Total cross-section inflatable floatation machine

A flotation machine, inflatable technology, used in flotation, solid separation and other directions, can solve the problems of high cost, low sorting efficiency, high energy consumption, etc., to prolong the life of wearing parts, improve the sorting recovery rate, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

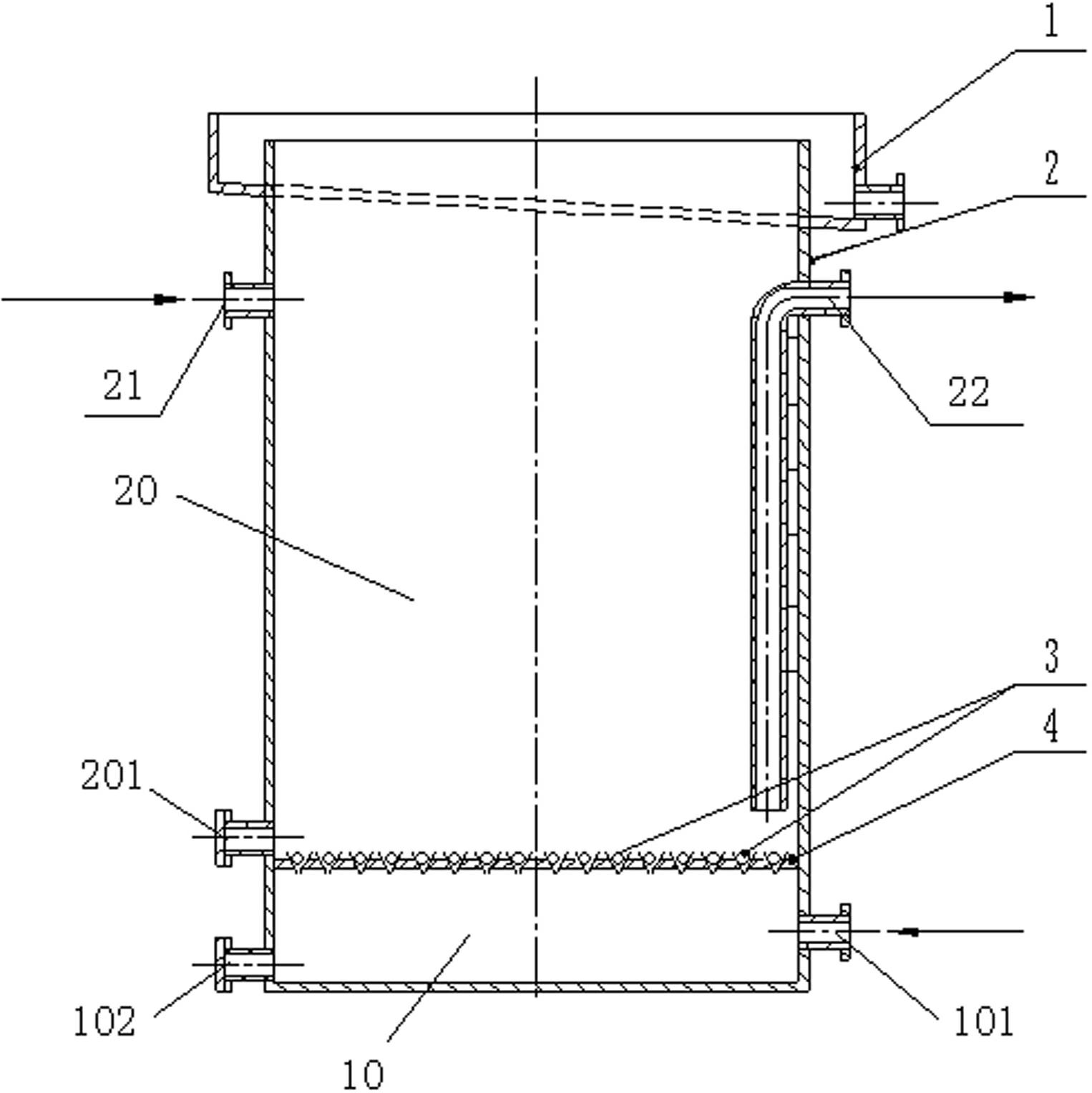

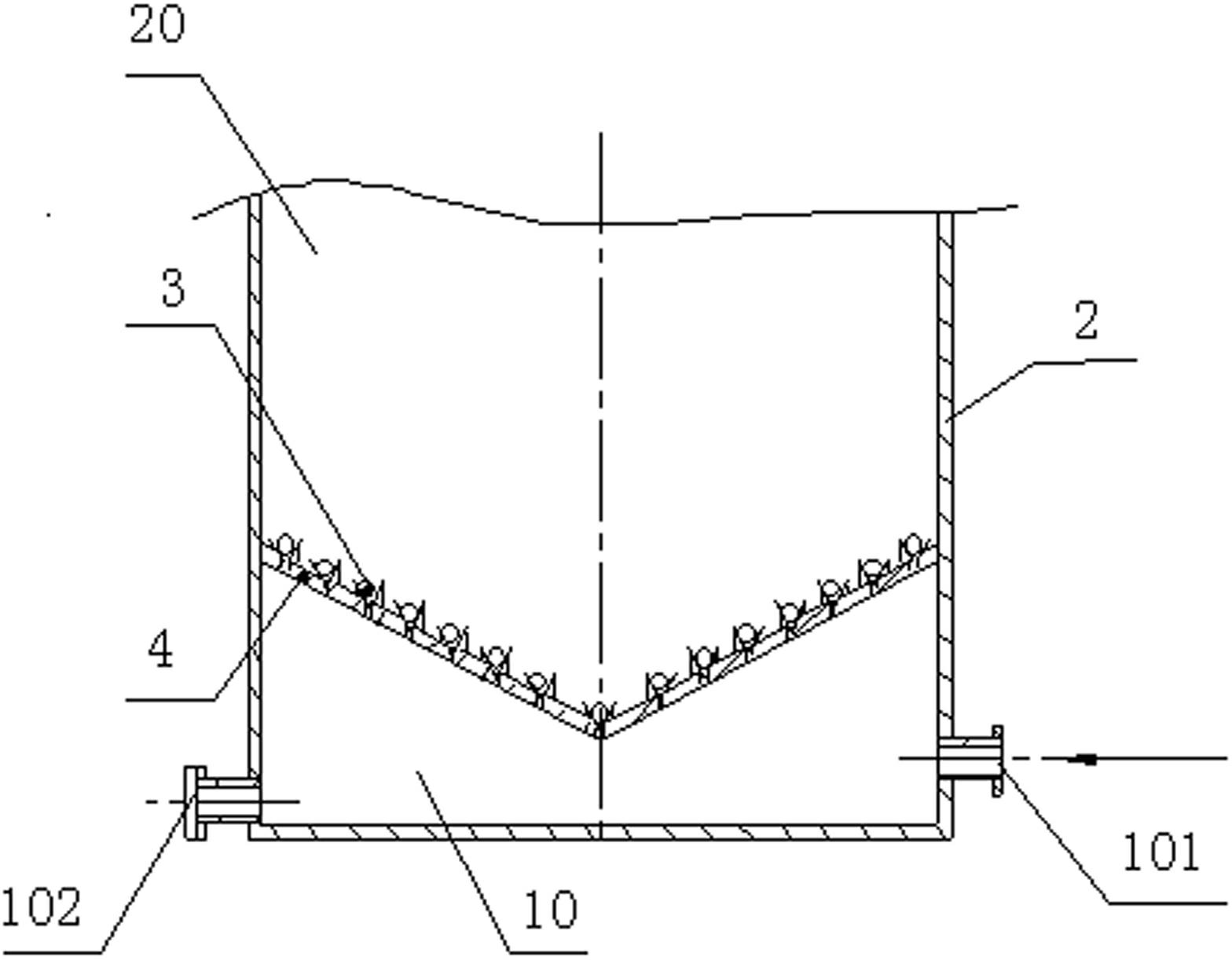

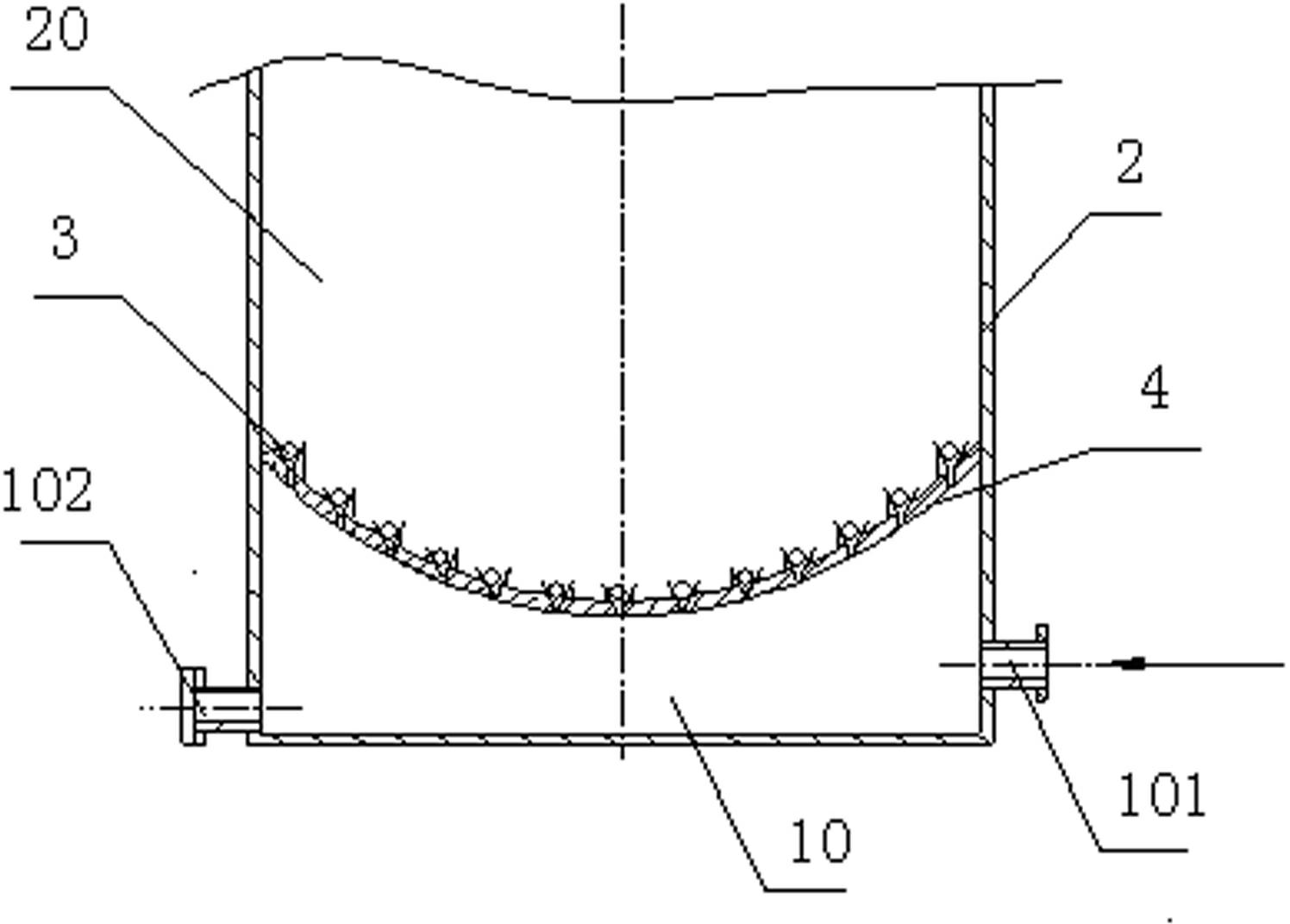

[0044] Such as figure 1As shown, a full-section inflatable flotation machine includes a flotation cell 2 and a foam overflow mechanism installed on the top of the flotation cell 2, and the upper side wall of the flotation cell 2 is provided with a pulp inlet 21 and a pulp outlet 22. A one-way valve mounting plate 4 is installed at the bottom of the flotation cell 2, and the shape of the one-way valve mounting plate 4 matches the cross-sectional shape of the bottom of the flotation cell 2, that is, the outer peripheral shape of the one-way valve mounting plate 4 It is the same as the cross-sectional shape of the bottom of the flotation cell 2, so that the flotation cell 2 is divided