 1-10 parts of citric acid, 1-20 parts of propylene glycol, 1-10 parts of sodium hydroxide, 1-10 parts of protease, 0.1-6 parts of amylase, 0.1-4 parts of lipase and 0.1-4 parts of cellulase. According to the biological multienzyme cleaning agent, the problem of the conventional multienzyme cleaning agent that enzymes have high possibility of inactivation and hydrolysis is solved; a stable environment is provided, so that the multiple enzymes can coexist in the environment in long term; the validity period of the biological multienzyme cleaning agent can be kept; meanwhile, the decomposition rate of the multiple enzymes cannot be reduced.

Owner:HUBEI MULAN TONGDA TECH

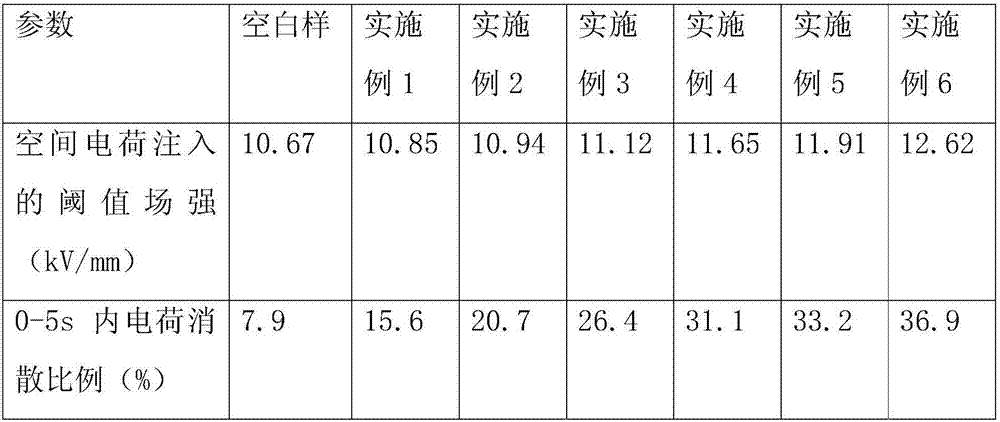

Method for preparing meta-aramid-fiber insulating paper capable of inhibiting space charge accumulation

ActiveCN107044073AInhibits space charge build-upSlow motion ratePlastic/resin/waxes insulatorsSpecial paperIonElectric field

The invention provides a method for preparing meta-aramid-fiber insulating paper capable of inhibiting space charge accumulation. Through modifying meta-aramid-fiber insulating paper by using nano TiO2, the meta-aramid-fiber insulating paper, which has excellent performance, can inhibit space charge accumulation, has excellent insulating property and mechanical properties and is applicable to high-electric-field environments. The method provided by the invention comprises the following steps: a. mixing meta-aramid-fiber chopped fibers and meta-aramid-fiber pulp, and carrying out dispersing, relieving and pulping, so as to prepare a paper pulp mixed solution; b. mixing the paper pulp mixed solution prepared in the step (a) with nano TiO2 and a deionized water solution, carrying out relieving, then, carrying out pulping, so as to prepare nano TiO2 modified meta-aramid-fiber paper pulp; carrying out papermaking forming on the nano TiO2 modified meta-aramid-fiber paper pulp prepared in the step (b), thereby preparing the meta-aramid-fiber insulating paper capable of inhibiting space charge accumulation.

Owner:STATE GRID CORP OF CHINA +2

Double-static waste gas wet method electrostatic dust collector

InactiveCN104028380AImprove dust collection efficiencyReduce manufacturing costParticle charging/ionising stationsExternal electric electrostatic seperatorElectric fieldElectrostatic precipitator

The invention discloses a double-static waste gas wet method electrostatic dust collector. The double-static waste gas wet method electrostatic dust collector comprises a dust collector main body, wherein the dust collector main body comprises a dust collector shell; a first uniform direct-current high-voltage electric field mechanism and a second uniform direct-current high-voltage electric field mechanism are arranged in the dust collector shell; the first uniform direct-current high-voltage electric field mechanism is arranged at the front side of the second uniform direct-current high-voltage electric field mechanism; an air inlet communicated with the first uniform direct-current high-voltage electric field mechanism is formed in the left side of the middle of the dust collector shell; an air outlet is formed in the right side of the middle of the dust collector shell; a gas condenser is arranged in the inlet position of the air inlet; atomization spraying mechanisms are respectively arranged above the first uniform direct-current high-voltage electric field mechanism and the second uniform direct-current high-voltage electric field mechanism; and the first uniform direct-current high-voltage electric field mechanism, the second uniform direct-current high-voltage electric field mechanism and the atomization spraying mechanisms are all controlled by an electric control device.

