Metal powder conveying device and selective laser melting equipment

A conveying device, metal powder technology, applied in metal processing equipment, transportation and packaging, chemical instruments and methods, etc., can solve problems such as affecting part molding, final part printing failure, easy agglomeration, etc., and achieve the effect of complete crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

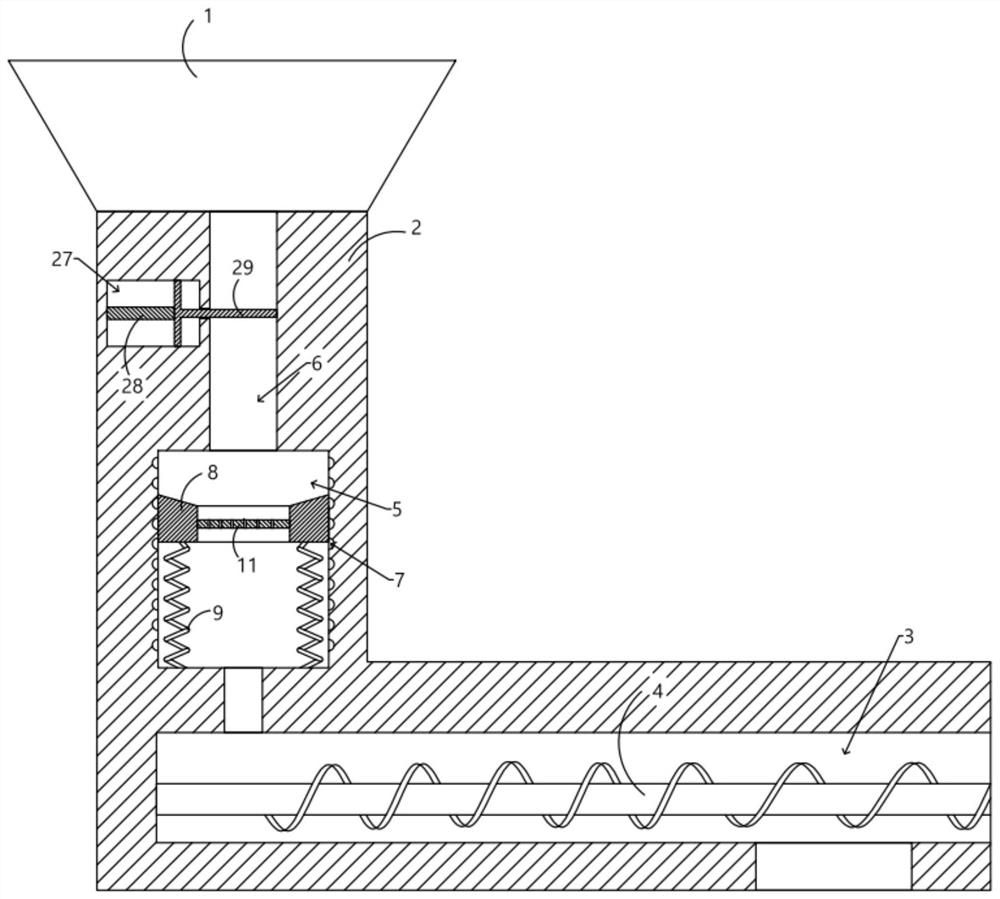

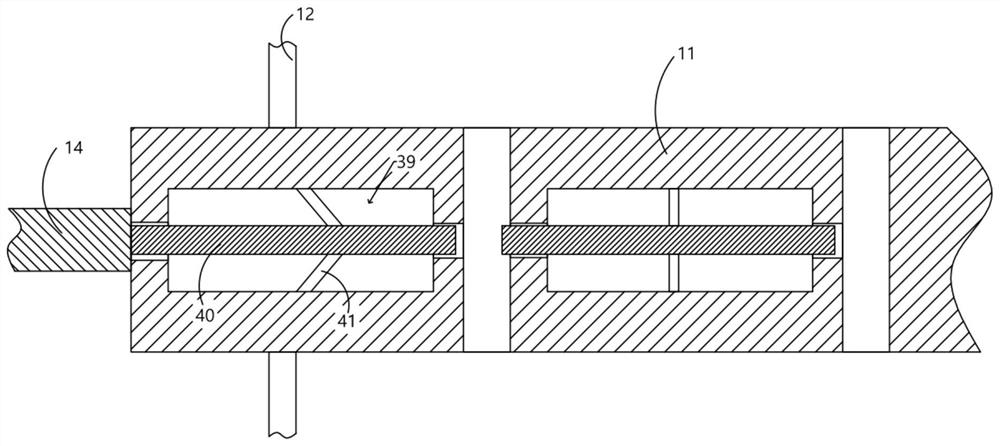

[0037] The inside of the installation cavity 5 is provided with a fixed frame 8, and a spring 9 is fixedly connected between the fixed frame 8 and the inner wall of the installation cavity 5. The inside of the fixed frame 8 is provided with an installation groove 10, and the inside of the installation groove 10 is movable with a filter screen plate 11. The screen plate 11 and the inner wall of the installation groove 10 are fixedly connected with the first elastic block 12, and the filter screen plate 11 and the installation groove 10 are connected by the first elastic block 12, so that the subsequent filter screen plate 11 can be bumped and vibrated by the impact plate 14, and at the same time The vibration of the fixed frame 8 can be transmitted to the screen plate 11 through the first elastic block 12;

