A multifunctional valve and its combination valve

A multi-functional valve and combined valve technology, applied in the direction of multi-way valves, valve details, valve devices, etc., can solve the problem that cylinder pistons cannot work well in sequence, piston and cylinder end cover wear, piston and cylinder end Cover damage and other problems, to achieve the effect of reasonable and practical structure, avoid collision wear and increase resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

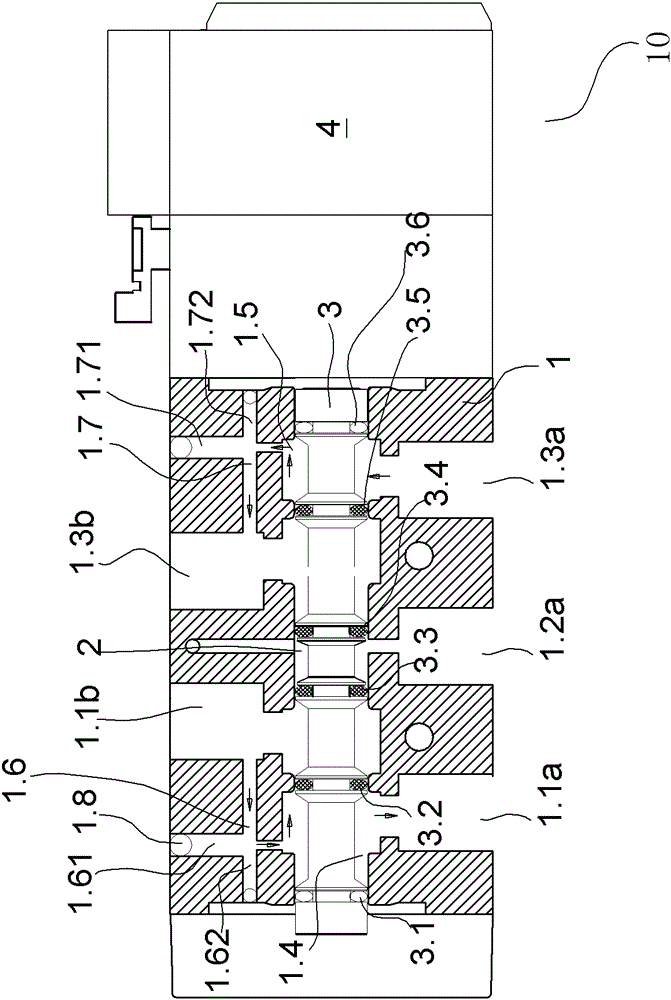

[0051] like figure 1 As shown, the multifunctional valve 10 includes a valve body 1 with a valve cavity 2 inside the valve body, and a valve stem 3 installed in the valve cavity 2, the valve stem 3 adopts an integral structure, so the valve body 1 is provided with a The middle inlet 1.2a for the pressure medium to enter, the left inlet 1.1a and the right inlet 1.3a for the pressure medium to enter selectively, and the other side of the valve body 1 is provided with the left outlet 1.1b and the right outlet 1.3b for the pressure medium to discharge. The left inlet 1.1a communicates with the left sub-chamber 1.4 in the valve chamber 2, the right inlet 1.3a communicates with the right sub-chamber 1.5 in the valve chamber 2, the left sub-cavity 1.4 communicates with the left outlet 1.1b through the damping channel 1.6, and the right sub-cavity The cavity 1.5 communicates with the right outlet 1.3b through the damping channel 1.7.

[0052] The damping channel 1.6 is formed by conn...

Embodiment 2

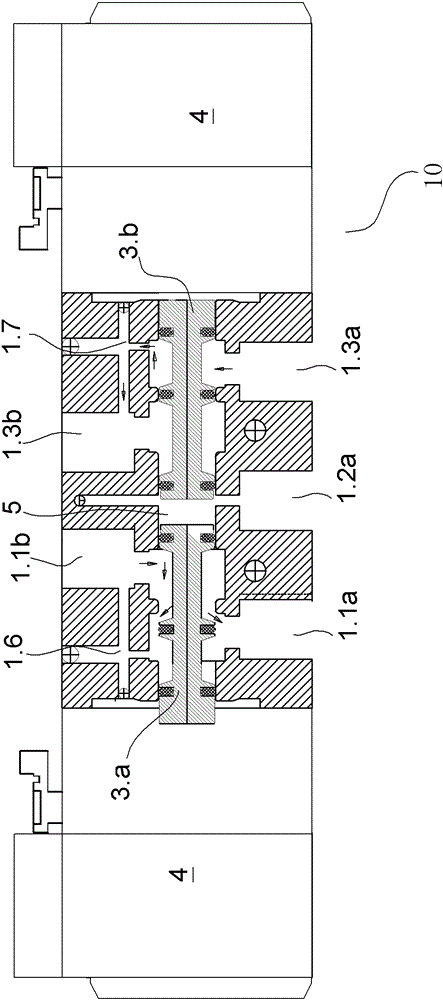

[0058] like figure 2 As shown, in the present implementation example, the valve stem 3 is divided into the left valve stem 3.a, the right valve stem 3.b, the gap cavity 5 and the pressure medium entering between the left valve stem 3.a and the right valve stem 3.b The middle inlet 1.2a is connected, and the ends of the left and right valve stems are respectively connected to their respective solenoid valves 4, so that the left inlet and the left outlet or the right inlet and the right outlet cannot be connected directly, but are connected through damping flow channels. , and others are similar to the implementation example 1.

Embodiment 3

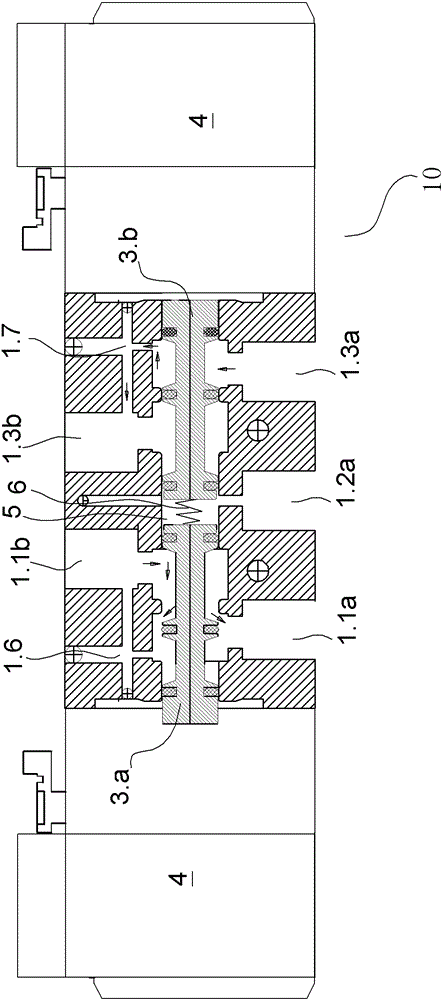

[0060] like image 3 As shown, in the present implementation example, the valve stem 3 is divided into the left valve stem 3.a, the right valve stem 3.b, the gap cavity 5 and the pressure medium entering between the left valve stem 3.a and the right valve stem 3.b The middle inlet 1.2a is connected, and the left and right valve stems are also provided with an elastic member 6 for the back movement of the left and right valve stems. Either the left inlet and the left outlet or the right inlet and the right outlet cannot be connected directly, but are connected through a damping flow channel, and the others are similar to the implementation example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com