Integrated device for liquefying and mechanizing kitchen waste

A food waste and stirring device technology, which is applied in the field of food waste liquefaction and mechanized treatment integrated devices, can solve the problems of hard to find food waste liquefaction treatment separation equipment, poor treatment effect, high energy consumption, etc., to ensure liquefaction and Separation efficiency, process stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

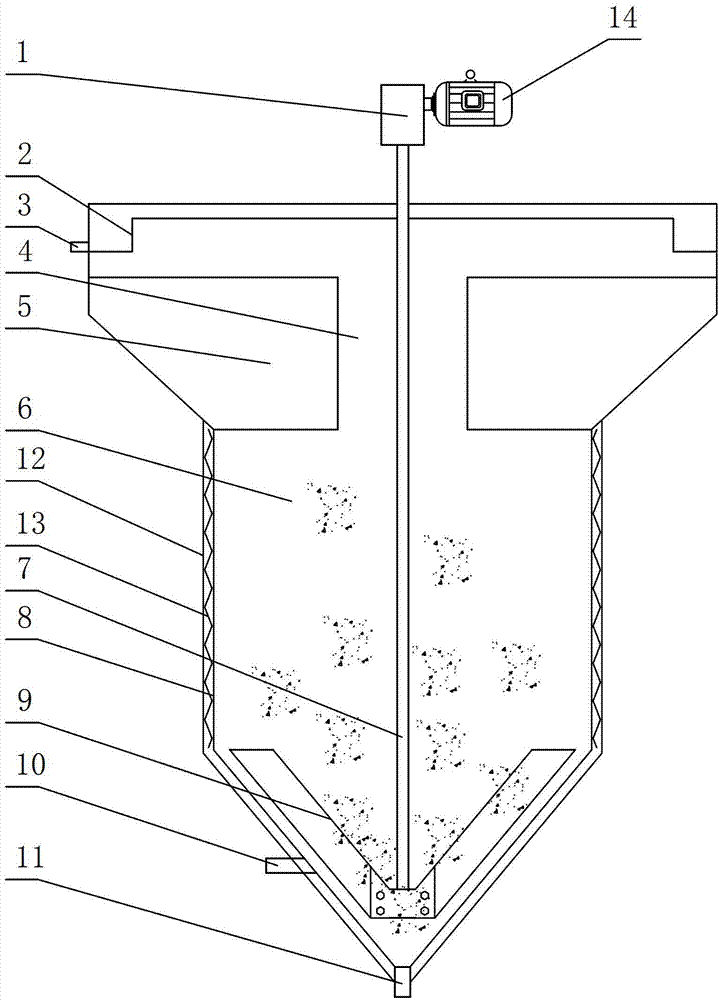

[0017] The application of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] refer to figure 1 , an integrated device for liquefying and mechanizing treatment of food waste, which includes a reactor 8 and a heating tracer 13 wrapped outside the reactor 8, heating the tracer 13 to keep the reactor 8 at 25-55°C, said The inner bottom of the reactor 8 is equipped with a stirring device that evenly stirs the food waste in the reactor 8, and the upper part of the reactor 8 is also equipped with a spoiler 5 that divides the reactor 8 into a reaction zone 6 and a liquid outlet zone, The spoiler 5 forms a settling zone 4 in the reactor 8 that facilitates solid-liquid separation of the food waste mixture.

[0019] Food waste is evenly fed into the reactor 8 through the feed port 10, and is quickly dispersed in the water body driven by the stirring device, and quickly enters a liquefied state under the action of special bacte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com