Bridge inspection vehicle leveling device and bridge inspection equipment

A bridge inspection vehicle and leveling device technology, applied in bridge construction, bridges, bridge parts, etc., can solve the problem of easy shaking of the truss maintenance platform, and achieve the effect of stable swing and reduced movement rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

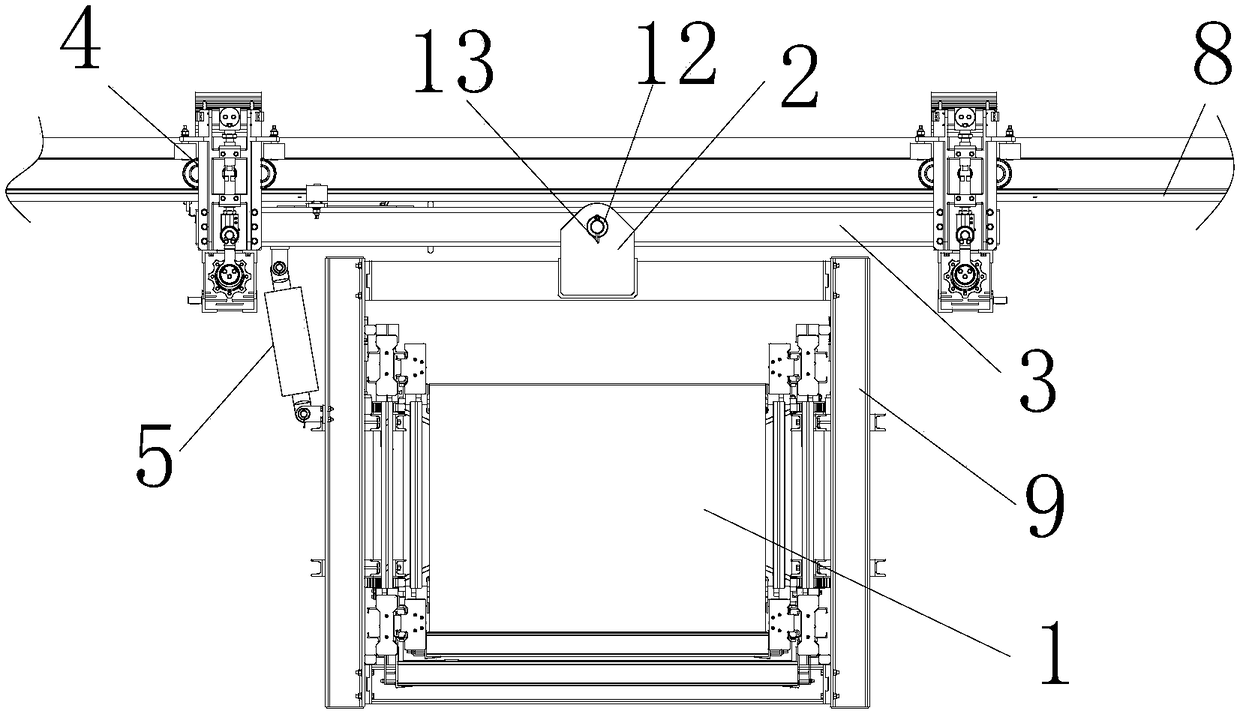

[0032] This embodiment provides a bridge inspection car leveling device, such as figure 2 shown, including:

[0033] The bridge inspection vehicle respectively includes a truss maintenance platform 1 and a gantry 9 surrounding the outside of the truss maintenance platform 1; a connecting piece 2, which is movably connected above the gantry; a walking beam 3, the connecting piece 2 The position is variably connected to the walking beam 3, and the walking beam 3 is driven by the running mechanism 4 to drive the connecting piece 2 to make the bridge inspection vehicle move along the extending direction of the track 8;

[0034] At least one damper 5 is connected between the walking beam 3 and the gantry, and the buffer device is used to drive the The truss inspection platform 1 is used to stabilize the truss inspection platform 1 in a horizontal state.

[0035] Specifically, as figure 2 As shown, the damper 5 is connected to the left side of the truss inspection platform 1, a...

