Combined valve

A combined valve and valve stem technology, applied to multi-way valves, valve devices, engine components, etc., can solve problems affecting fluid pressure, piston and cylinder end cover wear, and different working time sequences to ensure operational safety and stability, avoiding collision wear, reasonable and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

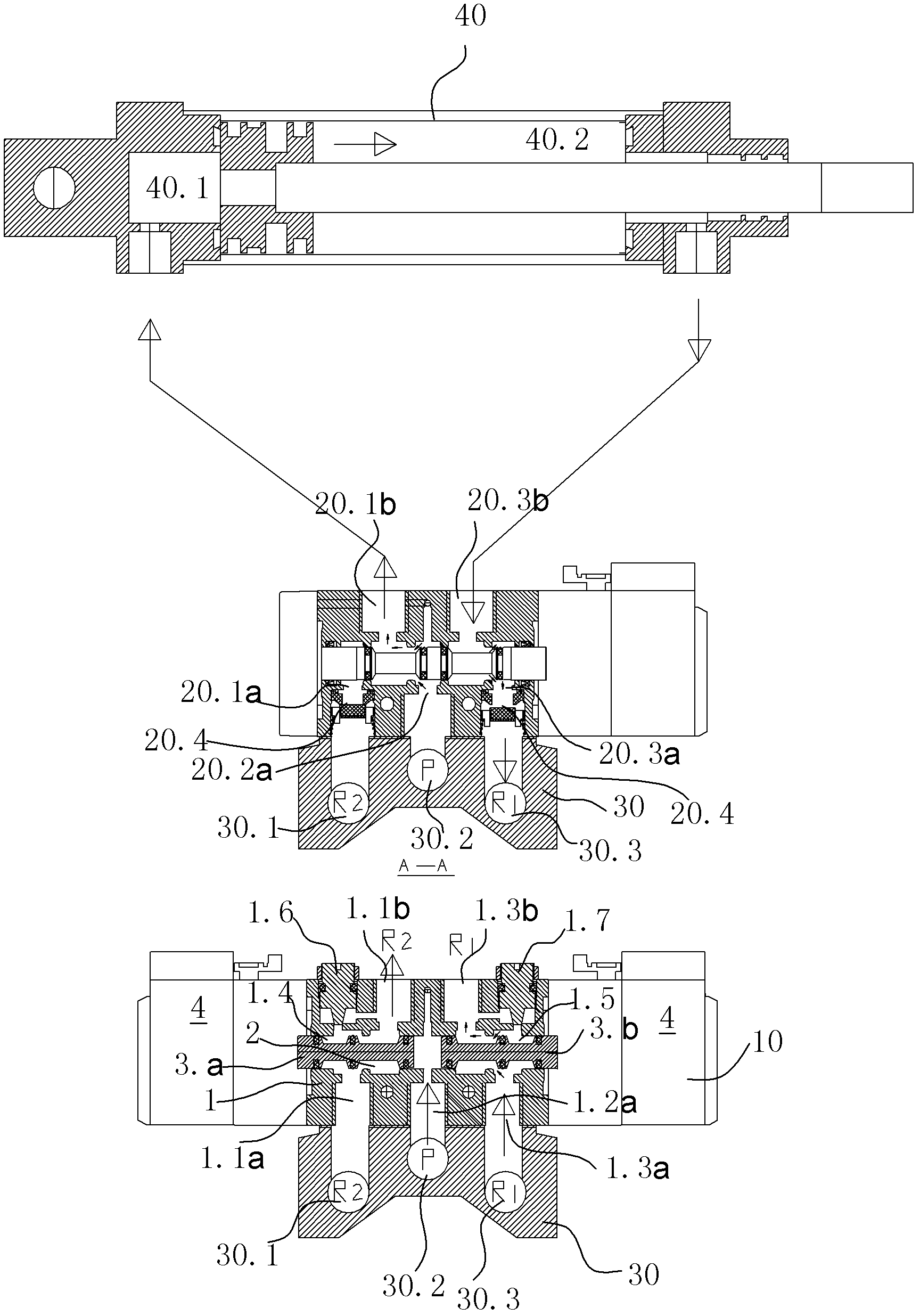

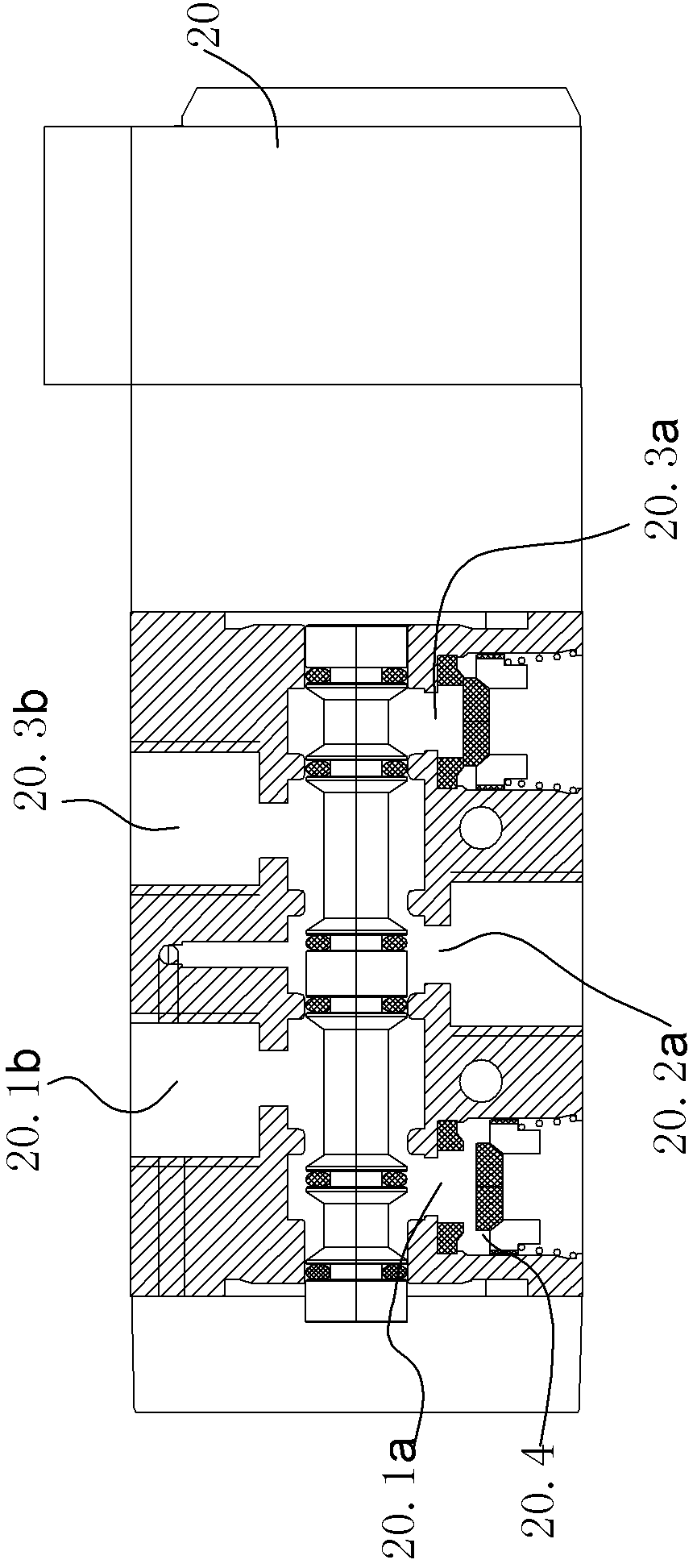

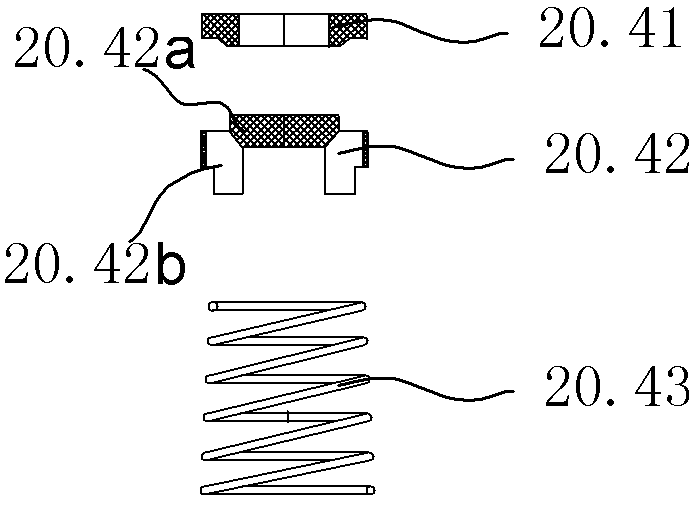

[0028] Such as figure 1 , 7 As shown, a combined valve or valve island, which includes a multi-function valve 10, three steering reversing valves 20 and a manifold 30; the left port 20.1b and right port 20.3b on one side of the steering reversing valve 20 The left cavity 40.1 and the right cavity 40.2 of the piston cylinder 40 are respectively connected, and the left return port 20.1a, the middle inlet 20.2a and the right return port 20.3a on the other side of the steering reversing valve 20 are respectively connected to the left flow channel 30.1 of the manifold 30 , the middle flow channel 30.2 and the right flow channel 30.3, and a check valve 20.4 is respectively arranged on the channel of the left backflow port 20.1a and the right backflow port 20.3a of the steering reversing valve. In this embodiment example, the check valve 20.4 is Se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com