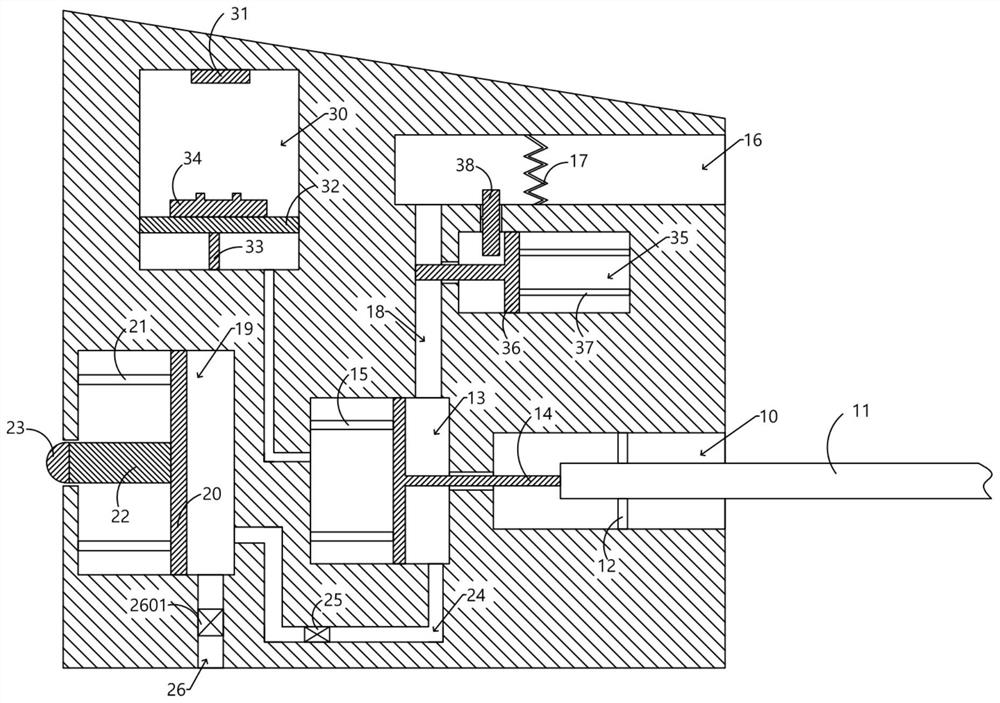

[0038] The inside of the fixed frame 8 is provided with an impact assembly for impacting the filter screen plate 11. The impact assembly includes an impact chamber 13 provid...

Embodiment 2

[0040] On the basis of Example 1, considering that the metal powder is generally caused by moisture, the final agglomeration is caused. In this embodiment, hot air is blown to the agglomerated metal powder to take away the moisture inside the agglomerated metal powder. To make the agglomerated metal powder more likely to break when it is shaken, a heating tank 16 is provided inside the fixed frame 8, and a heating wire 17 is fixed inside the heating tank 16, and the first air passage is passed between the heating tank 16 and the impact chamber 13 18 is connected, and the gas inside the impact chamber 13 is blown to the agglomerated metal powder through the heating tank 16, and the fixed frame 8 is provided with a gas-blocking assembly that blocks the first air passage 18 movably.

Embodiment 3

[0042] On the basis of Embodiment 1, in this embodiment, the impact component is firstly stored energy and then suddenly released energy, so that the degree of impact is more intense. The interior of the fixed frame 8 is provided with an inflatable component for inflating the impact chamber 13. The inflatable component includes In the inflatable chamber 19 inside the fixed frame 8, an inflatable board 20 is movable inside the inflatable chamber 19, and an airtight space is formed inside the inflatable board 20 and the inflatable chamber 19. The inflatable board 20 and the inner wall of the inflatable chamber 19 are fixedly connected with a third elastic block 21, The side of the inflatable board 20 close to the slot 7 is fixedly connected with a connecting rod 22 and a ball 23 movable into the inside of the slot 7. The ball 23 is a hemispherical meshing with the slot 7. Drive the inflatable plate 20 to move, the inflatable chamber 19 and the impact chamber 13 communicate throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com