Emergency hammer

A technology of safety hammer and hammer body, which is applied in the field of escape tools and can solve problems such as crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

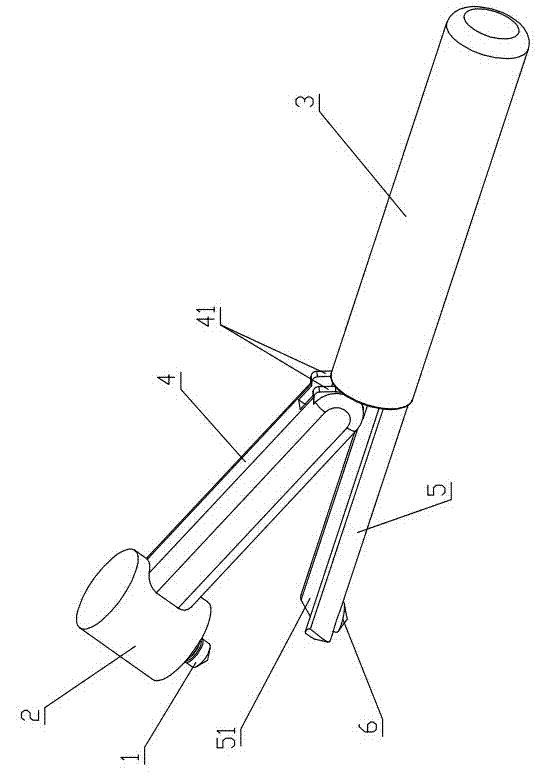

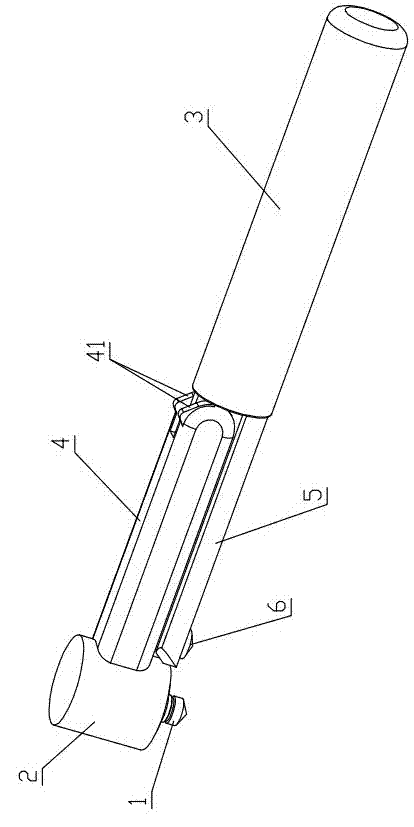

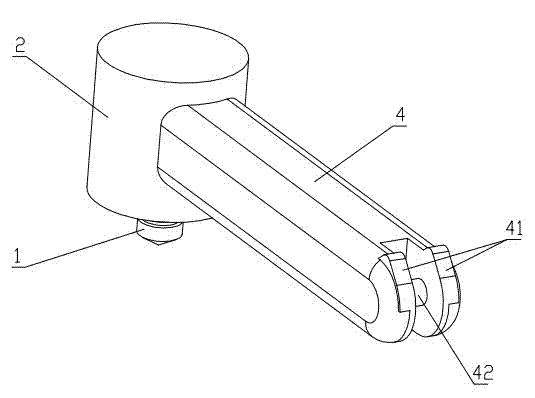

[0024] Depend on figure 1 , figure 2 , image 3 , Figure 4 It can be seen from the structural schematic diagram of the safety hammer of the present invention that it includes a first hammer head 1, a hammer body 2 and a handle 3, and the first hammer head 1 is arranged at one end of the hammer body 2, as figure 2 As shown, when the safety hammer is not in use, the conical tip of the first hammer head 1 faces downward, and a connecting rod 4 is arranged between the hammer body 2 and the handle 3, and one end of the connecting rod 4 is fixed to the hammer body 2 , the other end of the connecting rod 4 is hinged with the handle 3, that is to say, the end of the handle 3 is provided with an axial connecting seat 31, the connecting seat 31 is provided with a through hole, and the other end of the connecting rod 4 is provided with a pin shaft 42, The pin shaft 42 passes through the through hole on the connecting seat 31, so that the connecting rod 4 can rotate around the conne...

Embodiment 2

[0029] Depend on Figure 5 , Figure 6 , Figure 7 , Figure 8 It can be seen from the structural diagram of the safety hammer of the present invention that the limiting device for limiting the rotation angle of the connecting rod 4 at the hinge of the connecting rod 4 and the handle 3 is a protrusion 32 arranged on the handle 3, and the connecting rod 4 rotates to a certain degree. At an angle, the projection 32 is in contact with the connecting rod 4 to stop the connecting rod 4 from rotating. The structure of other parts of the safety hammer in this embodiment is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com