Embodiment 2

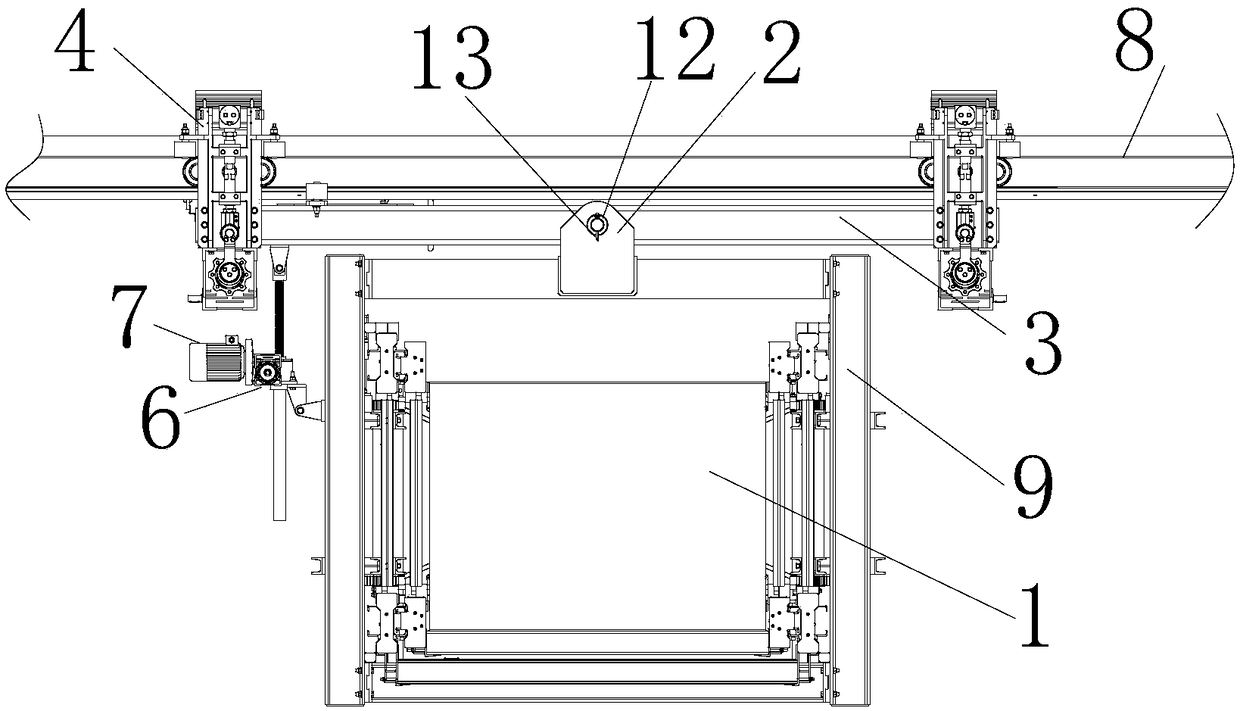

[0041] This embodiment is made on the basis of Embodiment 1. In this embodiment, the damper is replaced with a lead screw elevator 6. When the door frame 9 rotates synchronously with the walking beam 3, the lead screw The elevator 6 drives the truss maintenance platform 1 to rotate to a horizontal state by adjusting its own length.

[0042] Specifically, when the truss maintenance platform 1 tilts, the lead screw elevator 6 performs an elongation or shortening action consistent with the relative movement trend of the truss maintenance platform 1 relative to the walking beam 3 .

[0043] As a connector, the screw lift 6 can drive the synchronous movement of the walking beam 3, the gantry, and the truss maintenance platform. When the walking beam 3 tilts, the truss maintenance platform 1 will also tilt accordingly. At this time, the screw lift 6 can adjust its own length, so that the raised part of the truss maintenance platform 1 gradually becomes horizontal under the drive of ...

Embodiment 3

[0048] This embodiment provides a bridge inspection equipment, including at least two groups of bridge inspection vehicle leveling devices described in Embodiment 1 or 2, the bridge inspection vehicle leveling devices of the two groups are arranged in parallel to each other, and the bridge inspection vehicle leveling devices of each group are The car leveling device is connected with a track 8 respectively.

