Transmission group for polishing production line

A transmission group and production line technology, applied in the field of transmission group, can solve problems such as declining market competitiveness, poor operating environment, and high risk of personnel operation, and achieve the effects of improving market competitiveness, reducing product costs, and simple system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below according to the drawings and embodiments.

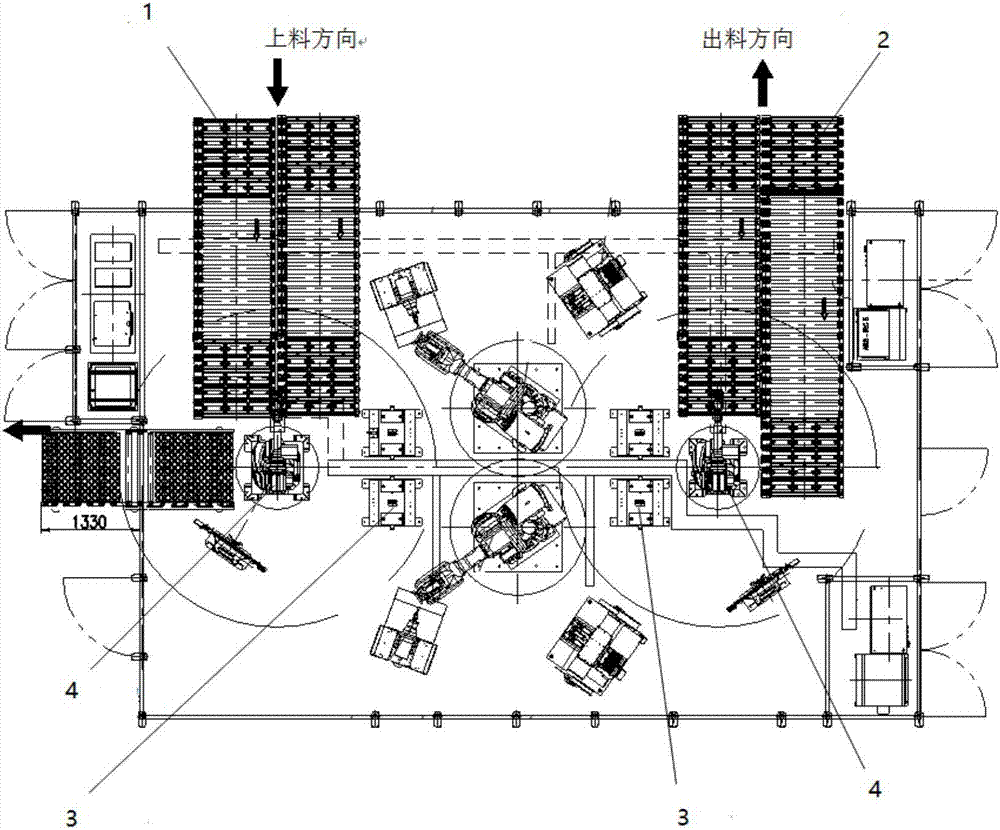

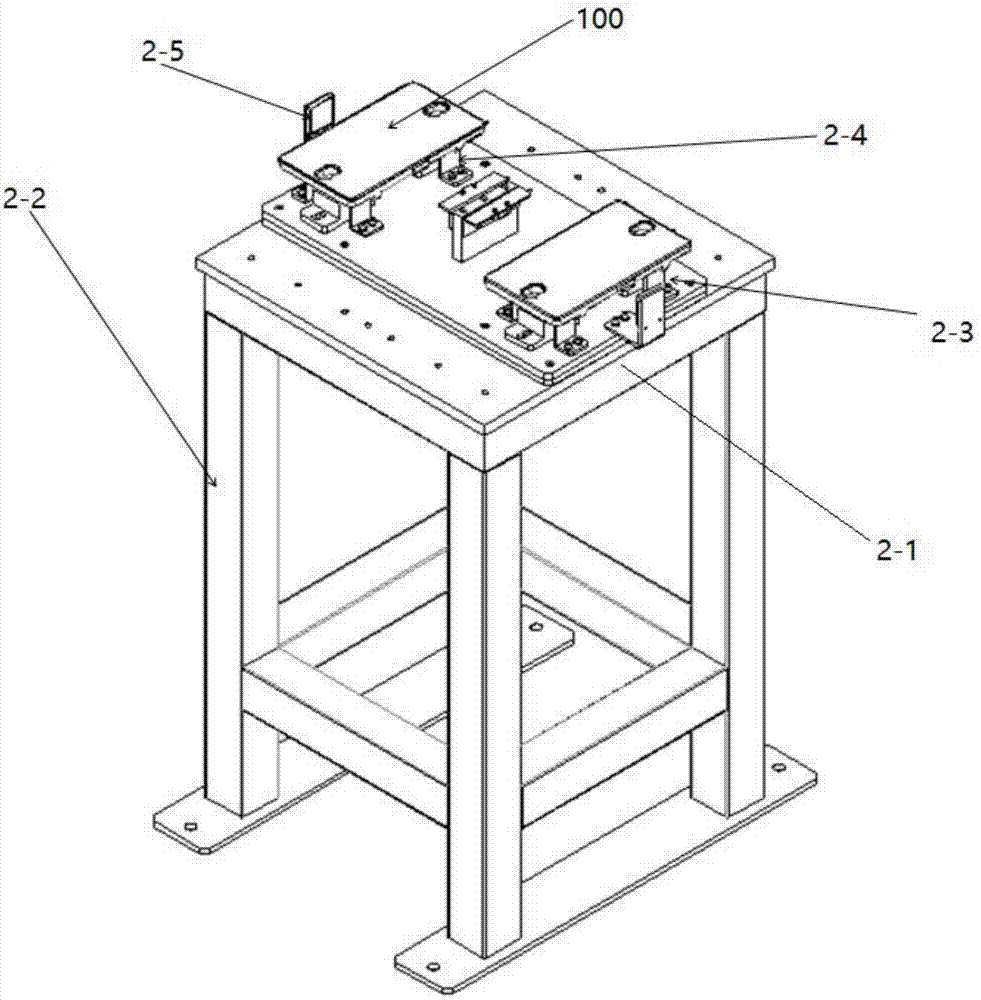

[0027] figure 1 It is a top view schematic diagram of the transmission group of the polishing production line of the present invention, referring to figure 1 According to the present invention, the