Polishing device for heat-isolation material, and polishing method thereof

A technology of thermal insulation material and grinding wheel, which is applied in the direction of grinding driving device, grinding machine, grinding machine parts, etc., can solve the problems of high price and large resilience of flexible thermal insulation materials, and achieves long grinding path and large grinding area. , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

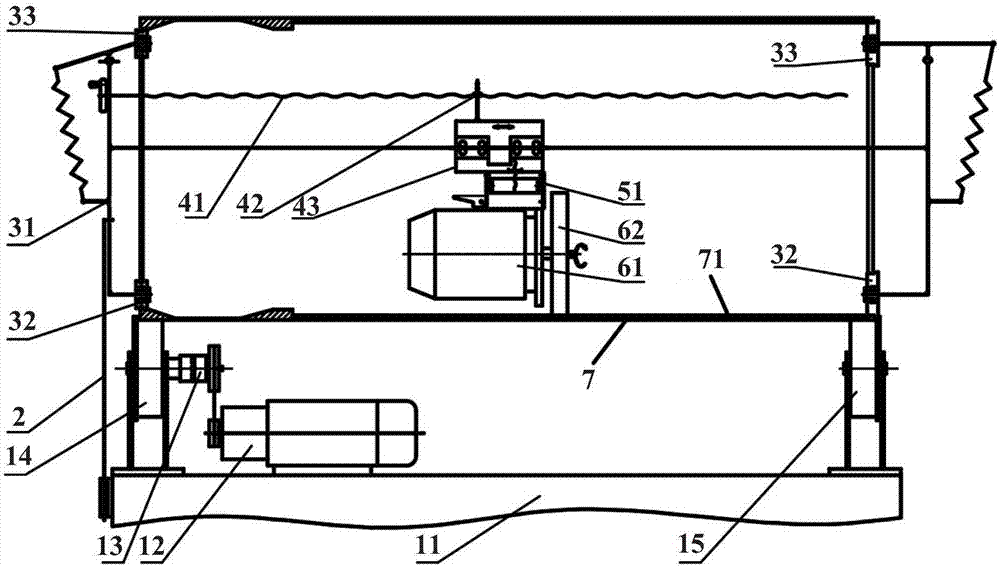

[0043] This embodiment provides a method for grinding heat insulating materials.

[0044] The workpiece to be polished is a metal cylindrical workpiece that is enclosed within the engine combustion chamber of the aircraft engine. The length of the metal cylindrical workpiece is 2m, and its diameter is 500mm. The metal to be polished is polished by the workpiece 7 to be polished. A thermal insulation material 71 is laid on the inner surface of the cylindrical workpiece, and the thermal insulation material is made of ceramic material. The inner surface of the metal cylindrical workpiece (that is, the heat insulation material) of the heat insulation material laid on the inner surface is generally ground.