Owner:ZHEJIANG HAILIANG ENERGY MANAGEMENT +2

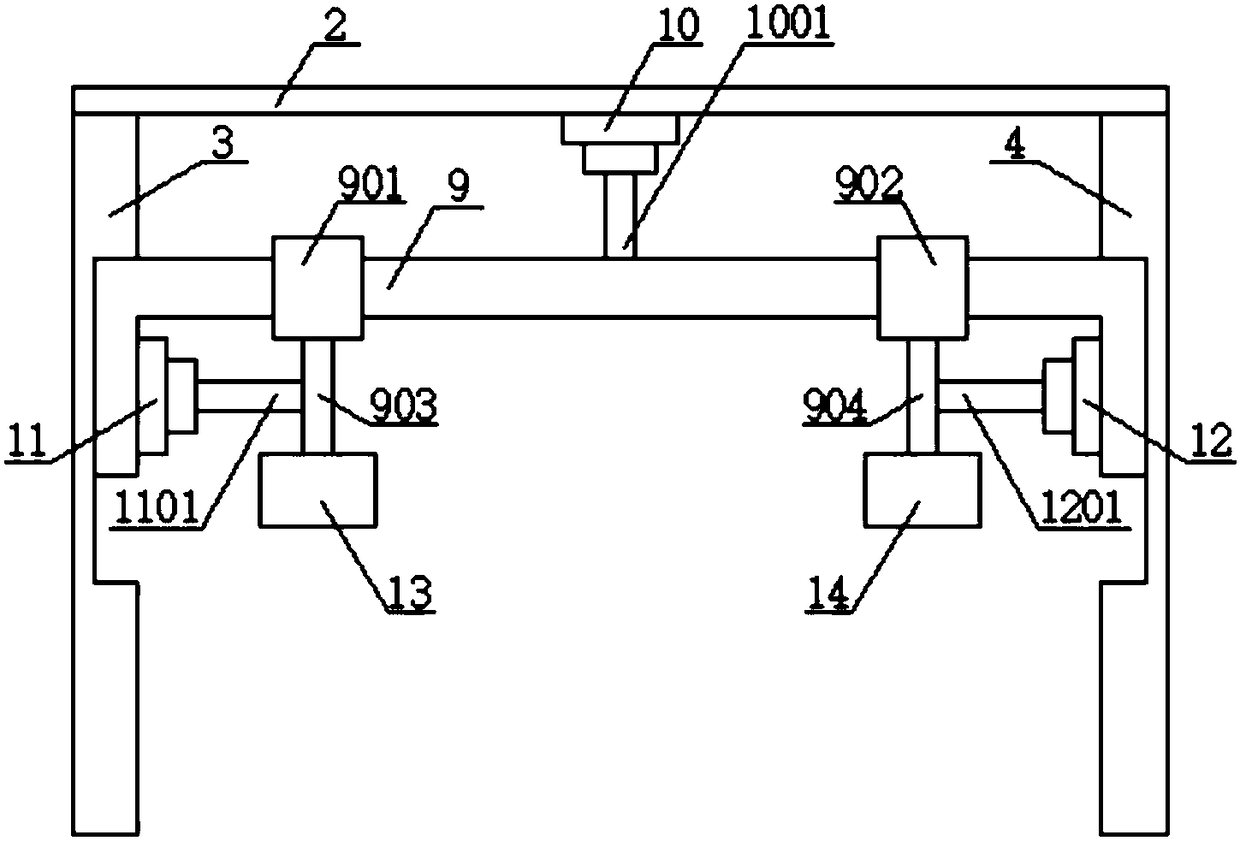

Polishing device for heat-isolation material, and polishing method thereof

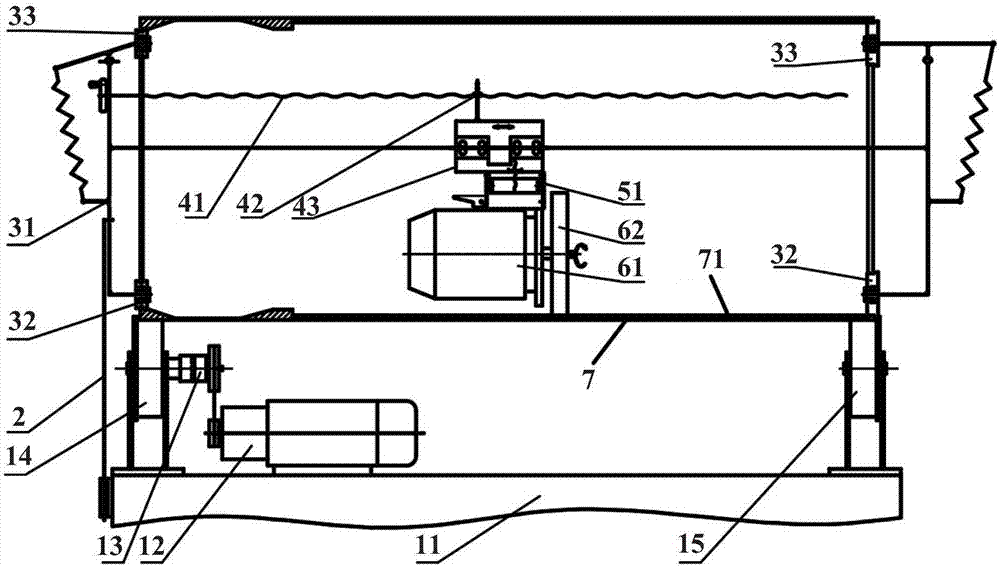

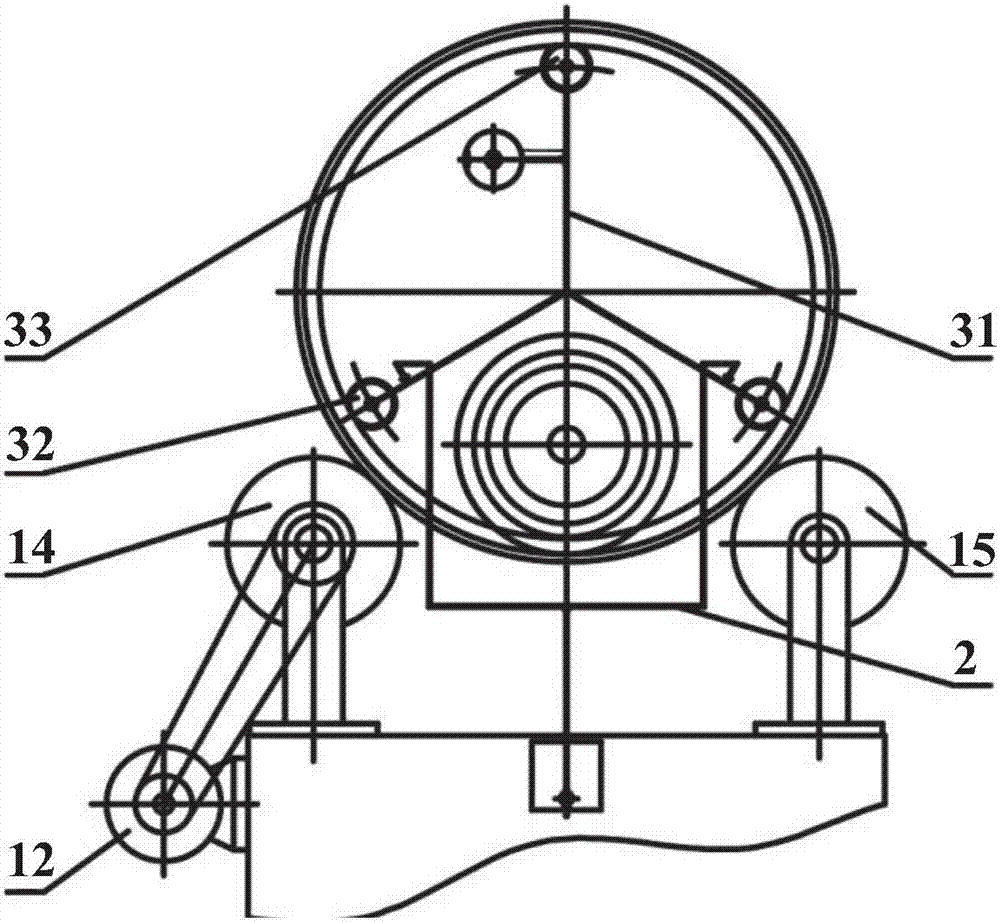

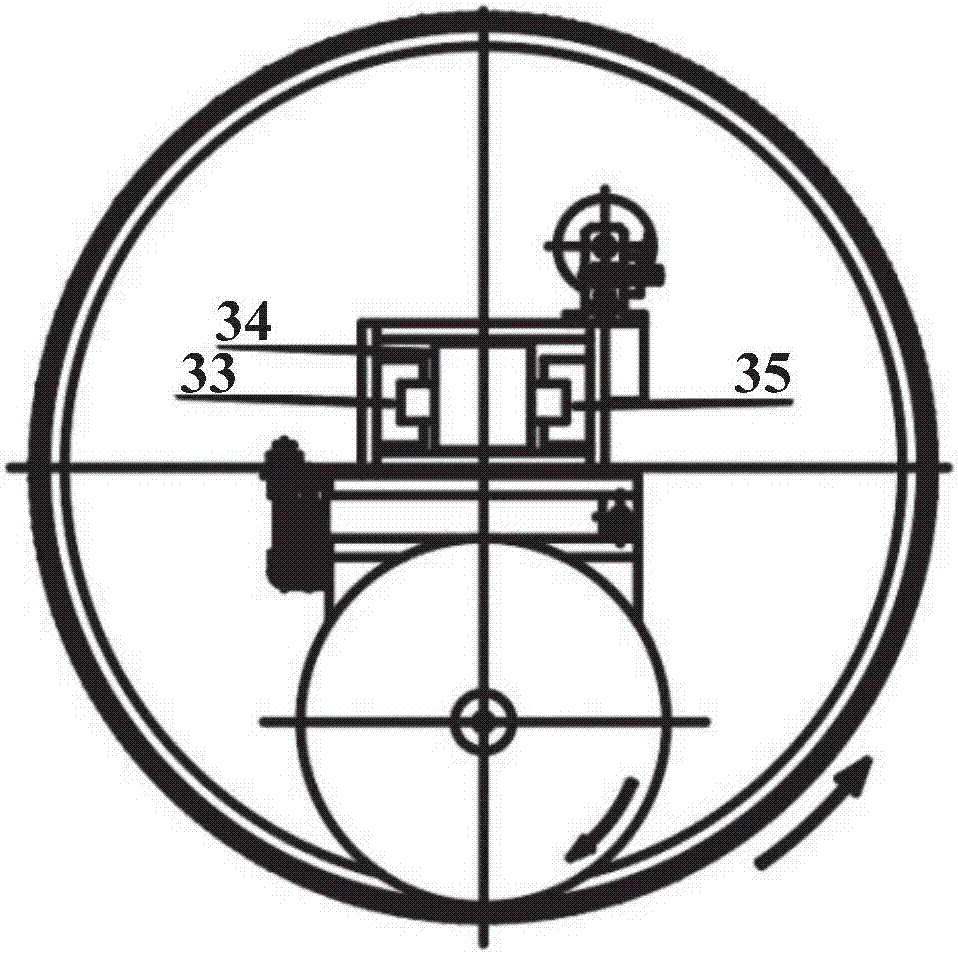

ActiveCN107139031ARealize automatic grinding processLarge grinding areaRevolution surface grinding machinesGrinding drivesSupporting systemElectronic control system

The invention provides a polishing device for a heat-isolation material, and a polishing method thereof. The polishing device for the heat-isolation material comprises a base bench system, a limit mechanism, a beam frame reference support system, a guide rail box movement system, a feeding adjustment clamping mechanism, a grinding power head and an electronic control system. According to the polishing device for the heat-isolation material, the polishing position of the grinding power head is strictly limited through the arrangement of the beam frame reference support system, so that more accurate polishing is achieved, and the roundness of the surface of the polished workpiece is improved.

