Kitchen waste liquefaction double cycle treatment integrated device

A food waste and double-cycle technology, which is applied in the field of food waste liquefaction dual-cycle treatment integrated device, can solve the problems of hard to find food waste liquefaction treatment separation equipment, poor treatment effect, and restrict the development of food waste biochemical treatment. , to achieve the effect of ensuring liquefaction and separation efficiency and process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

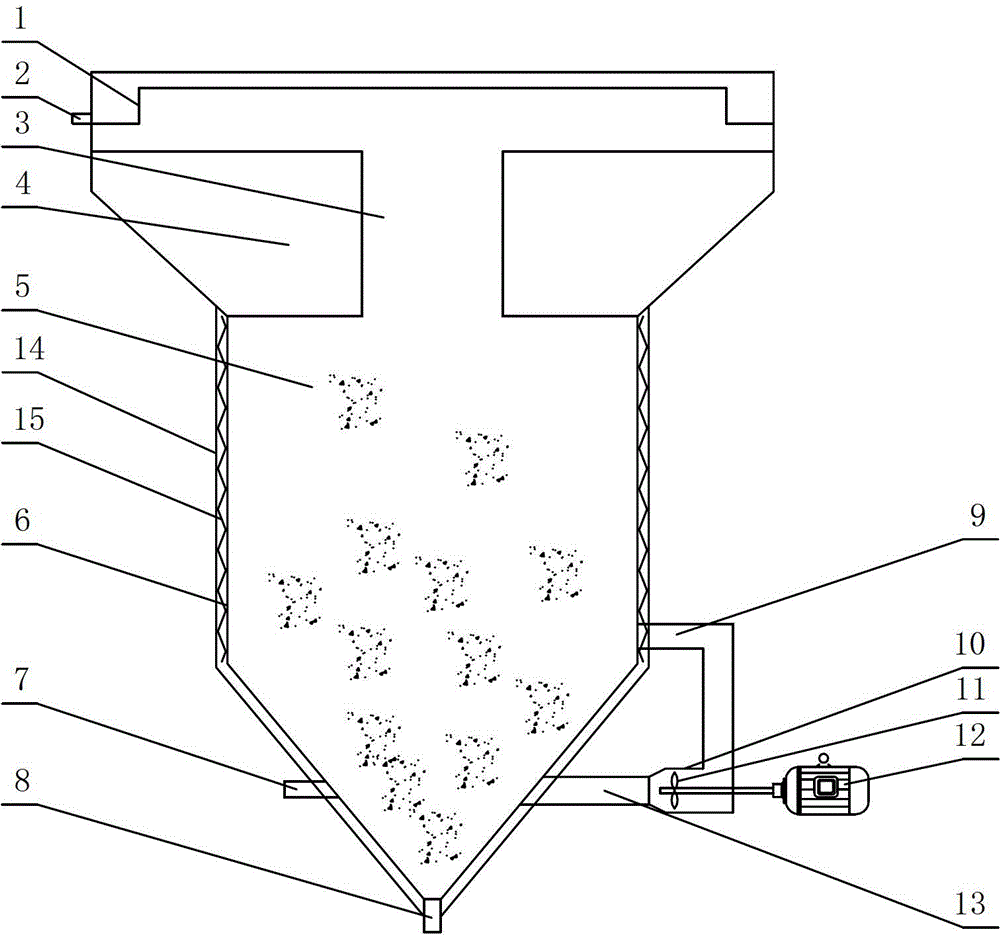

[0018] The application of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] refer to figure 1 , a food waste liquefaction double-cycle treatment integrated device, which includes a reactor 6 and a heating tracer 15 wrapped outside the reactor 6, heating the tracer 15 to keep the reactor 6 at 25~55°C, the The outside of the reactor 6 is also equipped with an external circulation device that communicates with the inside of the reactor 6 and uses the material flow to evenly stir the food waste in the reactor. And the spoiler 4 in the liquid outlet area, the spoiler 5 forms a settling zone 3 in the reactor 6 that facilitates solid-liquid separation of the food waste mixture.

[0020] The kitchen waste is uniformly fed into the reactor 6 through the feed port 7, quickly dispersed in the water body, and quickly enters a liquefied state under the action of special bacteria. The good flow state in the reactor 6 makes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com