Multistage fracturing and exploitation control method

A control method and fracturing technology, applied in the field of drilling, can solve problems such as mutual influence of joint mining, inability to increase production for a long time, and non-repeatable one-time operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

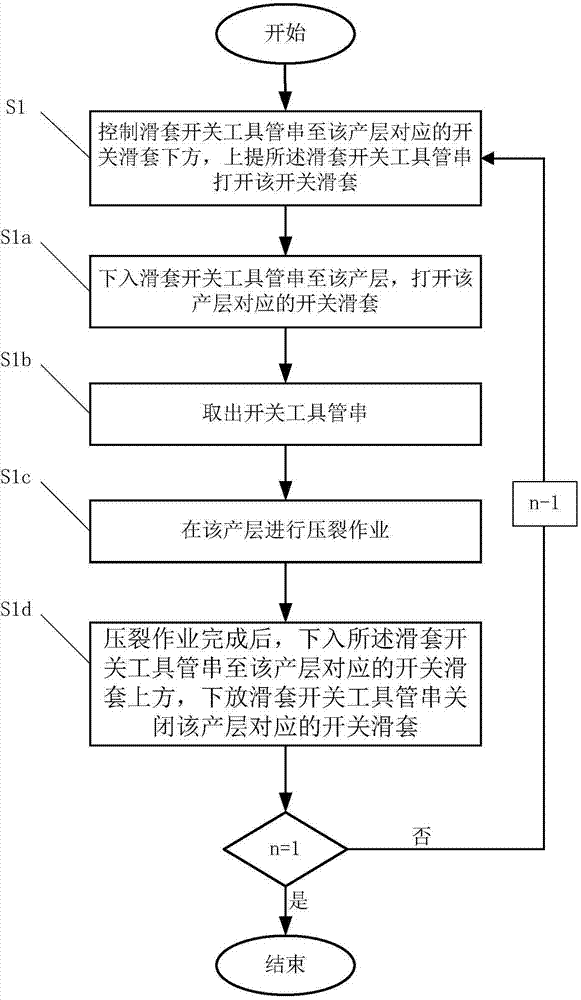

[0022] The multi-stage fracturing and production control method according to the embodiment of the present invention includes: setting switch sliding sleeves at the n production layers in the downhole, connecting adjacent switch sliding sleeves through packers, and passing A packer is connected to the completion casing, and the ball seat guide shoe is connected behind the switch sleeve at the end. When it is necessary to work in a production layer, the switch sleeve at the production layer is opened, and the switch sleeve is closed after the operation is completed. slip sleeve.

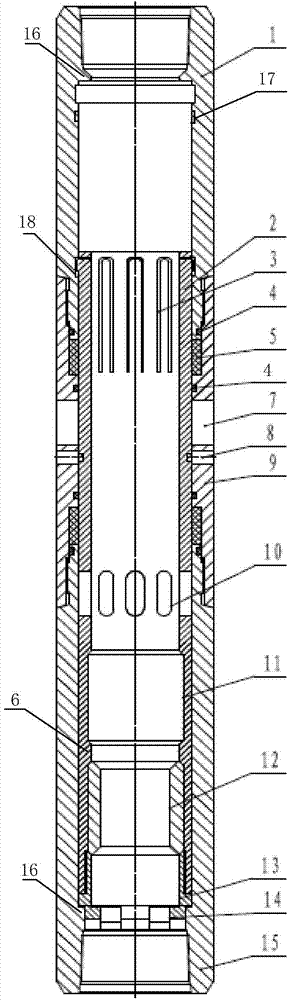

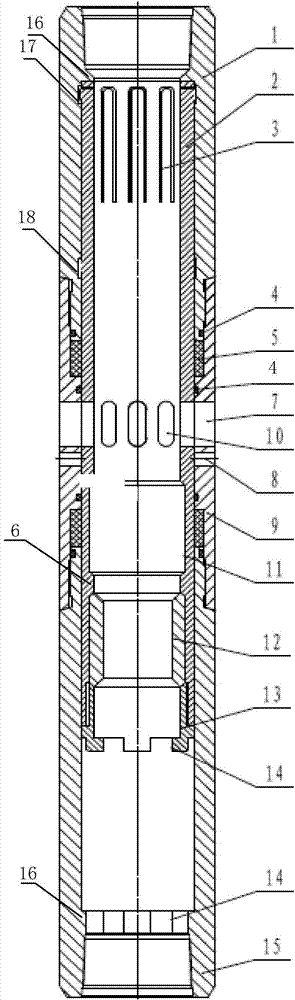

[0023] Among them, the implementation of the switch sliding sleeve can be as follows figure 1 and figure 2 As shown, its structure is as follows:

[0024] The switch sliding sleeve includes a sealing sleeve 2 and a housing. The housing includes an upper body 1, a middle body 9 and a lower body 15 connected by threads in turn. The middle part of the middle body 9 has an outer circulation hole 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com