Owner:CHINA BUILDING MATERIALS ACAD

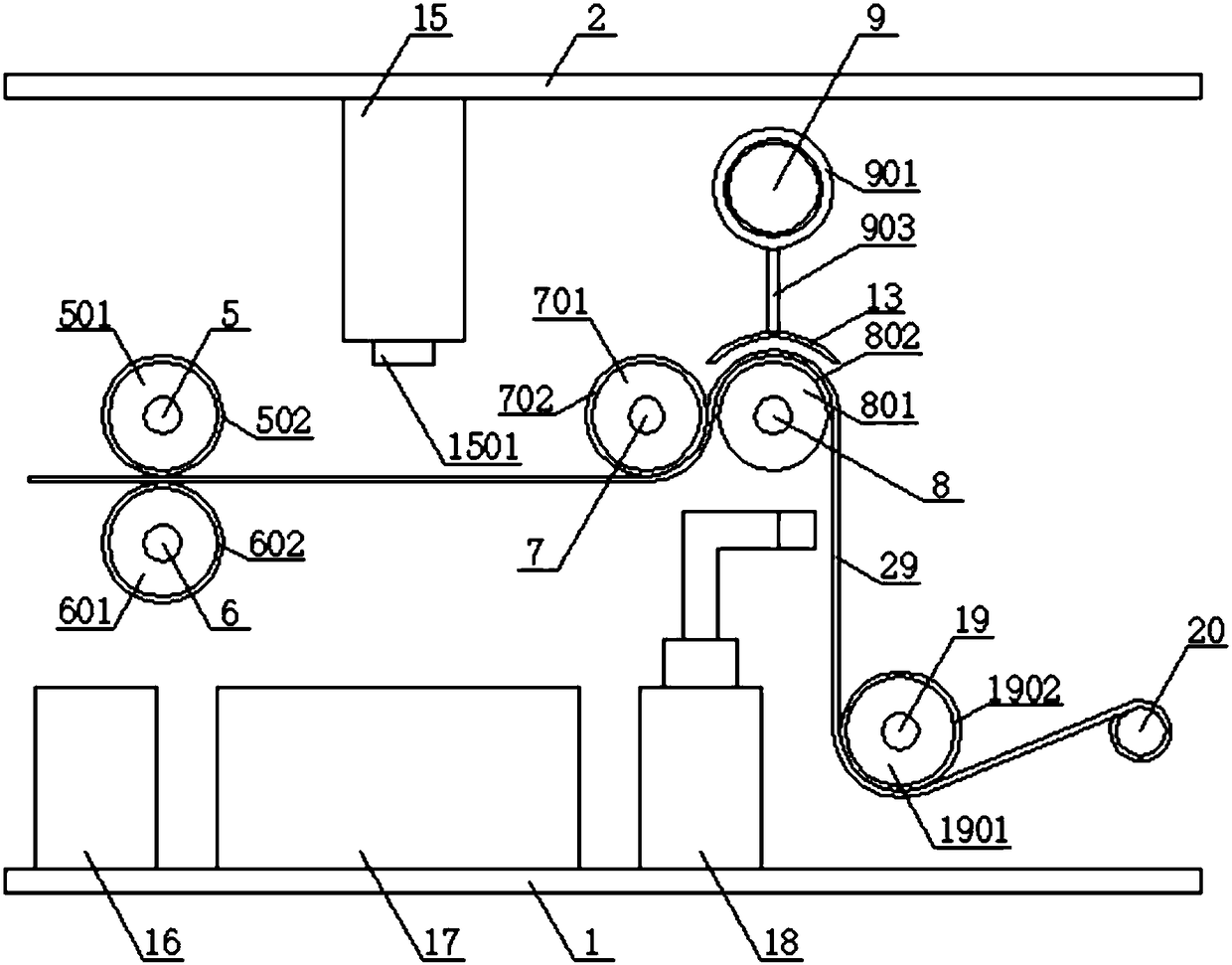

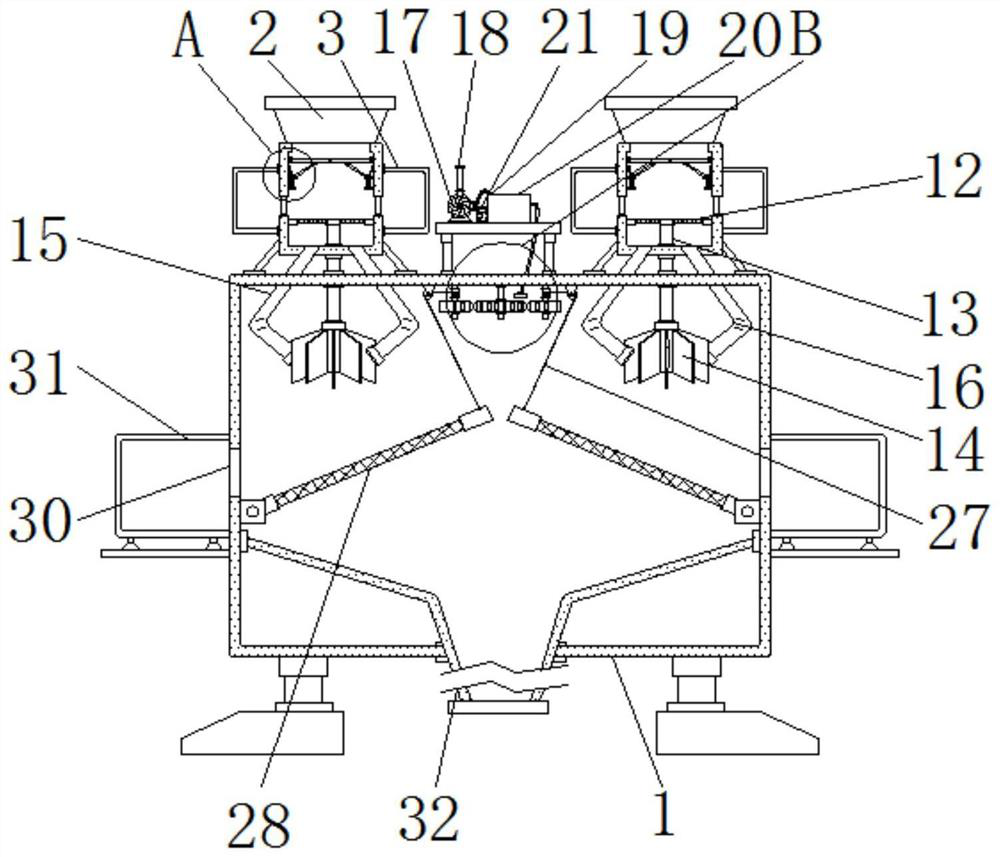

Knitwear product rolling-inspecting and selvedge-uncurling equipment

InactiveCN108342893ARealize the winding workRealize stripping workInspecting textilesWebs handlingTextileMechanical engineering

The invention relates to the technical field of knitting machinery, and discloses knitwear product rolling-inspecting and selvedge-uncurling equipment which comprises a base, wherein a second rack anda third rack are respectively mounted on a left side and a right side of the base; a first support shaft and a second support shaft are mounted directly behind centers of inner surfaces of the secondrack and the third rack; a third support shaft and a fourth support shaft are mounted directly in front of the first support shaft; an image collector with a camera at the bottom end is mounted rightabove a knitted textile product between the third support shaft and the first support shaft; the image collector is connected with a visual checker; the visual checker is connected with a PLC; the PLC is connected with a rejection controller; a selvedge uncurler is mounted right above a fourth shaft sleeve; a rolling shaft is mounted right above a front end of an upper surface of the base. The knitwear product rolling-inspecting and selvedge-uncurling equipment provided by the invention solves technical problems that the conventional knitwear product rolling machine cannot realize intelligentinspection, intelligent rejection of defective products and intelligent selvedge-uncurling at the same time.

Owner:桐乡市顺洪针织厂

A sewage treatment device for industrial production that is easy to clean up waste water scum

Owner:长三角义乌生态环境研究中心 +1

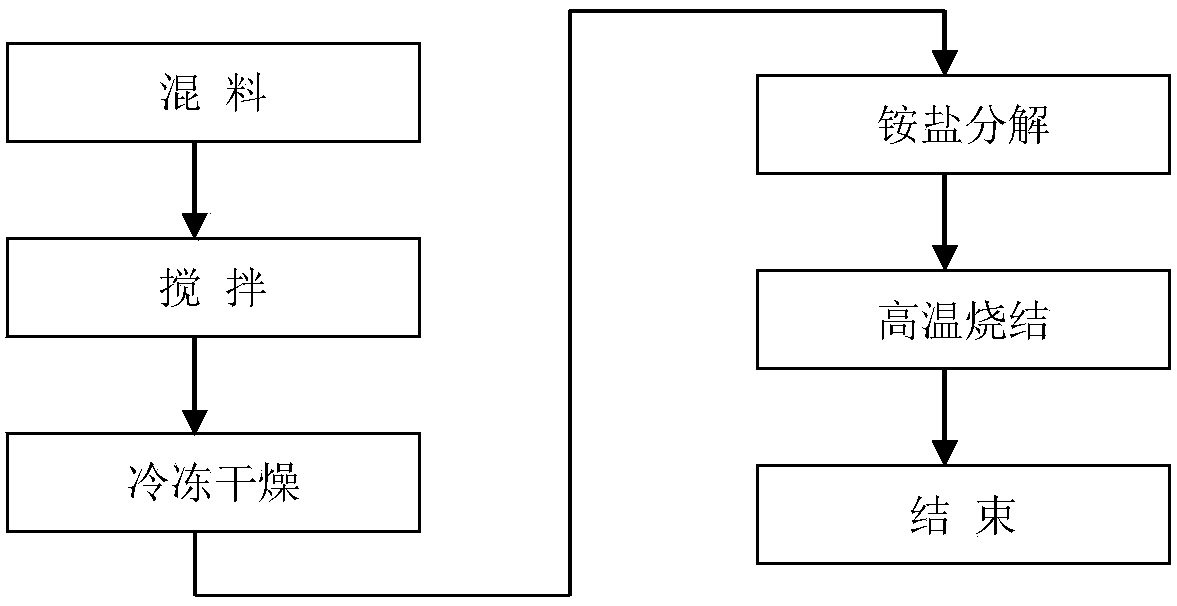

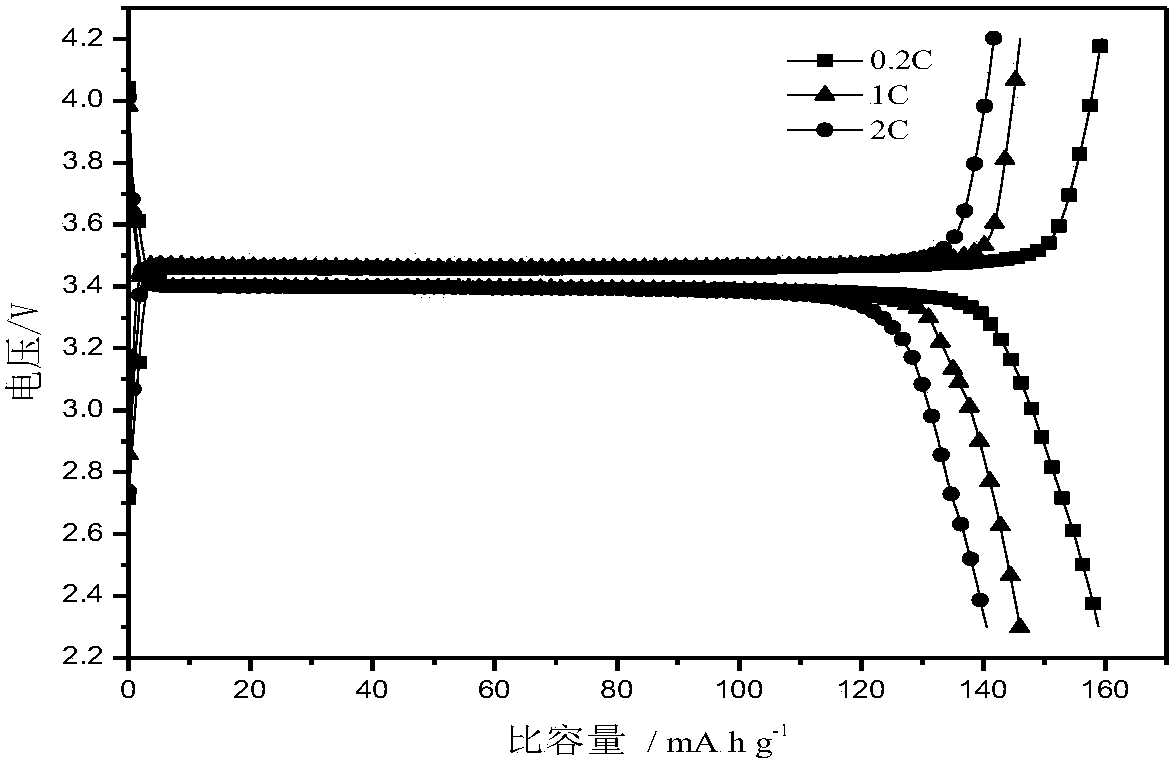

A kind of preparation method of porous carbon-coated lithium iron phosphate cathode material

ActiveCN105576220BIncreased diffusion rateImprove rate discharge performanceElectrode thermal treatmentSecondary cellsPorous carbonGas phase

