Electrostatic precipitator for exhaust gas through wet process

An electrostatic precipitator and precipitator technology, applied in the direction of external electrostatic separator, electrostatic separation, electrostatic effect separation, etc., can solve the problems of easy fire and explosion, slow down the movement speed, improve the purification efficiency, and increase the relative humidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

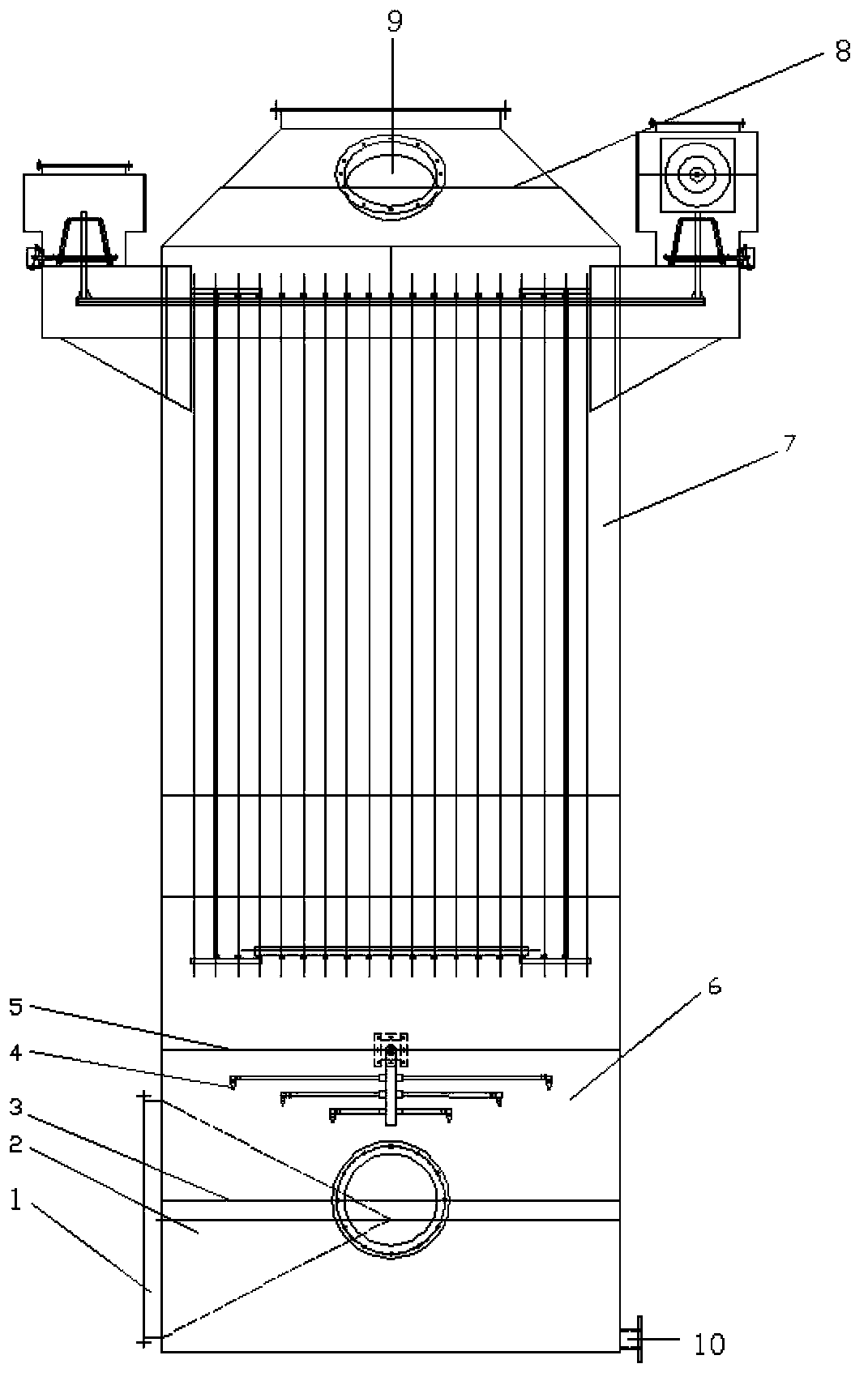

[0027] refer to figure 1 and figure 2 , an exhaust gas wet electrostatic precipitator, including a precipitator body, the precipitator body including a precipitator housing, and also including an atomizing spray mechanism 6, a uniform DC high-voltage electric field mechanism 7, and a mechanism for controlling the above two Electric control device for mechanism action;

[0028] One side of the bottom of the shell is provided with a cyclone air inlet 2, the other side is provided with a waste liquid outlet 10, and the top is provided with an air outlet 9; Condensed gas condenser 1 is used to liquefy the oil in the gas, reduce the temperature of the high-temperature gas from 220°C to about 130°C, cool down and condense the oil in the gas, liquefy and collect the oil, and prevent secondary pollution.

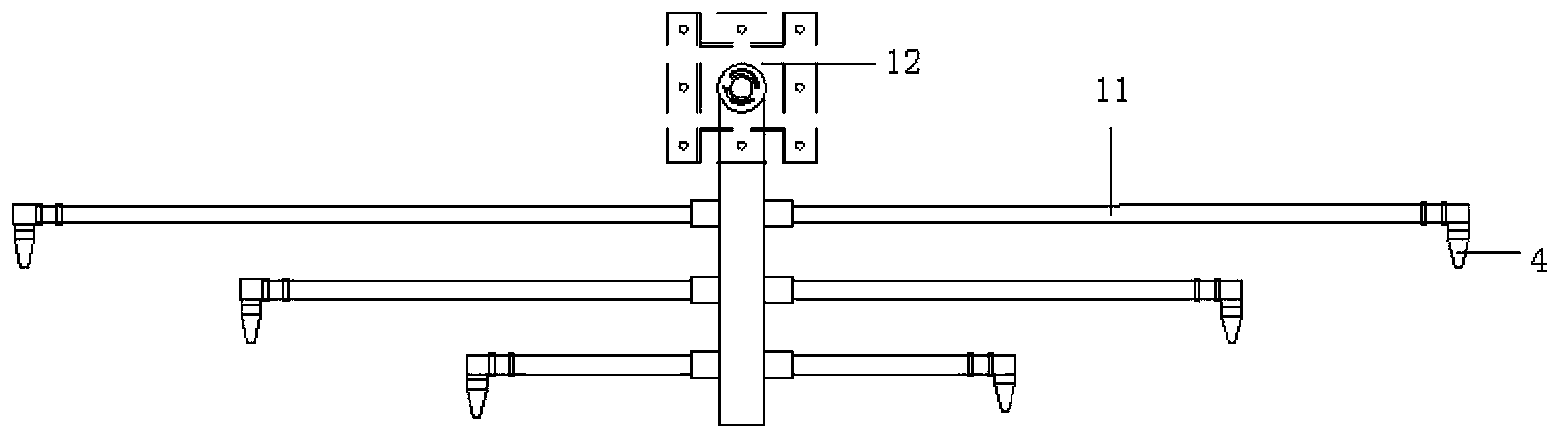

[0029] The atomizing spray mechanism 6 is arranged above the cyclone air inlet 2, and the uniform electric field mechanism 7 is arranged above the atomizing spray mechanism 6; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com