Automatic tea fermentation system

A technology of tea fermentation and fermentation box, applied in the direction of tea treatment before extraction, can solve the problems of unreliable working condition, harsh working environment, easy pollution of tea leaves, etc., achieve high consistency of repeated production, avoid mutual influence, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

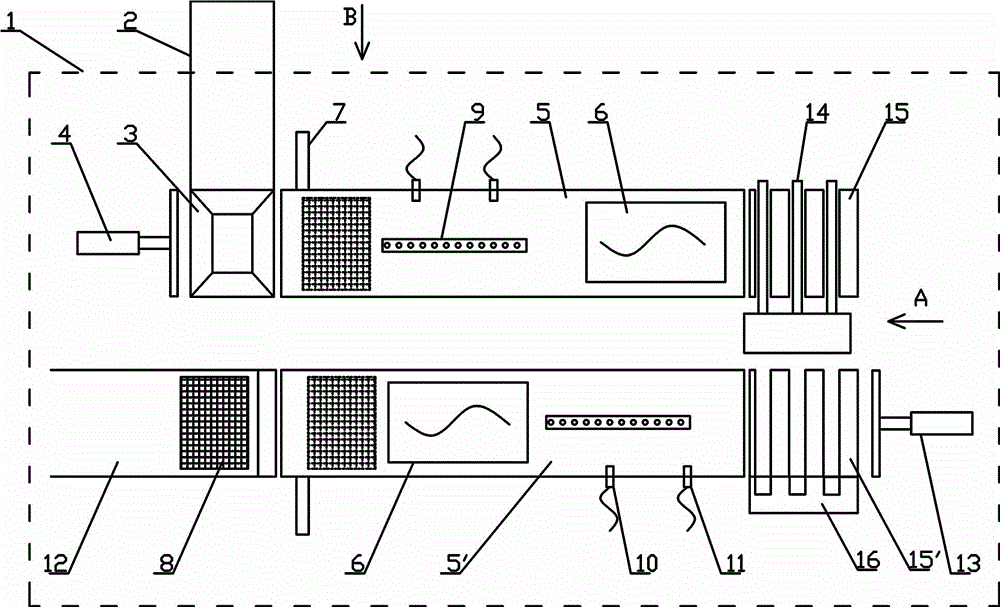

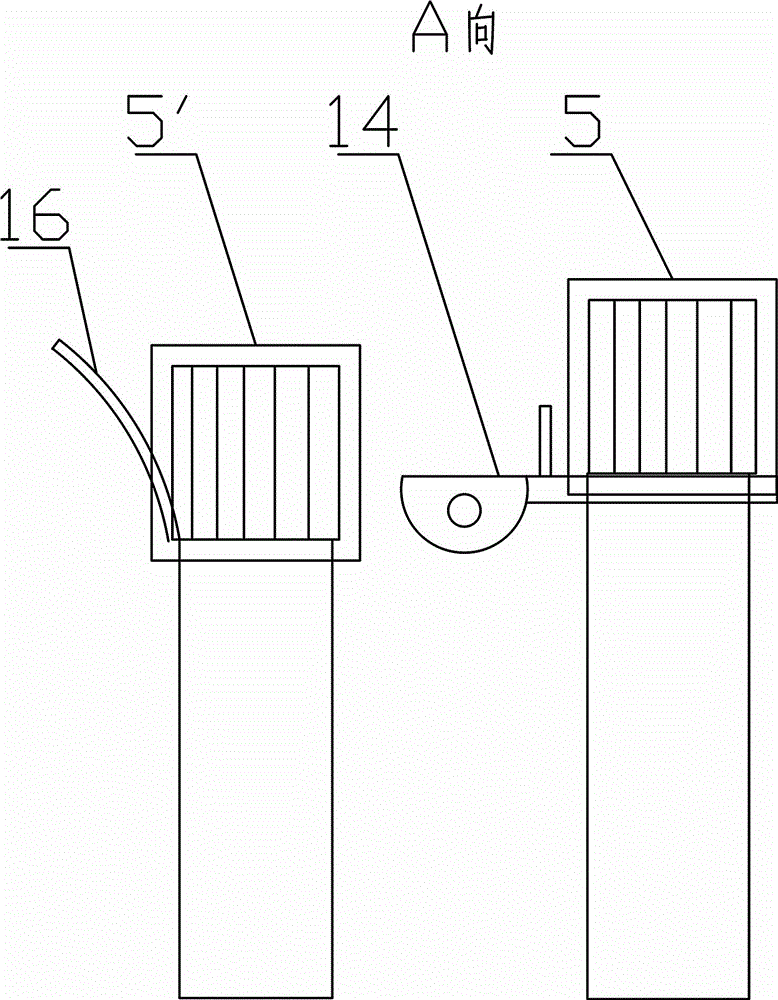

[0028] like Figure 1~3 Among them, an automated tea fermentation system, the fermentation tunnel is provided with a passage for the fermentation box 8 to pass through, a pushing device is provided at one end of the fermentation tunnel, and a discharge device 12 is provided at the other end;