transmission group of the grinding production line includes: a feeding roller table 1, a feeding roller table 2, and a positioning tooling table 3 respectively arranged on the feeding roller table 1 and the feeding roller table 2.

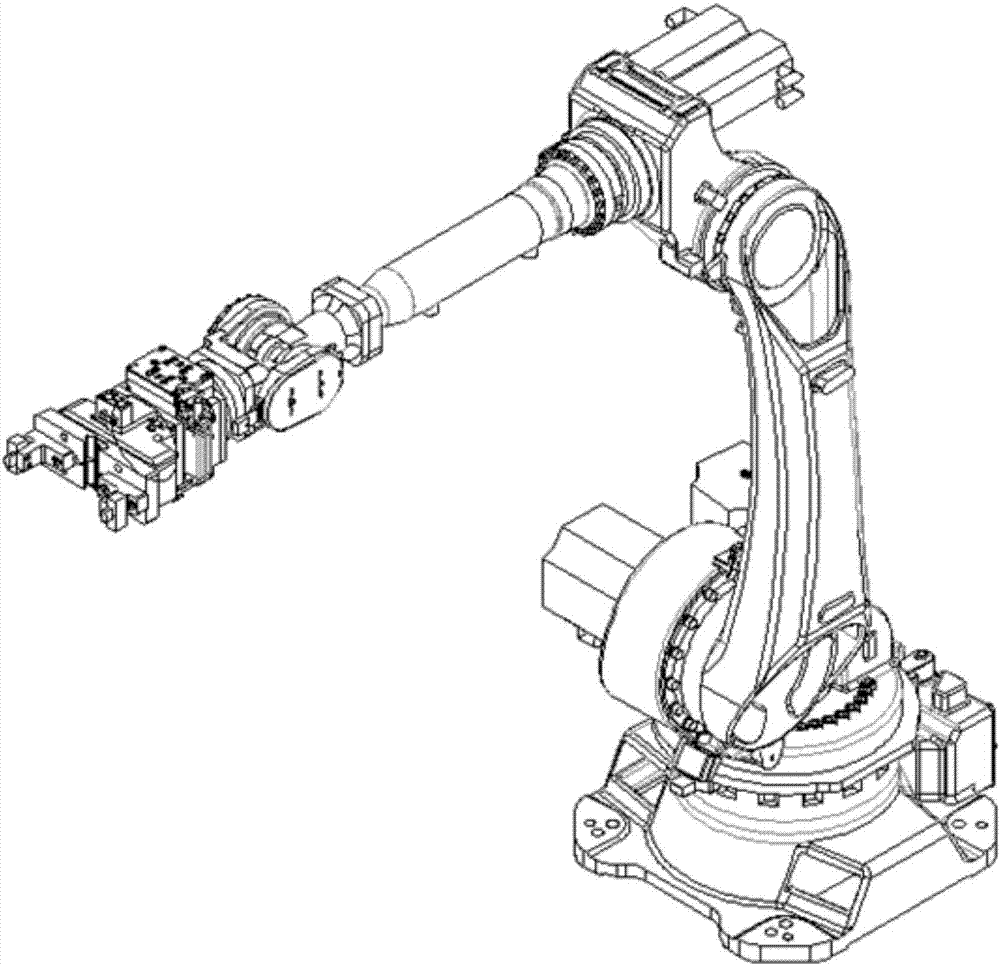

[0028] image 3 It is a structural schematic diagram of the visual recognition robot of the present invention, referring to image 3 , the visual recognition robot 4 can take pictures of the workpiece to identify the category and grabbing point of the product, and put the workpiece on the positioning tooling table 3 for fine positioning.

[0029] In this implementation case, EFORT is used, a 50kg robot, with a set of vision system on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com