Owner:江西智锂科技股份有限公司

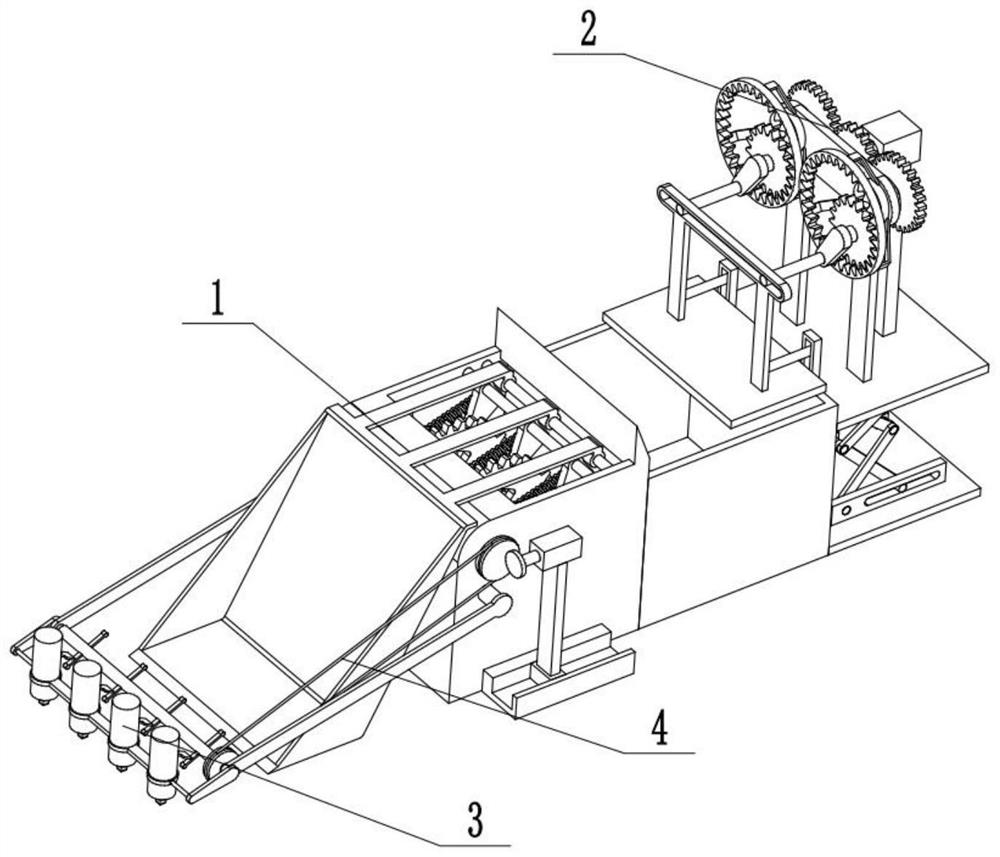

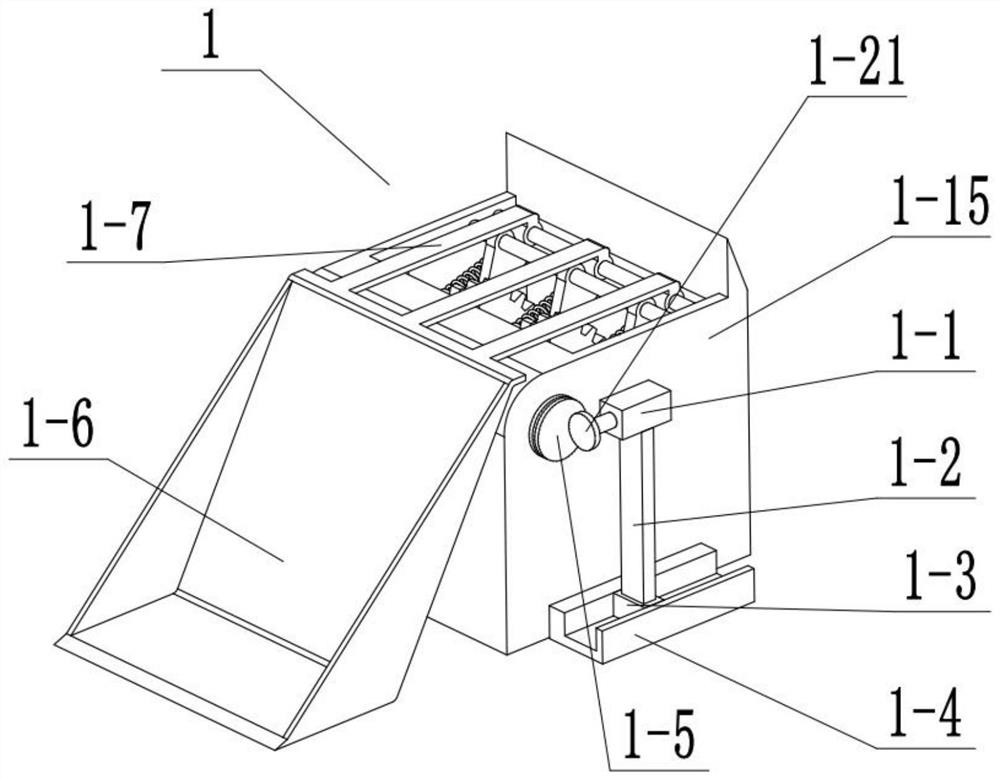

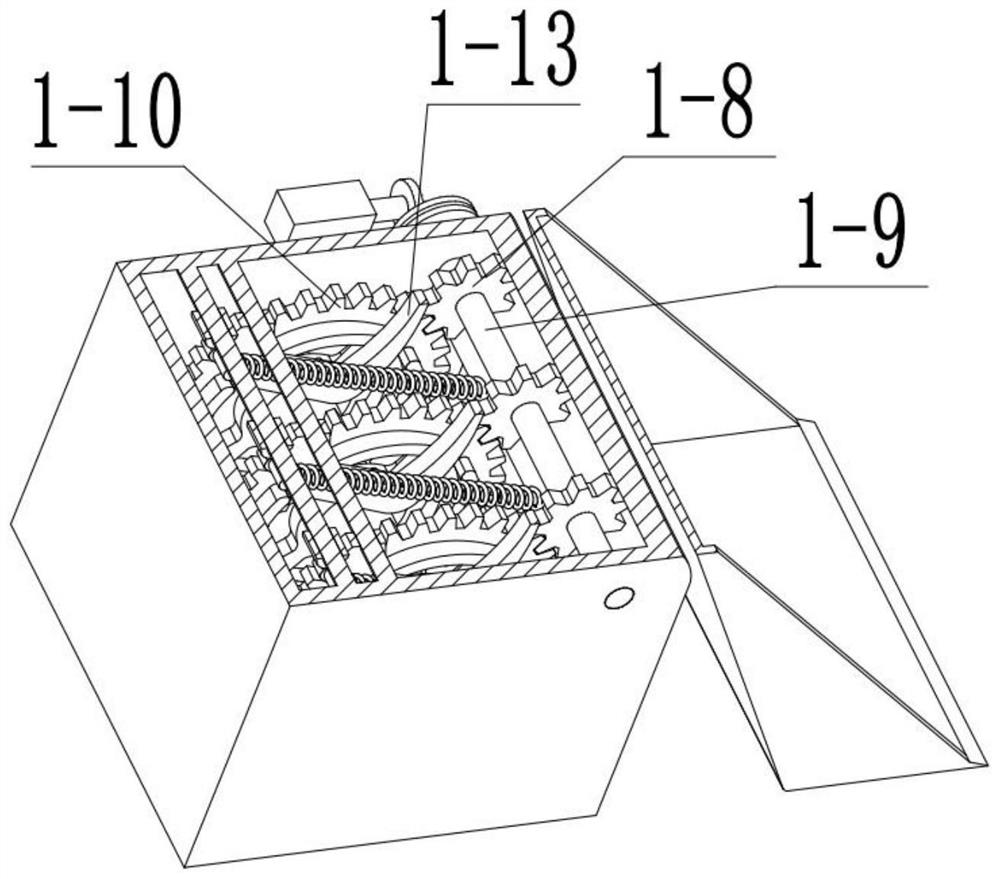

Automatic snow shoveling and loading device

InactiveCN112593521AChange initial positionChange rotation rateSnow cleaningElectric machineryEngineering

The invention relates to the field of engineering, in particular to an automatic snow shoveling and loading device. The functions of automatic snow collecting and truck loading can be achieved, the ice shaving function can be achieved, the position of the motor is changed, and the ice shaving and truck loading speed can be adjusted; and the automatic compaction height can be adjusted by adjustingthe height of the lifter. The device comprises a snow collecting device; a compaction device; an icebreaking device; and a belt which changes the rotating speed of the first rotating wheel, so that the snow collecting speed is changed, the snow collecting speed can be increased on the road surface with much blood and snow, the snow collecting speed can be decreased on the road surface with littlesnow, energy is saved, and variability is improved. The initial position of the compaction plate is changed, so that the snow compaction effect is changed; the rotating speed of the rotating wheel IIIis changed, so that the rotating speed of the functional rod is changed, the movement speed of the ice breaking head is changed, the ice breaking and snow hardening speed is changed, the speed can beincreased on a road with more ice, the speed can be reduced on a road with less ice, energy is saved, and variability is improved.