[0029] A water mist nozzle 9 and a heating device are provided in the fermentation tunnel. The outer wall of the fermentation tunnel is made of thermal insulation materials, such as foam boards, to reduce energy consumption and manufacturing costs. At the entrance and exit of the fermentation tunnel, there are silicone curtains to reduce the waste of hot air. The material pushing device in this example adopts a cylinder, and the fermentation tank 8 is pushed to feed by the material pushing device. In this example, the feed end is the head end, and the discharge end is the tail end. Unloading relies on the thrust transmitted between the fermentation tanks 8 to realize the discharge, an...

Embodiment 2

[0040] A method for tea fermentation using the above-mentioned automated tea fermentation system, comprising the following steps:

[0041] Put the fresh leaves into the fermentation box 8, and push the fermentation box 8 into the fermentation tunnel in turn by the pushing device to ferment, and control the oxygen content, temperature and humidity during the fermentation process;

[0042] After the fermentation is completed, the pushing device pushes the fermentation tank 8 to the unloading device;

[0043] Automatic tea fermentation is realized through the above steps.

[0044] More specific steps are:

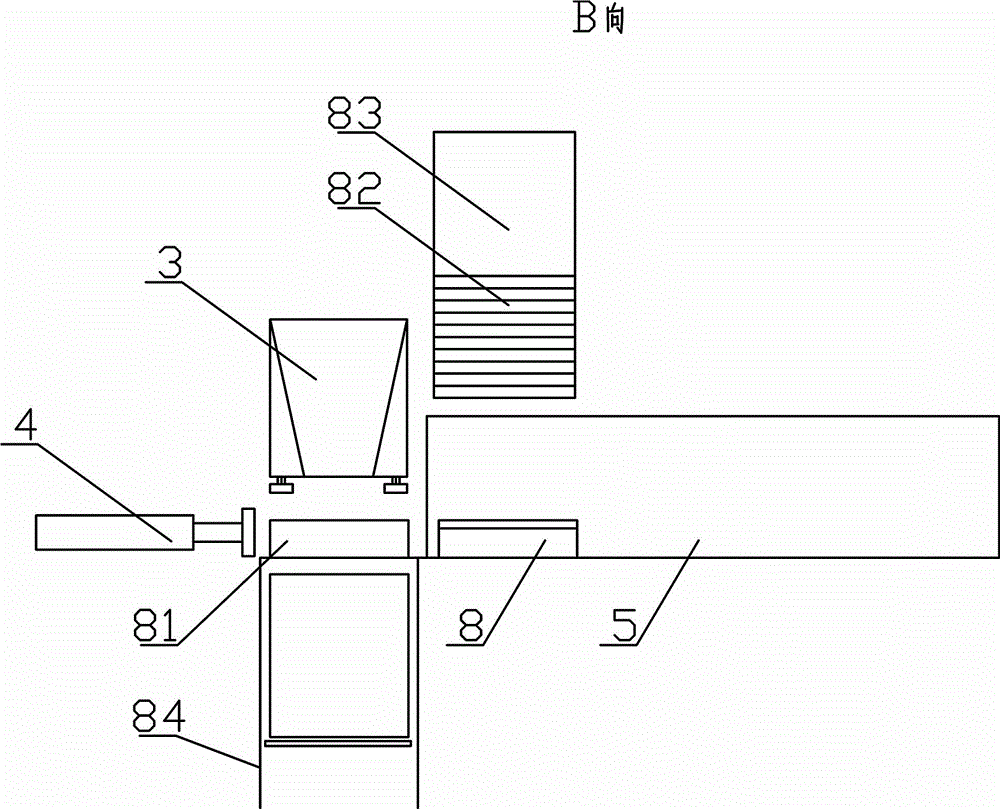

[0045] The feeding device 2 is usually a flat belt machine or a hoist, which transports the tea leaves after kneading and deblocking to the weighing hopper 3, and stops after reaching the set weight. The bottom box conveying device 84 transports the bottom box 81 of the fermentation box to the bottom of the weighing hopper 3, and the gate at the bottom of the weighing hopper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com