A kind of preparation method of porous carbon-coated lithium iron phosphate cathode material

A technology of carbon-coated lithium iron phosphate and positive electrode materials, which is applied in electrode manufacturing, battery electrodes, electrode heat treatment, etc., can solve problems such as unfavorable Li+ movement and obstruction of full contact, so as to reduce ion diffusion resistance and improve low-temperature performance. The effect of increasing the amount of diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

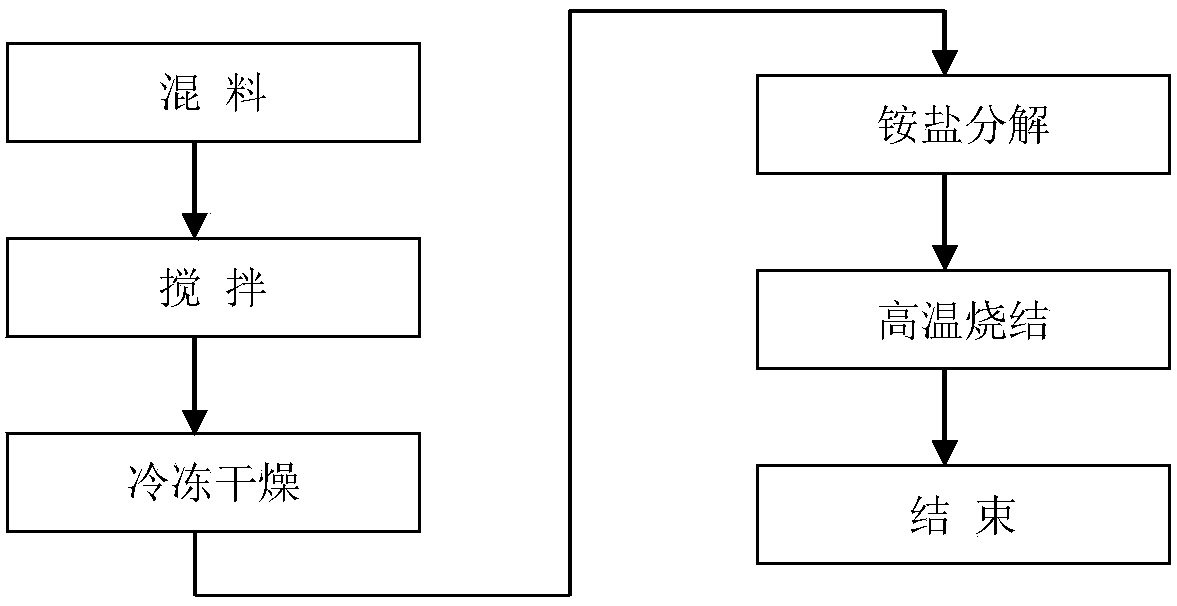

Method used

Image

Examples

Embodiment 1

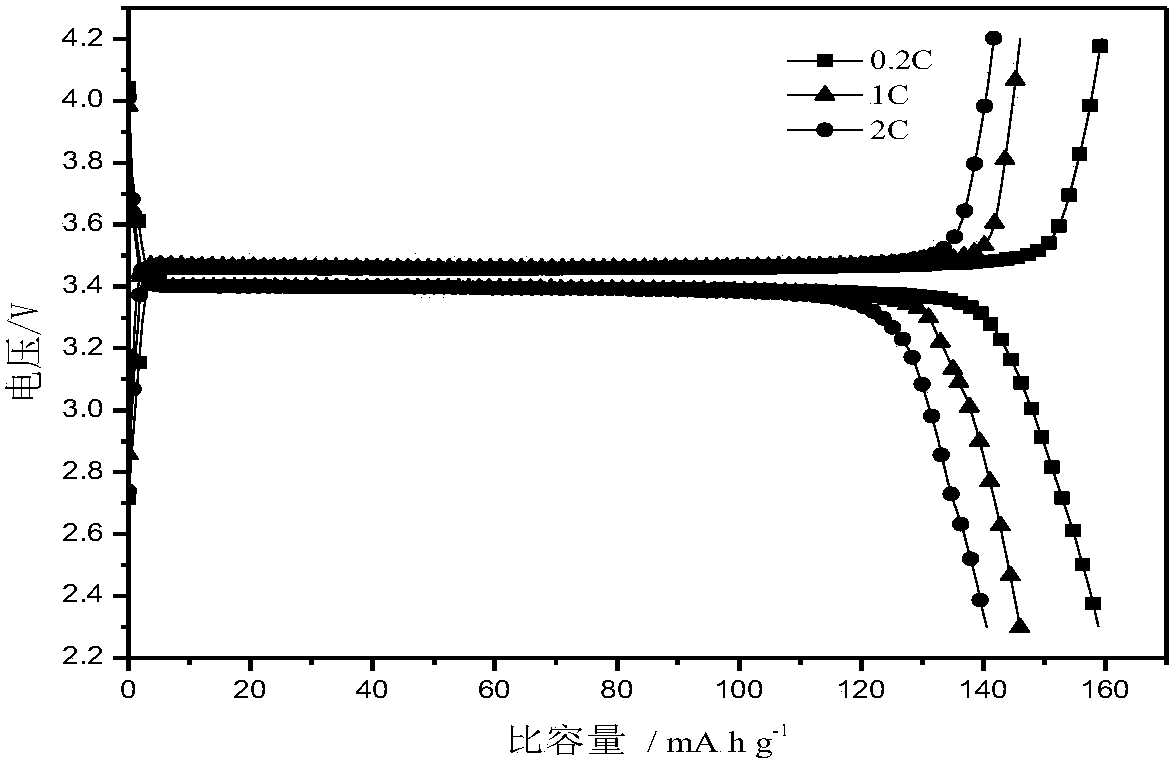

[0026] Weigh 136.2g of absolute ethanol (Tianjin Sunon Chemical Reagent Co., Ltd.) and dissolve it in 136.2g of deionized water, pour it into the reactor; weigh 157g of LiFePO 4 (1mol, 0.2um≤D 50≤1um), 19.4g glucose (0.098mol, because it contains a crystal water, the molecular weight is calculated according to 198, and the corresponding carbon molarity is 0.098*6=0.59mol, Tianjin North Tianyi Chemical Reagent Factory) and 88.2g ammonium carbonate (Tianjin Longyu Chemical Co., Ltd.) After mixing evenly, put it into the reaction kettle, and stir the mixture thoroughly for 1h. The evenly stirred slurry was put into a vacuum freeze dryer (Shanghai Bilang Instrument Co., Ltd.), frozen at -10°C for 1 h, and then dried in a vacuum environment of 13 Pa for 5 h. The dried solid was crushed into small pieces and placed in an oven at 100°C for 1 hour, and then sintered at 750°C for 2 hours under a nitrogen atmosphere. Cool to room temperature, pass through a 325-mesh sieve after grindi...

Embodiment 2