Owner:王辰

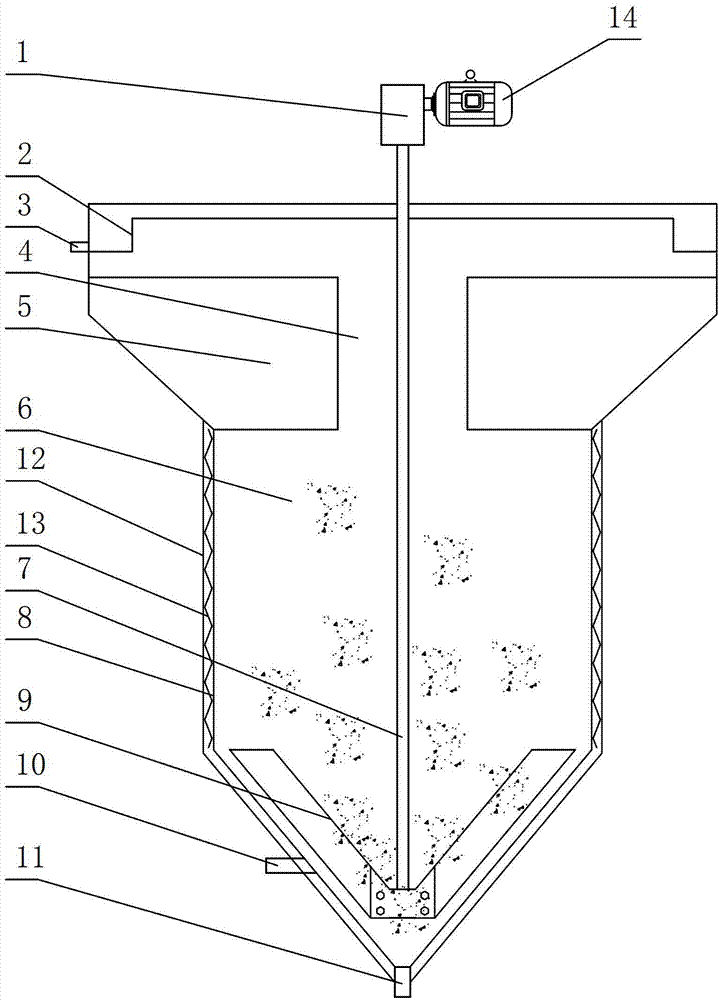

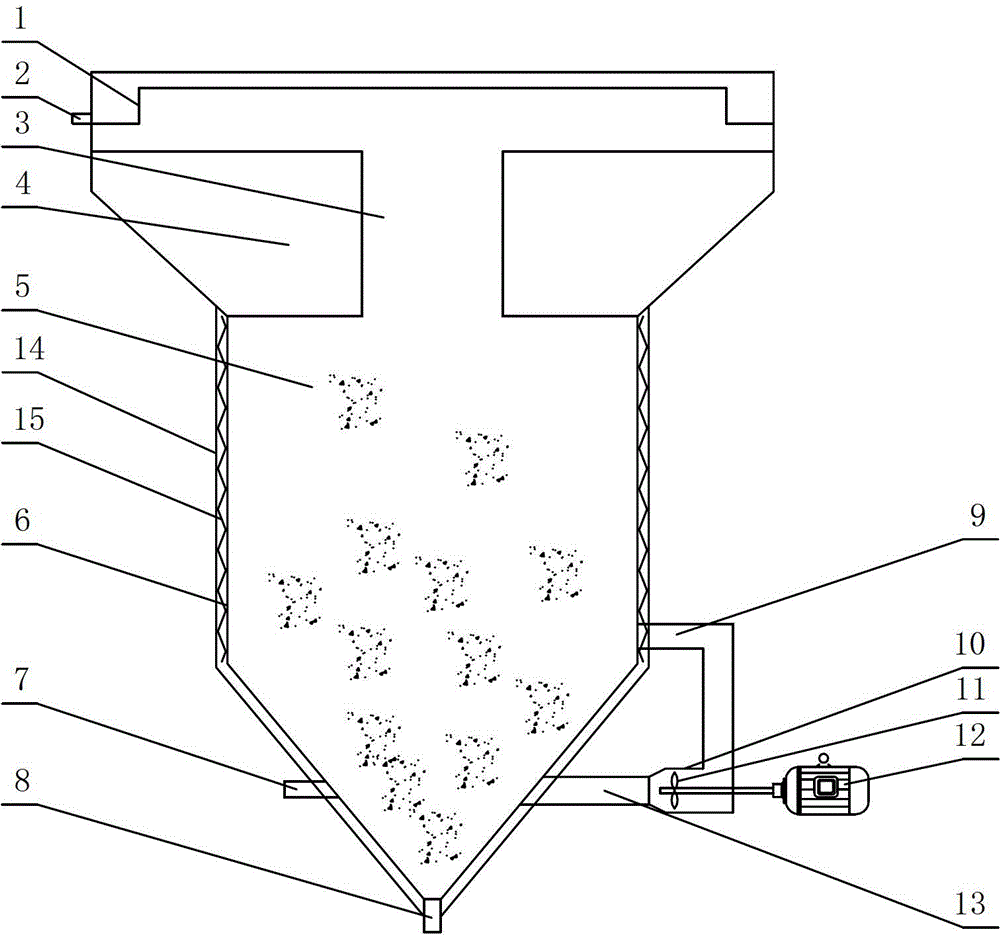

Integrated device for liquefying and mechanizing kitchen waste

ActiveCN103056150BReduce the concentration of dissolved liquidReduce line speedSolid waste disposalEngineeringIntegrated devices

The invention discloses an integrated device for liquefying and mechanizing kitchen waste. The integrated device for liquefying and mechanizing the kitchen waste comprises a reactor and a heating tracing device packed on the outer side of the reactor; a stirring device for uniformly stirring the kitchen waste inside the reactor is mounted at the bottom inside the reactor; a turbulent flow board for dividing the reactor into a reaction area and a liquid outlet area is further mounted at the upper part of the reactor; and a depression area for conveniently realizing solid-liquid separation of a kitchen waste mixture is formed by the turbulent flow board in the reactor. The integrated device for liquefying and mechanizing the kitchen waste, provided by the invention, controls a flow state of the kitchen waste in a liquefying reactor through mechanical stirring; when the integrated device for liquefying and mechanizing the kitchen waste is operated, the kitchen waste is rapidly scattered in the reaction area under the stirring effect of a stirring blade, so that the kitchen waste is in a liquefied state, the linear speed of the kitchen waste mixture is reduced through the turbulent flow board, and the solid-liquid separation of the kitchen waste mixture is realized in the depression area. The integrated device for liquefying and mechanizing the kitchen waste, provided by the invention, is applicable to liquefying the kitchen waste.

