Heat-preservation durable gas pipeline and preparation technology thereof

A kind of gas pipeline, durable technology, applied in the direction of protection of pipeline through thermal insulation, thermal insulation, pipeline protection, etc., can solve the problems of poor thermal insulation effect, short service life, etc., to improve transportation efficiency, prolong service life, superior antibacterial and antibacterial sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

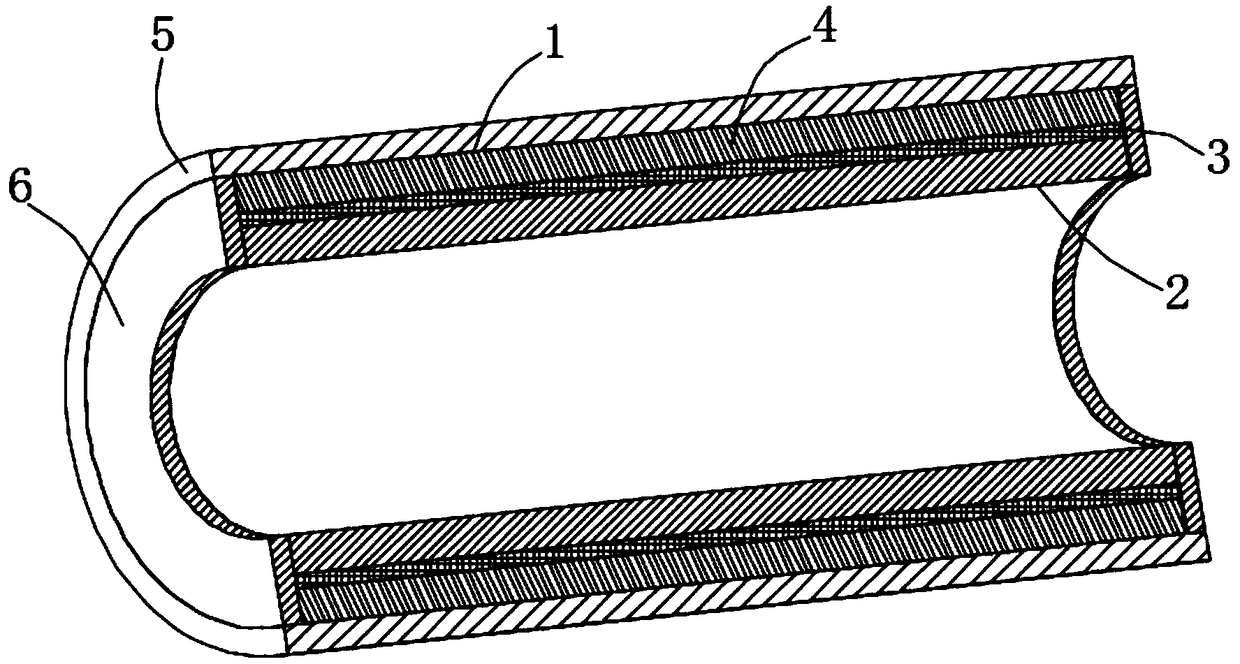

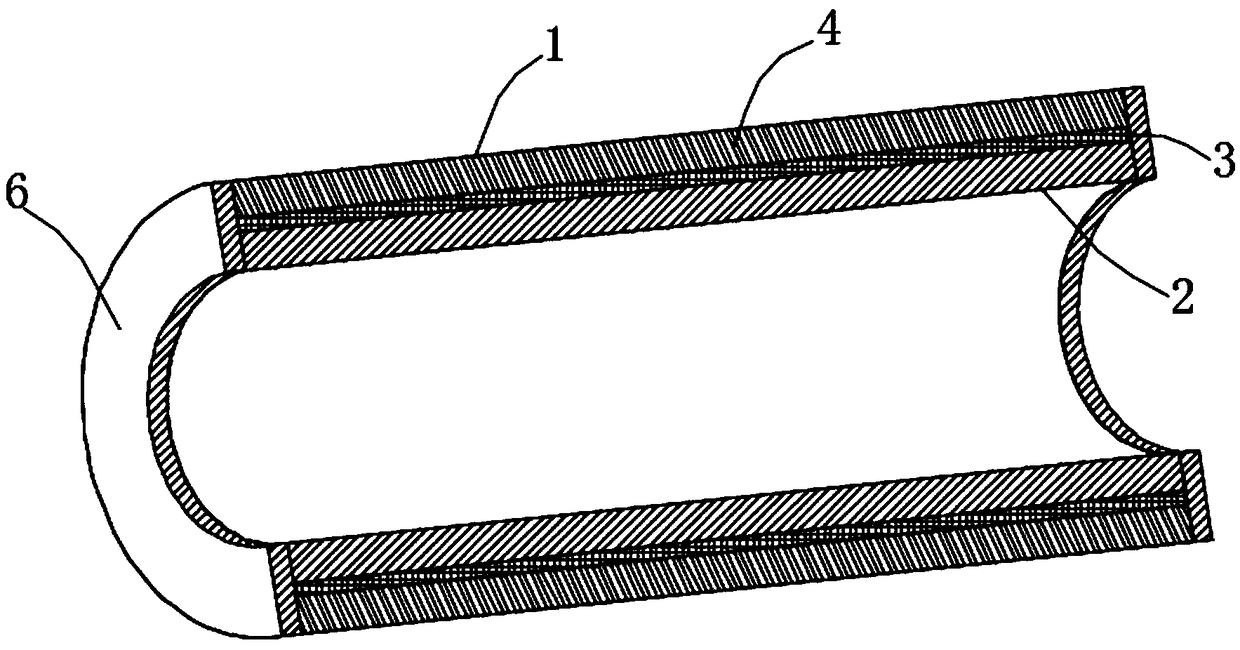

[0030] Such as Figure 1-2 As shown, a heat-insulating and durable gas pipeline includes a gas pipeline body 1, an outer sleeve 5 and an annular connecting piece 6; the gas pipeline body 1 sequentially includes an inner tube blank 2 and an insulation interlayer 3 And the outer tube blank 4; wherein, the outer wall of the outer tube blank 4 is sprayed with an anti-corrosion coating, the inner wall of the inner tube blank 2 is sprayed with a waterproof coating, and the inner tube blank 2 and the outer layer A thermal insulation interlayer 3 is embedded between the tube blanks 4, and the inner tube blank 2 and the outer tube blank 4 are connected by annular connecting pieces 6 welded at the left and right ends of the two; the outer sleeve 5 It is sleeved and fixed on the outer tube blank 4 .

[0031] Specifically, the anticorrosion coating used in the anticorrosion coating consists of the following components in terms of weight ratio: 45 parts of chlorosulfonated polyethylene em...

Embodiment 2