[0029] Weigh 136.2g of absolute ethanol (Tianjin Sunon Chemical Reagent Co., Ltd.) and dissolve it in 136.2g of deionized water, pour it into the reactor; weigh 157g of LiFePO 4 (1mol, 0.2um≤D 50 ≤1um), 19.4g of glucose (0.098mol, Tianjin North Tianyi Chemical Reagent Factory) and 88.2g of ammonium bicarbonate (Tianjin Longyu Chemical Co., Ltd.) were evenly mixed and put into the reaction kettle, and the mixture was fully stirred for 1h. The evenly stirred slurry was put into a vacuum freeze dryer (Shanghai Bilang Instrument Co., Ltd.), frozen at -10°C for 1 h, and then dried in a vacuum environment of 13 Pa for 5 h. After drying, the solid was put into an oven at 100°C, dried for 1 hour, and then sintered at 750°C for 2 hours under a nitrogen atmosphere. Cool to room temperature, pass through a 325-mesh sieve after grinding, and obtain porous carbon-coated LiFePO 4 / C. A button cell was prepared in a glove box (Lab2000 type, manufactured by Etelux Company). Fully charged ...

Embodiment 3

[0031] Weigh 24.7g absolute ethanol (Tianjin Sunon Chemical Reagent Co., Ltd.) and dissolve it in 247.6g deionized, pour into the reaction kettle; weigh 157gLiFePO 4 (1mol, 0.2um≤D 50 ≤1um), 19.4g glucose (0.098mol, Tianjin North Tianyi Chemical Reagent Factory) and 35.3g ammonium bicarbonate (Tianjin Jinhui Taiya Chemical Reagent Co., Ltd.) were mixed evenly and put into the reaction kettle, and the mixture was fully stirred for 1h . The slurry after stirring evenly was placed in a vacuum freeze dryer (Shanghai Bilang Instrument Co., Ltd.), frozen at -10°C for 1h, then dried in a vacuum of 13Pa for 5h, and the dried solid was placed in an oven and heated at 100°C for 1h, nitrogen Sinter at 750°C for 2h in a protective atmosphere. Cool to room temperature, grind and pass through a 325-mesh sieve to obtain the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com