Owner:广州中科建禹环保有限公司

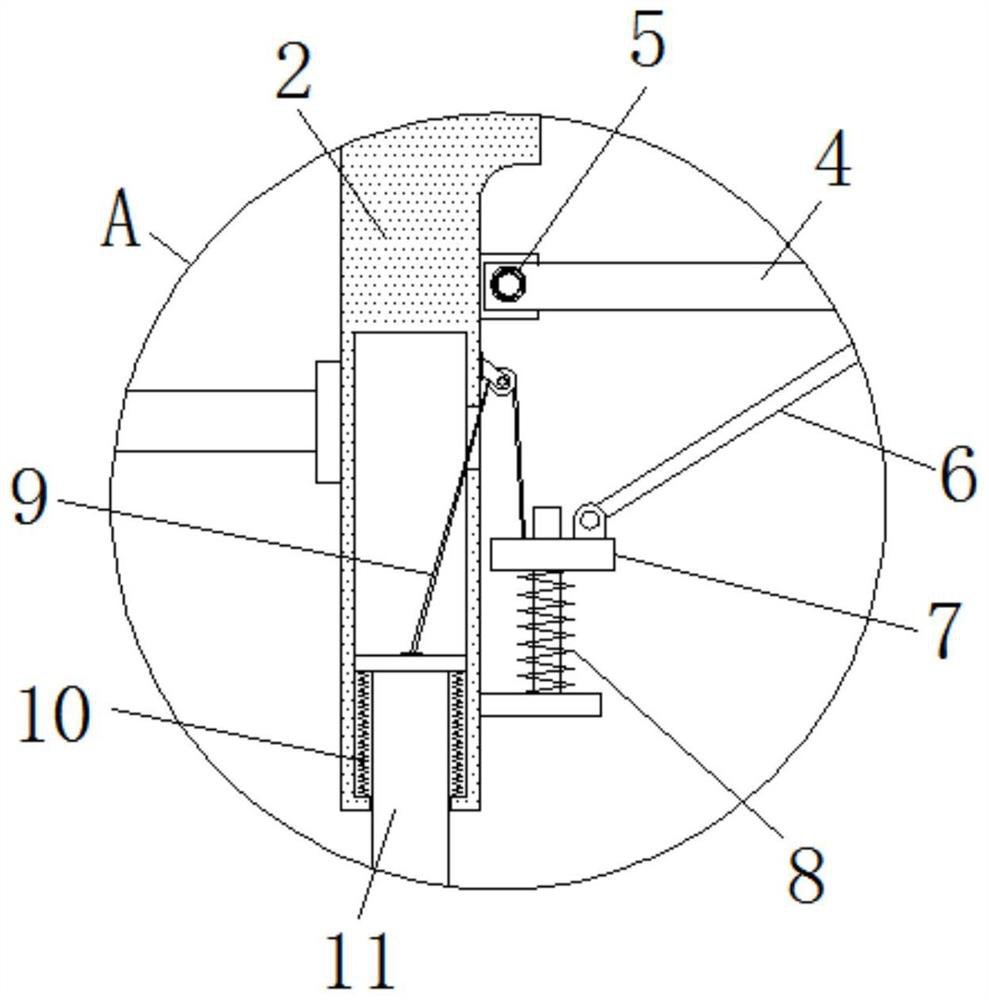

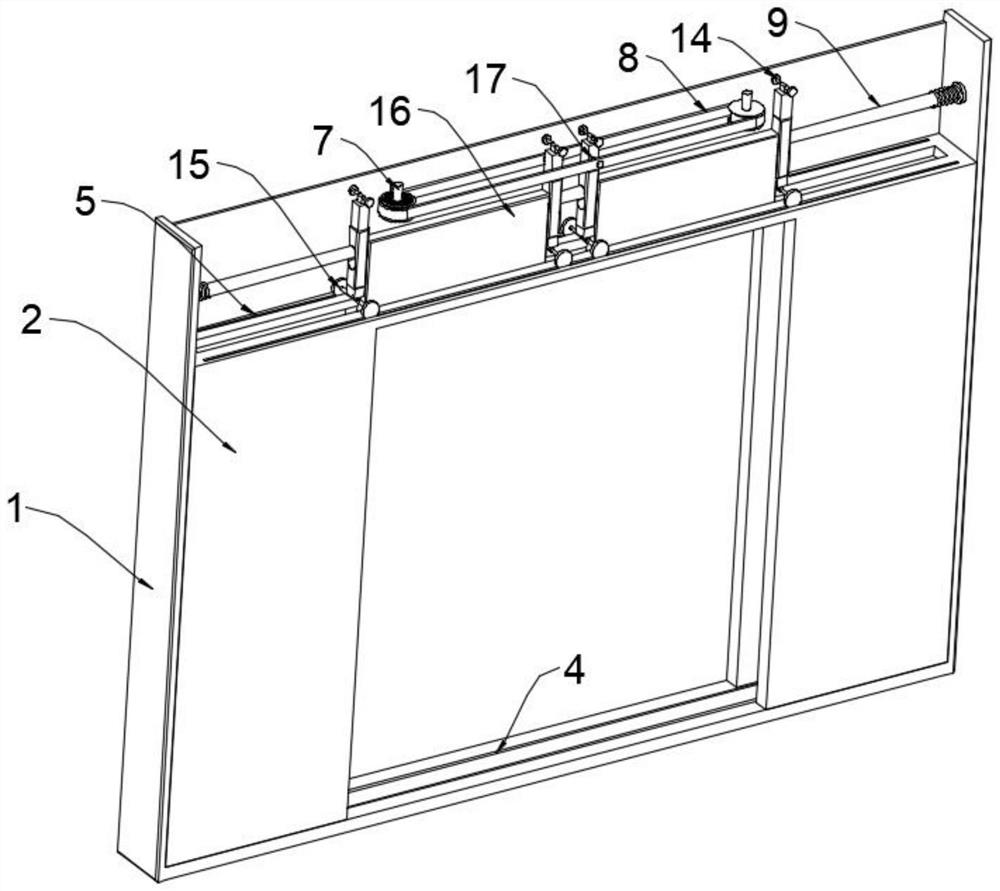

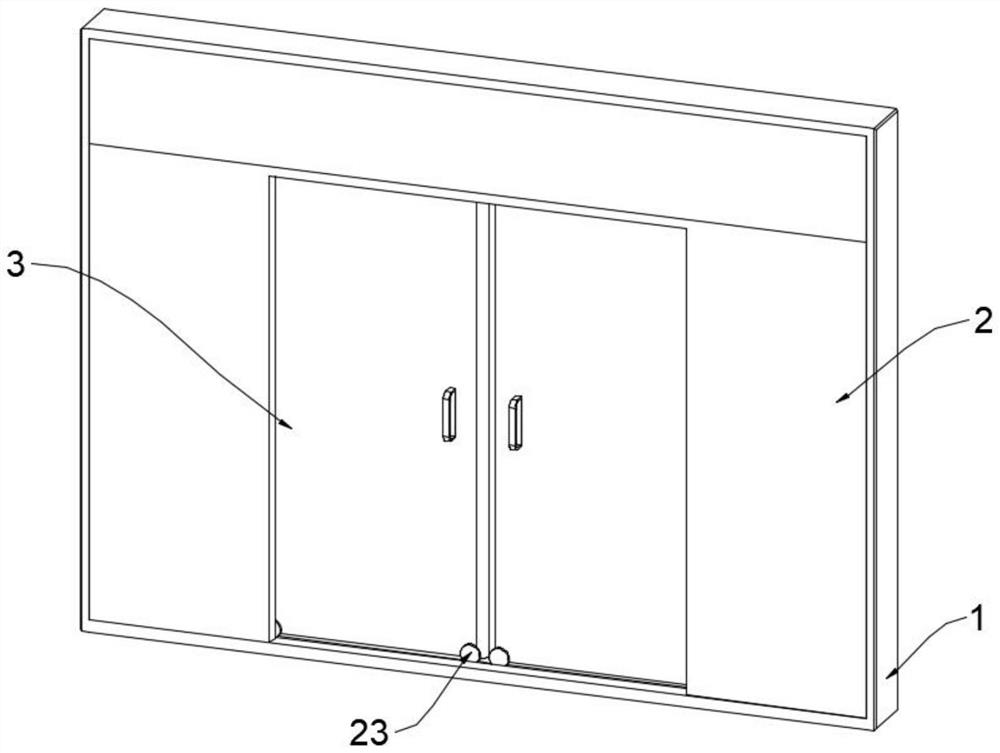

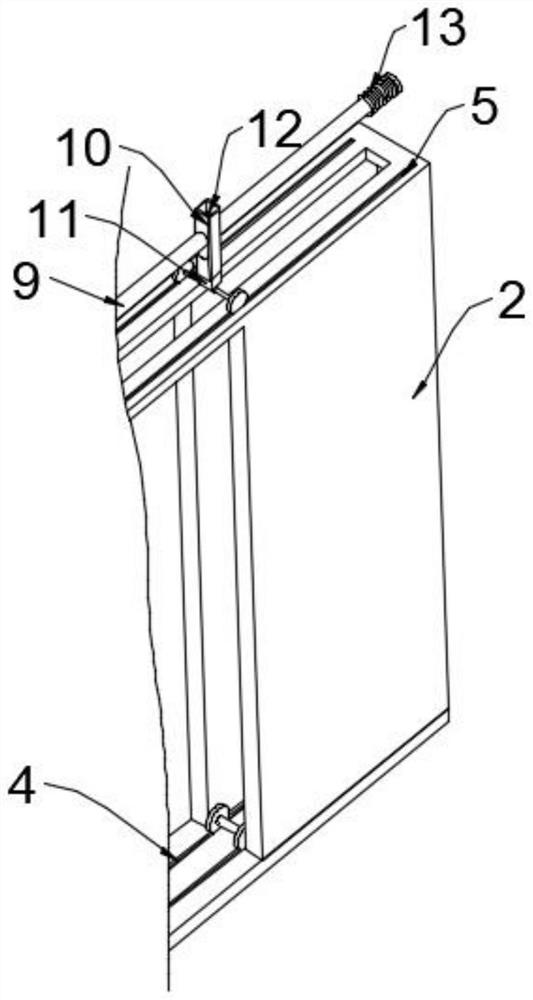

Damping type mute track structure applied to sliding door

InactiveCN114263419AEasy to useSlow motion rateBuilding braking devicesWing arrangementsTrackwayEngineering

The invention provides a damping type mute track structure applied to a sliding door, which comprises a frame body and partition plates fixedly mounted in the frame body and symmetrically arranged, and the frame body is further movably provided with symmetrically arranged movable doors; the first track structures are movably and symmetrically arranged on the frame body and connected with the movable door, and the first track structures move when the movable door is stressed so that the movable door can move; the second rail mechanisms are movably and symmetrically arranged between the frame body and the partition plate and are connected with the movable door; the limiting mechanism is movably arranged in the frame body and connected with the second track mechanism, and the limiting mechanism fixes the second track mechanism after the second track mechanism moves to the maximum stroke position; and the transmission assembly is connected with the second rail mechanism and the limiting mechanism.