to form a slurry chamber 20 and an air chamber 10 located below the slurry chamber 20, and the check valve mounting plate 4 is uniformly and densely distributed. One-way valve 3, the side of the bottom of the slurry chamber 20 is provided with an ore discharge port 201, and the slurry outlet 22 is c...

Embodiment 2

[0053] Such as Figure 8 As shown, the full-section inflatable flotation machine of the present invention can add a stirring device when necessary, and the stirring device 5 includes a motor 51, a transmission mechanism 52, a main shaft 53 and an impeller 54, and the top of the flotation cell 2 is provided with a support 6, The foam tank 1 is installed below the support 6, the top of the main shaft 53 is installed on the support 6, the impeller 54 is installed on the bottom of the main shaft 53, and the motor 51 drives the main shaft 53 to rotate through the transmission mechanism 52, thereby driving the impeller 54 to rotate.

[0054] The impeller 54 of the stirring device is not responsible for air suction, dispersing air bubbles, and stirring the ore pulp. Its purpose is only to assist in the further mixing of liquid, solid, medicine, and air bubbles in the ore pulp. Therefore, the linear speed of the impeller 54 is reduced, and the required The input power is greatly reduc...

Embodiment 3

[0056] Such as Figure 9 As shown, according to actual needs, corresponding bubble dampers 7 can be added inside the flotation machine cell body 2, such as Figure 10 As shown, the foam damper 7 is composed of four damping plates 71 and a support plate 72 connecting the four damping plates 71. The damping plates 71 are closely arranged with a plurality of through holes 710, and the four damping plates 71 pass through The support plate 72 is installed in the cell body 2 of the flotation machine. The through hole 710 may be a round hole or a square hole. The shape of the damping plate 71 matches the cross-sectional shape of the cell body 2 of the flotation cell.

[0057] The foam damper 7 can change the straight-line rising route of the bubbles and prevent small bubbles from agglomerating into large bubbles, prolong the rising time of the bubbles at the same height of the flotation machine tank and make the bubbles fully contact with the pulp, or no bubble damping can be provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com