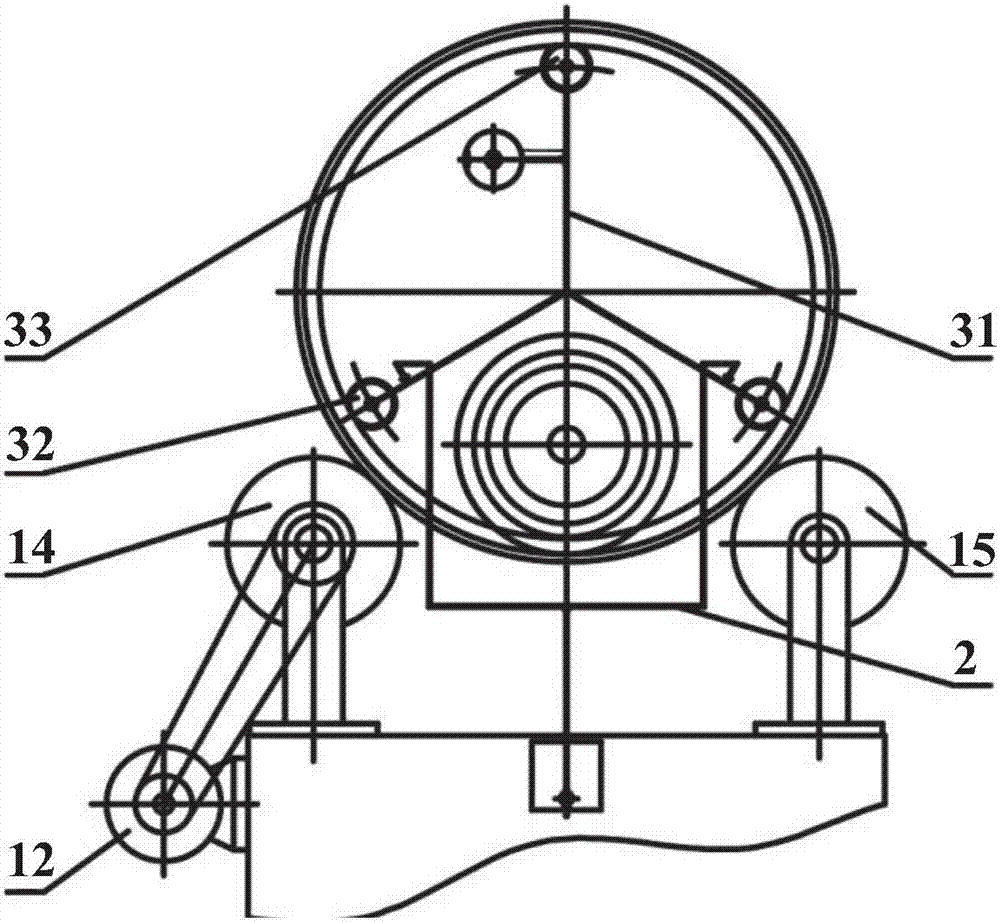

[0045] The workpiece described in this embodiment is placed on the support frame formed by the driving support wheel 14 and the driven support wheel 15;

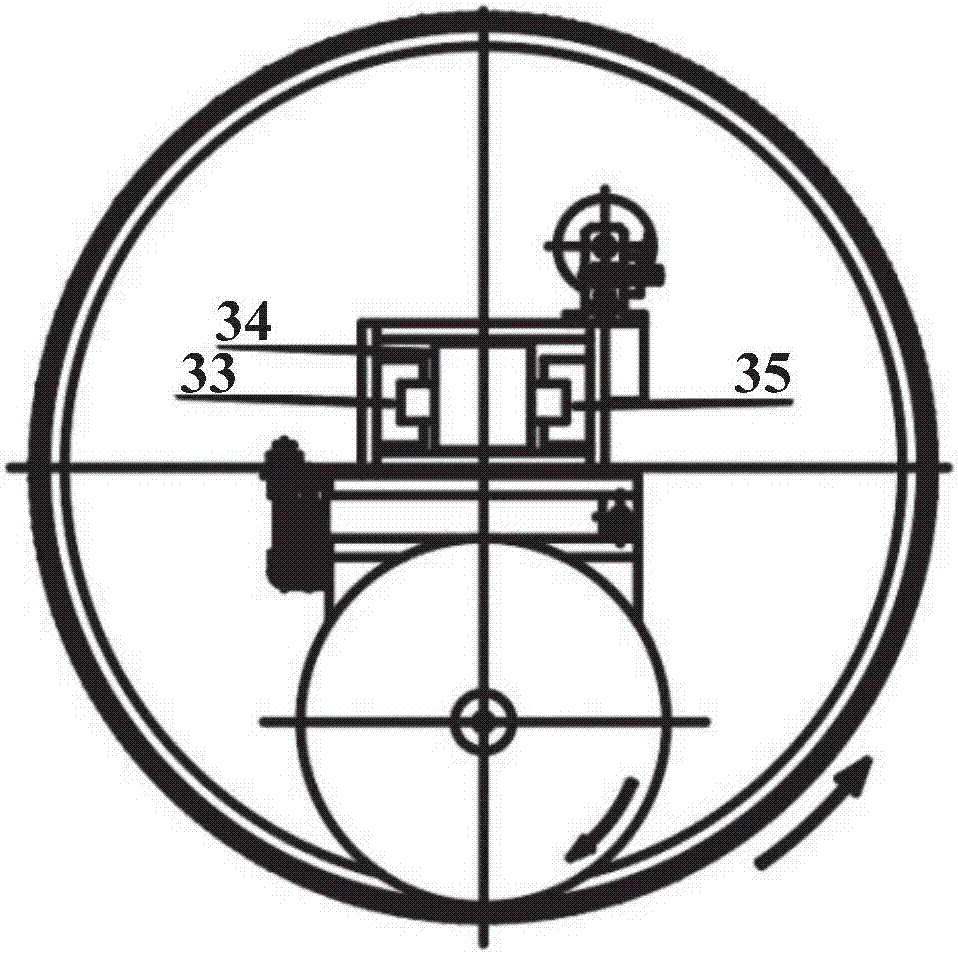

[0046] Described rolling guide rail pair 35 is connected with described alignment mechanism, and described rolling guide r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com