Owner:帅保军

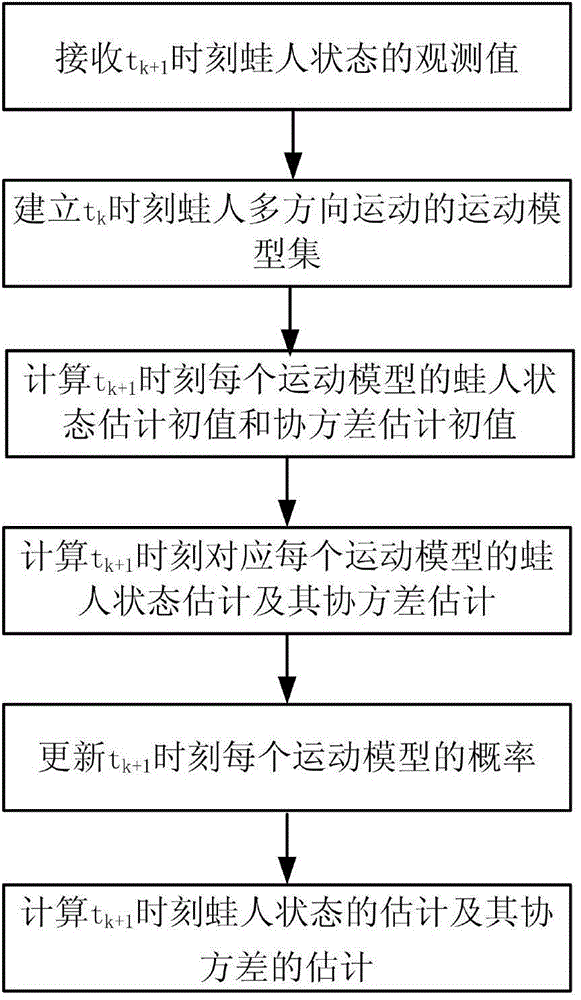

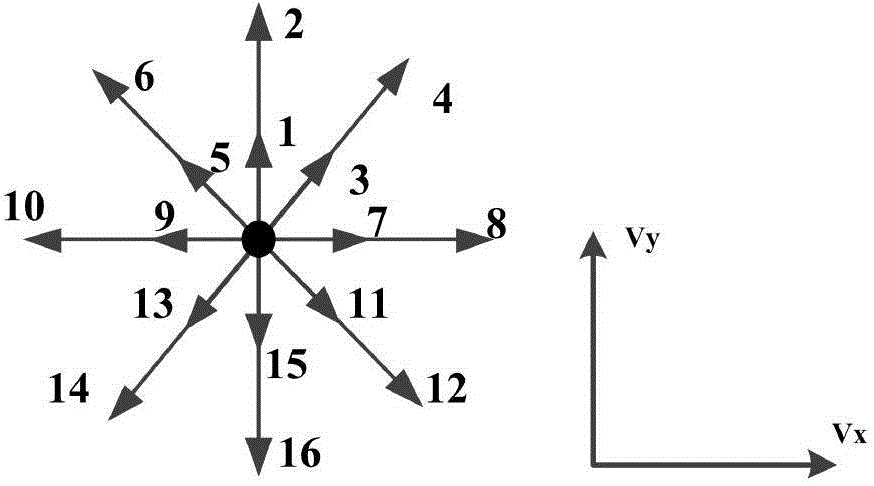

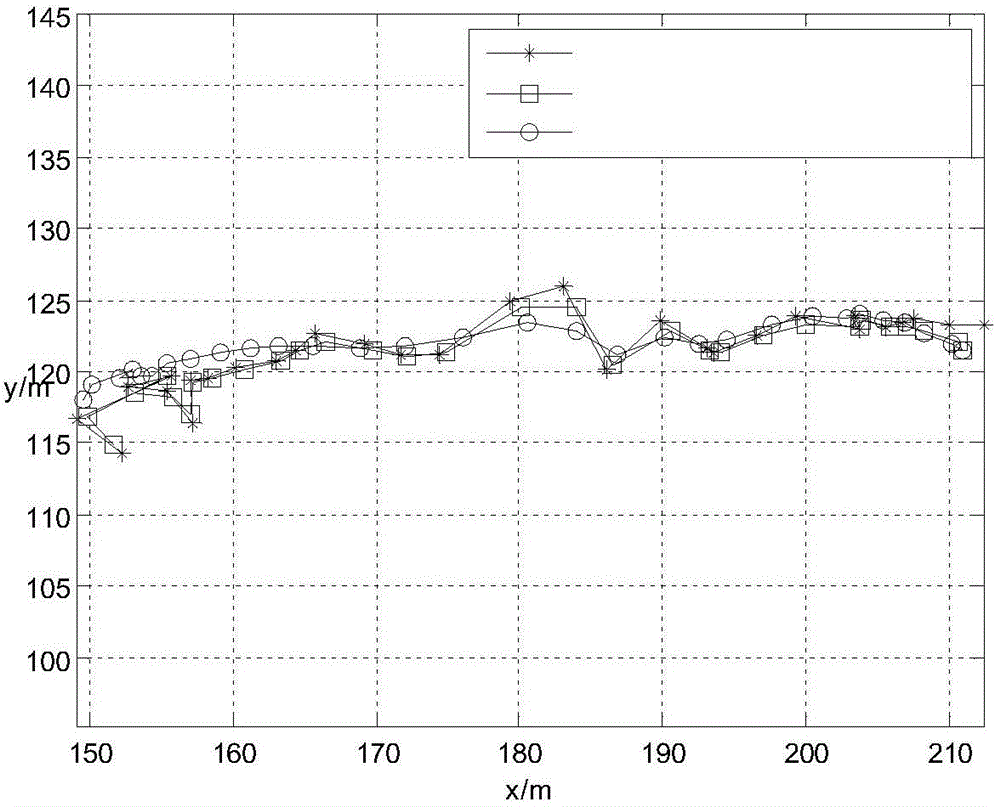

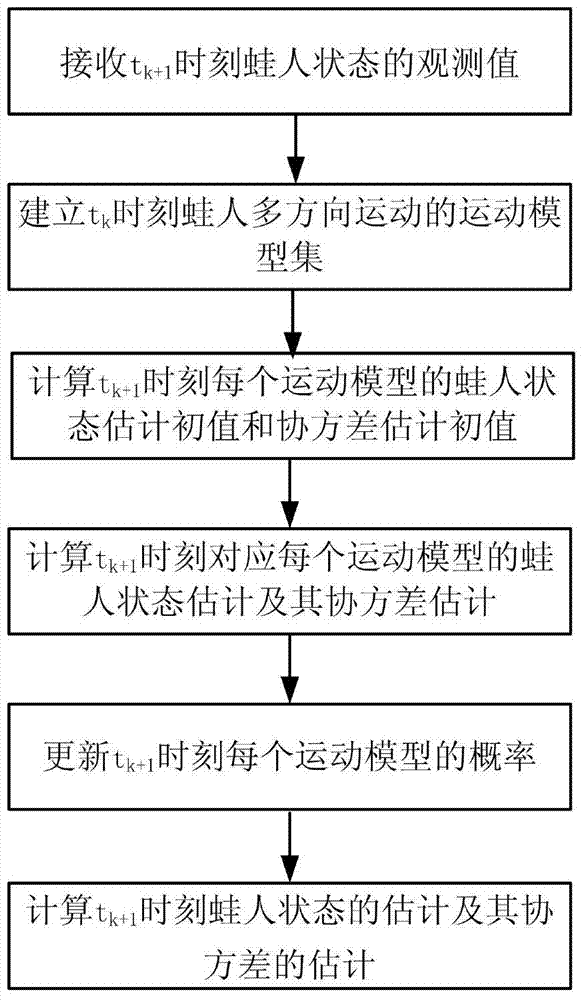

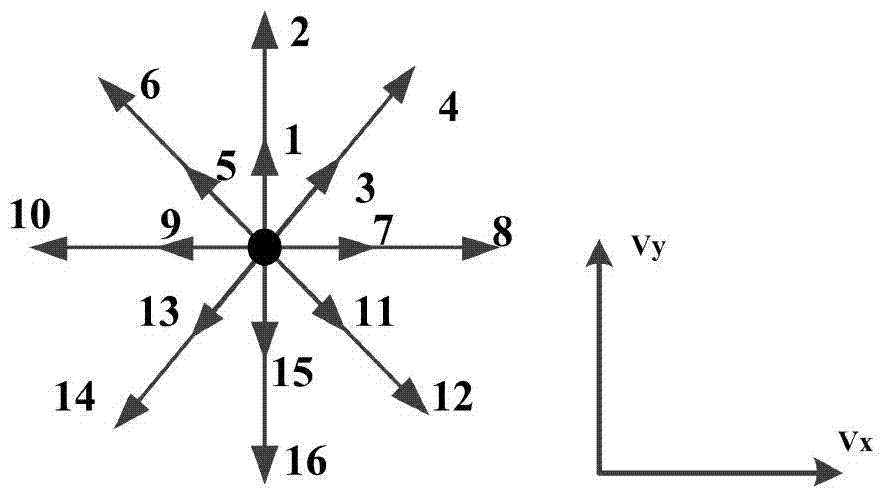

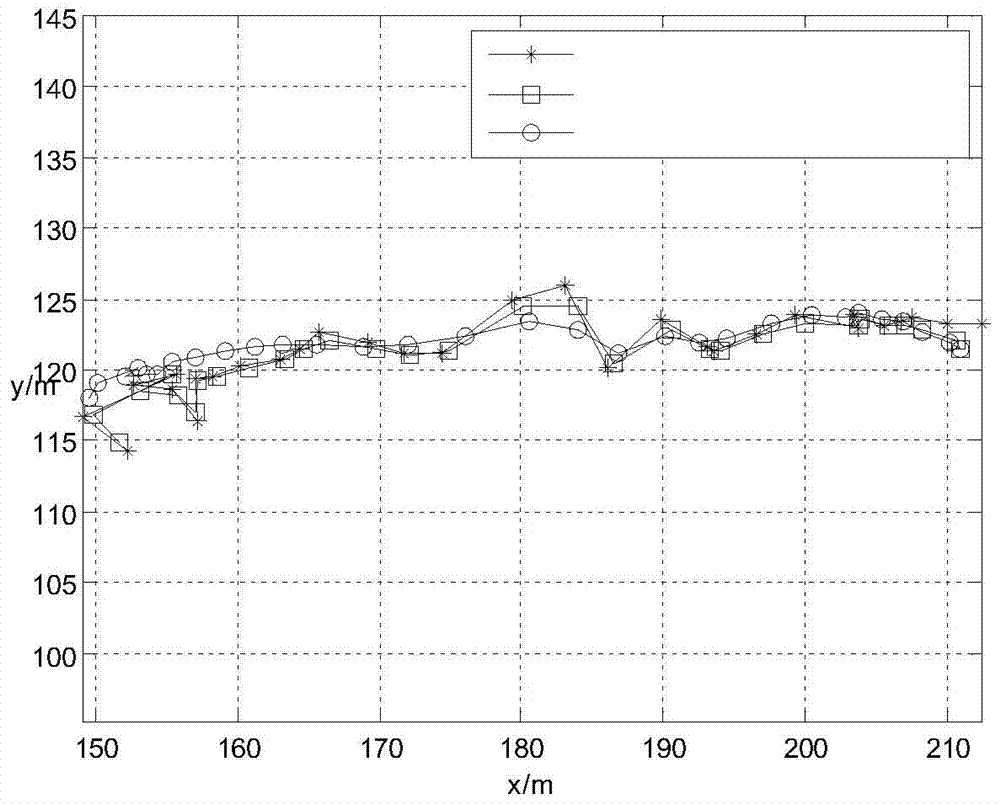

Tracking method of diver

ActiveCN105699977AAccurately reflectRobust reflectionAcoustic wave reradiationCovarianceComputer science

The invention relates to a tracking method of a diver. The method includes the following steps that: step 1) the observation value of the state of the diver at a tk+1 time point is received; step 2) a movement model set of the multi-direction movement of the diver at a tk time point is established; step 3) the diver state estimation initial value and covariance estimation initial value of each movement model at the tk+1 time point are calculated according to the movement model set; step 4) the diver state estimation initial value and covariance estimation initial value of each movement model at the tk+1 time point are inputted into a plurality of filters, and the diver state estimation and covariance estimation of each movement model are calculated based on the observation value of the state of the diver at the tk+1 time point; step 5) the probability of each movement model at the tk+1 time point is updated according to the diver state estimation and covariance estimation of each movement model at the tk+1 time point; and 6) fusion estimation is performed on the states of the diver according to the updated probability of each movement model, so that the estimation of the state of the diver and the estimation of the covariance of the state of the diver at the tk+1 time point can be realized. The method of the invention has the advantages of high precision and high stability.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Preparation method of meta-aramid insulating paper for suppressing space charge accumulation

ActiveCN107044073BTotal charge reductionPromote accumulationPlastic/resin/waxes insulatorsSpecial paperPulp and paper industryAqueous solution

The invention provides a method for preparing meta-aramid-fiber insulating paper capable of inhibiting space charge accumulation. Through modifying meta-aramid-fiber insulating paper by using nano TiO2, the meta-aramid-fiber insulating paper, which has excellent performance, can inhibit space charge accumulation, has excellent insulating property and mechanical properties and is applicable to high-electric-field environments. The method provided by the invention comprises the following steps: a. mixing meta-aramid-fiber chopped fibers and meta-aramid-fiber pulp, and carrying out dispersing, relieving and pulping, so as to prepare a paper pulp mixed solution; b. mixing the paper pulp mixed solution prepared in the step (a) with nano TiO2 and a deionized water solution, carrying out relieving, then, carrying out pulping, so as to prepare nano TiO2 modified meta-aramid-fiber paper pulp; carrying out papermaking forming on the nano TiO2 modified meta-aramid-fiber paper pulp prepared in the step (b), thereby preparing the meta-aramid-fiber insulating paper capable of inhibiting space charge accumulation.