[0049] As a modification, the bridge inspection equipment may have a bridge inspection vehicle leveling device in Embodiment 1 and a bridge inspection vehicle leveling device in Embodiment 2 at the same time.

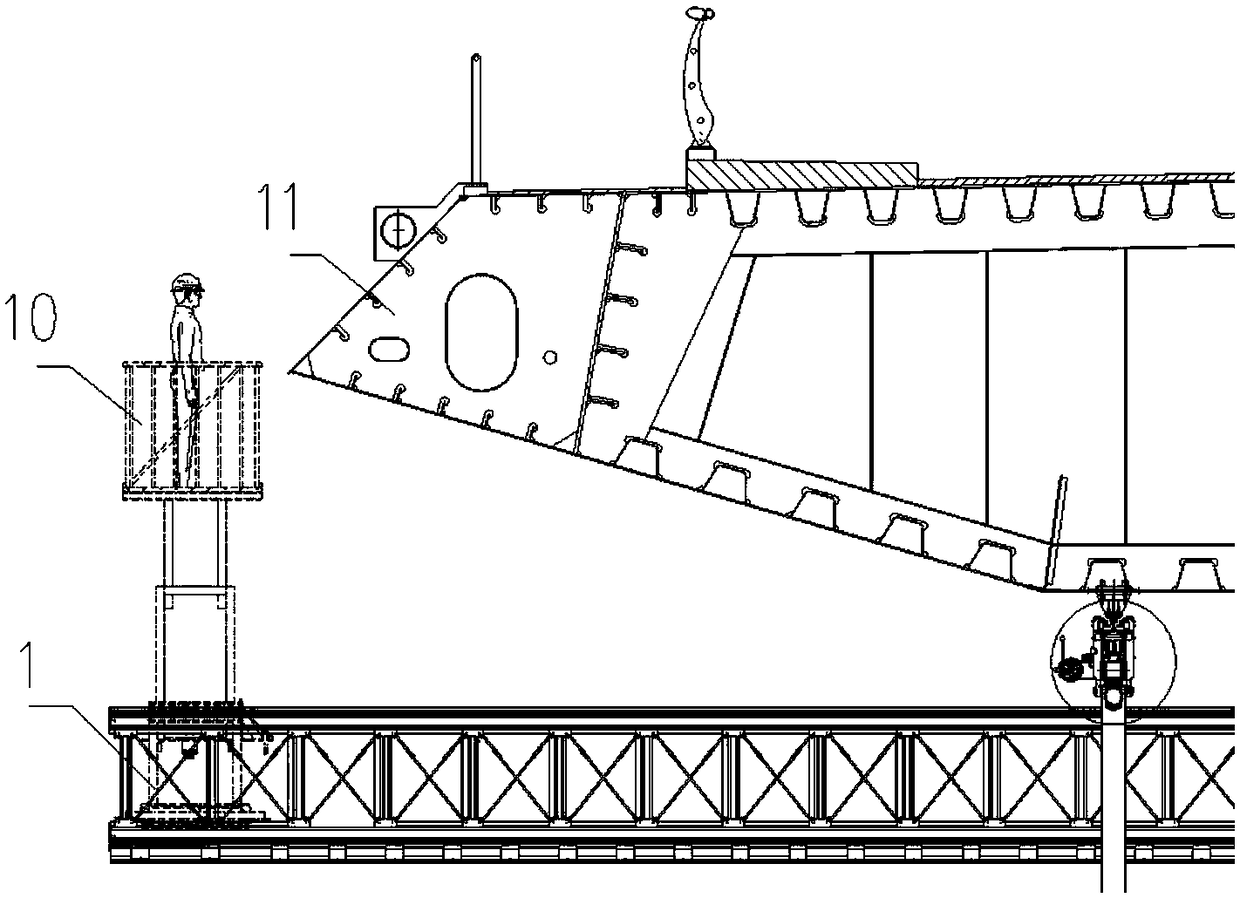

[0050] In this embodiment, at least one set of lifting and maintenance platforms is arranged inside the truss maintenance platform of the bridge inspection vehicle leveling device. When the height of the maintenance personnel cannot touch the box girder, the maintenance personnel stand on the lifting maintenance platform, and the lifting maintenance platform is rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com