[0042] Preferably, the anticorrosion coating used in the anticorrosion coating consists of the following components in terms of weight ratio: 40 parts of chlorosulfonated polyethylene emulsion, 3.5 parts of tributyl phosphate, 4.8 parts of nano barium sulfate, 5.6 parts of titanium dioxide, 12 parts of epoxy resin, 10 parts of xylene, 2.3 parts of cetearyl glucoside, 2.5 parts of zinc naphthenate, 3.2 parts of methyl methacrylate, and 1.5 parts of curing agent; the preparation method of the anticorrosive coating is: Add the above-mentioned raw materials into the reaction kettle, and mix them by ultrasonic stirring for 40 minutes to obtain the finished anti-corrosion coating.

[0043] Preferably, the thermal insulation interlayer 3 is composed of the following components in terms of weight ratio: the annular insulation board used in the thermal insulation interlayer 3 is composed of the following components in terms of weight ratio: 35 parts of Portland cement, vinyl acetate-eth...

Embodiment 3

[0047] Preferably, the anticorrosion coating used in the anticorrosion coating consists of the following components in terms of weight ratio: 50 parts of chlorosulfonated polyethylene emulsion, 3.9 parts of tributyl phosphate, 5.6 parts of nano barium sulfate, 6.5 parts of titanium dioxide, 16 parts of epoxy resin, 13 parts of xylene, 3.8 parts of cetearyl glucoside, 2.7 parts of zinc naphthenate, 5.3 parts of methyl methacrylate, and 1.8 parts of curing agent; the preparation method of the anticorrosive coating is: Add the above-mentioned raw materials into the reaction kettle, and mix them by ultrasonic stirring for 45 minutes to obtain the finished anti-corrosion coating.

[0048] Preferably, the thermal insulation interlayer 3 is composed of the following components in terms of weight ratio: the annular insulation board used in the thermal insulation interlayer 3 is composed of the following components in terms of weight ratio: 38 parts of Portland cement, vinyl acetate-eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com