Owner:STATE GRID CORP OF CHINA +2

A multifunctional valve and its combination valve

InactiveCN103133720BIncrease resistanceSlow motion rateMultiple way valvesFluid-pressure actuatorsEngineeringOperation safety

The invention relates to a multifunctional valve and a multifunctional valve combination valve. The multifunctional valve and the multifunctional valve combination valve comprise a valve body, a valve cavity which is arranged in the valve body and a valve rod which is arranged in the valve cavity, wherein a middle inlet, a left inlet and a right inlet are arranged on one side of the valve body, the middle inlet is used for the entering of pressure mediums, the left inlet and the right inlet are used for the selective entering of the pressure mediums, a left outlet and a right outlet are arranged on the other side of the valve body, the left outlet and the right outlet are used for the discharging of the pressure mediums, and the left inlet and the left outlet and the right inlet and the right outlet are selectively communicated in a corresponding mode through the matching of the valve cavity and the valve rod. The multifunctional valve and the multifunctional valve combination valve are characterized in that the left inlet is communicated with a left cavity correspondingly, the right inlet is communicated with a right cavity correspondingly, and correspondingly, the left cavity and the right cavity are communicated with the left outlet and the right outlet through a left throttle valve and a right throttle valve. According to the multifunctional valve and the multifunctional valve combination valve, a piston can be slowly contacted with the end portion of a piston cylinder, the collision and the abrasion to a piston rod when the piston is moved rapidly are avoided, the service life of the piston cylinder is prolonged effectively, and meanwhile the operation safety of the piston cylinder and the stability of the piston cylinder are ensured.

Owner:皇甫美蓉

Multi-stage spray treatment device for waste gas of printing and dyeing setting machine

InactiveCN103405977BSlow motion rateImprove dust collection efficiencyUsing liquid separation agentSpray nozzleTower

The invention discloses a multi-stage spray treatment device for waste gas of a printing and dyeing setting machine. The multi-stage spray treatment device comprises purification chambers including a primary purification chamber and a secondary purification chamber, wherein the interior of the primary purification chamber is divided into multiple layers of purification areas through partition boards; the partition boards are horizontally arranged in parallel in a staggered manner; an all-directional fine atomization area is arranged above a second air inlet of the secondary purification chamber; a water curtain wall blockage area is arranged at the upper part of the fine atomization area; a plurality of tower plates are vertically arranged in the water curtain wall blockage area, a plurality of spray nozzles are placed between the inner wall of the water curtain wall blockage area and the tower plates and between every two tower plates in a staggered manner, and the outlet directions of the spray nozzles are opposite; the spray nozzles spray airflow and water to the inner wall of the water curtain wall blockage area or the tower plate walls simultaneously to form a water curtain wall, so that liquid drops flow downwards along the tower plate walls or the inner wall of the water curtain wall blockage area, and the purified gas runs upwards continuously. According to the invention, the spray mechanism has three different effects, so that the dust collecting efficiency is improved, the production cost is reduced, and the multi-stage spray treatment device can be widely applied to treatment of waste gas of the printing and dyeing setting machine.

Owner:ZHEJIANG HAILIANG ENERGY MANAGEMENT +2

Kitchen waste liquefaction double cycle treatment integrated device

ActiveCN103100556BReduce the concentration of dissolved liquidReduce line speedSolid waste disposalLiquefactionIntegrated devices

The invention discloses a kitchen waste liquefaction and double-cycle treatment integrated device comprising a reactor and a heat tracing device coated on the outer side of the reactor, wherein an outer cycle device which is communicated with the inside of the reactor and is used for uniformly stirring kitchen waste inside the reactor by using material flow is further mounted on the outer side of the reactor; a turbulent flow board for dividing the reactor into a reaction area and a liquid outlet area is further mounted at the upper part of the reactor, and forms a depression area for realizing solid-liquid separation of kitchen waste mixture in the reactor. The kitchen waste liquefaction and double-cycle treatment integrated device provided by the invention controls a flow state of the kitchen waste inside the liquefaction reactor through the outer cycle device; the kitchen waste is quickly diffused in the reaction area when the kitchen waste liquefaction and double-cycle treatment integrated device is operated, so that the kitchen waste is in a liquefaction state; the kitchen waste flows under the effect of the outer cycle device; and the turbulent flow board reduces an online speed of the kitchen waste mixture, and realizes the solid-liquid separation of the kitchen waste mixture in the depression area. The kitchen waste liquefaction and double-cycle treatment integrated device provided by the invention is applicable to liquefaction treatment of the kitchen waste.

Owner:广州中科建禹环保有限公司

A tracking method for a moving frogman

The present invention relates to a kind of tracking method of moving frogman, said method comprises: step 1) receiving the observation value of frogman state at tk+1 moment; Step 2) establishing the movement model set of multi-directional movement of frogman at tk moment; Step 3 ) Calculate the initial value of the frogman state estimation and the covariance estimation initial value of each motion model according to the motion model set at tk+1 moment; Step 4) estimate the initial value and the initial value of the frogman state of each motion model at tk+1 moment Input the initial value of covariance estimation into several filters, and calculate the frogman state estimation and covariance estimation of each motion model in combination with the observation value of frogman state at tk+1 moment; step 5) each movement The model’s frogman state estimation and its covariance estimate update the probability of each motion model at time tk+1; step 6) perform fusion estimation on the frogman state according to the updated probability of each motion model, and obtain the frogman state at tk+1 time Estimates of human states and their covariances. The method of the invention has the characteristics of high precision and strong stability.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

A multifunctional valve and its combination valve

InactiveCN103291959BIncrease resistanceReduce resistanceOperating means/releasing devices for valvesMultiple way valvesEngineeringMechanics

The invention relates to a multifunctional valve and a combination valve thereof. The multifunctional valve comprises a valve body, a valve cavity formed in the valve body and a valve rod arranged in the valve cavity, wherein a middle inlet allowing pressure media to enter, a left inlet and a right inlet are formed in one surface of the valve body, and the pressure media can selectively enter the left inlet and the right inlet; a left outlet and a right outlet which allow the pressure media to be discharged are formed in the other surface of the valve body; and the left inlet and the left outlet as well as the right inlet and the right outlet are selectively and correspondingly communicated through matching of the valve cavity and the valve rod. The multifunctional valve is characterized in that the left inlet and the right inlet are communicated with the left outlet and the right outlet through respective damping channels, so that a piston can slowly touch the end part of a piston cylinder, a piston rod is prevented from being collided and abraded when the piston moves at a high speed, the service life of the piston cylinder is effectively prolonged, and simultaneously, operation safety and stability of the piston cylinder are guaranteed.

Owner:靖江市华信科技创业园有限公司

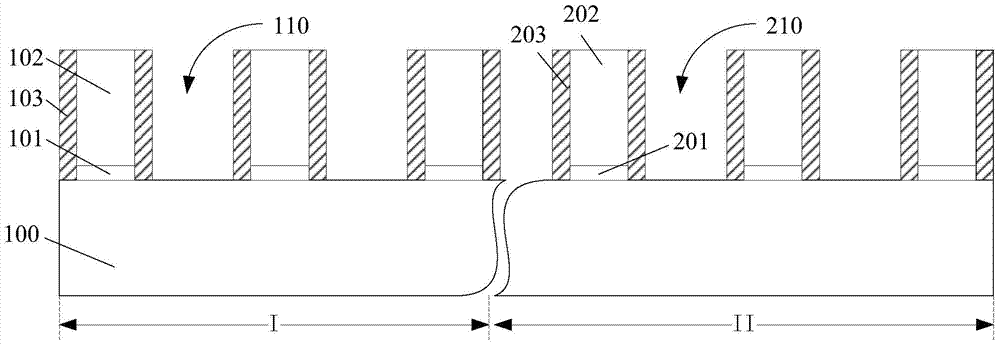

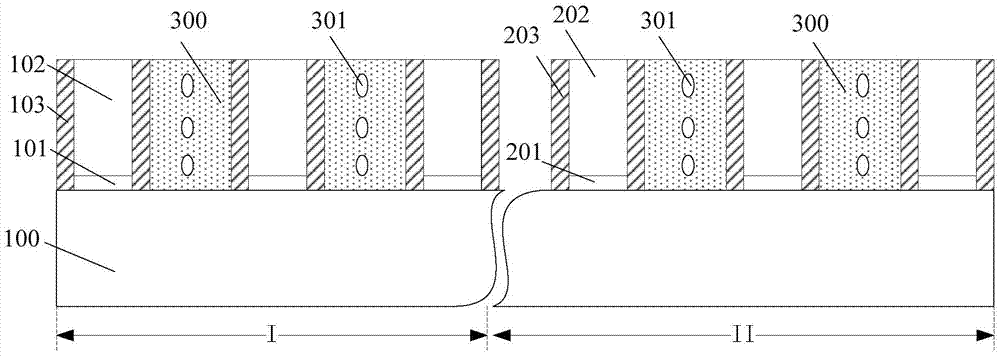

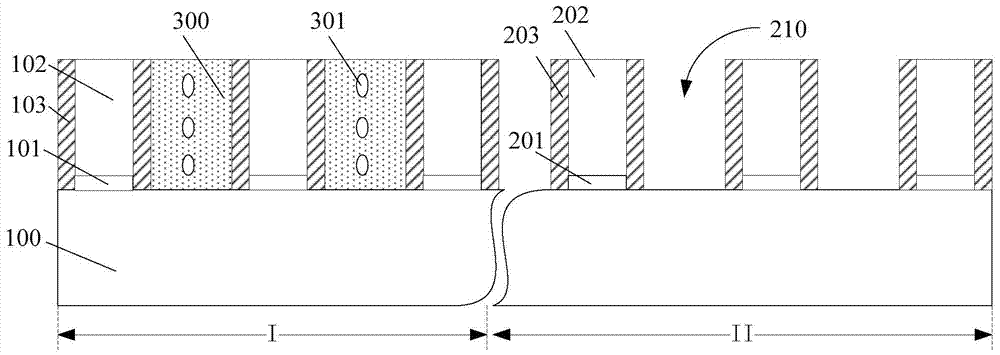

Formation method of semiconductor structure

ActiveCN104952716BSlow motion rateLow average permittivitySemiconductor devicesSemiconductor structureGas phase

A method for forming a semiconductor structure, comprising: providing a semiconductor substrate, the semiconductor substrate has a first region, a plurality of protruding first gate structures are formed on the first region, adjacent to the first gate structure There is a first groove between them; hydrophobic treatment is carried out on the surface of the side wall of the first groove, so that the first groove has a hydrophobic side wall; a first medium is formed in the first groove by a fluid chemical vapor deposition process layer, the reactant used in the fluid chemical vapor deposition process is a hydrophilic substance, and under the action of the hydrophobic sidewall, there is an air gap in the first dielectric layer. The method can reduce the dielectric coefficient of the first dielectric layer and reduce the parasitic capacitance between adjacent first gate structures.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com